replacing hydraulic pump on log splitter factory

LOG SPLITTER PARTS for all makes of wood splitters. Hydraulic pumps cylinders control valves tanks. Kits to repair or for building your on hydraulic LOG SPLITTER.

This product is a Hi-Lo cast iron hydraulic gear pump with max pressures of 900 PSI for the low pressure and 3000 PSI for the high pressure pump. Typical applications are log splitters and presses, where alternating low and high pressures are required to move a cylinder.

This product is a Hi-Lo cast iron hydraulic gear pump with max pressures of 900 PSI for the low pressure and 3000 PSI for the high pressure pump. Typical applications for this 13 GPM hydraulic pump are log splitters and presses, where alternating low and high pressures are required to move a cylinder.

Find Original Equipment hydraulic pumps for all log splitter applications. Original replacement pumps all 20-ton, 22-ton, 25-ton, 27-ton and 33-ton models. For Troy-Bilt, Craftsman, MTD, Cub Cadet, Yard-Man, Huskee, Yard Machines and Bolens Log splitter Models, shipped Factory-Direct.

The hydraulic pump controls the flow of fluid within the pump system. Most log splitter hydraulic pumps will be two-stage pumps, meaning that they can force the liquid within them to move in two different directions, which allows for the hydraulic arm to be pushed forward to split wood, and also retracted so the machine can be reloaded with a new log. The seals on these pumps wear over time and eventually can cause hydraulic fluid to leak out of the system. If fluid is leaking from your pump, disassemble it and replace all seals. When repairing a damaged pump it is important to carefully analyze and address the rest of the hydraulic system. When the pump fails it will often send metal debris throughout the hydraulic system. At a minimum it will be necessary to thoroughly flush the hydraulic fluid and replace the filter. Debris left in the system can quickly ruin a new pump.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

This is an excellent replacement pump for log splitters, hydraulic presses, snow plow power units and a variety of other agricultural power equipment. Mounting Positions: Horizontal & Vertical This two-stage gear pump provides faster cycle times with an over-all higher pressure rating, so you can squeeze every bit of power out of your equipment.

The motor is built to last, and the tank has been specifically designed to not crack & leak under harsh conditions. Its high-quality starter ensures long life and a fast-starting each time.

This log splitter hydraulic fluid constructed with high-quality oil suck pipes, which needed to be cleaned often, our pump work in a low-noise condition.

This hydraulic pump is equipped with other hydraulic tools that can carry out lifting, pressure type, elbow, bending row, straightening, cutting, assembly, demolition and many other works. Reduce labor intensity.

Used in applications where extending a hydraulic cylinder is needed, truck tailgate lift, RV leveling, scissor lift, dump trailer, lift truck, snow plow, aerial platform, road signs, material handling, wheelchair lifts, etc.

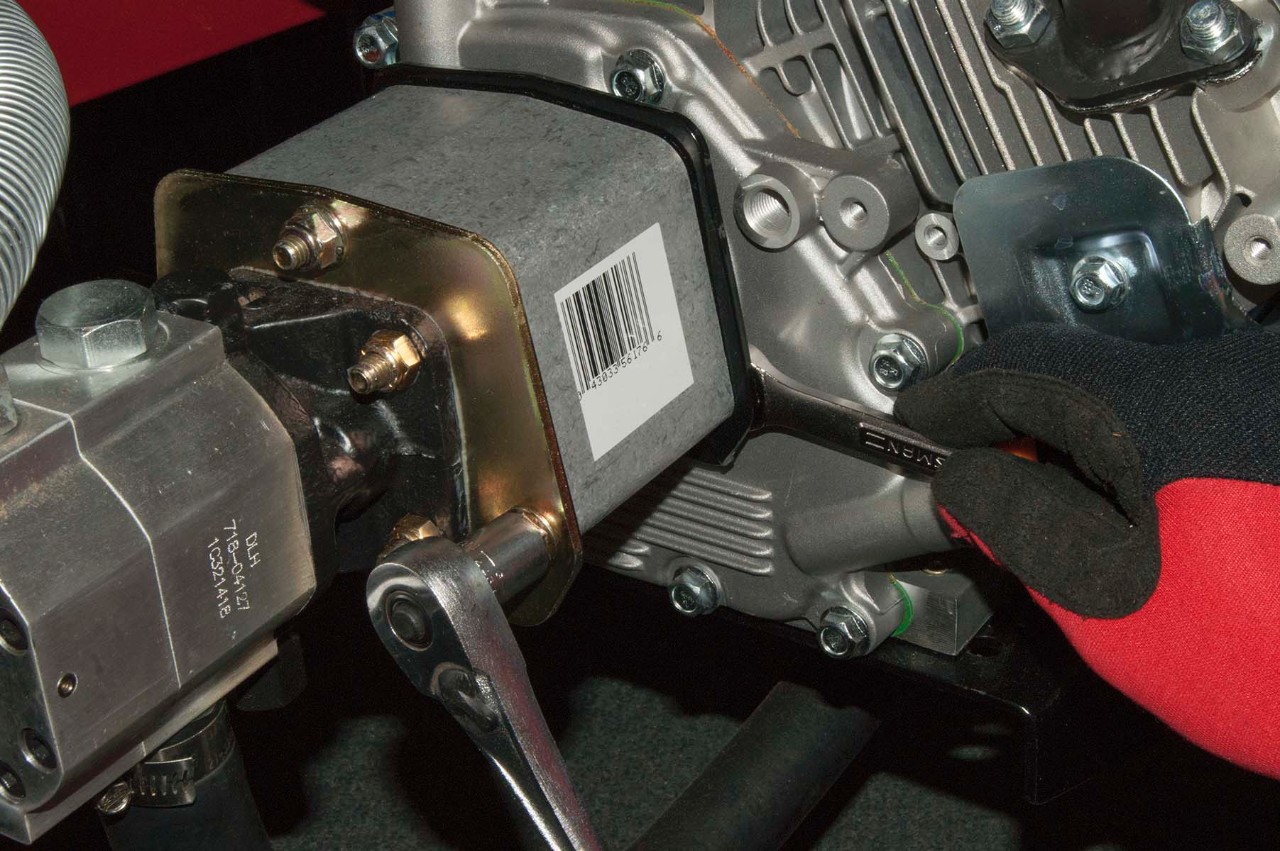

Aftermarket replacement for MTD 918-04127 log splitter pump Hi/Lo 2 stage hydraulic gear pump. 11 GPM @ 3600 RPM, 3 GPM @ 400 PSI and 8 GPM @ 3000 PSI. 3600 RPM rated speed, SAE 4 bolt flange mount. 1" metal tube inlet port with 1/2" NPT outlet port. 1/2" keyed shaft. Right hand rotation (clockwise). Cast iron housing. The pump will automatically switch from low pressure (400 PSI) to high pressure when it reaches 900 PSI and then advance to 3000 PSI.

Beiler Hydraulics offers all the components needed to build your own log splitter as well as supply manufacturers of log splitters. We stock the log splitter two-stage pumps, log splitter valves, and a wide variety of hydraulic cylinders ranging from light duty tie-rod cylinders to heavy duty welded cylinders. So whether you are replacing a part on your log splitter or want a new set up, Beiler Hydraulics can help. Please contact our professional sales team for your specific log splitter needs.

IMPORTANT! Never operate a log splitter without the appropriate amount of approved hydraulic fluid in the reservoir tank. Operating a log splitter without sufficient reservoir fluid in the hydraulic system may result in severe damage the hydraulic pump and would be reason to void the factory warranty.

DO NOT MIX DIFFERENT TYPES OF HYDRAULIC FLUIDS. Use only one type of an approved lubricant. If the type of fluid already installed in a unit is unknown, the recommended procedure is to drain that fluid completely and refill it with all of the same type fluid.

Our log splitters have varying fluid capacities depending on the model and style. Most units have either a 3.5 gallon, 4 gallon, or 7 gallon reservoir. Please refer to the appropriate product Operator"s Manual to determine the capacity of the hydraulic reservoir of a particular model.

These fluids are all non-foaming hydraulic fluids and available from our Online Parts Store, most hardware stores, automotive supply, farm equipment retailers, and other major home improvement supply stores.

Keep in mind that the volume of the reservoir tank is less than the unit"s total fluid capacity. Fluid also needs to be primed into the hydraulic system (hoses, filter, valve, pump & cylinder), which may require as much as an extra gallon when filling the complete system.

To prime the hydraulic system, fill the fluid to the appropriate level as instructed in your Operator"s Manual. Disconnect the spark plug wire and ground it against the engine. Then pull the starter rope on the engine 10 to 15 times. This will allow the pump to push fluid into these other areas of the hydraulic system. Your reservoir level should go down, so you will need to re-check it and fill to the appropriate level.

This is my first post here, although I"ve been lurking for a while! As I"m posting from Ireland, please excuse the non US spellings that I will use from time to time.

I have an electric hydraulic log- splitter that I bought in a German low- cost supermarket that is here in Ireland (Lidl) with a 3 year warranty around 6 or 7 years ago. It has been a brilliant piece of kit that works very well. However, there are no parts available as it is probably a Chinese jobbie that was meant to last not much longer than the 3 years to which the original warranty applied. As a hydraulic valve mechanism broke on it after it was out of warranty, I bought a spare that had other problems and I harvested the mechanism already a few years ago.

My original one got flooded last year and I"d left it aside when it wouldn"t work afterwards. I have now established that the electric motor is toast- full of water and rustier than the Titanic. I have a good motor on the spare that I want to transfer. When I was checking out the bad one, it was held on to the housing for the hydraulic pump by three 8mm screw-bolts that removed easily. However, removing the actual motor from the hydraulic housing was an absolute nightmare! I got it removed eventually using a lot of brute force and ignorance, but bent the shaft to the hydraulic pump in the process. That didn"t bother me as the motor is scrap anyway.

However, when I went to the spare, while the 3 holding screw-bolts removed easily, I was only able to move the motor about 1-2 mm out from the housing. I don"t want to use the same level of brute force and ignorance on this motor as I am afraid that I will damage it.

I ran out to Northern Tool and picked up the thread locker #27100 and used that on the press fitting. I’m going to seal around it today with an extra layer of protection with some RVT for good measure but wanted to give it the full 24 hour cure time before I did that. While I was there I picked up a gallon of hydro fluid and a new filter.

It’s probably a good thing that this happened as when I drained the fluid it smelled like burnt electrical components. She was probably way overdue a fluid change. What did surprise me was the amount of fluid that the thing had in it. I don’t have exact numbers, but it filled my oil change drain bucket. If I had to guess I would say there is 8 or more quarts. I’m going to put the 1 gallon of new fluid I bought in there, and then pour the used back into the gallon jug and see what I have left in the bucket after that. Then I will get more fluid based on that.

8613371530291

8613371530291