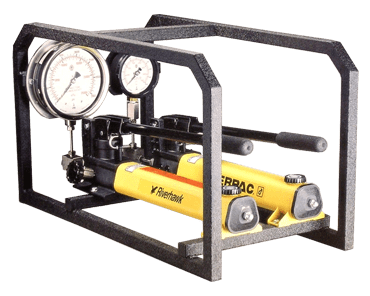

riverhawk hydraulic pump kit supplier

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

![]()

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

Riverhawk is committed to providing electronic accessibility to all individuals under the Americans with Disabilities Act (ADA.) If you need assistance accessing information on our website, please utilize the “Accessibility Menu” at the top of the screen. If you need further assistance, please contact our HR Department at (315) 768-4855 or email us at hr@riverhawk.com and we will work with you to provide the information, item or transaction you seek through a communication method that is accessible for you.

First and foremost, you should consider the desired pressure rating that you need for your application. You will want to review the job with your engineering team and field service personnel to help determine the appropriate pressure output that is needed for your hydraulic equipment.

Manual pumps typically come in two pressure ranges: a low-pressure range and a high-pressure range. Low pressure pumps are rated for 10,000 psi or lower and are used to supply hydraulic pressure to a variety of hydraulic tooling. High pressurehydraulicpumps can reach operational pressures of up to 40,000 psi and are commonly used for dilation during the installation or removal of a keyless tapered coupling hub.

Air driven pumps can be preset to a desired maximum pressure rating at the factory, and traditionally have a maximum operational pressure of 22,000 – 40,000 psi.Air operated hydraulic pumpsare commonly used for tensioning bolts and nuts during the installation of compressors and other machinery.

There will be times where you will find yourself in need of a varying supply of hydraulic pressure to your equipment or tooling in order to finish a job. Determining the type of supply that is needed will help you select the appropriate pump for the job.

One of the main differences between a manual pump and an air driven pump is the quantity of hydraulic pressure that is supplied to your tooling or equipment.

A Riverhawk hydraulic pusher mated with a low-pressure pump allows the operator to accurately install the coupling to the desired position along the tapered shaft while maintaining control of the hydraulic pressure feeding to the pusher tool.

Anair powered hydraulic pumpconstantly supplies a set amount of hydraulic pressure so long as the pump is actuated. This makes the pump ideal for operating multiple pieces of equipment at once without requiring constant mechanical input from the operator. An example of this would be the installation of a casing on a compressor.

The casing requires multiple studs and nuts be properly and evenly tightened, which can be difficult to achieve through mechanical torquing methods. By utilizing an air driven pump and multiple Riverhawk hydraulic nuts daisy-chained in succession, hydraulic pressure is applied evenly to each of the nuts. This allows for even load distribution to each of the studs, thus eliminating the concerns of excessive or erratic bolt loads.

Riverhawk has designed the Manual Hydraulic Pump Kit as a comprehensive solution with two pumps and the associated gauges installed on a welded sledge. The kit, furthermore, comes with all the necessary adapters, fittings and hoses.

The hoses supplied with the hydraulic pump kit feature six layers of wound steel pressure support, a nylon outer cover as well as swivel fittings at both ends and Derlin inner liner.

![]()

When it comes to portable hydraulic air-driven pumps, Riverhawk"s offering makes for an excellent choice. Their pumps supply instant, reliable hydraulic power. The incoming air is filtered before intake.

The pumps feature an air regulator which ensures that the system can maintain any desired output pressure within the units total range. Swivel fittings facilitate easy and safe connection of the equipment to be pressurized.

![]()

Riverhawk designs and manufactures hydraulically tensioned studs and nuts, tensioning tools, and plug and ring gauges. We also provide source inspections and training seminars.

At Riverhawk, we meet the daily challenges of the rotation equipment industry by offering auxiliary equipment such as air driven and manual hydraulic pressure kits and pusher/pullers for the installation of coupling hubs, thrust discs, and compressor wheels.

Our equipment is proudly supplied to the top OEMs and end users of the turbomachinery industry. No matter what your needs, Riverhawk’s team of engineers is ready to assist you. Contact us for more information on how we can provide the products and services you need.

Riverhawk is a member of the American Petroleum Institute (API) and sits on the coupling committee of the American Gear Manufacturers Association (AGMA).

Incorporated in the year 2005, at Ludhiana (Punjab, India), we, “Ranjit Hydraulics Engineers”, are engaged in manufacturing, exporting and supplying Deep Draw Press Machine, Hydraulic Shearing Machine, Hydraulic Press Brake Machine Type Press Machine, C Frame Press Machine, 4 Pillar Press Machine, Workshop Press Machine, Hydraulic Cylinders & Power Packetc. leading organizations engaged in manufacturing and supplying a wide range of Hydraulic Presses (Sheet Metal Machinery).The presses offered by us are manufactured using optimum quality raw material, which is sourced from reliable and authentic vendors of the market. Owing to their features like optimum performance, low maintenance, longer function and easy installation, these presses are widely demanded by customers. Moreover, clients can also avail of these presses in customized forms as per their specific requirements.

Designed to be a complete solution, our kits come standard with two pumps and fitted with gauges, appropriate fittings, adapters and hoses. To learn more about these and the rest of our Hydraulic Pump Kit line, Click here:http://riverhawk.com/hydraulic-pump-kits-accessories/…

General InfoFounded in 1993, Riverhawk Company is an engineering and consulting firm that provides hydraulic bolt tensioners, high-temperature envelops, torque blockers, peak shavers, clamp rings, internal shaft clamps, lapping tools and vibration monitoring systems. It serves power generation and petro chemical markets. The company also serves the mining, construction, wind power, nuclear, manufacturing, reciprocating and steel industries. Riverhawk Company also offers manual pump kits, hydraulic fittings, bolt loading calculators and gas turbine hardware systems. It offers various hydraulic pump and accessories, including air-operated pump kits and high-pressure flexible hose assemblies. In addition, the company provides online installation manuals. Located in New Hartford, N.Y., Riverhawk Company organizes various in-house or off-site training seminars on a variety of topics on the installation and operation of products.EmailBBB RatingPayment methodamex, master card, visaAKARiverhawk Corporation

Char-Lynn Spool Valve Hydraulic Motors Repair Information W Series Geroler Motors with Parking Brake 004 Nut Key Ring, Retaining Bearing Ring, Retaining Ring, Retaining Washer (Thick), Pressure Washer,

RANGE OF HYDRAULIC BOLT TENSIONERS TensionMax The Next Generation of Bolt Tensioners has Arrived Hydratight, one of the world s leading bolt tensioning and joint integrity companies, introduces TensionMax.

M113 VEHICLE FAMILY RUBBER TRACK INSTALLATION INSTRUCTIONS (SPLIT IDLER) 1 # TABLE OF CONTENTS List of parts and tools................................................3 Installation of complete kit...................................................5

APPLICATIONS Process Industry Weak Acids Alkalies Compressed Air Pulp & Paper MODELS ASM - Flanged Connection OPTIONS Control Rods Oil & Gas Water & Waste Pump suction & discharge Sea water Chemical lines

FAG Hydraulic nuts Technical Product Information Contents Application 2 Design 2 Design variants 3 Pressure generators, connectors 4 Dimension tables for FAG hydraulic nuts (metric) 6 Dimension tables

Char-Lynn Hydraulic Motor October, 1997 Repair Information Geroler Motor Two Speed 001 27 Retainer inside bore of valve plate bearingless motors only 4 15 16 3 6 35 Parts Drawing 25 2 2 1 19 17 36 40 47

WHAT YOU DON T KNOW ABOUT ACCUMULATORS CAN KILL YOU! Atlanta (Monroe) GA 770-267-3787 gpm@gpmhydraulic.com www.gpmhydraulic.com What You Don t Know About Hydraulic Accumulators Can Kill You TABLE OF CONTENTS

47 Brakes - Hydraulic Components (Page GR-47) FS III front brake calipers, servicing Front brake caliper piston, removing and installing FN 3 front brake calipers, servicing Front caliper piston, removing

P7100 PUMP INSTALLATION INSTRUCTIONS Diesel Care & Performance Inc Installation Timing Pin Location CAUTION: Before installing the injection pump, be sure that number 1 cylinder is at the Top Dead Center

-J0 REV. 0-0-0 DYNA RIDER FOOTBOARD KIT GENERAL Kit Number 000 Models For model fitment information, see the P&A Retail Catalog or the Parts and Accessories section of www.harley-davidson.com (English

Rexroth Hydraulic Pump A10VO Series User Manual Rexroth Hydraulic pump A10VO Series User Manual Revised 5/1/2009 Page 1 of 12 Functional Purpose This pump is preferred over a fixed displacement (gear)

Char-Lynn Hydraulic Motors April, 1999 Repair Information W Series Geroler Motors 002, 003 W Series Geroler Motors Tools Required 5/16 inch Hex Key Bullet for Shaft Installation - Eaton Tool No. 600633

BQ FIXED DISPLACEMENT HYDRAULIC VANE PUMPS BQ SERIES Versatility, power, compactness and low running costs are the main characteristics of B&C vane pumps. All the components subject to wear are contained

Part#: 013255 Ford F-250 / 350 2-1/2 Coil Kit Ford F-250, F350 2011-2015 Rev.040815 491 W. Garfield Ave., Coldwater, MI 49036. Phone: 517-279-2135 Web/live chat: www.bds-suspension.com. E-mail: tech@bds-suspension.com

92154000 Thank you for choosing Rough Country for your suspension needs. 2011-14 F250 6 RADIUS ARM KIT Rough Country recommends a certified technician installs this system. In addition to these instructions,

BQ FIXED DISPLACEMENT HYDRAULIC VANE PUMPS BQ SERIES Versatility, power, compactness and low running costs are the main characteristics of B&C vane pumps. All the components subject to wear are contained

VERTICAL TURBINE AND PROPELLER PUMPS INTRODUCTION Vertical Turbine and Propeller Pumps Model 7000 Series Turbine Pump Model 800 Series Axial Flow Propeller Pump Model 800 Series Mixed Flow Propeller Pump

BQ FIXED DISPLACEMENT HYDRAULIC VANE PUMPS BQ SERIES Versatility, power, compactness and low running costs are the main characteristics of B&C vane pumps. All the components subject to wear are contained

Table of Contents Overview 1 Pump Disassembly 2 Control Disassembly / Reassembly 7 Pump Reassembly 13 Adjustment Procedures DR Control 19 Adjustment Procedures DRG Control 20 Adjustment Procedures DFR

TELEDYNE CONTINENTAL AIRCRAFT ENGINE SERVICE ULLETIN Compliance Will Enhance Safety SUJECT: PROPELLER STRIKES AND HYDRAULIC LOCKS. CATEGORY 3 S96-11 FAA APPROVED Supersedes S96-11A, S96-11, M84-16 PURPOSE:

Part #: HT-1 1965-82 CORVETTE O-RING CONVERSION front CALIpER REbUILdING TUTORIAL Choosing a Brake Caliper Rebuild Kit Standard Lip Seals vs. O-Ring Seals Lip seal design seals are used on 1965-1982 Corvette

Founded in 1993 in Yorkville, NY., the Riverhawk Company has more than 85 years of experience with roots deep in the Rotating Machinery Industry. Serving primarily the Power Generation and Petro Chemical Markets during these start up years, we have expanded our customer base to establish new markets in Mining, Construction, Wind Power, Nuclear, Manufacturing, Reciprocating and Steel industries. The steady growth from an initial "buy and assemble" operation using hand tools to the current (9) computer controlled and (30) conventional machine tools, enables Riverhawk to maintain a dominant position in an expanding global market.\r\n\r\nRiverhawk Hydraulic Mounting Equipment products consist of specialized tools for the installation and removal of compressor wheels, thrust discs and hydraulically fitted coupling hubs. Hydraulic hand pumps and air over hydraulic pumps offer pressures up to 60,000 psi.\r\n\r\nRiverhawk Tensioning Systems products include standard and custom designs that provide controllable and accurate pre-loads of bolts and studs for reliability and ease of installation and removal. We also design and manufacture engineered studs, nuts and bolts for special applications requiring strength and resistance to fatigue, temperature and corrosion.\r\n\r\nRiverhawk Shaft Joining Technology products include Hydraulic Clamp Rings that eliminate the need for keyed, splined or tapered shafts. Integrating this technology with torque protection, the Torqueblocker protects heavy duty equipment from torque overloads. Applications requiring continuous operation with momentary torque spikes, the Peak Shaver offers drive through torque protection. Applications involving alternating torque conditions, the Viscous Rotational Damper provides superior damping without traditional elastomeric elements. We also manufacture traditional plug and ring gages for hydraulically fitted coupling hub applications.\r\n\r\nUtilizing the latest finite element analysis (FEA) software, Riverhawk Engineers are able to design equipment and confirm stress and/or deflection patterns for both linear and non-linear conditions. We can also build two-dimensional axisymetric models for essentially cylindrical components or three-dimensional solid models for more complex part configurations.\r\n\r\nWe offer in-house or off-site training seminars on a varity of topics on the installation and operation of Riverhawk products. Our experienced field service engineers will work with your field personnel to maximize the use of our products to increase productivity at the job site.\r\n\r\n

8613371530291

8613371530291