pto hydraulic pump meaning quotation

Road planers, dredges, and other equipment require power from some type of engine to perform their designed function. Without a power take-off, it would be necessary to add a second engine to provide the power required to run hydraulic pumps and other driveline attached equipment.

Adding an additional engine is simply not practical, which makes power take-off (PTO) a valuable element in providing power to secondary functions. To recognize their value requires a better understanding of these systems, their various types, and their diverse applications.

Power take-offs allow mobile crushing plants, road milling machines, and other vehicles to perform auxiliary functions without needing an additional engine to power them. A PTO is a device (a mechanism) usually seated on the flywheel housing, which transfers power from the driveline (engine) to a secondary application. In most cases, this power transfer applies to a secondary shaft that drives a hydraulic pump, generator, air compressor, pneumatic blower, or vacuum pump.

PTO choice is critical to provide sufficient power to the auxiliary equipment without severely limiting the main function of the prime mover. Selection of a power take-off requires specific information relating to the application and the power needs of the secondary or driven component.

Speed and rotation requirements of a PTO are among the most critical specifications in the list above, with speed being necessary for calculating torque. The torque and horsepower requirements of the driven component are essential for optimal performance.

Keep in mind that these calculations only apply to PTOs that drives a hydraulic pump. In cases where power take-off is providing power to a different type of drive component, it will require the manufacturer’s specifications of the driven element.

Though they perform the same general function—transferring power from the primary drive shaft to a secondary drive shaft for a driven component—there are various PTO types available that serve specific industrial applications. These diversifications are why WPT Power supplies OEM’s units in agricultural, energy, forestry, and road building sectors, among others.

The distinguishing characteristic of this type of PTO is the intentional removal of the pilot bearing. Benefits of this design feature come with an increased side load capacity, reduced inventory, increased uptime and engine life, and a quicker and easier installation. Industrial applications of the Pilotless Mechanical PTO include:

This type of flywheel PTO applies to either inline or sideload uses. It includes a sealed-for-life pilot bearing, utilizing a lever-actuated manual clutch. The benefit of this type of PTO is a straightforward installation which minimizes downtime and maintenance requirements. This type most commonly applies to:

This is a rugged, high-capacity power take off used in a broad range of industrial functions. Characteristic of this type of PTO are the sheaves between heavy-duty spherical roller bearings designed to utilize their full load potential. This bearing arrangement reduces the damage produced by crankshaft loading. Among the most common applications for the Type 1 PTO are:

The design of the Type 2 PTO features a heavy-duty side loading capacity using sizeable spherical roller bearings. Actuation of this PTO can be either hydraulic or pneumatic. It is self-adjusting and removes the need for the pilot bearing inside the engine flywheel. Features include reduced maintenance, less chance of premature failures, and improved engine and bearing life since there is no direct loading to the crankshaft. Common applications for Type 2 PTOs include:

This PTO design eliminates the need for the pilot bearing while providing increased side loading or inline potential. Its engineering accommodates the most demanding requirements of high-loading diesel engines. Features include simple installation, reduced downtime, and improved engine service life. This style of PTO is used on inline applications with its hydraulic and air fittings. They are mounted near the bell housing instead of at the rear of the shaft like type 1 and type 2.

The GM Style PTO reduces maintenance time and cost by using sealed main bearings and eliminating the need for the pilot bearing. Designed to mount directly to GM® style engines, these operate without the need for any particular PTO or engine adaptations. Notable features include clutch adjustments using an external ball stud and jam nut adjustment points.

Also known as “flat-faced” style PTOs, they incorporate similar design characteristics, features, and benefits of the GM style PTO. It is a spring-loaded clutch making it easier to engage and disengage than over the center power take-offs. Typical uses include irrigation units, brush chippers, or other gas or diesel engine applications.

PTOs are relatively simple mechanical units with minimal operational problems, but a few common issues are associated with them, and each has a straightforward solution. Here are some of the most frequently encountered issues:

PTO is hot. A newly installed PTO will run hot for the first 10-20 hours of operation after installation. Several issues contribute to overheating (220º F measured by infrared thermometer at the bearing carrier), including too much or too little grease, excessive sideload, or a new installation. Follow proper lubrication specifications and reduce the sideload to remedy the first two problems.

Getting the appropriate PTO to meet your operational needs is a priority at WPT Power. Manufacturing our PTOs takes place in our ISO 9001:2015 facilities, where all our products are engineered to meet the highest standards of quality demanded by our customers. ABS type approvals and ATEX certifications minimize risks, time, and costs. Type approval certification available: DNV & ABS (Others available on request)

Our broad range of products is developed to meet most requirements on standard industrial applications. Custom or modified PTOs are available for original equipment manufacturers (OEM) requiring specialized design and where volume is needed.

Power take-offs play an essential role in allowing for the transfer of power from a primary mover to a secondary or driven component without needing an additional separate engine. Various PTO types serve many applications, from smaller-scale operations to major industrial and construction projects. Choosing the correct PTO for a specific application is critical to the proper performance of the driven component.

Contact us for more information about the range of solutions offered by WPT Power Corporation, for assistance in selecting the right PTO to fit your specific application, or request a quote from one of our experts.

Hydraulic pumps convert mechanical energy into fluid power energy. All hydraulic pumps are positive displacement which means the outlet flow is sealed from the inlet flow. A small amount of fluid is designed to leak internally to lubricate and cool the internal components of the pump. The only function of the pump is to produce flow in a system. Bailey International, LLC provides a wide range of pumps and accessories including clutch pumps, dump, gear, jaw couplers, mounting brackets, pistons, PTO, vane and two stage pumps.

A PTO water pump allows you to utilize the power of one of our pumps, without the addition of a seperate power supply unit to run it. Generally our pumps are diesel over hydraulic, but by using a PTO our pumps will be driven mechanically, not hydraulically. This means there won’t be any hydraulic hoses or pumps to worry about while pumping.

Utilizing one of our Wheel Pumps, simply connect the wheel pump to your tractor or truck that sports a PTO and back the pump into the water. These water pumps are cost effective if you already own a machine that’s PTO driven.

The first benefit of PTO water pumps is the ease of use. There is relatively little you need to do to use a PTO water pump. Simply hook the pump motor up to the PTO. For wheel pumps, simply back the pump into the water or set the pump where you want to begin siphoning, then connect your discharge and you’re ready to begin pumping.

Another major benefits is that maintenance is much simpler for PTO pumps than it is with an all-in-one pump. There are less moving parts and no power units to troubleshoot when problems arise.

A power take-off or power takeoff (PTO) is one of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine.

Semi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory. In the case of a marine application, such shafts may be used to power fire pumps.

In aircraft applications, such an accessory drive may be used in conjunction with a constant speed drive. Jet aircraft have four types of PTO units: internal gearbox, external gearbox, radial drive shaft, and bleed air, which are used to power engine accessories. In some cases, aircraft power take-off systems also provide for putting power into the engine during engine start.Coffman starter.

Various power transmission methods were available before power take-offs became common, but there were applications which would benefit more from some of the attributes that PTOs would provide. Flat belts were generally only useful for applications where the engine was stationary, such as factory steam engines, portable stationary engines, or traction engines parked in front of the work. For moving vehicles such as a traction engine or early tractor towing a farm implement, the implement could receive rotary power by taking it from one of its own wheels (whose turning was imparted by the towing) and distributing it via roller chains (to a sickle bar"s crank, for example), but such a transmission ceases if the vehicle stops traveling, and the workload"s resistance tends to make the wheel skid rather than turn, even if cleated. The concept of a shaft drive with easily connected and disconnected couplings, and flexibility for driving at changing angles (such as when an articulated tractor-and-trailer combination turns), was a goal to pursue.

Experimental power take-offs were tried as early as 1878, and various homemade versions were constructed over the subsequent decades.International Harvester Company (IHC) was first to market with a PTO on a production tractor, with its model 8-16, introduced in 1918.Case models. In 1920, IHC offered the PTO option on their 15-30 tractor, and it was the first PTO-equipped tractor to be submitted for a Nebraska tractor test. The PTO was a competitive advantage for IHC in the 1920s, and other companies eventually caught up with PTO implementation.

Inside the transmission, the exact point along the gear train where the power is taken off determines whether the PTO can be run independently of vehicle travel (ground speed). Early PTOs were often taken off the main output shaft, meaning that the vehicle had to be "in gear" in order to run the PTO. Later this was improved by so-called live PTO (LPTO) designs, which allow control of the PTO rotation independently of the tractor motion. This is an advantage when the load driven by the PTO requires the tractor motion to slow or stop running to allow the PTO driven equipment to catch up. It also allows operations where the tractor remains parked, such as silo-filling or unloading a manure spreader to a pile or lagoon rather than across a field. In 1945, Cockshutt Farm Equipment Ltd of Brantford, Ontario, Canada, introduced the Cockshutt Model 30 tractor with LPTO. Most PTOs built today

The PTO and its associated shafts and universal joints are a common cause of incidents and injury in farming and industry. According to the National Safety Council, six percent of tractor related fatalities in 1997 in the United States involved the PTO. Incidents can occur when loose clothing is pulled into the shaft, often resulting in bone fractures, loss of limb, or death to its wearer. On April 13, 2009 former Major League Baseball star Mark Fidrych died as a result of a PTO related accident; "He appeared to have been working on the truck when his clothes became tangled in the truck"s power take-off shaft", District Attorney Joseph Early Jr. said in a statement.

Some implements employ light free-spinning protective plastic guards to enshroud the PTO shaft;Health and Safety Executive guidance is contained in a leaflet.

Agricultural PTOs are standardized in dimensions and speed. The ISO standard for PTOs is ISO 500, which as of the 2004 edition was split into three parts:

Due to ever-increasing horsepower requirements from farm implements, and higher horsepower engines being installed in farm tractors, a still larger type (designated as Type 4) has been added to ISO 500. It operates at a higher rotational speed of 1300 rpm in order to allow for power transfer at reduced levels of torque. The shaft has 22 splines with a major diameter of 57.5 millimeters (mm). It is meant to handle PTO powers up to 450 kilowatts (kW), or roughly 600 horsepower (hp).

A 10-spline type was used with some early equipment such as the 1948 Land Rover. A six-spline adapter was usually supplied. It is customary for agricultural machines manufacturers to provide the nominal PTO power specification, an indication of the available instantaneous power at the shaft. Newer tractors may come equipped with 540/540E and/or 1000/1000E options that allow the tractor to power certain low-power-demand implements like hay rakes or tedders using lower engine speeds to maintain the revolutions per minute needed, using less fuel and placing less stress on the engine – thereby improving efficiency and reducing costs.

The first industry standard for PTO design was adopted by ASAE (the American Society of Agricultural Engineers) in April 1927. The PTO rotational speed was specified as 536 ± 10 rpm; the direction was clockwise. The speed was later changed to 540 rpm.

Truck transmissions have one or more locations which allow for a PTO to be mounted. The PTO must be purchased separately and care is required to match the physical interface of the transmission with a compatible PTO. PTO suppliers will usually require details of the make, model and even serial number of the transmission. Care is also needed to ensure that the physical space around the transmission allows for installation of the PTO. The PTO is engaged and disengaged using the main transmission clutch and a remote control mechanism which operates on the PTO itself. Typically, an air valve is used to engage the PTO, but a mechanical linkage, electric or hydraulic mechanism are also options.

Units will be rated according to the continuous and intermittent torque that can be applied through them and different models will offer different "PTO shaft rotation to engine RPM" ratios.

In the majority of cases, the PTO will connect directly to a hydraulic pump. This allows for transmission of mechanical force through the hydraulic fluid system to any location around the vehicle where a hydraulic motor will convert it back into rotary or linear mechanical force. Typical applications include:

A split shaft PTO is mounted to the truck"s drive shaft to provide power to the PTO. Such a unit is an additional gearbox that separates the vehicle"s drive shaft into two parts:

The unit itself is designed to independently divert the engine"s power to either the axle-facing shaft or the additional PTO output shaft. This is done by two independent clutches like tooth or dog clutches, which can be operated at total driveline standstill only. Because the main gearbox changes the rotation speed by selection of a gear, the PTO cannot be operated while the vehicle is moving.

On 4x4 vehicles, only the rear drive shaft is used by the split shaft PTO gearbox, requiring the vehicle"s 4x4 drive scheme to be of the selectable 4WD type to keep the front axle drive shaft completely decoupled during PTO operation.

A "sandwich" type split shaft unit is mounted between engine and transmission and used on road maintenance vehicles, fire fighting vehicles and off-road vehicles. This unit gets the drive directly from the engine shaft and can be capable of delivering up to the complete engine power to the PTO. Usually these units come with their own lubricating system. Due to the sandwich mounting style, the gearbox will be moved away from the engine, requiring the driveline to accommodate the installation.

Privette, Charles (2002-03-01). "Farm Safety & Health - PTO Safety". Department of Agricultural and Biological Engineering. Clemson University. Archived from the original on 2005-03-28. Retrieved 2022-07-29. shields and guards were developed to prevent injury from these rotating shafts

A power take-off or power takeoff (PTO) transfers the mechanical power from a power source, such as a running engine, and transfers it to another piece of equipment or attached implement.

This allows for the power to move throughout the equipment to transmit energy even if it doesn’t have a motor or engine itself. Most often, a PTO it is a splined draft shaft installed on a tractor or truck allowing attached implements to be powered directly by the engine. Semi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory.

When it comes to PTO hydraulic pumps, there are a lot of things to consider. If you’re not familiar with the jargon, it can be tough to know where to start.

In this guide, we’ll take you through everything you need to know about PTO hydraulic pumps so that you can make an informed decision for your business. We’ll discuss what they are, how they work, and the different types available on the market. Plus, we’ll give you some tips for choosing the right one for your needs.

A PTO hydraulic pump is a type of pump that is used to pressurize fluids within a closed system.This pump is usually driven by a power take-off shaft from a tractor or other vehicle, and it can be used for a variety of applications such as powering hydraulic cylinders or operating hydraulic tools.

The main benefit of using a PTO hydraulic pump is that it can be used to operate hydraulic machinery without the need for an external power source. Hydraulic PTO motors are also very efficient, as they are able to make use of the engine’s power directly rather than losing any energy in transmission.

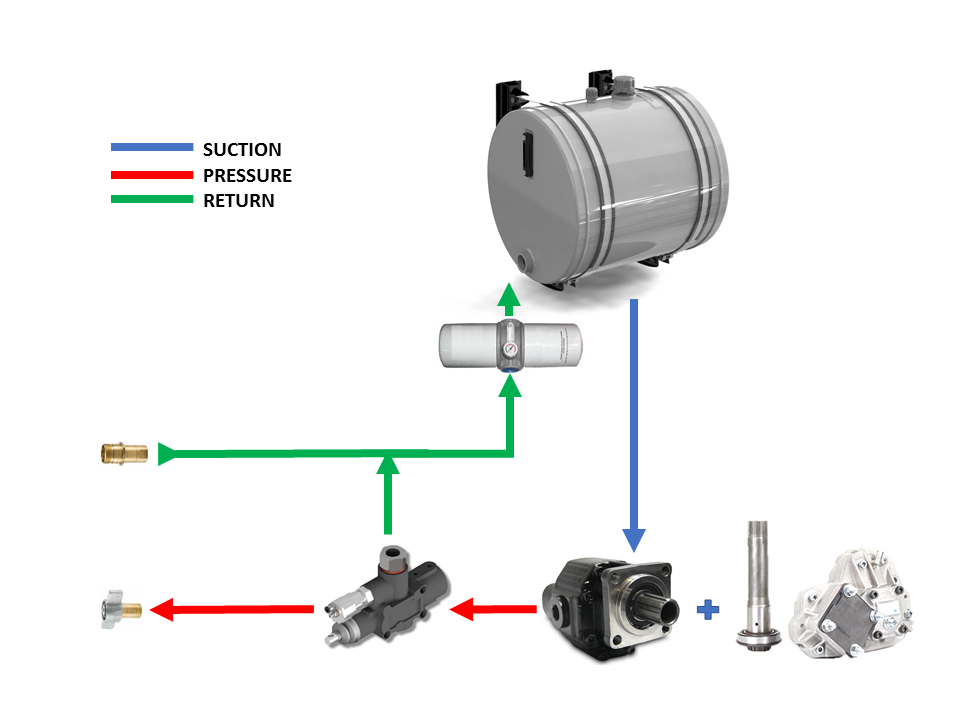

PTO hydraulic pumps work by using the power take-off (PTO) shaft of a tractor or other vehicle to drive a pump. The pump then pressurizes hydraulic fluid, which is used to power hydraulic cylinders or motors.

PTO hydraulic pumps are usually gear-driven, meaning that they have gears that mesh together in order to transfer power from the PTO shaft to the pump. The number of gears in the pump will determine its flow rate, or how much hydraulic fluid it can deliver per minute.

The PTO hydraulic power pack is made up of several different parts, each with its own specific function. Here’s a look at the most important components and what they do:

These are the components that actually move the fluid through the pump. They’re typically made of metal or plastic and are located inside the body of the pump.

The check valve helps prevent hydraulic fluid from flowing back into the pump. They’re located inside the body of the pump and are typically made of metal or plastic.

These are the most important parts of the PTO driven hydraulic pump and its function. Without these parts, the pump wouldn’t be able to operate properly. Make sure to keep an eye on them and keep them clean and free of debris to ensure optimal performance.

A PTO hyd pump is a powerful and versatile tool that can be used in a variety of applications. It is important to know the key features of this type of pump so that you can choose the right one for your needs. Here are some of the most important features to look for in a PTO power pack:

Easier To OperateOne of the biggest features of a PTO hydraulic pump is that it is much easier to operate than a standard hydraulic pump. You will not need to worry about connecting hoses or dealing with leaks, as the pump is self-contained. This makes it ideal for use in a wide range of situations, including on construction sites and in agricultural settings.

Higher PSI OutputAnother key feature of a PTO powered hydraulic pump is that it can generate higher PSI output than a standard pump. This means that you will be able to use the pump for more powerful applications, such as breaking concrete or operating heavy machinery.

More EfficientPTO hydraulic pumps are also more efficient than standard pumps, as they do not require a power source other than the PTO shaft. This means that you will be able to save on energy costs, as well as improve the pump’s overall performance.

Improved DurabilityFinally, PTO hydraulic pumps are designed to be more durable than standard pumps. This means that they will be able to withstand heavy use and last for many years.

When choosing a PTO hydraulic pump, it is important to consider all of the features that are important to you. By doing so, you will be able to find the perfect PTO dump pump for your needs.

There are 3 main types of PTO hydraulic pumps that are available in the market. Here is a quick guide on the different types to help you choose the right one for your needs.

The screw type is the most common and popular type of PTO hydraulic pump. It uses a screw to move fluid from the inlet to the outlet. This type of pump is simple to operate and maintain.

The vane type is another common type of high flow PTO hydraulic pump. It works by using vanes that are mounted on a rotor to draw in fluid and then push it out under pressure.

The plunger type is the least common type of PTO hydraulic pump. It uses a plunger to draw fluid into a chamber and then push it out under pressure. This type of pump is more complex than the other two types and requires more maintenance.

These are the 3 main types of PTO hydraulic pumps that are available on the market. Each type has its own advantages and disadvantages. Choose the one that best fits your needs.

PTO hydraulic pumps are used in agricultural machineries, such as tractors, combines, and irrigation systems. They are used to power hydraulic cylinders that operate implements, such as plows, harvesters, and sprayers.

PTO hydraulic pumps are used in construction equipment, such as excavators, cranes, and backhoes. They are used to power hydraulic cylinders that operate implements, such as buckets, booms, and jacks.

PTO hydraulic pumps are used in mining equipment, such as shovels, loaders, and drills. They are used to power hydraulic cylinders that operate implements, such as buckets, booms, and jacks.

PTO hydraulic pumps are used in forestry equipment, such as log loaders, skidders, and feller-bunchers. They are used to power hydraulic cylinders that operate implements, such as buckets, booms, and jacks.

PTO hydraulic pumps are used in material handling equipment, such as forklifts, reach stackers, and straddle carriers. They are used to power hydraulic cylinders that operate implements, such as forks, booms, and jacks.

These are only a few examples of the many industries that use PTO hydraulic pumps. If you have an application that requires a hydraulic pump, chances are there is a PTO hydraulic pump that can do the job.

A PTO hydraulic pump is a great way to power your equipment. However, it can be expensive to purchase one. The average cost of a PTO hydraulic pump can range from around $1,000 to $3,000. This price can vary depending on the size and brand of the pump.

It is important to do your research before purchasing a PTO hydraulic pump so that you are getting the best deal possible. There are many different brands and sizes of PTO hydraulic pumps available on the market, so it is important to shop around before making your purchase.

If you are looking for a PTO hydraulic pump for sale, be sure to check out our selection at Uphyd. We offer a 2 stage PTO hydraulic pump at great prices. Contact us today to learn more about our products and to find the perfect PTO hydraulic pump for your needs.

If you need a PTO hydraulic pump for tractor, there are a few things to keep in mind when working with a PTO hydraulic pump manufacturer. Here are some tips:

Before contacting any manufacturers, sit down and make a list of everything you need from the pto hydraulic pump. This includes specifications like flow rate, pressure, and power. Knowing exactly what you need will make it easier for the manufacturer to provide you with a PTO hydraulic pump that meets your needs.

When you’re ready to start contacting manufacturers, be sure to communicate your budget upfront. This will help the manufacturer determine if they are able to work within your budget and provide you with a PTO mounted hydraulic pump that meets your needs.

When you’ve narrowed down your choices, be sure to request samples from the manufacturers. This will allow you to test out the 540 PTO hydraulic pump and make sure it meets your needs before making a final decision.

Working with a PTO hydraulic pump manufacturer can take some time. Be patient and work with the manufacturer to ensure you get the PTO hydraulic pump that’s right for your business.

These are just a few tips to keep in mind when working with a PTO hydraulic pump manufacturer. By following these tips, you can be sure to get the best possible product for your needs.

There are several online directories that list PTO hydraulic pump manufacturers. This can be a great way to get an overview of the different options available and to find contact information for each one.

If you know someone who has used a PTO hydraulic pump before, they may be able to give you a personal recommendation. This can be a great way to get an unbiased opinion on a particular manufacturer.

A simple Google search can also turn up a lot of results for PTO hydraulic pump manufacturers. This is a great way to get a broad overview of the different options that are available.

These are just a few of the best places to look when you are trying to find a reliable PTO hydraulic pump manufacturer. By taking the time to do your research, you can be sure to find a manufacturer that will meet your needs and provide you with a quality product.

If you’re looking for a PTO hydraulic pump, check out our website at Uphyd. We offer a wide variety of PTO hydraulic pumps to choose from. Visit us today to find the perfect PTO hydraulic pump for your needs!

When it comes to finding a PTO hydraulic pump, there are a few things that you will want to keep in mind to ensure that you get the best possible product for your needs. Here are a few tips to help you make the right choice when purchasing a PTO hydraulic pump:

The first thing to consider is what the pump will be used for. There are different types of pto hydraulic pumps on the market, each designed for specific applications. Make sure you choose a pump that is designed for the job you need it to do to ensure optimal performance.

The next thing to consider is the flow rate of the pump. This is particularly important if you will be using the pump for high-pressure applications. Choose a pump with a higher flow rate if you need to move large volumes of fluid quickly.

Another important consideration is the pressure rating of the pump. This will determine how much pressure the pump can handle before it fails. Choose a pump with a higher pressure rating if you need to use it for high-pressure applications.

The speed of the pump is also an important consideration. You’ll want to make sure that the pump can operate at the speed you need it to in order to get the job done efficiently. There are different speeds available such as:

Of course, you will also want to consider cost when choosing a PTO hydraulic pump. There are a variety of pumps on the market, each with its own price tag. Make sure you choose a pump that fits within your budget to avoid overspending.

These are just a few things to keep in mind when choosing a PTO hydraulic pump. Make sure you take the time to consider your needs before making a purchase to ensure that you get the best possible product for your money.

So there you have it, the ultimate guide to PTO hydraulic pumps. We hope you found this article helpful and informative. If you have any questions or would like more information on PTO hydraulic pumps, please do not hesitate to contact us at Uphyd. We are always happy to help!

Gear pumps have an input shaft that drives an inner gear or “drive” gear. When the shaft turns the drive gear, the drive gear turns the “driven” gear. As these two gears rotate, oil is pulled into the suction port, split and carried around the perimeter of the gears, and finally, combined and pushed out the discharge port.

When determining the rotation of a gear pump, one must decide on the viewing orientation. As an industry standard a pump’s rotation is determined when viewed looking at the input shaft. If your viewing orientation is at the rear of the pump, the technical rotation of the pump is opposite the visual rotation.

The suction and discharge ports are determined by the rotation of the input shaft. As with rotation, the position of each port is dependent upon the viewing orientation. Here to, the industry standard, when looking at the input shaft, is for the drive gear to be oriented above the driven gear, also known as “belly down”. In this orientation, a clockwise pump will have suction on the left and discharge on the right and vice versa. If the pump is oriented with the “belly up”, the suction and discharge ports will appear opposite.

In an industrial capacity, the need for heavy-duty components that can handle transmitting the power required for machinery to operate translates into one specific part: the power take-off. The Power Take-Off (PTO) is an essential element that transfers an engine’s power to another mechanical device. However, there isn’t just a single type of engine driven PTO, and each unit is uniquely suited for various, specific industrial applications.

Parker Chelsea is a market leader in Power Take-Off products for the truck and mobile vocational markets. Our PTOs are designed with a wide range of internal speeds, torque capacities and output options to match up with virtually all driven equipment requirements. We offer a complete line of Power Take-Offs for North America, Asia Pacific, Australia, China, India and Europe, including cast iron 6-Bolt, 8-Bolt, 10-Bolt, countershaft, split-shaft and front engine mount applications. Features include mechanical shift, powershift, constant engaged shift options, overspeed controls and flanges for direct or remote mounting of hydraulic pumps, blowers, water pumps, product pumps and generators. Bottom line is if you need a reliable and rugged performer, think Parker Chelsea.

We offer a variety of pumps for OEM and other equipment manufacturers. This includes open loop gear pumps, open loop piston pumps, and open loop vane pumps.

Within an open loop hydraulic system, the actuator-return and inlet ports are both connected to the hydraulic reservoir. This allows the pump to provide continuous fluid power to the system. Because of this design, open loop systems are generally able to run cooler (as the reservoir lets more heat dissipate).

While an open loop hydraulic system may be more complex than its closed loop counterpart, they allow for a wider variance in system design. Furthermore, a higher level of control can be achieved through stacking multiple control valves in a series. This isn’t a functionality allowed for in closed loop hydraulic systems.

If you’re looking for pumps for an open loop hydraulic system, we can help. Contact our experts today to discuss your open loop hydraulic system or manufacturing process.

In conventional drives the torque of the hydraulic motor can be transmitted to the cardan shaft only by means of a dropbox. For further optimization of the drive train Linde Hydraulics developed the PTO Through-Drive Motor. Based on the standard hydraulic motor of the Series 02 with just one shaft end, the PTO Through-Drive Motor offers two shaft ends to transmit the torque. Hence the machine designer can conceive the hydraulic motor to fit directly and immediately into the drive train thus saving mounting space. The dropbox usually needed in a conventional propulsion drive can be saved. This reduces both noise emission and fabrication cost of the entire vehicle while overall efficiency increases.

8613371530291

8613371530291