permco hydraulic pump manual factory

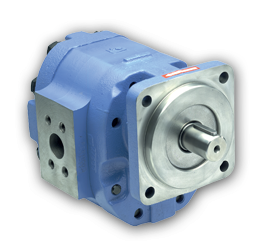

Permco is a leading manufacturer of high-pressure hydraulic gear/vane pumps and motors, flow dividers, intensifiers, and accessories. Available in a wide variety of sizes and configurations to suit your application needs.

In the two line operation, one line is connected from the oil tank to the inlet of the pump and one line is connected from the cylinder port of the valve to the cylinder. With the pump engaged and the valve spool in the neutral position, oil will recirculate inside the unit.It has been determined through testing that the rise in temperature per every minute of operation in this mode is 7.5°F.If operation is allowed to continue beyond the recommended 5 minute time interval, a reduction in clearances of the rotating group due to excessive heat and subsequent expansion will occur. The result may lead to the unit locking up and premature failure of the drive shaft or other internal components.

In a three line application, one line is connected from the oil tank to the inlet of the pump, one line is connected from the cylinder port to the cylinder and one line is connected from the pumps return port back to the oil tank. To connect this port, a 1" pipe plug must be removed for hose connection and a metal sleeve, Permco P/N RZ-0206 (DM-512, DM-640, DMD-20 and DMD-25) P/N 400-00870 (DMR-300, DMR-400, DMD-300 and DMD-400), must be inserted into the inlet port of the valve. By inserting the sleeve into the inlet port, flow from either the cylinder retracting, pump running over the relief, or with the spool in neutral, will be diverted directly back to the oil tank.

It should be noted that the operation of the Dump Pump with the 3-line circuit will reduce the possibility of premature failure due to excessive heating but will not eliminate it. It is therefore recommended that the unit be run in this mode of operation for no longer than 10 minutes.

As discussed earlier with the 3-line operation, the metal sleeve inserted in the inlet port of the pump diverts flow back to the oil tank. With this sleeve installed in a 3-line system, only a minimal amount of oil will pass across it. The majority of the oil will be blocked from recirculating internally. If the pump is engaged and the spool is in the neutral position, flow may be directed back, into the cylinder port and extend the cylinder.

Like any control valve, there are inherent pressure drops within the dump pump due to internal core configurations. During cylinder retraction, fluid velocities may increase to the point that excessive back pressures may be seen at the pump seal area. For this reason, Permco installs high pressure motor seals in all Dump Pump units to prevent premature seal failure. It is also suggested that movement of the valve spool from the neutral to the raise position in rapid succession be avoided as this may also contribute to the premature failure of the shaft seal.

Today, hydraulic systems are widely used in various applications, including heavy-duty equipment. Many manufacturers use them because they have numerous advantages over mechanical and electrical systems, such as providing a lot of power in a small space. Imagine moving a giant boulder out of the way so you can start constructing a house. This won’t be possible without the use of construction equipment that uses a hydraulic system. However, just like any other system in your heavy-duty equipment, the hydraulic system is also bound to break down due to malfunctioning components after some time. When this happens, there’s only one name that you can count on for replacement hydraulic parts, and that’s none other than Permco.

Permco is a leading manufacturer and supplier of high-pressure hydraulic gear pumps and motors, intensifiers, flow dividers, and accessories. Formerly known as the Perfection Machining Company, Permo was established in 1964 as a replacement part manufacturer for the mining industry. Four years later, the company decided to expand its manufacturing capabilities to include replacement hydraulic components, cast iron parts, and the resulting complete units for the transportation industry. Over the years, Permco has built a solid reputation as a hydraulic parts manufacturer. Many customers have come to rely on this brand, so it remains committed to developing and providing innovative products that will help them reduce their costs while keeping their hydraulic systems working for a longer period of time.

Precision manufacturing and solid engineering expertise are the keys to Permco’s solid reputation for quality, reliability, and durability. All Permco parts are manufactured to meet or exceed OEM standards for superior performance and maximum efficiency every time.

124 Series - These are small frame, heavy-duty, sleeve-bushing gear pumps and motors with dowelled and high-strength cast iron construction. These are also made with a high-strength alloy steel gear, shaft sets, and pressure-balanced wear plates designed to maintain efficiency no matter the operating conditions. Available in seven different gear sizes, these gear pumps and motors can be used on crane equipment vehicles, snowplows, roll-off trucks, and refuse trucks.

197 Series - These are small to medium frame, heavy-duty, sleeve bushing gear pumps and motors that share the same features as the 124 Series. Their typical applications include refuse trucks, winches, and cranes.

257 Series - These are medium displacement sleeve bushing pumps and motors designed for use on large winch motors, cranes, and mobile crushers and screens.

Bearing pumps and motors may be small parts, but they play a critical role by bearing the load of the pump, allowing rotation. When these go bad, they can gravely affect the hydraulic system’s overall performance. Good thing, Permco has got a wide range of bearing pumps and motors, and this includes the following:

Permco is proud to offer an expansive line of vane pumps and motors. These vane pumps are made versatile and ruggedly built for the toughest of applications. When you need a new vane pump from Permco, the options are listed below.

Dump and refuse pumps, which are used on a typical dump truck, are composed of a hydraulic pump, a pressure relief valve, and a directional valve. Their main function is to convert mechanical energy into fluid power energy and produce flow in a hydraulic system. Permco is a proud manufacturer of these products, and they are available for use on light-, medium, and heavy-duty dump trucks and dump trailers. One of the most popular products under this line is the GEMINI DG-20 / RG-20. Designed to be used with dual-use applications, this dual dump pump is equipped with a field adjustable dual pressure relief valve—low for dump trailer and high for other applications—and heavy-duty roller bearings. They can also be mounted directly using SAE “B” bolt or twin shafted remote mounted with a bracket.

Permco’s flow dividers and intensifiers are constructed using the same components, but they have different placements in a hydraulic system. They also function differently—the flow dividers work by accepting flow and dividing it (equally or unequally) or combining flow in the reverse direction, while intensifiers function by dividing flow to increase pressure.

Versa-Pak Flow Control/Unloader System - This plays a crucial function in protecting the system’s main relief valve from being flooded since it only allows a preset amount of flow to the hydraulic system.

Versa-Pak Dry Valve System - Designed to permit hydraulic operation while the vehicle is in motion, this Versa-Pak option is equipped with an air-operated dry valve.

Restore your hydraulic system’s efficient performance with top-quality Permco parts and accessories. These include in-line and pilot relief valves, filters, thrust plates, gears, shafts, castings, valves, and flow meters. All these products are made to exacting standards for a precise fit and functionality.

8613371530291

8613371530291