power steering pump used as hydraulic pump brands

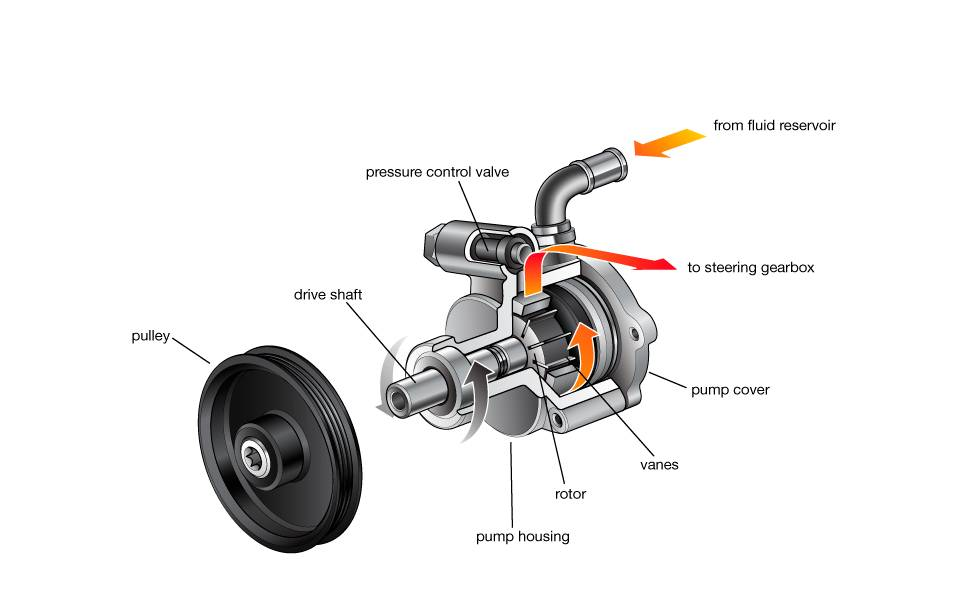

A power steering pump provides the required hydraulic pressure to steer your vehicle with minimal effort on the steering wheel. The power steering pump is driven by the engine’s crankshaft via a belt-pulley. The pump is usually located in the front of the engine, opposite to the alternator or AC compressor. The steering pump compresses the hydraulic fluid at a rate directly proportional to the speed of the engine.

The mechanical hydraulic steering pump, also called servo pump, power steering pump or hydraulic pump, is driven by the vehicle engine via a V-belt. In this way, the pump generates the hydraulic pressure required by the power steering system to make the vehicle easier and thus more comfortable to steer when driving.

Two types of steering pumps, single and tandem, can be installed in commercial vehicles. Both have the same function, but tandem pumps also have an attached fuel pump driven by the same shaft.

This product carries our 12 Month Limited Warranty. All warranties are limited to the original purchaser and are not transferable to subsequent owners of the product. The warranty period begins on the purchase date.

Specifically excluded from this warranty are failures caused by lack of maintenance, misuse, negligence, modification, abuse, improper application, crash damage, installation or operation, or failures caused by unauthorized service or use of unauthorized parts.

Additionally excluded from this warranty are parts which are subject to normal wear and tear, such as bushings, fluids, hoses, gaskets, belts, etc. Products not manufactured by Trail-Gear Inc. are excluded from any warranty and shall be handled with the original manufacturer.

All parts used in a competitive racing environment are excluded from this warranty. If, after inspection, a part returned, under any warranty, is deemed to be ineligible for warranty repair or replacement, the part may be repaired or replaced for a discounted cost. Return shipping charges will apply. Any part for which a warranty replacement is sought must be returned to Trail-Gear Inc. before any replacement items can be shipped. All replacement parts shipped before the suspect part has been received and evaluated by Trail-Gear, MUST BE PAID IN FULL. In such a case, after the suspect part has been received and approved for a warranty replacement, the purchase price for the replacement will be refunded.

Please contact Trail-Gear Inc. at 559-252-4950 or email sales@trail-gear.com prior to returning any product(s) under warranty to verify that warranty is still in effect.

I have seen pumps that are internally regulated between 900 psi and 2000 psi, so there is some variance. A lot of the newer GM pumps are around 2.0 GPM, with the truck pumps largely being 3.0-3.5+ GPM. This link should get you started:

I recently had to rebuild a GM/Toyota pump (from a 2004-2007 Cadillac CTS-V) to match the volume requirements and pressure limitations of the rack in my Jaguar. I called A-1 Cardone, a company that remanufactures power steering pumps, and their techs were able to give me the PS volume and pressure of their rebuilt units, which in theory, should be about the same as the stock units. With that information, I was able to go to a salvage yard and buy an old pump to tear apart for parts.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A liquid reservoir powers hydraulic steering pump manufacturers at neutral pressure (atmospheric pressure), then this latter compresses it to reach an outlet pressure at the order of 60-80 bars. If you opt for belt power steering systems, this is your lucky day as we bring you some of the best power steering pulleys at preferential wholesale prices. We also have some pumps with integrated power steering pump reservoirs. This type of steering pump connects to the rack through a high-pressure steering pump hose.

There are two main types of hydraulic steering pump manufacturers. The hydraulic power steering pumps are considered as an old version of steering pumps, and they need to be equipped with the belt to run properly. Electric power steering pumps, on the other hand, don"t require any accessories circuit. As the name suggests, they have an electric motor to pressurize the steering fluid.

You should replace your power steering pump when observing any of the following signs: growls in the direction, the steering system no longer works, or fluid leakage in the power steering system. Once you identify that your steering pump is faulty, you can search for a new hydraulic steering pump manufacturers in our collections. We are sure you will be pleased with the affordable cost of our hydraulic steering pump manufacturers.

MAVAL power steering pumps come turn-key ready for installation. The pressure fitting and pressure relief valve of the pump are inspected while the existing seals and bearings are replaced with OEM parts. The rotor, cam ring, vanes and pressure plates are inspected and replaced as needed during the reman process. Each pump has the MAVAL part number etched into the housing as well as a serial number for traceability.

MAVAL power steering pumps come turn-key ready for installation. The pressure fitting and pressure relief valve of the pump are inspected while the existing seals and bearings are replaced with OEM parts. The rotor, cam ring, vanes and pressure plates are inspected and replaced as needed during the reman process. Each pump has the MAVAL part number etched into the housing as well as a serial number for traceability.

I know there has been some discussion in the past about using a power steering pump to drive a hydraulic winch, but I wonder if anybody else has used one of these to power any other kind of hydraulics?

I didn"t know it, but one of my friend"s sons works at a auto junk yard, and I now have access to some cheap parts. I just wondered if a power steering pump would have enough power to drive a couple of small cylinders and what the strength would be? I can see where I might be able to use one of these to make a log clamp and possibly a log turner for the home made bandmill--- if it would work and be strong enough. I would be driving it with a 12hp briggs lawn mower engine. Also, is there anything on a car or truck that one could modify to act as a drive motor- driven by the power steering pump? If so, I might could use this to drive the head rig...

Actually I have built several wood splitters using Saginaw power steering pumps and they do a commendable job. Pressure capability is more than adequate 850-1600 psi as it comes out of the car or truck. Small car=lower pressure, bigger truck=more pressure and more volume. The built in pressure reliefs can be bypassed.

I believe the Saginaw pumps, as in bobw53"s photo, came in two displacements, .94 cu in per revolution and 1.06 cu in per revolution so you"ll have to do the math for whatever you plan to power with it as far as required HP, speed or flow required.

I know on some of the splitters I built, a 5 HP B&S had it"s belly dragging the ground in order to drive it so it can suck up a bit of power fast. This was while pushing a 3.5" bore cylinder at about 1500 psi. This works out to about 14,000 lbs output force.

Older cars would slow the engine down while cranking the wheel, newer ones have a switch that senses pressure and sends a signal to the ECM to increase idle speed.

Flow is easily controlled with any one of many types of control valves and don"t worry about the tiny reservoir as that is probably the least of your worries. Whatever size you need whether it"s 1/2 pt. or 500 gallons is entirely up to you.

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system.

Hydrostatic pumps are positive displacement pumps while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or variable displacement pumps, which have a more complicated construction that allows the displacement to be adjusted. Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types all work on the principle of Pascal"s law.

Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or displacement of gear pumps for hydraulics will be between about 1 to 200 milliliters. They have the lowest volumetric efficiency (η

A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside a cavity. In some cases these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates. A critical element in vane pump design is how the vanes are pushed into contact with the pump housing, and how the vane tips are machined at this very point. Several type of "lip" designs are used, and the main objective is to provide a tight seal between the inside of the housing and the vane, and at the same time to minimize wear and metal-to-metal contact. Forcing the vane out of the rotating centre and towards the pump housing is accomplished using spring-loaded vanes, or more traditionally, vanes loaded hydrodynamically (via the pressurized system fluid).

Screw pumps (fixed displacement) consist of two Archimedes" screws that intermesh and are enclosed within the same chamber. These pumps are used for high flows at relatively low pressure (max 100 bars (10,000 kPa)).ball valves

The major problem of screw pumps is that the hydraulic reaction force is transmitted in a direction that"s axially opposed to the direction of the flow.

Bent axis pumps, axial piston pumps and motors using the bent axis principle, fixed or adjustable displacement, exists in two different basic designs. The Thoma-principle (engineer Hans Thoma, Germany, patent 1935) with max 25 degrees angle and the Wahlmark-principle (Gunnar Axel Wahlmark, patent 1960) with spherical-shaped pistons in one piece with the piston rod, piston rings, and maximum 40 degrees between the driveshaft centerline and pistons (Volvo Hydraulics Co.). These have the best efficiency of all pumps. Although in general, the largest displacements are approximately one litre per revolution, if necessary a two-liter swept volume pump can be built. Often variable-displacement pumps are used so that the oil flow can be adjusted carefully. These pumps can in general work with a working pressure of up to 350–420 bars in continuous work.

By using different compensation techniques, the variable displacement type of these pumps can continuously alter fluid discharge per revolution and system pressure based on load requirements, maximum pressure cut-off settings, horsepower/ratio control, and even fully electro proportional systems, requiring no other input than electrical signals. This makes them potentially hugely power saving compared to other constant flow pumps in systems where prime mover/diesel/electric motor rotational speed is constant and required fluid flow is non-constant.

A radial piston pump is a form of hydraulic pump. The working pistons extend in a radial direction symmetrically around the drive shaft, in contrast to the axial piston pump.

The Power steering pump supplies pressurized fluid which allows you to turn the steering wheel so easily. The power steering pump is a vital component used in your vehicle"s power steering system. The power steering pump allows the driver to direct the vehicle without exerting the effort it would require to turn the wheel physically. In a power steering system, movements made on the steering wheel cause fluid pressure inside the hydraulic pump to move to one side or the other of the pump. This pressure causes a piston to move, and that cylinder directs the gears to steer the car.

8613371530291

8613371530291