positive displacement hydraulic pump in stock

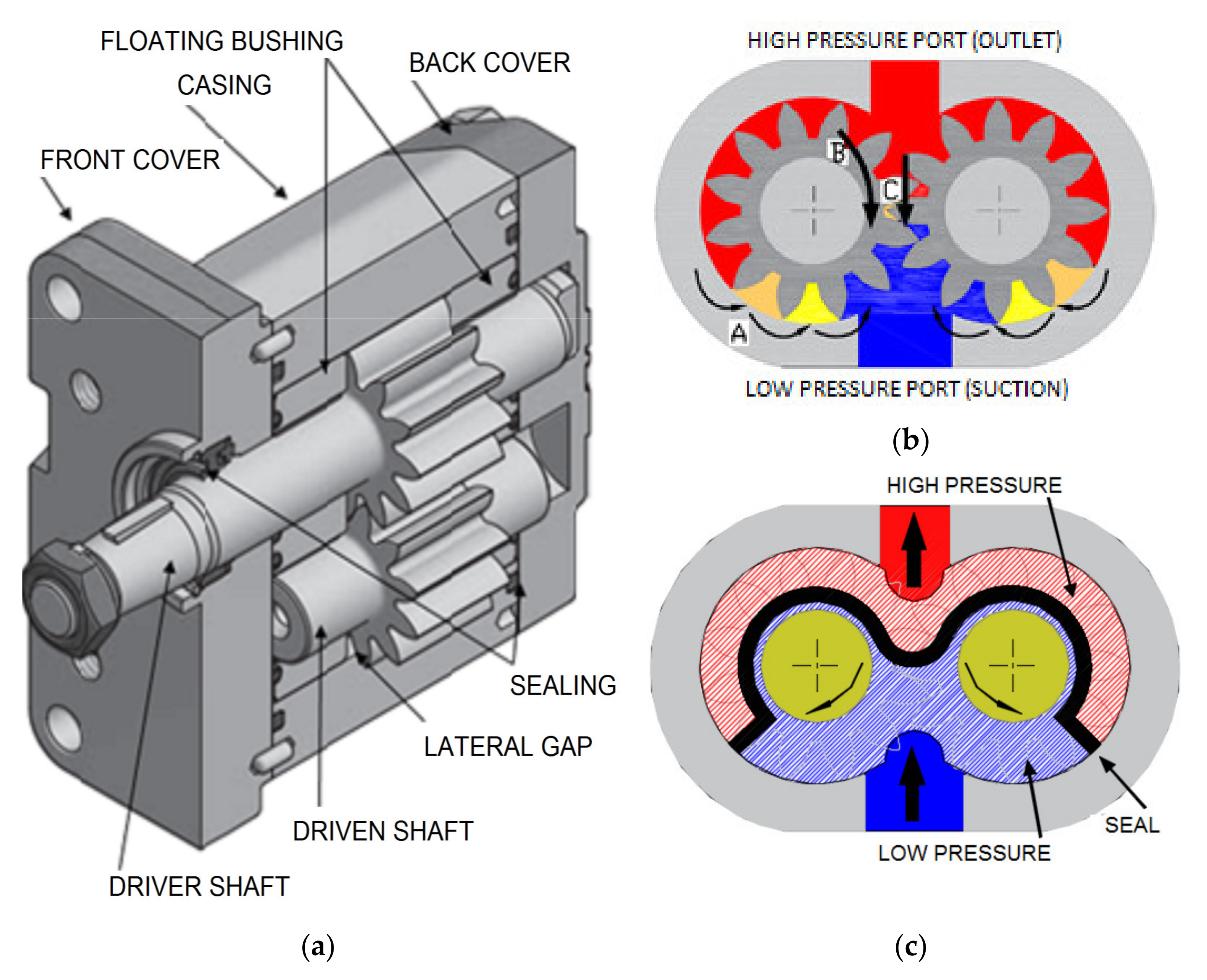

Gear pumps are one of the most common types of positive displacement pumps. They provide a constant volume of fluid that passes between the teeth of two meshing gears and the casing. The rotating gears and separation of teeth create a suction that pulls fluid in through the inlet. The gears then trap the liquid and move it around the casing to the discharge or outlet. Each revolution creates consistency in the flow of fluid.

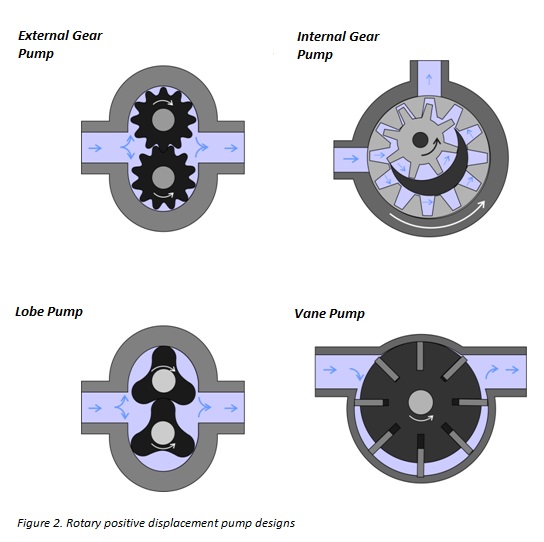

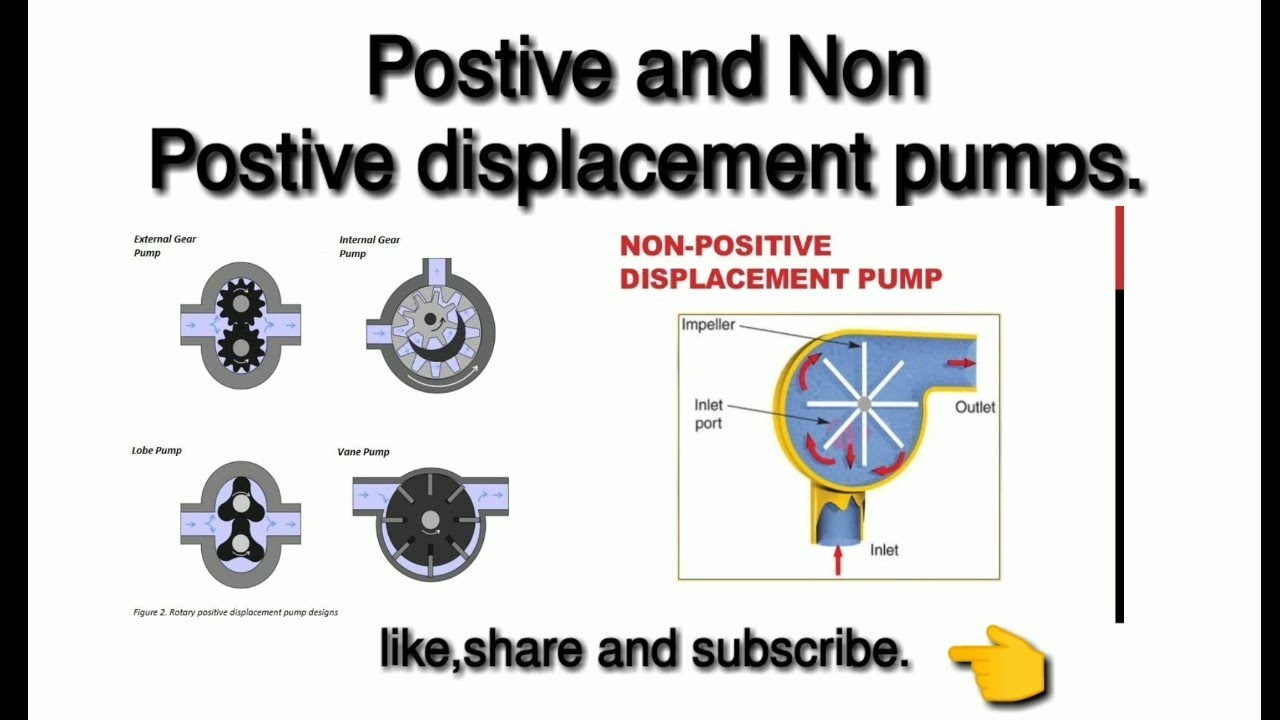

There are two main types of rotary gear pumps, internal and external. Both types use similar principles for pumping fluids. Two gears are inside a casing in a way that the teeth lock together. As a motor turns one of the gears the locking teeth turn the other. The difference in the two designs is that an external gear pump uses side-by-side gears (typically the same size), so when the motor turns one gear, the other rotates in the opposite direction. The internal gear pump design uses two different size gears. A motor turns the small gear, which is inside the larger gear, rotating it in the same direction.

DAE Pumps offers economical rotary gear pumps of both types in a variety of sizes. No other gear pumps can match the performance and durability of our pumps. Because of the close tolerance between the gears and casing, most gear pumps are highly susceptible to wear, but DAE Pumps gear pumps outperform all others. Our pumps process a wide range of viscosities and are ideal for handling fluids at high pressures and low flow rates. DAE Pumps rotary gear pumps are widely used in chemical installations to pump high viscosity fluids. They are one of the most common types of pumps for moving corrosive liquids and hydraulic fluid power applications.

DAE pumps gear pumps provide consistency in moving a variety of slurry materials and are suitable for several industries like paints, food processing, chemicals, oil & gas, and others. Our rotary gear pumps are available in duplex steel, cast steel, and cast iron, among other materials. Contact DAE Pumps to customize a pump to your specific needs.

These pumps have a number of vanes that are free to slide into or out of slots in the pump rotor. When the pump driver turns the rotor, centrifugal force,...

DNOW provides both sales and service/repair for a wide wide variety of positive displacement pumps. Our product line is offered through our Odessa Pumps and Power Service divisions, use the filter below to see all DNOW products or those specialized by Odessa Pumps and Power Service.

Also known as gear pumps, these have few moving parts so they"re less prone to wear than other hydraulic pumps. Combine with an electric motor to generate flow in a hydraulic system. To mount to a NEMA C-face motor, use a Pump-to-Motor Mount (sold separately).

DXP represents several world class lobe pump suppliers and applies lobe pumps in multiple markets including food & beverage, pharmaceutical, biotechnology, chemical, municipal and other industrial markets. Typically lobe pumps are used in sanitary or ultraclean applications but they can also be applied when transporting various forms of sludge, bio-solids or greases. Unlike other rotary positive displacement pumps, lobe pump use timing gears to prevent the two rotors from contacting one another, allowing them to be more tolerant of solids and also to be more shear sensitive.

As a leading global supplier of Reciprocating Pumps, Power Zone offers a wide range of Direct Acting Steam Pumps and Power Plunger Pumps in both Single Acting and Double Acting configurations. We have a large stock of new, used, and rebuilt plunger pumps including Triplex Pumps, Quintuplex Pumps, Duplex Pumps and more in Non-API and API 674 reciprocating pump design standards. Reciprocating Pumps, or sometimes referred to as Plunger Pumps, are a type of Positive Displacement Pumps (PD Pumps) and are ideal for high pressure, low flow applications. We supply plunger pumps from all leading brands including National, Gardner Denver, Oil Well, Gaso and Wheatley for various applications like salt water disposal (SWD), well service, descaling and hydraulic fracturing. Reciprocating pumps are commonly used in a wide range of industries, including Oil & Gas, Manufacturing and Mining.

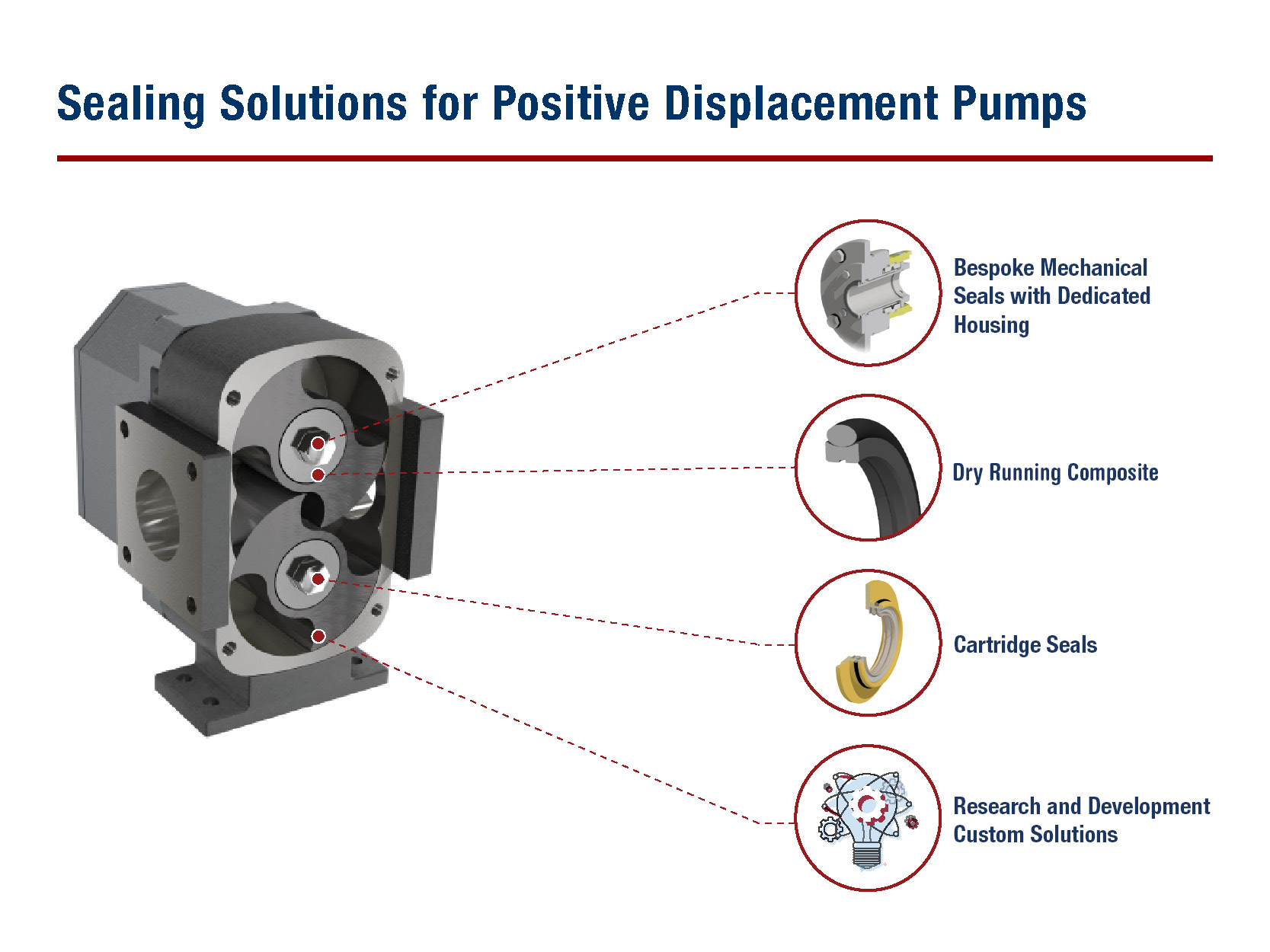

High temperature applications can be found in nearly every industry, making an understanding of how to handle them critical. Use of a standard or stock pump on a high temperature application may lead to leaking seals, stalled drives, or even break the pump.

No two applications are the identical so it’s critical to gather all of the details before selecting the right high temperature pump. Pump sizing, material selection, seal selection, flow required, pressure required, liquid viscosity, suction conditions, duty cycle, and of course, the range of temperatures that the pump will have to operate in.

Anderson Process partners with trusted high temperature pump manufacturers — including Blackmer Gear Pumps and Liquiflo— to offer a large selection of positive displacement high temperature pumps for nearly any industrial process application.

Viking Pump, a Unit of IDEX Corporation, leads the world in the design and manufacture of rotary Positive Displacement Pumps for use in some of the toughest applications. Since 1911, our innovative products have been key contributors to successful operations in virtually every industry—from military, to food and beverage, to chemicals, fuels, and plastics—reliably pumping materials that are thin, thick, hot, cold, liquid, solid, etc.

Positive Displacement pumps are used to move fluids more viscous than water. There are multiples types of positive displacement pumps including progressive cavity pumps, gear pumps, and lobe pumps. We are suppliers of used positive displacement pumps with traits such as sanitary positive displacement pumps and stainless steel positive displacement pumps. Our inventory includes used WAUKESHA positive displacement pumps, MOYNO pumps, and ROBBINS & MYERS pumps as well as other brands in a variety of capacities and horsepower.

At Coker Pump & Equipment Company, we are proud of our history of providing high quality pumping products since 1956. Our customers in Nevada and Central Valley / East Bay California have access to a wide selection of pumps, including positive displacement pumps. We offer gear, rotary lobe, air operated, and high pressure positive displacement pumps from many top manufacturers. Coker stocks gear pumps from Liquiflo and Viking Internal/External that can handle tough materials, including asphalt, chemical, corn syrup, fuel oil, resins, and many more. They can accommodate flows up to 1500 GPM and temperatures up to 800°F. We also carry rotary lobe pumps that serve industries from cosmetics and beverages to meat packing, chemical, and industrial. And our selection of air operated and high pressure pumps come from well-known brands like Graco, Lutz, and Versa-Matic.

The global positive displacement pumps (PDP) market size stood at USD 6.90 billion in 2019 and is projected to reach USD 11.25 billion by 2027, exhibiting a CAGR of 6.9% during the forecast period.

Fast-paced investments in various hydrocarbon assets to conduct exploration & production (E&P) activities are projected to boost the global PDP market. Furthermore, the increasing number of new chemical processing plants coupled with growing measures to treat wastewater to remove harmful effluents is set to propel the industry landscape further. A positive displacement pump is another type of pump which is used to push a fixed volume of fluid into the discharge zone. These units operate with a high power density and deliver a considerably high discharge pressure for effective integration in various industrial operations.

Several industry players are readily increasing their focus on providing end-to-end pump monitoring to minimize any risk of component failure. Various technologies are integrated to provide cost-effective solutions for observing temperature, vibration, flow rate, and fluid movement by installing tools like sensors, Wi-Fi, data analytics, advanced variable frequency drives, and Industrial Internet of Things (IIoT). Furthermore, these innovative solutions widely help to perform predictive analysis and precisely evaluate the equipment’s life cycle, performance indication and preclude the facility from unplanned downtime.

Various authorities and organizations across different regions have enacted stern norms to keep a check on harmful releases from numerous industrial establishments. Wastewater treatment involves pumping of discharged effluents from the outlet pipes of various industries to a separate unit for removal of hazardous content and uses the cured fluid for other operations. For instance, the U.S. Environmental Protection Agency (EPA) implemented the Clean Water Act (CWA) under 33 U.S.C. §1251 to regularize and standardize the pollutant discharges into clean surface waters across the country.

Positive displacement pumps are widely integrated into various industry verticals owing to their high operational efficiency and less frequent maintenance needs. These are also used significantly in numerous mining operations across the globe due to their ability to diminish abrasive wear & tear of its components by working at slow speeds. A PDP also offers substantial energy savings by working with high effectiveness and are installed for mine dewatering & pumping fluids with solid content. Furthermore, economical operations, varying pressure output, reliable operations, and optimum displacement design are some of the factors propelling the adoption of these units in power generation stations.

Industrial infrastructures across several regions are expanding rapidly with ongoing investments in new chemical plants to boost the PDP market. The units deliver easy pumping operations of medium to very high viscous fluids with high pressures. Besides, these products also help in thrusting fluids with low vapor pressures and handle corrosive chemicals like liquid foods, brines, and acids.

The movement of pistons in a positive displacement pump often creates pulsations between the outlet and inlet ports of the body. These severe pulsations are likely to impart significant damage to nearby systems if they are not treated. Hence, a pulsation dampener is required in an oscillating PDP unit to treat the oscillations and mitigate risks to other equipment. Additionally, the products require pressure relief or safety valves along with many other wear & tear prevention parts as it does not put restrictions on the pressure of the fluid. PD pumps are also susceptible to high speeds owing to their complex mass balancing to solve vibrating issues.

Based on type, the industry is trifurcated into reciprocating pumps, rotary pumps, and peristaltic pumps. Reciprocating pumps segment is projected to lead the PDP market owing to its extensive features and a wide range of applications. The pump primarily uses a plunger, piston, or diaphragm in continuous back-and-forth movement to provide high-pressure output with accurate metering of pump discharges. Reciprocating PDPs are available in single-acting and double-acting system designs based upon the number of discharges and suction per crankshaft revolution.

Minimal fluid leakage or slippage along with fixed casing sizes to maintain clearances between stationary and rotating parts is projected to complement the installation of the rotary pump type segment. These units are readily deployed to propel high viscous fluids like oil and slurries, along with numerous abrasive fluids at high pressures. Subsequently, the peristaltic type of PDPs uses the movement of surrounding walls at fixed intervals to effectively transfer mechanical energy to the pumping fluid. The systems offer significant advantages like less exposure towards cavitation problems coupled with the contact of pumping fluid with the smooth surface only to throw liquid to the discharge point effectively.

Based on end-user, the market can be primarily divided into water & wastewater, mining, oil & gas, chemicals, power generation, food & beverage, and others. Growing need to pump liquids with high thickness at elevated pressures to effectively carry out different operations has positively influenced the adoption of positive displacement pumps (PDP) for various purposes. The oil & gas segment is likely to shape the market trends owing to increasing expenditures on E&P activities along with discoveries of new high potential reserves. Positive displacement pumps are used in vital operations in oil & gas operations, including drilling to pump drilling fluids, cementing, well treatment, hydraulic fracturing, and many others.

Consequently, water & wastewater is also projected to account for a substantial portion during the forecast timeline owing to stringent government norms to keep a check on the contamination of clean water sources. Additionally, various industry players have also revealed noteworthy decisions to recycle the discharged liquids for other operations. The food & beverage end-user industry is likely to observe a considerable increase due to the constant need for pumping food ingredients like syrups & vinegar with smooth, hygienic, and quick operations.

Geographically, the positive displacement pumps (PDP) market has been analyzed across five key regions, including North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. Asia Pacific is anticipated to lead the industry over the forecast period. Increasing hydrocarbon activities to suffice the expanding energy demand among different countries is likely to propel the regional industry landscape. Major nations actively participating in the territory are India, China, Australia, Japan, and numerous Southeast Asian countries.

In November 2019, the Weir group’s mineral division announced the successful integration of their GEHO positive displacement pumps in SIMEC mining’s project in South Australia. The company’s GEHO units help to transport slurry at the rate of around 300 tons per hour through a pipeline to a steel producing facility.

Different players across the positive displacement pumps market are increasingly participating in organic & inorganic developments to fortify their market position globally. Additionally, the companies are also expanding their product portfolios by introducing high power and more efficient pump units to increase the applicability of their offerings in different industrial verticals. For instance, in October 2019, the Bran+Luebbe brand, under its parent organization, SPX Flow fabricated a new type of reciprocating pump unit called Novados double-acting, double-diaphragm (DADD) pumps for installations in chemical injection processes. The new product will be lighter in weight and possess a compact design along with precise & safe handling of hazardous chemicals for offshore oil & gas installations.

In June 2021, A major supplier of process equipment, Anderson Process, acquired a leading pump service provider and distributor Premier Pump Inc., based in Ohio. Afte After the acquisition, Anderson Process will supply a series of process equipment, including pumps, filtration, and more, for the firm situated in the Midwest region.

In June 2021, A prime leader in reciprocating compressor technology and specialty pumps, Blackmer, declared that its new sliding vane pump is now available. The new product named Blackmer TLGLF3HD is a special flange-mounted pump designed to increase pump safety and reliability by optimizing the unloading and loading speeds of LPG products for trucks.

In January 2021, IDEX corporation announced the acquisition of Abel Pumps, L.P., valued at USD 103.5 million and is expected to complete in the first quarter of 2021. Abel Pumps, a German-based company majorly focused on manufacturing and designing engineered reciprocating positive displacement pumps.

In January 2021, A global leader in the supply of positive displacement pumps, Unibloc Pump, declared that the firm had been acquired by a Midwest private equity company May River Capital. May River Capital is a private equity firm based in Chicago majorly focused on investing in industrial growth companies, including investments in engineered products, precision manufacturing, and specialized industrial services.

The expansion of positive displacement pumps market is propelled by expanding oil & gas operations across different regions, coupled with significant investments in chemical production units. Furthermore, growing measures to curb the effluent discharge in clean waters and the introduction of new policies to treat commercial & industrial water releases will upsurge the PD pumps demand. Consequently, rising investments in mining operations to continuously produce various metals and minerals is set to shape the future market trends.

The positive displacement pumps market report offers qualitative and quantitative insights on the positive displacement pumps and the detailed analysis of market size & growth rate for all possible segments in the market.

Along with this, the report provides an elaborative analysis of market dynamics, emerging trends, and competitive landscape. Key insights offered in the report are the advancement in technology for PD pumps market by individual segments, recent industry developments such as partnerships, mergers & acquisitions, consolidated SWOT analysis of key players, Porter’s five forces analysis, business strategies of leading market players, macro and micro-economic indicators, and key industry trends.

A Positive Displacement pump (PD pump) is a mechanical device which displaces a known quantity of liquid for every revolution or cycle that the pump completes. The flow rate through a positive displacement pump is directly proportional to its speed and number of cycles over a given time.

A positive displacement pump works by using a screw, a blade, a vane, a lobe, a gear or diaphragm. It creates a chamber or cavity between the pumping elements and the cavity in which the fluid is temporarily stored is moved by the reciprocating or rotary motion along the pipe to its destination.

Progressive Cavity Pump has a rotor rotating within a housing called a stator. The rotor is always metallic and the stator is made up of a rubber type of material. It looks somewhat like a screw thread – the fluid is between the cavities and the rotary motion of the rotor forces the fluid through from one end to the other. It has a low to moderate capacity, low to high pressure, good solids handling capability, one seal, low shear, constant flow and a low pulsation.

Rotary Lobe Pumphas moderate to high capacity, low to moderate pressure, good solids handling capability, two/four seals, a constant flow and moderate pulsation.

Screw Pump –the screw pump has multi versions known as multi screw pumps featuring moderate to high capacity, high pressures, only lubricative liquids, no solids handling capability, one seal and a constant flow.

Diaphragm Pump – Air Operated Diaphragm Pump has low to moderate capacity, low to moderate pressure, very low efficiencies, no seal and high pulsation.

Positive Displacement pumps are generally used for fluids with a relatively high viscosity. They can be used where high accuracy is required e.g metering or dosing. They can also be used where high pressures are required i.e high pressure washing. Waste Water Treatment is another application e.g Netzsch Tornado Rotary Lobe Pump

The main advantages of a Positive Displacement Pump is that it can handle highly viscous fluids whereas a Centrifugal Pump would be inefficient and require high driver powers. PD pumps also have a good volumetric efficiency & driver power is kept to a minimum. The flow rate is easily adjustable via a speed control because the flow rate is directly proportional to its speed. Driver sizing is not as critical as with a Centrifugal pump because the pump will deliver the known quantity of fluids regardless of system back pressure (losses). A Positive Displacement Pump can produce a very low shear action in the case of sensitive fluids.

The main disadvantages of a Positive Displacement Pump vs a Centrifugal pump is that dry running can be catastrophic due to either close clearances of parts or in the case of progressive cavity pumps the interference fit between the rotor and stator. All PD pumps require the installation of a pressure relief valve to prevent failure of the pump or piping in case of accident or closure of the delivery valve or blockage in the piping. Main pd pumps will produce pulsations which can lead to undesirable effects i.e vibration, product damage & water hammer. PD pumps have a limited flow range ~1000m³/hr vs 180,000m³/hr Centrifugal Pumps. The material of construction of PD pumps are more limited in range of available materials than that of Centrifugal Pumps and finally PD pumps have limited solids handling ability in terms of size and/or content.

A Positive Displacement Pump will usually self-prime due to the very small clearances which exist within the pump. This will help it pull a vacuum and thus expel the air through the pump until the liquid reaches the pump. Care should be taken on the suction line i.e installation of a “goose neck” which will ensure there is some liquid in the pump during the priming cycle which will prevent dry running & consequently failure.

An Air Operated Diaphragm pump (AODD pump) is able to self-prime without any liquid being present but this capability to lift is limited if the line is empty of fluid.

Certain Positive Displacement Pumps can run dry i.e Air Operated Diaphragm pumps have no parts requiring lubrication or no close clearances between parts. Peristaltic pumps can run dry as the hose is lubricated in a bath of its own fluid. Other types of PD pumps should not be run dry.

Every pump has a NPSH (Net pressure suction head) required to ensure reliable and trouble-free operation without damage caused by cavitation therefore therefore the system should be designed to ensure there is a sufficient margin between NPSHA (Net pressure suction head available) and NPSHR (Net pressure suction head required).

Unlike a centrifugal pump which produces pressure, a positive displacement pump does not produce pressure – it is the system itself that develops pressure from the pressure drop which then creates a back pressure which largely depends on the flow rate through the system i.e higher flow rates will result in higher losses and as a result a higher back pressure. The back pressure is also dependent on the pressure in the vessel at the point of discharge i.e a hydrogen blanket present or steam. The pressure is controlled largely by the pumping rate, therefore, pressure is controlled by varying the speed of the pump. In cases where the variable speed drive is not deployed the system pressure will be controlled to a degree by the setting of the pressure relief valve.

Positive Displacement Metering pumps are usually used where a high degree of accuracy is required e.g in dosing applications where pH control is required e.g Waste Water Treatment Plants or where filling lines require accuracy of volumes of fluid dispersed into containers.

Flexachem are the leading distributors for Netzsch Positive Displacements Pumps in Ireland – Progressive Cavity Pump, Rotary Lobe Pump (Industrial applications) & Screw Pump. We also supply Inoxpa Sanitary Rotary Lobe Pump and Flotronic Air Operated Diaphragm Pumps for the Food & Beverage & Pharma sectors.

We provide localised technical support & on-site service engineering to support the operational needs of our clients. We also hold a heavily stocked inventory to help take the pressure off you in the event of unexpected emergencies. Why not contact one of our Pump Specialists if you have a particular application in mind.

The global positive displacement pumps market size reached US$ 13.5 Billion in 2022. Looking forward, IMARC Group expects the market to reach US$ 19.1 Billion by 2028, exhibiting a growth rate (CAGR) of 5.85% during 2023-2028.

The growing need for wastewater treatment from the refining, chemical and pharmaceutical industries is the key factor driving the growth of the market. Growing population and industrialization have resulted in a burgeoning demand for crude oil which has consequently augmented the demand for positive displacement pumps. Furthermore, various water-dependent industries such as marine and textile are increasingly installing water treatment systems that consist PMPs to enhance reliability, sustainability and profitability of their operations. Moreover, increased exploratory activities in the oil and gas industry along with various technological advancements such as the mixture of hydraulic fracturing and horizontal drilling have boosted the global levels of oil production, thus attracting numerous vendors to invest in this market.

IMARC Group provides an analysis of the key trends in each sub-segment of the global positive displacement pumps market report, along with forecasts at the global and regional level from 2023-2028. Our report has categorized the market based on product type, capacity, pump characteristics, raw material and end use industry.

The report has also analysed the competitive landscape of the market with some of the key players being Flowserve Corporation, Grundfos A/S, ITT Inc., KSB SE & Co. KGaA, SPX FLOW, ALFA LAVAL Corporate AB, Schlumberger Corporate Communications, Colfax Corporation, HERMETIC-Pumpen GmbH, Xylem, Inc., Sulzer Management Ltd., Baker Hughes Company, EBARA CORPORATION, WEIR GROUP PLC, FRISTAM Pumpen KG (GmbH & Co.), Altra Industrial Motion Corp., A.R. North America, Inc., Verder International B.V., and Watson-Marlow Fluid Technology Group.

Flowserve Corporation, Grundfos A/S, ITT Inc., KSB SE & Co. KGaA, SPX FLOW, ALFA LAVAL Corporate AB, Schlumberger Corporate Communications, Colfax Corporation, HERMETIC-Pumpen GmbH, Xylem, Inc., Sulzer Management Ltd., Baker Hughes Company, EBARA CORPORATION, WEIR GROUP PLC, FRISTAM Pumpen KG (GmbH & Co.), Altra Industrial Motion Corp., A.R. North America, Inc., Verder International B.V., and Watson-Marlow Fluid Technology Group

8613371530291

8613371530291