plunger hydraulic pump free sample

Our firm promises all users on the first-class products and solutions along with the most satisfying post-sale assistance. We warmly welcome our regular and new buyers to join us for Free sample for China “Germany Rexroth A4vg Plunger Variable Displacement Piston Pump A4vg180ep4dt2/32r-NZD02f011dp, We adhere for the tenet of “Services of Standardization, to meet Customers’ Demands”.

Our firm promises all users on the first-class products and solutions along with the most satisfying post-sale assistance. We warmly welcome our regular and new buyers to join us for China Hydraulic Pump, Hydraulic Motor, If any product meed your demand, remember to feel free to contact us. We’re sure your any inquiry or requirement will get prompt attention, high-quality solutions, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

8. It can be widely used in industry, such as plastic machine, shoe machine, die casting machinery and forklift and other industries hydraulic system, especially for servo variable frequency drive energy saving system.

Each serves a unique purpose and they’re typically not interchangeable. That’s especially true with plunger pumps and diaphragm pumps. First, we’ll give a brief explanation of how each pump works. Then, we’ll outline the pros and cons of each and how to know which one to choose for your application.

Plunger pumps — sometimes referred to as piston pumps — have a reciprocating plunger that moves back and forth, forcing liquids through a set of valves. Some simple examples in our everyday lives might include a bicycle pump, spray bottle, or squirt gun.

Commercially, plunger pumps are commonly used in soft wash, cleaning, disinfection, pest control, agriculture, and other applications in their electrically powered equipment such as pressure washers, misters and sprayers.

There are similarities between plunger pumps and diaphragm pumps. Both are considered reciprocating pumps, however, the end of the plunger in a diaphragm pump is connected to a flexible diaphragm that flexes back and forth. The human heart, for example, is a type of naturally occurring diaphragm pump.

Another notable difference between plunger and diaphragm pumps that must be considered is the power source. A diaphragm pump can be manufactured to accommodate a gas-powered engine or electric-powered motor. However, a gas-powered diaphragm pump is required to achieve the desired output and power needed for commercial use. Those using electric power are typically sold for residential use in small hand-held sprayers, RV sinks, and other low-impact use.

Positive displacement pumps refers to their ability to capture and move fluid forward through the system. Plunger pumps have a stable flow by use of a pressure regulator. The liquids are dispensed through the plunger pump system at a steady, fixed flow rate due to rigid components, providing consistent, even coverage. Diaphragm pumps also require a pressure regulator but, because some of the components are flexible, the flow is also “flexible,” meaning they’re notorious for losing pressure and having inconsistent flow.

Once again, the flexible components in a diaphragm pump can be its downfall, especially when it comes to applications requiring high PSI. The flexible diaphragm can rupture under high pressure whereas a plunger pump is engineered to withstand repeated high-pressure use. If you’re constantly replacing diaphragm pumps used in your high PSI applications, you may simply need to switch to a more durable plunger pump for an easy solution.

Equipment that uses 12V motors are much quieter than gas engines. If you’re in the pest control industry, for example, but your clients don’t want to call attention to the services you provide to their residences, a 12V pump system will quietly do the job.

Quiet operation also benefits lawn care professionals by increasing the hours of service available to them. In many areas, there are noise restrictions that limit the hours that gas engine diaphragm pumps can be operated. A 12V plunger pump system would not be controlled by this rule.

Unlike a typical centrifugal pump which requires priming to remove air from the pump chamber and avoid becoming inoperable, both the plunger pump and diaphragm pump will self prime. The step of priming a pump isn’t always straightforward, and inexperienced operators may encounter issues, losing precious time and raising labor costs.

Battery technology has advanced significantly in recent years. Today’s 12V plunger pump systems use batteries with extended run times that outlast the capacity of many gas-powered diaphragm pump engines. The operator doesn’t have to stop in the middle of a job to refuel or adjust the throttle, and safety is improved by not having to transport volatile substances. With a 12V system, operators can even ‘refill’ their batteries while driving between jobs.

The battery used in plunger pump systems is comparable to a marine battery and is about the same size. Therefore, the battery-powered unit is much more compact and maneuverable than a gas-powered diaphragm unit, making jobs less taxing on operators and improving safety. If you’re looking for a pump with a smaller footprint, the plunger pump wins out.

If you’re like many organizations that have green initiatives, battery-powered 12V equipment offers the benefits of ‘green’ technology. Concern over gas prices, oil dependency, and pollution will continue to rise, and the latest 12V plunger pump technology is an environmentally responsible power source. Users of 12V equipment may receive more business as a result of these trends in the market compared to diaphragm pumps.

The bottom line is that electric-powered plunger pumps may help your bottom line. Gas engines typically cost more than batteries, and you also need to purchase fuel on an ongoing basis which can experience price volatility over time. Marine-type batteries can be recharged again and again and are generally price-stable. Over time you’ll likely experience significant cost savings with a battery-powered plunger pump, not only from limiting fuel consumption but because of fewer breakdowns, downtime, and repairs.

For commercial cleaning, soft wash, disinfection, pest control, agriculture, lawn care, portable sanitation, and other pump sprayers and misters, an electric-powered plunger pump is clearly the best option. There are several other types of pumps in the industry, too. Learn about seven of the most common types in our Pump Comparison Cheat Sheet below.

A plunger pump is a type of positive displacement pump where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. This makes them different from piston pumps and allows them to be used at higher pressures. This type of pump is often used to transfer municipal and industrial sewage.

Piston pumps and plunger pumps are positive displacement pumps that use a plunger or piston to move media through a cylindrical chamber. The plunger or piston is actuated by a steam powered, pneumatic, hydraulic, or electric drive.

Rotary piston and plunger pumps use a crank mechanism to create a reciprocating motion along an axis, which then builds pressure in a cylinder or working barrel to force gas or fluid through the pump. The pressure in the chamber actuates the valves at both the suction and discharge points. Plunger pumps are used in applications that could range from 70 to 2,070 bar (1,000 to 30,000 psi). Piston pumps are used in lower pressure applications. The volume of the fluid discharged is equal to the area of the plunger or piston, multiplied by its stroke length. The overall capacity of the piston pumps and plunger pumps can be calculated with the area of the piston or plunger, the stroke length, the number of pistons or plungers and the speed of the drive. The power needed from the drive is proportional to the pressure and capacity of the pump.

Seals are an integral part of piston pumps and plunger pumps to separate the power fluid from the medium that is being pumped. A stuffing box or packing is used to seal the joint between the vessel where the medium is transferred and the plunger or piston. A stuffing box may be composed of bushings, packing or seal rings, and a gland.

Plunger pumps" component materials are chosen for wear and contact with the type of medium. Component materials include bronze, brass, steel, stainless steel, iron, nickel alloy, or other material. For example, plunger pumps that function in general service or oil service applications often have an iron cylinder and plunger. The plunger, discharge valves, and suction valves come in contact with the transferred medium, and material choices are based on the fluid transferred. In power applications where continuous duty plunger pumps are needed, solid ceramic plungers may be used when in contact with water and oil, but may not be compatible for use with highly acidic media types.

Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. Hydraulic pumps are sometimes incorrectly referred to as “hydrolic” pumps.

They are an important device overall in the hydraulics field, a special kind of power transmission which controls the energy which moving fluids transmit while under pressure and change into mechanical energy. Other kinds of pumps utilized to transmit hydraulic fluids could also be referred to as hydraulic pumps. There is a wide range of contexts in which hydraulic systems are applied, hence they are very important in many commercial, industrial, and consumer utilities.

“Power transmission” alludes to the complete procedure of technologically changing energy into a beneficial form for practical applications. Mechanical power, electrical power, and fluid power are the three major branches that make up the power transmission field. Fluid power covers the usage of moving gas and moving fluids for the transmission of power. Hydraulics are then considered as a sub category of fluid power that focuses on fluid use in opposition to gas use. The other fluid power field is known as pneumatics and it’s focused on the storage and release of energy with compressed gas.

"Pascal"s Law" applies to confined liquids. Thus, in order for liquids to act hydraulically, they must be contained within a system. A hydraulic power pack or hydraulic power unit is a confined mechanical system that utilizes liquid hydraulically. Despite the fact that specific operating systems vary, all hydraulic power units share the same basic components. A reservoir, valves, a piping/tubing system, a pump, and actuators are examples of these components. Similarly, despite their versatility and adaptability, these mechanisms work together in related operating processes at the heart of all hydraulic power packs.

The hydraulic reservoir"s function is to hold a volume of liquid, transfer heat from the system, permit solid pollutants to settle, and aid in releasing moisture and air from the liquid.

Mechanical energy is changed to hydraulic energy by the hydraulic pump. This is accomplished through the movement of liquid, which serves as the transmission medium. All hydraulic pumps operate on the same basic principle of dispensing fluid volume against a resistive load or pressure.

Hydraulic valves are utilized to start, stop, and direct liquid flow in a system. Hydraulic valves are made of spools or poppets and can be actuated hydraulically, pneumatically, manually, electrically, or mechanically.

The end result of Pascal"s law is hydraulic actuators. This is the point at which hydraulic energy is transformed back to mechanical energy. This can be accomplished by using a hydraulic cylinder to transform hydraulic energy into linear movement and work or a hydraulic motor to transform hydraulic energy into rotational motion and work. Hydraulic motors and hydraulic cylinders, like hydraulic pumps, have various subtypes, each meant for specific design use.

The essence of hydraulics can be found in a fundamental physical fact: fluids are incompressible. (As a result, fluids more closely resemble solids than compressible gasses) The incompressible essence of fluid allows it to transfer force and speed very efficiently. This fact is summed up by a variant of "Pascal"s Principle," which states that virtually all pressure enforced on any part of a fluid is transferred to every other part of the fluid. This scientific principle states, in other words, that pressure applied to a fluid transmits equally in all directions.

Furthermore, the force transferred through a fluid has the ability to multiply as it moves. In a slightly more abstract sense, because fluids are incompressible, pressurized fluids should keep a consistent pressure just as they move. Pressure is defined mathematically as a force acting per particular area unit (P = F/A). A simplified version of this equation shows that force is the product of area and pressure (F = P x A). Thus, by varying the size or area of various parts inside a hydraulic system, the force acting inside the pump can be adjusted accordingly (to either greater or lesser). The need for pressure to remain constant is what causes force and area to mirror each other (on the basis of either shrinking or growing). A hydraulic system with a piston five times larger than a second piston can demonstrate this force-area relationship. When a force (e.g., 50lbs) is exerted on the smaller piston, it is multiplied by five (e.g., 250 lbs) and transmitted to the larger piston via the hydraulic system.

Hydraulics is built on fluids’ chemical properties and the physical relationship between pressure, area, and force. Overall, hydraulic applications allow human operators to generate and exert immense mechanical force with little to no physical effort. Within hydraulic systems, both oil and water are used to transmit power. The use of oil, on the other hand, is far more common, owing in part to its extremely incompressible nature.

Pressure relief valves prevent excess pressure by regulating the actuators’ output and redirecting liquid back to the reservoir when necessary. Directional control valves are used to change the size and direction of hydraulic fluid flow.

While hydraulic power transmission is remarkably useful in a wide range of professional applications, relying solely on one type of power transmission is generally unwise. On the contrary, the most efficient strategy is to combine a wide range of power transmissions (pneumatic, hydraulic, mechanical, and electrical). As a result, hydraulic systems must be carefully embedded into an overall power transmission strategy for the specific commercial application. It is necessary to invest in locating trustworthy and skilled hydraulic manufacturers/suppliers who can aid in the development and implementation of an overall hydraulic strategy.

The intended use of a hydraulic pump must be considered when selecting a specific type. This is significant because some pumps may only perform one function, whereas others allow for greater flexibility.

The pump"s material composition must also be considered in the application context. The cylinders, pistons, and gears are frequently made of long-lasting materials like aluminum, stainless steel, or steel that can withstand the continuous wear of repeated pumping. The materials must be able to withstand not only the process but also the hydraulic fluids. Composite fluids frequently contain oils, polyalkylene glycols, esters, butanol, and corrosion inhibitors (though water is used in some instances). The operating temperature, flash point, and viscosity of these fluids differ.

In addition to material, manufacturers must compare hydraulic pump operating specifications to make sure that intended utilization does not exceed pump abilities. The many variables in hydraulic pump functionality include maximum operating pressure, continuous operating pressure, horsepower, operating speed, power source, pump weight, and maximum fluid flow. Standard measurements like length, rod extension, and diameter should be compared as well. Because hydraulic pumps are used in lifts, cranes, motors, and other heavy machinery, they must meet strict operating specifications.

It is critical to recall that the overall power generated by any hydraulic drive system is influenced by various inefficiencies that must be considered in order to get the most out of the system. The presence of air bubbles within a hydraulic drive, for example, is known for changing the direction of the energy flow inside the system (since energy is wasted on the way to the actuators on bubble compression). Using a hydraulic drive system requires identifying shortfalls and selecting the best parts to mitigate their effects. A hydraulic pump is the "generator" side of a hydraulic system that initiates the hydraulic procedure (as opposed to the "actuator" side that completes the hydraulic procedure). Regardless of disparities, all hydraulic pumps are responsible for displacing liquid volume and transporting it to the actuator(s) from the reservoir via the tubing system. Some form of internal combustion system typically powers pumps.

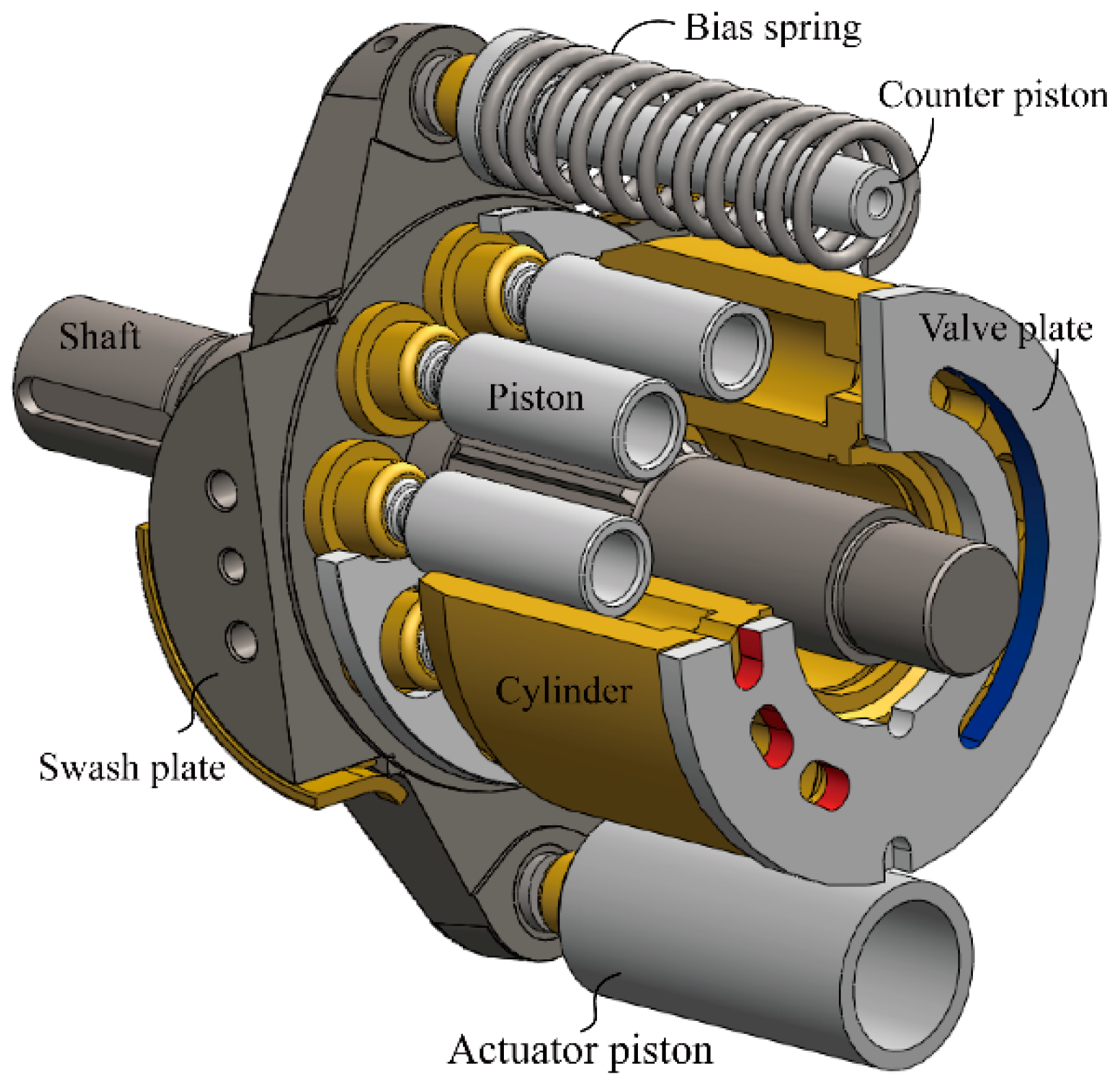

While the operation of hydraulic pumps is normally the same, these mechanisms can be split into basic categories. There are two types of hydraulic pumps to consider: gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps. Axial pumps produce linear motion, whereas radial pumps can produce rotary motion. The gear pump category is further subdivided into external gear pumps and internal gear pumps.

Each type of hydraulic pump, regardless of piston or gear, is either double-action or single-action. Single-action pumps can only pull, push, or lift in one direction, while double-action pumps can pull, push, or lift in multiple directions.

Vane pumps are positive displacement pumps that maintain a constant flow rate under varying pressures. It is a pump that self-primes. It is referred to as a "vane pump" because the effect of the vane pressurizes the liquid.

This pump has a variable number of vanes mounted onto a rotor that rotates within the cavity. These vanes may be variable in length and tensioned to maintain contact with the wall while the pump draws power. The pump also features a pressure relief valve, which prevents pressure rise inside the pump from damaging it.

Internal gear pumps and external gear pumps are the two main types of hydraulic gear pumps. Pumps with external gears have two spur gears, the spurs of which are all externally arranged. Internal gear pumps also feature two spur gears, and the spurs of both gears are internally arranged, with one gear spinning around inside the other.

Both types of gear pumps deliver a consistent amount of liquid with each spinning of the gears. Hydraulic gear pumps are popular due to their versatility, effectiveness, and fairly simple design. Furthermore, because they are obtainable in a variety of configurations, they can be used in a wide range of consumer, industrial, and commercial product contexts.

Hydraulic ram pumps are cyclic machines that use water power, also referred to as hydropower, to transport water to a higher level than its original source. This hydraulic pump type is powered solely by the momentum of moving or falling water.

Ram pumps are a common type of hydraulic pump, especially among other types of hydraulic water pumps. Hydraulic ram pumps are utilized to move the water in the waste management, agricultural, sewage, plumbing, manufacturing, and engineering industries, though only about ten percent of the water utilized to run the pump gets to the planned end point.

Despite this disadvantage, using hydropower instead of an external energy source to power this kind of pump makes it a prominent choice in developing countries where the availability of the fuel and electricity required to energize motorized pumps is limited. The use of hydropower also reduces energy consumption for industrial factories and plants significantly. Having only two moving parts is another advantage of the hydraulic ram, making installation fairly simple in areas with free falling or flowing water. The water amount and the rate at which it falls have an important effect on the pump"s success. It is critical to keep this in mind when choosing a location for a pump and a water source. Length, size, diameter, minimum and maximum flow rates, and speed of operation are all important factors to consider.

Hydraulic water pumps are machines that move water from one location to another. Because water pumps are used in so many different applications, there are numerous hydraulic water pump variations.

Water pumps are useful in a variety of situations. Hydraulic pumps can be used to direct water where it is needed in industry, where water is often an ingredient in an industrial process or product. Water pumps are essential in supplying water to people in homes, particularly in rural residences that are not linked to a large sewage circuit. Water pumps are required in commercial settings to transport water to the upper floors of high rise buildings. Hydraulic water pumps in all of these situations could be powered by fuel, electricity, or even by hand, as is the situation with hydraulic hand pumps.

Water pumps in developed economies are typically automated and powered by electricity. Alternative pumping tools are frequently used in developing economies where dependable and cost effective sources of electricity and fuel are scarce. Hydraulic ram pumps, for example, can deliver water to remote locations without the use of electricity or fuel. These pumps rely solely on a moving stream of water’s force and a properly configured number of valves, tubes, and compression chambers.

Electric hydraulic pumps are hydraulic liquid transmission machines that use electricity to operate. They are frequently used to transfer hydraulic liquid from a reservoir to an actuator, like a hydraulic cylinder. These actuation mechanisms are an essential component of a wide range of hydraulic machinery.

There are several different types of hydraulic pumps, but the defining feature of each type is the use of pressurized fluids to accomplish a job. The natural characteristics of water, for example, are harnessed in the particular instance of hydraulic water pumps to transport water from one location to another. Hydraulic gear pumps and hydraulic piston pumps work in the same way to help actuate the motion of a piston in a mechanical system.

Despite the fact that there are numerous varieties of each of these pump mechanisms, all of them are powered by electricity. In such instances, an electric current flows through the motor, which turns impellers or other devices inside the pump system to create pressure differences; these differential pressure levels enable fluids to flow through the pump. Pump systems of this type can be utilized to direct hydraulic liquid to industrial machines such as commercial equipment like elevators or excavators.

Hydraulic hand pumps are fluid transmission machines that utilize the mechanical force generated by a manually operated actuator. A manually operated actuator could be a lever, a toggle, a handle, or any of a variety of other parts. Hydraulic hand pumps are utilized for hydraulic fluid distribution, water pumping, and various other applications.

Hydraulic hand pumps may be utilized for a variety of tasks, including hydraulic liquid direction to circuits in helicopters and other aircraft, instrument calibration, and piston actuation in hydraulic cylinders. Hydraulic hand pumps of this type use manual power to put hydraulic fluids under pressure. They can be utilized to test the pressure in a variety of devices such as hoses, pipes, valves, sprinklers, and heat exchangers systems. Hand pumps are extraordinarily simple to use.

Each hydraulic hand pump has a lever or other actuation handle linked to the pump that, when pulled and pushed, causes the hydraulic liquid in the pump"s system to be depressurized or pressurized. This action, in the instance of a hydraulic machine, provides power to the devices to which the pump is attached. The actuation of a water pump causes the liquid to be pulled from its source and transferred to another location. Hydraulic hand pumps will remain relevant as long as hydraulics are used in the commerce industry, owing to their simplicity and easy usage.

12V hydraulic pumps are hydraulic power devices that operate on 12 volts DC supplied by a battery or motor. These are specially designed processes that, like all hydraulic pumps, are applied in commercial, industrial, and consumer places to convert kinetic energy into beneficial mechanical energy through pressurized viscous liquids. This converted energy is put to use in a variety of industries.

Hydraulic pumps are commonly used to pull, push, and lift heavy loads in motorized and vehicle machines. Hydraulic water pumps may also be powered by 12V batteries and are used to move water out of or into the desired location. These electric hydraulic pumps are common since they run on small batteries, allowing for ease of portability. Such portability is sometimes required in waste removal systems and vehiclies. In addition to portable and compact models, options include variable amp hour productions, rechargeable battery pumps, and variable weights.

While non rechargeable alkaline 12V hydraulic pumps are used, rechargeable ones are much more common because they enable a continuous flow. More considerations include minimum discharge flow, maximum discharge pressure, discharge size, and inlet size. As 12V batteries are able to pump up to 150 feet from the ground, it is imperative to choose the right pump for a given use.

Air hydraulic pumps are hydraulic power devices that use compressed air to stimulate a pump mechanism, generating useful energy from a pressurized liquid. These devices are also known as pneumatic hydraulic pumps and are applied in a variety of industries to assist in the lifting of heavy loads and transportation of materials with minimal initial force.

Air pumps, like all hydraulic pumps, begin with the same components. The hydraulic liquids, which are typically oil or water-based composites, require the use of a reservoir. The fluid is moved from the storage tank to the hydraulic cylinder via hoses or tubes connected to this reservoir. The hydraulic cylinder houses a piston system and two valves. A hydraulic fluid intake valve allows hydraulic liquid to enter and then traps it by closing. The discharge valve is the point at which the high pressure fluid stream is released. Air hydraulic pumps have a linked air cylinder in addition to the hydraulic cylinder enclosing one end of the piston.

The protruding end of the piston is acted upon by a compressed air compressor or air in the cylinder. When the air cylinder is empty, a spring system in the hydraulic cylinder pushes the piston out. This makes a vacuum, which sucks fluid from the reservoir into the hydraulic cylinder. When the air compressor is under pressure, it engages the piston and pushes it deeper into the hydraulic cylinder and compresses the liquids. This pumping action is repeated until the hydraulic cylinder pressure is high enough to forcibly push fluid out through the discharge check valve. In some instances, this is connected to a nozzle and hoses, with the important part being the pressurized stream. Other uses apply the energy of this stream to pull, lift, and push heavy loads.

Hydraulic piston pumps transfer hydraulic liquids through a cylinder using plunger-like equipment to successfully raise the pressure for a machine, enabling it to pull, lift, and push heavy loads. This type of hydraulic pump is the power source for heavy-duty machines like excavators, backhoes, loaders, diggers, and cranes. Piston pumps are used in a variety of industries, including automotive, aeronautics, power generation, military, marine, and manufacturing, to mention a few.

Hydraulic piston pumps are common due to their capability to enhance energy usage productivity. A hydraulic hand pump energized by a hand or foot pedal can convert a force of 4.5 pounds into a load-moving force of 100 pounds. Electric hydraulic pumps can attain pressure reaching 4,000 PSI. Because capacities vary so much, the desired usage pump must be carefully considered. Several other factors must also be considered. Standard and custom configurations of operating speeds, task-specific power sources, pump weights, and maximum fluid flows are widely available. Measurements such as rod extension length, diameter, width, and height should also be considered, particularly when a hydraulic piston pump is to be installed in place of a current hydraulic piston pump.

Hydraulic clutch pumps are mechanisms that include a clutch assembly and a pump that enables the user to apply the necessary pressure to disengage or engage the clutch mechanism. Hydraulic clutches are crafted to either link two shafts and lock them together to rotate at the same speed or detach the shafts and allow them to rotate at different speeds as needed to decelerate or shift gears.

Hydraulic pumps change hydraulic energy to mechanical energy. Hydraulic pumps are particularly designed machines utilized in commercial, industrial, and residential areas to generate useful energy from different viscous liquids pressurization. Hydraulic pumps are exceptionally simple yet effective machines for moving fluids. "Hydraulic" is actually often misspelled as "Hydralic". Hydraulic pumps depend on the energy provided by hydraulic cylinders to power different machines and mechanisms.

There are several different types of hydraulic pumps, and all hydraulic pumps can be split into two primary categories. The first category includes hydraulic pumps that function without the assistance of auxiliary power sources such as electric motors and gas. These hydraulic pump types can use the kinetic energy of a fluid to transfer it from one location to another. These pumps are commonly called ram pumps. Hydraulic hand pumps are never regarded as ram pumps, despite the fact that their operating principles are similar.

The construction, excavation, automotive manufacturing, agriculture, manufacturing, and defense contracting industries are just a few examples of operations that apply hydraulics power in normal, daily procedures. Since hydraulics usage is so prevalent, hydraulic pumps are unsurprisingly used in a wide range of machines and industries. Pumps serve the same basic function in all contexts where hydraulic machinery is used: they transport hydraulic fluid from one location to another in order to generate hydraulic energy and pressure (together with the actuators).

Elevators, automotive brakes, automotive lifts, cranes, airplane flaps, shock absorbers, log splitters, motorboat steering systems, garage jacks and other products use hydraulic pumps. The most common application of hydraulic pumps in construction sites is in big hydraulic machines and different types of "off-highway" equipment such as excavators, dumpers, diggers, and so on. Hydraulic systems are used in other settings, such as offshore work areas and factories, to power heavy machinery, cut and bend material, move heavy equipment, and so on.

Fluid’s incompressible nature in hydraulic systems allows an operator to make and apply mechanical power in an effective and efficient way. Practically all force created in a hydraulic system is applied to the intended target.

Because of the relationship between area, pressure, and force (F = P x A), modifying the force of a hydraulic system is as simple as changing the size of its components.

Hydraulic systems can transfer energy on an equal level with many mechanical and electrical systems while being significantly simpler in general. A hydraulic system, for example, can easily generate linear motion. On the contrary, most electrical and mechanical power systems need an intermediate mechanical step to convert rotational motion to linear motion.

Hydraulic systems are typically smaller than their mechanical and electrical counterparts while producing equivalents amounts of power, providing the benefit of saving physical space.

Hydraulic systems can be used in a wide range of physical settings due to their basic design (a pump attached to actuators via some kind of piping system). Hydraulic systems could also be utilized in environments where electrical systems would be impractical (for example underwater).

By removing electrical safety hazards, using hydraulic systems instead of electrical power transmission improves relative safety (for example explosions, electric shock).

The amount of power that hydraulic pumps can generate is a significant, distinct advantage. In certain cases, a hydraulic pump could generate ten times the power of an electrical counterpart. Some hydraulic pumps (for example, piston pumps) cost more than the ordinary hydraulic component. These drawbacks, however, can be mitigated by the pump"s power and efficiency. Despite their relatively high cost, piston pumps are treasured for their strength and capability to transmit very viscous fluids.

Handling hydraulic liquids is messy, and repairing leaks in a hydraulic pump can be difficult. Hydraulic liquid that leaks in hot areas may catch fire. Hydraulic lines that burst may cause serious injuries. Hydraulic liquids are corrosive as well, though some are less so than others. Hydraulic systems need frequent and intense maintenance. Parts with a high factor of precision are frequently required in systems. If the power is very high and the pipeline cannot handle the power transferred by the liquid, the high pressure received by the liquid may also cause work accidents.

Even though hydraulic systems are less complex than electrical or mechanical systems, they are still complex systems that should be handled with caution. Avoiding physical contact with hydraulic systems is an essential safety precaution when engaging with them. Even when a hydraulic machine is not in use, active liquid pressure within the system can be a hazard.

Inadequate pumps can cause mechanical failure in the place of work that can have serious and costly consequences. Although pump failure has historically been unpredictable, new diagnostic technology continues to improve on detecting methods that previously relied solely on vibration signals. Measuring discharge pressures enables manufacturers to forecast pump wear more accurately. Discharge sensors are simple to integrate into existing systems, increasing the hydraulic pump"s safety and versatility.

Hydraulic pumps are devices in hydraulic systems that move hydraulic fluid from point to point, initiating hydraulic power production. They are an important device overall in the hydraulics field, a special kind of power transmission that controls the energy which moving fluids transmit while under pressure and change into mechanical energy. Hydraulic pumps are divided into two categories namely gear pumps and piston pumps. Radial and axial piston pumps are types of piston pumps. Axial pumps produce linear motion, whereas radial pumps can produce rotary motion. The construction, excavation, automotive manufacturing, agriculture, manufacturing, and defense contracting industries are just a few examples of operations that apply hydraulics power in normal, daily procedures.

With higher pump pressures and flow rates, Graco priming piston pumps handle a broad range of inks and high viscosity fluids with ease. These Graco designed pumps offer durability, power and reliability for any ink manufacturing or printing application. Choose from two reliable motor options: pneumatic or hydraulic, each capable of generating high pressures to meet your manufacturing demands.

Elephant Fluid Power: Provide SAUER series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Persisting in "High quality, Prompt Delivery, Aggressive Price", we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients" higher comments for Yuken Pump A 100 Pump, Hawe Pump Si...

Elephant Fluid Power: Provide Good Quality P80 Valve - Control valve for CAT series piston pump,guarantee quality and appropriate prices.owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Dakin P36-A3, Linde Pump Hpv, Kayaba Gear Pump Krp4...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We always get the job done to be a tangible staff to ensure that we can easily offer you the best high-quality and the greatest value for Denison Hydraulic pump parts, Yuken Pump A3h 16 Pump, Uchida A8v, We are going to empower people by communicatin...

Elephant Fluid Power: Provide Nabtesco Pump Parts - Yuken Series Hydraulic Pump Parts,original OEM pump parts and auxiliary factory pump parts.The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for Piston Type Hydraulic Pump Animation, Pump K3v180, Italy Sam Pump H2v 75 H1c108, If you are interested in any of our products or would like to discuss a cus...

Elephant Fluid Power: Provide Dakin series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Italy Sam Pump H2v 226 H1c55, Hpv 118 Pump, Toshiba Sg, We put genuine and health a...

Elephant Fluid Power: Provide Uchida series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for Caterpillar Pump, Oilgear Pvv 250 Pump, Danfoss Orbital Motors Pdf, If you are interested in our products, please fee...

Elephant Fluid Power: Provide SAUER series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Always customer-oriented, and it"s our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Hydraulic Spare Parts For Construction Machine, Kawasaki K7v Pump, Directional C...

Elephant Fluid Power: Provide Nabtesco Pump Parts - NACHI series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for Kayaba Gear Pump Catalogue, Komatsu Pc300-6 Hydraulic Pump, Hydraulic Spare Parts For Construction Machine, ...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for Heavy Equipment Parts Edmonton, Heavy Equipment Parts Trin...

Elephant Fluid Power: Provide Linde series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Based on domestic market and expand overseas business" is our development strategy for Foton Ft150, Piston Type Hydraulic Pump Animation, Eaton Orbital Motors, With superb service and quality, and an enterprise of foreign trade featuring validity an...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We consistently carry out our spirit of ""Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for Liebherr Grease Pump, Kayaba Gear Pump Seal Kit, Directional Control Valve, ...

Elephant Fluid Power: Provide Dakin series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Linde Pump Hpv, 083 Hmt125ac/Ae Travel, Hydraulic Piston Kayaba Pumps Psv2-55t, We sincerely count on exchange and cooperation ...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Denison Pv6 10 Pump, Italy Sam Pump H2v 160 H1c108, Hitachi 1100 Hitachi 1800 Pump, We warmly welcome you to build cooperation and genera...

Elephant Fluid Power: Provide JEIT series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.The purchaser fulfillment is our primary focus on. We uphold a consistent level of professionalism, high quality, credibility and service for Kato 311 Walking Travel, Korea Hydraulic Jmf 80 S, Axial Piston Type Hydraulic Pump, Our products enjoy good...

Elephant Fluid Power: Provide Kayaba series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We pursue the management tenet of "Quality is remarkable, Company is supreme, Name is first", and will sincerely create and share success with all clientele for Hydraulic pump parts, Yuken Pump A 70 Pump, Oilgear Pvv 200 Pump, Trust us, you will find...

Elephant Fluid Power: Provide Uchida series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Komatsu Pump Factory China...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Based on domestic market and expand overseas business" is our improvement strategy for Sauer Danfoss 90 Series 75cc Pump Parts Manual, Hydraulic Piston Kayaba Pumps Msg-10/33vp, Rexroth A10vg Pump, We welcome new and previous buyers from all walks o...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy ...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Korea Hydraulic Jmv 275/172 Travel, Kayaba Pump Hydraulic, Toshiba Sg, We are also frequently hunting to determine relationship with new su...

Elephant Fluid Power: Provide Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Gaining purchaser gratification is our firm"s intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services fo...

Elephant Fluid Power: Provide Kayaba series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we"re devoted to supplying the top benefit for our customers for Vickers Vane Pump Catalog...

Elephant Fluid Power:Provide Cat OEM pump piston pump spare parts 9T series,guarantee quality and appropriate prices, and perfect after-sales service.Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Foton 39 Excavator Rotary Swing, Liebherr Boom Pump, Piston Hydraulic Pump, Our tenet is "Reasonable prices, efficient prod...

Elephant Fluid Power: Provide Cat OEM pump piston pump spare parts 9T series,guarantee quality and appropriate prices, and perfect after-sales service.We normally believe that one"s character decides products" quality, the details decides products" high-quality ,while using the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Rexroth A10vso Series Piston Pump, Continental Hpv Pump, Yuken Pump A3...

Elephant Fluid Power: Provide Denison Pv6 10 Pump - Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Hydraulic Piston Linde Pumps Hmf50, Dakin V50 Vd2-15a Vd5-15a Mf18 Pump, Komatsu Pump Adjustment, Welcome all custo...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Italy Sam Pump H2v 75 H1c55, Pump K3v140, Heavy Equipment Spare Parts Suppli...

Elephant Fluid Power: Provide Linde series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Heavy Equipment Used Parts Near Me, Hpv 102 Hydraulic Pump, Sauer Pumps Hydraulic, Winning customers" trust is d...

Elephant Fluid Power: Provide Komatsu series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Always customer-oriented, and it"s our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Hmgc16 Travel, Pump K3v, Hydraulic Piston Pump For Sale, Through our hard work, we have...

Elephant Fluid Power: Provide JEIT series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Korea Hydraulic Jmv 53/34 Travel, Piston Shoe Hydraulic...

Elephant Fluid Power: Provide Teijin Seiki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we"ve earned an outstanding track record amongst our consumers across the whole world for Hmgc16 Travel, Kawasaki Pump Shoe, Yuken Pump A 70 Pu...

Elephant Fluid Power: Provide Kayaba series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Based on domestic market and expand overseas business" is our development strategy for Toshiba Shibaura Lucus400 Hd450v-2 Pump, Komatsu Pump Controller, Denison Pv6 15 Pump, We have now ISO 9001 Certification and qualified this item .in excess of 16...

Elephant Fluid Power: Provide Denison Pv6 10 Pump - JEIT series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Hmt36fa Ex200 Travel, Eaton Vickers Pump Distributors, Oilgear Pvk 140 Pump, We aim at Ongoing system innovation...

Elephant Fluid Power: Provide Yuken Series Hydraulic Pump Parts,original OEM pump parts and auxiliary factory pump parts.We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Italy Sam Pump H1v 160, Linde Pump Repair, Sauer Pumps Hydraulic, With us your money in safe your business in safe . Hope we can be your trust...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for Sauer Danfoss Pump Model Code, Italy Sam Pump H2v 75 H1c75, Korea Hydraulic Jmf 36 S, With our rules of "...

Elephant Fluid Power: Provide Eaton Vickers series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for Kayaba Pump, Kawasaki Pump K3vi80, Main Pump Pc300 Komatsu, Our aim is to help customers realize their go...

Elephant Fluid Power: Provide Paker series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts."Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Cat Pump Parts, Hpv 135 Pump, Heavy Eq...

Elephant Fluid Power: Provide Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for Italy Sam Pump H2v 226 H1c55, Yuken Pump A3h 56 Pump, Heavy Equipment Parts Canada, Welcome your enq...

Elephant Fluid Power: Provide Dakin series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Rexroth A10vso Series Piston Pump, Orbital Motors Danfoss, Hmgf36 Travel, We welcome buy...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Hydraulic Piston L...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Sauer piston pump series Seal kit,guarantee quality and appropriate prices.Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Piston Axial Hydraulic Pump, Korea Hydraulic Jmf 151 S, Vickers Vane Pump V210 Pdf, We neve...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Nachi series pump seal kit,guarantee quality and appropriate prices.To be able to ideal satisfy client"s requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Cat Pump 240, A4vg56 Rexroth Pump, Kawasaki Pump Distributors, Our Ent...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Kawasaki Series Pump Seal kit,guarantee quality and appropriate prices.We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Oilgear Pvv 540 Pump, Linde Pump Hpv, Vickers Vane Pump Identification, Welcome all prospects of residence and abroad to visit our organi...

Elephant Fluid Power: Provide K3v280dtp Main Pump - Eton Vickers series pump Seal kit,guarantee quality and appropriate prices.Persisting in "High high quality, Prompt Delivery, Aggressive Price", we"ve established long-term cooperation with clients from the two overseas and domestically and get new and old clients" superior comments for Kayaba Gear Pump Krp4, Rexroth Pump P...

Elephant Fluid Power: Provide Cat Series pump parts seal kit,original OEM pump parts and auxiliary factory pump parts.High-quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is constantly observed and pursued by our business for Rexroth Pump Pdf, Kayaba Pump Hydraulic, Sauer Danfoss 90 Series Pu...

Elephant Fluid Power: Provide NACHI series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Ap-12 Cat320 Pump, Sauer Pump Pu, Italy Sam Pump ...

Elephant Fluid Power: Provide Liebherr series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Korea Hydraulic Jmf 53 S, Hitachi Pump Manual, Uchida Gear Pump Gsp2, With a wide range, top...

Elephant Fluid Power: Provide Kawasaki series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer"s trust for Korea Hydraulic Jmf 80 S, Dakin Opv1-23...

Elephant Fluid Power: Provide Eaton Vickers series Hydraulic pump parts,original OEM pump parts and auxiliary factory pump parts.We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Toshiba Pvb 80/92 Pump, Directional Control Valv...

A positive displacement (PD) pump moves a fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes.

A Reciprocating Positive Displacement pump works by the repeated back-and-forth movement (strokes) of either a piston, plunger or diaphragm (Figure 1). These cycles are called reciprocation.

In a piston pump, the first stroke of the piston creates a vacuum, opens an inlet valve, closes the outlet valve and draws fluid into the piston chamber (the suction phase). As the motion of the piston reverses, the inlet valve, now under pressure, is closed and the outlet valve opens allowing the fluid contained in the piston chamber to be discharged (the compression phase). The bicycle pump is a simple example. Piston pumps can also be double acting with inlet and outlet valves on both sides of the piston. While the piston is in suction on one side, it is in compression on the other. More complex, radial versions are often used in industrial applications.

Plunger pumps operate in a similar way. The volume of fluid moved by a piston pump depends on the cylinder volume; in a plunger pump it depends on the plunger size. The seal around the piston or plunger is important to maintain the pumping action and to avoid leaks. In general, a plunger pump seal is easier to maintain since it is stationary at the top of the pump cylinder whereas the seal around a piston is repeatedly moving up and down inside the pump chamber.

A diaphragm pump uses a flexible membrane instead of a piston or plunger to move fluid. By expanding the diaphragm, the volume of the pumping chamber is increased and fluid is drawn into the pump. Compressing the diaphragm decreases the volume and expels some fluid. Diaphragm pumps have the advantage of being hermetically sealed systems making them ideal for pumping hazardous fluids.

The cyclic action of reciprocating pumps creates pulses in the discharge with the fluid accelerating during the compression phase and slowing during the suction phase. This can cause damaging vibrations in the installation and often some form of damping or smoothing is employed. Pulsing can also be minimized by using two (or more) pistons, plungers or diaphragms with one in its compression phase whilst the other is in suction.

The repeatable and predictable action of reciprocating pumps makes them ideal for applications where accurate metering or dosing is required. By altering the stroke rate or length it is possible to provide measured quantities of the pumped fluid.

Rotary positive displacement pumps use the actions of rotating cogs or gears to transfer fluids, rather than the backwards and forwards motion of reciprocating pumps. The rotating element develops a liquid seal with the pump casing and creates suction at the pump inlet. Fluid, drawn into the pump, is enclosed within the teeth of its rotating cogs or gears and transferred to the discharge. The simplest example of a rotary positive displacement pump is the gear pump. There are two basic designs of gear pump: external and internal (Figure 2).

An external gear pump consists of two interlocking gears supported by separate shafts (one or both of these shafts may be driven). Rotation of the gears traps the fluid between the teeth moving it from the inlet, to the discharge, around the casing. No fluid is transferred back through the centre, between the gears, because they are interlocked. Close tolerances between the gears and the casing allow the pump to develop suction at the inlet and prevent fluid from leaking back from the discharge side. Leakage or “slippage” is more likely with low viscosity liquids.

An internal gear pump operates on the same principle but the two interlocking gears are of different sizes with one rotating inside the other. The cavities between the two gears are filled with fluid at the inlet and transported around to the discharge port, where it is expelled by the action of the smaller gear.

Gear pumps need to be lubricated by the pumped fluid and are ideal for pumping oils and other high viscosity liquids. For this reason, a gear pump should not be run dry. The close tolerances between the gears and casing mean that these types of pump are susceptible to wear when used with abrasive fluids or feeds containing entrained solids.

In the case of the lobe pump, the rotating elements are lobes instead of gears. The great advantage of this design is that the lobes do not come into contact with each other during the pumping action, reducing wear, contamination and fluid shear. Vane pumps use a set of moveable vanes (either spring-loaded, under hydraulic pressure, or flexible) mounted in an off-centre rotor. The vanes maintain a close seal against the casing wall and trapped fluid is transported to the discharge port.

A further class of rotary pumps uses one or several, meshed screws to transfer fluid along the screw axis. The basic principle of these pumps is that of the Archimedes screw, a design used for irrigation for thousands of years.

There are two main families of pumps: positive displacement and centrifugal. Centrifugal pumps are capable of higher flows and can work with lower viscosity liquids. In some chemical plants, 90% of the pumps in use will be centrifugal pumps. However, there are a number of applications for which positive displacement pumps are preferred. For example, they can handle higher viscosity fluids and can operate at high pressures and relatively low flows more efficiently. They are also more accurate when metering is an important consideration.

In general, positive displacement pumps are more complex and difficult to maintain than centrifugal pumps. They are also not capable of generating the high flow rates characteristic of centrifugal pumps.

Positive displacement pumps are less able to handle low viscosity fluids than centrifugal pumps. To generate suction and reduce slippage and leaks, a rotary pump relies on the seal between its rotating elements and the pump housing. This is considerably reduced with low viscosity fluids. Similarly, it is more difficult to prevent slippage from the valves in a reciprocating pump with a low viscosity feed because of the high pressures generated during the pumping action.

A pulsing discharge is also a characteristic of positive displacement, and especially reciprocating, pump designs. Pulsation can cause noise and vibration in pipe systems and cavitation problems which can ultimately lead to damage or failure. Pulsing can be reduced by the use of multiple pump cylinders and pulsation dampeners but this requires careful system design. Centrifugal pumps, on the other hand, produce a smooth constant flow.

The back-and-forth motion of a reciprocating pump can also be a source of vibration and noise. It is therefore important to construct very strong foundations for this type of pump. As a consequence of the high pressures generated during the pumping cycle it is also vital that either the pump or discharge line has some form of pressure relief in case of a blockage. Centrifugal pumps do not need over-pressure protection: fluid is simply recirculated in this eventuality.

Feeds containing a high level of abrasive solids can cause excessive wear on the components of all types of pumps and especially valves and seals. Although the components of positive displacement pumps operate at considerably lower speeds than those of centrifugal pumps, they remain prone to these problems. This is particularly the case with piston and plunger style reciprocating pumps and gear rotary pumps. With this type of feed, a lobe, screw or diaphragm pump may be suitable for more demanding applications.

Positive Displacement pumps are commonly used for pumping high viscosity fluids such as oil, paints, resins or foodstuffs. They are preferred in any application where accurate dosing or high pressure output is required. Unlike centrifugal pumps, the output of a positive displacement pump is not affected by pressure so they also tend to be preferred in any situation where the supply is irregular. Most are self priming.

A positive displacement pump moves a fluid by repeatedly enclosing a fixed volume, with the aid of seals or valves, and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, lobes, diaphragms or vanes. There are two main types: reciprocating and rotary.

Positive displacement pumps are preferred for applications involving highly viscous fluids such as thick oils and slurries, especially at high pressures, for complex feeds such as emulsions, foodstuffs or biological fluids, and also when accurate dosing is required.

The present invention relates to free piston internal combustion engines, and, more particularly, to a free piston internal combustion engine having a hydraulic output and one or more accumulators.

A free piston internal combustion engine (FPE) likewise includes a plurality of pistons which are reciprocally disposed in a pluralit

8613371530291

8613371530291