replacing hydraulic pump on log splitter in stock

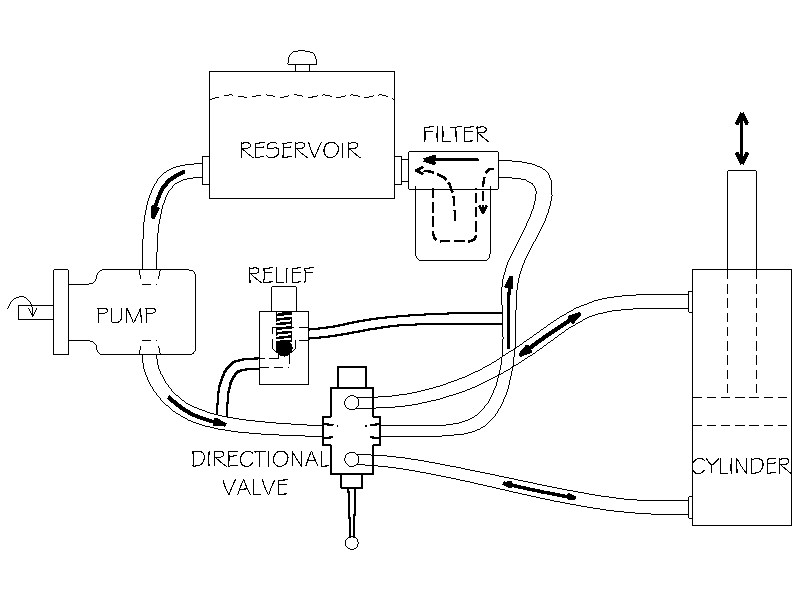

The hydraulic pump controls the flow of fluid within the pump system. Most log splitter hydraulic pumps will be two-stage pumps, meaning that they can force the liquid within them to move in two different directions, which allows for the hydraulic arm to be pushed forward to split wood, and also retracted so the machine can be reloaded with a new log. The seals on these pumps wear over time and eventually can cause hydraulic fluid to leak out of the system. If fluid is leaking from your pump, disassemble it and replace all seals. When repairing a damaged pump it is important to carefully analyze and address the rest of the hydraulic system. When the pump fails it will often send metal debris throughout the hydraulic system. At a minimum it will be necessary to thoroughly flush the hydraulic fluid and replace the filter. Debris left in the system can quickly ruin a new pump.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

We recommend using an L-style jaw coupling to connect the pump to an engine. Couplings and mounting brackets are available. You should use at least a 5hp 163cc engine to maintain 3,600 RPM under load.

This 2-Stage pump fits a wide variety of log splitters and outdoor power equipment and works in both horizontal and vertical orientations. The included inlet nipple requires a 1" inner diameter suction hose.

Rated for up to 3,000 PSI at 3,600 RPM, this pump can power log splitters from 5 to 35 tons, depending on the inner diameter of the hydraulic cylinder. It features a fast cycle time by moving quickly when unloaded. It automatically shifts to low-flow/high-pressure mode at 500 PSI.

Be sure to use AW-32 10-Weight (ISO 32) or AW-46 20-Weight (ISO 46) light hydraulic fluid or Dexron III automatic transmission fluid. This pump is not designed for use with “universal” or "tractor" transmission oil, such as "303". The use of incorrect fluid may damage the pump and void the warranty.

Make sure the hydraulic fluid reservoir is not below the pump to ensure a sufficient flow of fluid to the pump. Suction-side filtration should be no finer than 150 microns. The use of a 10-25 micron filter on the suction side of the pump is too restrictive and will cause failure.

The mounting flange on this pump has a 4-bolt, 2 inches on center, mounting pattern. The bolt circle is 2.85" and the bolt hole diameter is M8 (.344").

Aftermarket replacement for MTD 718-04127 log splitter pump Hi/Lo 2 stage hydraulic gear pump. 11 GPM @ 3600 RPM, 3 GPM @ 400 PSI and 8 GPM @ 3000 PSI. 3600 RPM rated speed, SAE 4 bolt flange mount. 1" metal tube inlet port with 1/2" NPT outlet port. 1/2" keyed shaft. Right hand rotation (clockwise). Cast iron housing. The pump will automatically switch from low pressure (400 PSI) to high pressure when it reaches 900 PSI and then advance to 3000 PSI.

We ordered this for our troy bilt wood splitter. Everything fit well and we have used it twice since putting on. We had to use coupler that was sent to get it to work with ours. The price was very reasonable and shipping was very fast sent through the usps. We use wood to heat our home so that was a tremendous plus.

I called several other companies that said that it was in stock only to find out that it wasn"t. I called Fremont expecting the same. They had it and shipped the same day. These guys do what they say they will do. Kudos to Fremont Industrial Supply

Bolted right up on my Troy Built 27 ton log splitter. Fired right up and did the job with no leaks. Happy to find this company thanks to Google search!

Northern Hydraulics offers a full line of 2-stage hydraulic pumps for your log splitters, compactors, and press-type applications. Haldex/Concentric pumps have a cast iron gear housing and are available in flows ranging from 9 GPM to 28 GPM. These 2-stage hydraulic pumps are designed for heavy-duty use and long cycle times. The Haldex brand assures you are getting top-quality, high-performing products. Northern Hydraulics replacement pumps also have a cast iron gear housing and are available in flows ranging from 5 GPM to 28 GPM. These log splitter hydraulic pumps are ideal for the recreational wood splitter user, as they are still a quality product, but offered at a much lower price point.

This 2 stage pump can give you much faster cycle times and higher possible pressures with a small engine. Excellent for use on log splitters. 85% efficient.

Model GP-CBN is a HI/LO hydraulic gear pump with 12 different displacement combinations with maximum pressures of 900 psi for the low pressure pump and 3000 psi for the high pressure. The change from LO to HI pressure is automatic with the LO side pressure pre set from 400 psi to 900 psi.

The HI/LO section of the pump is all aluminum and the end plates are cast steel. Applications for the HI/LO pump are log splitters, presses etc where rapid movement of the cylinder at low pressure is required prior to automatically switching to the high pressure mode to meet load requirements.

This 2 stage pump can give you much faster cycle times and higher possible pressures with a small engine. Excellent for use on log splitters. 85% efficient.

Model GP-CBN is a HI/LO hydraulic gear pump with 12 different displacement combinations with maximum pressures of 900 psi for the low pressure pump and 3000 psi for the high pressure. The change from LO to HI pressure is automatic with the LO side pressure pre set from 400 psi to 900 psi.

The HI/LO section of the pump is all aluminum and the end plates are cast steel. Applications for the HI/LO pump are log splitters, presses etc where rapid movement of the cylinder at low pressure is required prior to automatically switching to the high pressure mode to meet load requirements.

Hey, it happens. We break stuff. Wait… are your log splitter parts breaking or getting damaged by your usage or your wrong equipment? Answer these questions first:

“A log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Most log splitter parts consist of a hydraulic or electrical rod and piston assembly and rated by the tons of force they can generate. The higher the pressure rating, the greater the thickness or length of the rounds are split.”

For most commercial or home-based splitters, it doesn’t matter much if you power the log splitter by an electric motor, a gas engine, or even a diesel engine. They all drive a hydraulic pump. And regardless of the power source and pump combination, a log splitter typically uses a hydraulic piston to drive the log through a fixed wedge or blade.

Let’s start with the heart of the log splitter – the hydraulic pump. Did you notice I didn’t mention the engine or motor? Don’t get hung up on how big the engine or motor is. It is the primary mover, but it’s only good as the hydraulic pump it will operate.

Hydraulic pumps for log splitters usually are either a single-stage or a two-stage pump. Cheaper, often off-brand log splitters, and even some larger well-known commercial log splitters may come with a single-stage pump. A single stage pump will do the task, but it moves the hydraulic cylinder slower. Splitting time is increased. If you’re not concerned about time, then there’s no real concern about using this type of hydraulic pump.

Hydraulic two stage pumps are ideal for log splitters. A two-stage pump will first produce high volumes of low-pressure fluid (first stage). This stage moves the hydraulic cylinder in and out quickly. The two-stage model is great for moving the splitter ram up against the wood fast, and for retracting it fast.

When the pump encounters resistance (splitting wood), the second stage of operation engages. A calibrated valve will sense the pressure change and divert service to the pump’s high-pressure fluid stage for splitting. The volume of fluid (speed of the ram) will drop considerably during the second stage, but the force increases significantly. For example, a typical first-stage log splitter pump may unload fully around 450 psi while the second stage operates up to 3000 psi.

The effectiveness of a log splitter ram determined by the bore size, the stroke length, and rod diameter. Bigger isn’t always better in this case. You have to have the correct amount of fluid volume and pressure matched to the cylinder for it to provide the proper force. For example: let’s say you placed a much more significant, higher volume ram in place of a smaller one. You may experience inadequate performance simply because your splitter isn’t able to handle the increased demand for fluid pressure and return.

Your return lines and fluid reservoir may be too small placing back pressure on the cylinder. The control valve porting may be too little doing the same. Your pump may not be able to deliver enough pressure due to a lack of fluid volume.

Since pressure creates heat, it’s recommended to use a reservoir that can hold a 3/1 ratio of fluid. Meaning, if your system uses one gallon of fluid each cycle, then your reservoir should hold three gallons. This gives the fluid time to cool down.

It’s best to be sure you have matched components on your log splitter. Often a larger tonnage no-brand splitter may look very attractive at first, but the parts may be miss-matched, or of poor quality.

Determine your replacement log splitter parts needs by using calculators. Give Don’s Hydraulic Cheat Sheet a try. Just change the fields marked “Bore, Rod, Stroke, Pressure and GMP” to calculate your force and speed. To find a bore size, input the desired force you need and applied pressure to the ram. This will output the required bore size.

Whether you need a hydraulic filter or just cylinder repairs, Cylinder Services carries a quality range of log splitter parts including control valves, Prince Hydraulic Cylinders, NBC hydraulic log splitter pumps, and accessories. Be sure to check out our store.

This DIY repair guide explains how to replace the flexible log splitter pump coupler. The hydraulic pump coupling connects the engine drive shaft to the hydraulic pump. The coupler is designed to break if the hydraulic pump seizes up, protecting the engine from damage. The log splitter pump coupler deteriorates over time, causing vibration and noise when the hydraulic pump is running. If the log splitter hydraulic pump coupling breaks or the coupler is worn, use the manufacturer-approved replacement part to install a new one.

Replacement Log Splitter Pump Kit: This replacement log splitter hydraulic pump kit consists of high-quality parts with high strength and hardness, which is capable of good wear resistance, durable in use and is replaceable and compatible with OEMs like Speeco, Huskee, and Champion, etc.

Powerful Hydraulic Pump: This powerful pump is a 2-stage 16GPM hydraulic pump offer you the fastest possible cycle times, which ensures a fast start and long using period for each time. It dramatically reduces the labor intensity, improves work efficiency.

Excellent Performance: Equipped with other hydraulic tools like jaw coupler and pump bracket, it can carry out lifting, pressure type, elbow, bending row, straightening, cutting, assembly, demolition and many other works with a hydraulic log splitter.

Multiple Model Combinations: As this log splitter pump kit is designed for meeting the replacement of a variety brand, the parts of this kit have a standard specification that is suited for your multiple combinations for your demands.

Wide Application: Used in applications where extending a hydraulic cylinder is needed, truck tailgate lift, scissor lift, dump trailer, lift truck, snowplow, aerial platform, road signs, material handling, wheelchair lifts, etc.

Beiler Hydraulics offers all the components needed to build your own log splitter as well as supply manufacturers of log splitters. We stock the log splitter two-stage pumps, log splitter valves, and a wide variety of hydraulic cylinders ranging from light duty tie-rod cylinders to heavy duty welded cylinders. So whether you are replacing a part on your log splitter or want a new set up, Beiler Hydraulics can help. Please contact our professional sales team for your specific log splitter needs.

8613371530291

8613371530291