putzmeister hydraulic pump manufacturer

As a general rule, only mineral hydraulic fluids of type HLP may be used for concrete pumps and industrial technologies. These hydraulic fluids must also meet the minimum requirements of DIN 51524-2.

Only fluids that meet the minimum requirements of DIN 51524-2 and these Putzmeister specifications for the viscosity grade ISO VG 46 and are confirmed in writing by the manufacturer may be used.

As a general rule, only bio-degradable hydraulic fluids of category 4 (HEES – synthetic ester) of DIN ISO 15380 and viscosity grade ISO VG 46 may be used for concrete pumps and industrial technologies. These hydraulic fluids must also meet the minimum requirements of this standard.

Only fluids that meet the minimum requirements of DIN ISO 15380 and these Putzmeister specifications for the viscosity grade ISO VG 46 and are confirmed in writing by the manufacturer may be used.

Today concrete pumps are predominantly operated by hydraulic systems. Putzmeister places its trust in the benefits of free-flow hydraulics because the most important performance factors are the concrete pressure, low-loss oil delivery and costs.

When large quantities of concrete are pumped, large quantities of oil also flow inside the hydraulic system. More power is transferred inside a closed free-flow hydraulic circuit because the oil is conveyed from the pump to the drive cylinders without loss. The adapted hydraulic System ensures extremely powerful interaction between components. Compared to the open circuit, this ingenious drive technology requires significantly less oil and does not generate as much heat. The system is also economical to operate because it achieves a high degree of energy efficiency and is easy to service.

The KOS pump is particularly suitable for conveying highly viscous sludges and other material with a high proportion of extraneous material. The main fields of application of the KOS are with materials which present the most extreme requirements, such as dewatered sludges containing solids, oil sludges, high viscosity solids and so on. For extreme applications, a wide range of task specific components and functions are available from Putzmeister. The pump’s simple design and the fewer wear parts offer a robust, low maintenance pump with low operating costs.

The seat valve pump is used for arduous applications. The HSP series is used with paste-like and highly viscous material with a low content of foreign bodies and small particle sizes (< 5 mm).

Precise sealing of the valves means that extremely high pumping pressures can be achieved. The principle behind the design of the hydraulic and pumping pistons is the same as in the Putzmeister KOS and KOV series. This ensures maximum reliability and availability.

Two special features of the Putzmeister design are that not only is it a simple matter to replace the valves but the design also means a long service life for all wearing parts. Valves and valve seatings are made of highly wear-resistant steels and can be used at either end. This doubles their service life. Valves can be easily replaced without dismantling the delivery lines.

A pulsation-free conveyance can be achieved with the PCF system (Pressure Constant Flow,optional). All of the familiar Putzmeister options and variations (ex-protection, materials) are availablewith the HSP series on request as well.

The valves are passively operated, which makes it an inexpensive pump with maximum availability. There are no issues or complications when pumping fine-grained mortar and low consistency slurries, even when they contain foreign bodies up to 10 mm in size.

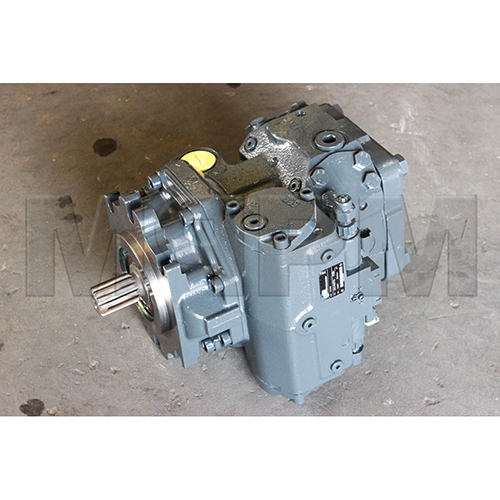

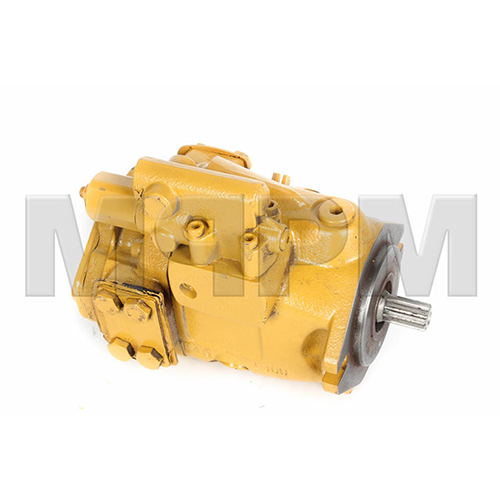

The heart of everypiston pump. These power packs have proved their effectiveness more than 10,000 times with concrete pumps and now they power up industrial pumps that convey the material.

Depending on the quantity of oil needed, an open or closed oil-circuit can be used. The closed oil-circuit is used when reaching large delivery capacities, which means considerable cost-savings. The oil-circuits are designed for hydraulic pressures of up to 300 bar. This equals delivery capacities of up to 150 bar, for a short time up to 160 bar.

Depending on your application, the sliding frame can take the form of a rectangular silo discharge system (ladder system) / PDSL or a round silo discharge system / PDSF. The ladder system with multiple parallel sliding frames is particularly suitable for wide or long receiving bunkers. This ensures an efficient transmission of force and increases the availability of the system thanks to the redundancy. The product range includes silos and bunkers from 10m³ to 1,000 m³ for loading trucks and for feeding sludges to solid pumps and their onward conveyance. Material is discharged from the silos by means of specially adapted screw conveyors, with a lateral or central discharge. If several end users have to be supplied, multiple discharge augers can be used.

As an alternative to steel silos, the receiving bunkers and sometimes the storage silo can be made of concrete. Putzmeister designs and delivers in these cases the sliding frame technology and discharge screws as well as the special concrete embedment parts.

The Putzmeister sliding frame system has been designed especially to meet the requirements of 24/7 operation. Thanks to modern Finite Element Analysis and proven Putzmeister hydraulic components, the sliding frame’s design, as well as its service life is optimised .

One important feature is the space-saving design achieved by integrating the sliding frame piston rodinto the silo base tunnel. The piston seal used in the high pressure pumps reliably prevents thesludge from escaping.

Putzmeister concrete pumps with the S-Valve are continually setting new world records in vertical and horizontal delivery. For example, in 1994 at Riva del Garda in Italy concrete was pumped vertically over 1,745-feet (532m), or a pump height of 1,990-feet (606m) at the Burj Khalifa job site. Even in these cases both machines and accessories were not operating at their limits, Putzmeister pumps can be counted on to perform reliably on demanding projects around the world.

With high delivery pressures up to 1,855 psi (130 bar), and maximum delivery outputs of up to 238 yd³/h (182m³/h), Putzmeister pumps are ideally suited for all concreting tasks.

Ideal for high pressure applications, our Big Mouth S-Valve effortlessly handles extremely harsh concrete mixes. It"s huge 9-inch (230mm) intake opening provides a superior filling rate, while the long and controlled reduction of the S-Valve ideally forms the concrete for pumping.

Stationary concrete pumps with the S-transfer tube are continually setting new world records in vertical and horizontal delivery. For example, in 1994 at Riva del Garda (.pdf, 372 kB) in Italy, concrete was pumped vertically over 532m! Or a pump height of 606m at the Burj Khalifa job site. Even in these cases, both the machines and accessories were not operating at their limits. Even when dealing with difficult concrete Putzmeister machines can be counted on to perform continiously and reliably.

Wherever extremely stiff and highly abrasive mixes are encountered this system is used. Of course it is also available with truck-mounted concrete pumps. In pre-cast factories you will find always find a piston pump when it comes to high strength concrete, steel fibre concrete or when there is a longer distance to cover.

The S-valve is the first choice for concrete pressures above 85 bars. This is especially useful for long pumping distances over stationary pipelines. The Putzmeister S-valve is especially designed for long life and high concrete pressure. This results in long service intervals and increased availability of the machine. To extend the life of the S-valve, the inside wall can be rebuilt by hard face welding.

NN Hydraulic India is a reliable manufacturer, supplier and distributors of Putzmeister Hydraulic Pumps based in Delhi India offering the genuine Putzmeister Hydraulic Pumps and Motors to keep your equipment running at peak performance.

NN Hydraulic India is a well-known wholesaler and dealer of Putzmeister Hydraulic Pump Spares, Putzmeister Hydraulic Pump, Putzmeister Concrete Pumps Spares. All these products are quality assured by the executive to ensure perfect qualities and longer life. Highly demanded, these products are accessible from the market in different sizes and designs.

Hydrocap is a Bulgarian company, manufacturer of mini-units and stations for industry. The company also offers a huge range of hydraulic products, spare parts and accessories.

Leading Manufacturer of Hydraulic Agitator Motor, HYDRAULIC PUMP 290243004, HYDRAULIC PUMP 235383000, SOLENOID COIL 24V 407263, HYDRAULIC MOTOR 229178001 and HYDRAULIC MOTOR 222864008 from Chennai.

Avoid any downtime at your construction site with the range of rexroth hydraulic pump for putzmeister machine from Alibaba.com. You can check out the fully-stocked parts at Alibaba by manufacturer and model and affordable wholesale prices. The wholesale rexroth hydraulic pump for putzmeister machine collection of spare parts from China’s wholesaler, Alibaba, fits well with a wide range of heavy-duty equipment, from bulldozers, excavators, and hammers, among others. Plus, you can find parts for your tractors, skid steer loaders, wheel loaders, backhoe loaders, and crawler dozers.

If you have a limited cash allocation, the used or remodeled parts will go a long way in accommodating your budget. Alibaba’s rexroth hydraulic pump for putzmeister machine and tools make it easy to replace, modify and enhance your equipment for their optimal performance. For electrical and mechanical applications, you can find your match at Alibaba.com for everything you need to make your vehicle perform better. Get engine oils, batteries, hydraulic parts, transmissions, injectors, hoses, and starters from the rexroth hydraulic pump for putzmeister machine at Alibaba.com.

The new parts from manufacturers have warranties, and you can buy them by matching the part numbers. Such parts, including hoses, plugs, or filters, will help you quickly deal with downtime on site. The used parts, on the other hand, sell for a lower price. Remember, Alibaba partners with sellers who have certificates of operation. So, you can use these second-hand rexroth hydraulic pump for putzmeister machine to get your heavy machine running. You can also get rebuild models from the collection at Alibaba.com. These are sustainable choices that use recycled materials and perform as well as the new parts. And depending on your seller of choice, you might get a warranty to accompany them.

Warranty items will be inspected upon receipt for use, wear, or damage. Full credit, partial credit, or no credit may be offered based on the condition of the item.If replacement items or exchanges are required Concrete Pump Supply will bill for replacement inventory and will only give credit to the original invoice.

To start a return, you can contact us at returns@concretepumpsupply.com or fill out this RMA form and send it to returns@concretepumpsupply.com. Please note that returns will need to be sent to the address in which it was sent from.

N N HYDRAULIC INDIA From Delhi based manufacture aftermarket spare parts of concrete pumps and mixers for the brands like Putzmeister, Schwing, Cifa, Sermac, Reich, Waitzinger, Elba, Junjin, Wibau and the other brands. We manufacture high quality and reasonable priced concrete pump pistons, couplings, kidney seals, repair kits, concrete pipe fittings, valve cup bodies, clamps, tapered pipes, pipe bands, bearings, concrete pump hoses, rubber seals and other concrete pump and mixer components in our rubber & metal manufacturing lines

8613371530291

8613371530291