power up and down hydraulic pump manufacturer

Bucher power up/gravity down pump with 6 qt poly tank. Port size is 3/8" NPT. Reservoir is 6.7" x 6.7" x 13". 1.25 gpm at 1,750 psi. Horizontal mount. Direct replacement for Light, Medium, and Heavy Duty dump kits.

We Use Cookies! Cookies make everything work well on our site. We understand if you don"t want to use them. However, many of the features are required to make the site work well. If you would like to not use these cookies, call us on our 1-800 number from a burner phone, place your order, then dispose of the phone after removing battery and disassembling.

Hydraulic systems are in general members of the fluid power branch of power transmission. Hydraulic pumps are also members of the hydraulic power pack/hydraulic power unit family. Hydraulic units are encased mechanical systems that use liquids for hydraulics.

The hydraulic systems that hydraulic pumps support exist in a range of industries, among them agriculture, automotive manufacturing, defense contracting, excavation, and industrial manufacturing. Within these industries, machines and applications that rely on hydraulic pumps include airplane flaps, elevators, cranes, automotive lifts, shock absorbers, automotive brakes, garage jacks, off-highway equipment, log splitters, offshore equipment, hydraulic motors/hydraulic pump motors, and a wide range of other hydraulic equipment.

When designing hydraulic pumps, manufacturers have many options from which to choose in terms of material composition. Most commonly, they make the body of the pump–the gears, pistons, and hydraulic cylinders–from a durable metal material. This metal is one that that can hold up against the erosive and potentially corrosive properties of hydraulic fluids, as well as the wear that comes along with continual pumping. Metals like this include, among others, steel, stainless steel, and aluminum.

First, what are operating specifications of their customer? They must make sure that the pump they design matches customer requirements in terms of capabilities. These capabilities include maximum fluid flow, minimum and maximum operating pressure, horsepower, and operating speeds. Also, based on application specifications, some suppliers may choose to include discharge sensors or another means of monitoring the wellbeing of their hydraulic system.

Next, what is the nature of the space in which the pump will work? Based on the answer to this question, manufacturers will design the pump with a specific weight, rod extension capability, diameter, length, and power source.

Manufacturers must also find out what type of substance does the customer plan on running through the pumps. If the application calls for it, manufacturers can recommend operators add other substances to them in order to decrease the corrosive nature of certain hydraulic fluids. Examples of such fluids include esters, butanol, pump oils, glycols, water, or corrosive inhibitors. These substances differ in operating temperature, flash point, and viscosity, so they must be chosen with care.

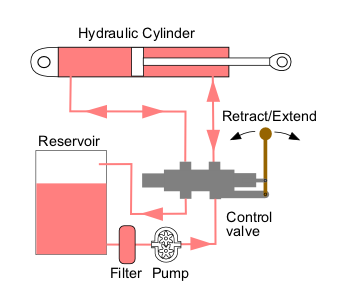

All hydraulic pumps are composed in the same basic way. First, they have a reservoir, which is the section of the pump that houses stationary fluid. Next, they use hydraulic hoses or tubes to transfer this fluid into the hydraulic cylinder, which is the main body of the hydraulic system. Inside the cylinder, or cylinders, are two hydraulic valves and one or more pistons or gear systems. One valve is located at each end; they are called the intake check/inlet valve and the discharge check/outlet valve, respectively.

Hydraulic pumps operate under the principle of Pascal’s Law, which states the increase in pressure at one point of an enclosed liquid in equilibrium is equally transferred to all other points of said liquid.

To start, the check valve is closed, making it a normally closed (NC) valve. When the check is closed, fluid pressure builds. The piston forces the valves open and closes repeatedly at variable speeds, increasing pressure in the cylinder until it builds up enough to force the fluid through the discharge valve. In this way, the pump delivers sufficient force and energy to the attached equipment or machinery to move the target load.

When the fluid becomes pressurized enough, the piston withdraws long enough to allow the open check valve to create a vacuum that pulls in hydraulic fluid from the reservoir. From the reservoir, the pressurized fluid moves into the cylinder through the inlet. Inside the cylinder, the fluid picks up more force, which it carries over into the hydraulic system, where it is released through the outlet.

Piston pumps create positive displacement and build pressure using pistons. Piston pumps may be further divided into radial piston pumps and axial piston pumps.

Radial pumps are mostly used to power relatively small flows and very high-pressure applications. They use pistons arranged around a floating center shaft or ring, which can be moved by a control lever, causing eccentricity and the potential for both inward and outward movement.

Axial pumps, on the other hand, only allow linear motion. Despite this, they are very popular, being easier and less expensive to produce, as well as more compact in design.

Gear pumps, or hydraulic gear pumps, create pressure not with pistons but with the interlocking of gear teeth. When teeth are meshed together, fluid has to travel around the outside of the gears, where pressure builds.

External gear pumps facilitate flow by enlisting two identical gears that rotate against each other. As liquid flows in, it is trapped by the teeth and forced around them. It sits, stuck in the cavities between the teeth and the casing, until it is so pressurized by the meshing of the gears that it is forced to the outlet port.

Internal gear pumps, on the other hand, use bi-rotational gears. To begin the pressurizing process, gear pumps first pull in liquid via a suction port between the teeth of the exterior gear, called the rotor, and the teeth of the interior gear, called the idler. From here, liquid travels between the teeth, where they are divided within them. The teeth continue to rotate and mesh, both creating locked pockets of liquid and forming a seal between the suction port and the discharge port. Liquid is discharged and power is transported once the pump head is flooded. Internal gears are quite versatile, usable with a wide variety of fluids, not only including fuel oils and solvents, but also thick liquids like chocolate, asphalt, and adhesives.

Various other types of hydraulic pumps include rotary vane pumps, centrifugal pumps, electric hydraulic pumps, hydraulic clutch pumps, hydraulic plunger pumps, hydraulic water pumps, hydraulic ram pumps, portable 12V hydraulic pumps, hydraulic hand pumps, and air hydraulic pumps.

Rotary vane pumps are fairly high efficiency pumps, though they are not considered high pressure pumps. Vane pumps, which are a type of positive-displacement pump, apply constant but adjustable pressure.

Centrifugal pumps use hydrodynamic energy to move fluids. They feature a rotating axis, an impeller, and a casing or diffuser. Most often, operators use them for applications such as petroleum pumping, sewage, petrochemical pumping, and water turbine functioning.

Electric hydraulic pumps are hydraulic pumps powered by an electric motor. Usually, the hydraulic pump and motor work by turning mechanisms like impellers in order to create pressure differentials, which in turn generate fluid movement. Nearly any type of hydraulic pump can be run with electricity. Most often, operators use them with industrial machinery.

Hydraulic clutch pumps help users engage and disengage vehicle clutch systems. They do so by applying the right pressure for coupling or decoupling shafts in the clutch system. Coupled shafts allow drivers to accelerate, while decoupled shafts allow drivers to decelerate or shift gears.

Hydraulic ram pumps are a type of hydraulic pump designed to harness hydropower, or the power of water, to elevate it. Featuring only two moving hydraulic parts, hydraulic ram pumps require only the momentum of water to work. Operators use hydraulic ram pumps to move water in industries like manufacturing, waste management and sewage, engineering, plumbing, and agriculture. While hydraulic ram pumps return only about 10% of the water they receive, they are widely used in developing countries because they do not require fuel or electricity.

Hydraulic water pumps are any hydraulic pumps used to transfer water. Usually, hydraulic water pumps only require a little bit of energy in the beginning, as the movement and weight of water generate a large amount of usable pressure.

Air hydraulic pumps are hydraulic pumps powered by air compressors. In essence, these energy efficient pumps work by converting air pressure into hydraulic pressure.

Hydraulic pumps are useful for many reasons. First, they are simple. Simple machines are always an advantage because they are less likely to break and easier to repair if they do. Second, because fluid is easy to compress and so quick to create pressure force, hydraulic pumps are very efficient. Next, hydraulic pumps are compact, which means they are easy to fit into small and oddly shaped spaces. This is especially true in comparison to mechanical pumps and electrical pumps, which manufacturers cannot design so compactly. Speaking of design, another asset of hydraulic pumps is their customizability. Manufacturers can modify them easily. Likewise, hydraulic pumps are very versatile, not only because they are customizable, but also because they can work in places where other types of pump systems can’t, such as in the ocean. Furthermore, hydraulic pumps can produce far more power than similarly sized electrical pumps. Finally, these very durable hydraulic components are much less likely to explode than some other types of components.

To make sure that your hydraulic pumps stay useful for a long time, you need to treat them with care. Care includes checking them on a regular basis for problems like insufficient fluid pressure, leaks, and wear and tear. You can use diagnostic technology like discharge sensors to help you with detect failures and measure discharge pressure. Checking vibration signals alone is often not enough.

To keep yourself and your workers safe, you need to always take the proper precautions when operating or performing maintenance and repairs on your hydraulic pumps. For example, you should never make direct contact with hydraulic fluid. For one, the fluid made be corrosive and dangerous to your skin. For two, even if the pump isn’t active at that moment, the fluid can still be pressurized and may potentially harm you if something goes wrong. For more tips on hydraulic pump care and operation, talk to both your supplier and OSHA (Occupational Safety and Health Administration).

Pumps that meet operating standards are the foundation of safe and effective operations, no matter the application. Find out what operating standards your hydraulic pumps should meet by talking to your industry leaders.

The highest quality hydraulic pumps come from the highest quality hydraulic pump manufacturers. Finding the highest quality hydraulic pump manufacturers can be hard, which is why we have we listed out some of our favorites on this page. All of those whom we have listed come highly recommended with years of experience. Find their information nestled in between these information paragraphs.

Before checking out any of these suppliers, we recommend you take some time to jot down your specifications. That way, you will have an easier time figuring out which ones have potential for you and which ones do not. Plus, when you are ready to talk to a supplier, your list will help you steer the conversation. Do not forget to include in your list the nitty-gritty details like your timeline, your budget and your delivery preferences.

Once you have put together you list, get to browsing. Pick out three or four hydraulic pump supply companies to which you’d like to speak, then reach out to each of them. After you’ve spoken with representatives from each company, decide which one will best serve you, and get started on your project.

Dump Trailer Hydraulic Pump also named as hydraulic pump for dump trailer .Target Hydraulics 12V DC hydraulic pump for dump trailer/ Tipping Trailer applications in different countries such as UK, Germany, France, Australia, USA, Canada etc.

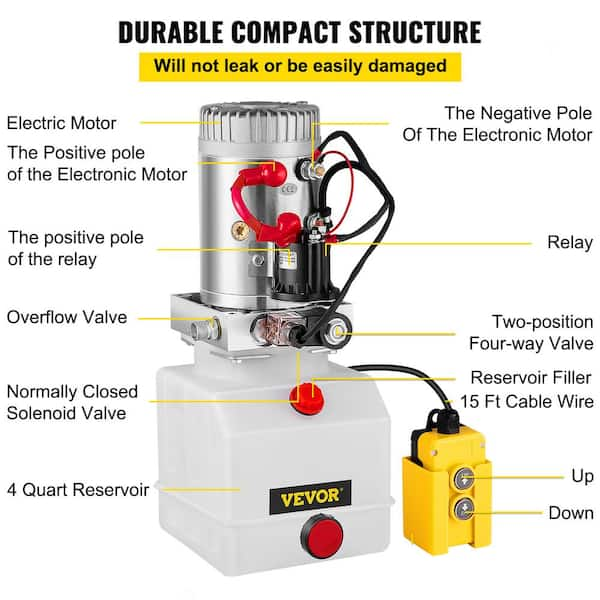

Lift Trailer Body, Push “up” button to start the motor to lift the Trailer by hydraulic cylinder, Push ”DW” button and the solenoid valve actives ,the cylinder lowering movement. Hydraulic oil back to tank and cylinder start closing. And dump trailer body start back to level position. Click technical data of single acting power unit troubleshooting you can learn.

It components by a high performance gear pump, a DC motor, a Aluminum Central Manifold, hydraulic cartridge valves and a hydraulic oil tank reservoir. There also come with a cable remote pendant or a wireless remote/radio remote to control hydraulic power pack .

This wireless remote works lets you operate your mini DC power pack from up to 200meters(650ft) without cables or switches. Just press the remote buttons and you’re ready to operate your small hydraulic power unit start and stop, make hydraulic cylinder in or out.

Wireless remote control receiver, two way non-power contact output, plastic shell, high sensitivity, strong anti-interference ability, widely used in industrial automatic control, power, motors, lights, security systems, such as, with convenient installation, safe and reliable, and other characteristics.

Our dump trailer pumps are widely use in different design of trailers, such as single acting hydraulic pump for dump trailer,heavy duty hydraulic pump for dump trailer,double acting hydraulic pump 12v dump trailer,etc

Dump trailer pumps are mainly 2 versions design, one is single acting, another is double acting. Both of them come with 2 buttons remote. We can also offer you customized ones.

Target Hydraulics manufacturer hydraulic valves, manifold blocks, and assembly dump trailer hydraulic pumps. Manifold endheads are 24 hours working, assembly hydraulic dump trailer work with the automatic production line.So, Our capability for dump trailer hydraulic pumps is fine.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

Check to enable permanent hiding of message bar and refuse all cookies if you do not opt in. We need 2 cookies to store this setting. Otherwise you will be prompted again when opening a new browser window or new a tab.

Double acting hydraulic power unit with 6 quarts plastic reservoir. Pressure relief valve at 2500 PSI, easily adjustable. Power up, power down application with wired remote included. 4.5″ motor works from battery 12V DC. Flow rated at 0.9 GPM flow @ 2500 PSI. 1-year warranty.

Hydraulic pumps have many benefits when it comes to unloading the heavy loads that dump trailers must haul on a regular basis. Hydraulic systems are easy to operate, and a pump seldom runs dry with proper maintenance. But, the real benefit of ahydraulic pump for dump trailersystem is the power these pumps can deliver.

Dump trailers get the greatest amount of power density from hydraulics when compared to other mechanical power transmission systems. This means, even the smallest hydraulic actuator can handle more force and power than a comparable electric or fuel-powered pump.

Hydraulic pumps for dump trailers are used to lift the truck’s trailer bed from the frame. Even though these pumps are workhorses and typically give many years of useful service, there are ways to extend the life of your dump trailers.

A dump trailer is a costly investment that will generally bring a full return when used consistently and maintained properly. And as in all mechanical systems, it is the moving parts of your dump trailer that wear out first. Here are some ways to extend the life of your dump trailer:

Top off fluids – Keep all fluids at their full levels and make sure all moving parts of the dump trailer are properly lubricated. You want to avoid dry hydraulic and lube conditions that will metal-to-metal damage. Also, make sure low fluid levels are not due to hydraulic pump leaks or hose seepage.

Keep strainer clean – Your pump’s strainer filter keeps coarse material out of the hydraulics system, but they themselves can become clogged. Remove any particles or debris from the strainer to improve the system’s efficiency and to prevent further damage to the pump for the dump trailer.

A dump pump is the type of hydraulic pump used for dump trailers. These pumps are not suited for continuous duty. They work by building pressure then releasing it through an assembly that features a three-way directional control valve.

Gear Pumps are the most common design, having fewer moving parts. These fixed displacement pumps will force oil through the system with each rotation of the pump’s shaft.

The first sign that the hydraulics pump on your dump trailer is bad is when the pump does not run at all. This is a total failure and will typically result in replacing the pump on your dump trailer. But, if the pump runs and the trailer doesn’t go up or down, then the hydraulics system does not have enough power to activate fluid solenoids that will activate the up and down valves.

Visit us at Panagon Systemsto learn more about our full line of hydraulic pumps, motors, and parts for a variety of industrial and mobile applications. Panagon Systems has been producing hydraulic parts on demand for a number of shops, manufacturers, and industries for over 25 years.

Our power units are some of the most reliable and durable units in the industry for use with dump trailers, dump trucks, RV"s, boat lifts, some liftgates, tow trucks, wreckers, car haulers, car lifts, agriculture equipment, snow plow equipment and a variety of other applications that require a powerful and compact hydraulic pump. If considering this item for your liftgate, please call to verify compatibility.

Get the most with your hydraulic power unit by upgrading to ourDeluxe Kit. Select theDeluxe Kitoption to include a hydraulic hose and fittings kit with your purchase.

Our power units are some of the most reliable and durable units in the industry for use with dump trailers, dump trucks, RVs, boat lifts, some liftgates, tow trucks, wreckers, car haulers, agriculture equipment, snow plow equipment, and a variety of other applications that require a powerful and compact hydraulic pump. If considering this item for your liftgate, please call to verify compatibility.

Get the most with your hydraulic power unit by upgrading to ourDeluxe Kit. Select theDeluxe Kitoption to include a hydraulic hose and fittings kit with your purchase.

The hydraulic pump is designed to be mounted horizontally or vertically – sight glass and dip stick can be switched on the round steel tank depending on the mounting direction of the pump to facilitate proper use. Dual location oil drain plugs are in easy to access positions regardless of pump orientation.

12-volt DC, 2 kW, 200-amp pump with sealed solenoid connections, to eliminate potential corrosion, produces an adjustable pressure up to 3200 PSI. 20-foot-long detachable pendant control has a magnetic base to easily attach to any metal location. Wires are protected with an all-weather jacket.

SPX FLOW brand Power Team specializes in high-pressure hydraulic technology. Through a broad range of leading-edge component parts, accessories and tools, Power Team enables the creation and upkeep of concentrated force delivery solutions that can meet any application criteria. These cover lifting, lowering, pushing, pulling, clamping, spreading and torquing activities. The Power Team portfolio features hydraulic pumps covering a wide variety of flow stage configurations and reservoir capacities, compact yet powerful jacks, cylinders (single and double action) and valves (load-lowering, shut-off, pressure-reducing, sequence, metering, etc.). In addition, Power Team supplies nut splitters, in-line drives, spreaders, bridge lifts, shop presses, mobile floor cranes and torque wrenches. Through this comprehensive portfolio, Power Team attends to the needs of the construction, automotive assembly, mining, shipbuilding, manufacturing and industrial processing sectors. Thanks to rugged design plus advanced protective coatings, Power Team equipment is able to cope with deployment in the most uncompromising of applications. It thereby delivers ongoing functional reliability under a range of stresses to an extent. As well as providing repair and maintenance services, Power Team also offers on-site safety training so customers can support the wellbeing of their workforce in potentially hazardous environments.

8613371530291

8613371530291