roper hydraulic pump manufacturer

We’ve spent more than a century and a half developing innovative pumping solutions for clients in a wide range of industries. Thousands of our pumps are currently in the field delivering superior performance every day.

Our product line boasts broad capabilities – from the workhorse 3600 and A series to a wide variety of Bulk Liquid Handling, High Pressure, and Severe Duty Pumps. Every Roper Pumps product is backed by expert technical support and customer service dedicated to getting the right pump at an economical price for every application.

At Liquid Handling Equipment, Inc. in Charlotte, NC, we are pleased to offer pump equipment from the Roper Pump Company, which is recognized worldwide as a leading provider of innovative fluid handling solutions including external gear pumps & flow dividers and progressing cavity power sections & pumps. Roper was established in 1857, and they leverage unsurpassed fluid dynamics expertise to deliver engineered offerings in the most challenging applications. Call us to help you configure the right Roper pump for your needs.

The Roper 18AM12 Series A pump is adaptable to a wide range of applications, pumping clean fluids such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer. The precise manufacturing tolerances provide minimum clearances for maximum pumping efficiency. Typical applications for the 18AM12 include Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer. This pump has an internal pressure relief valve with a factory setting that is not the same as the pressure setting required in your application. The relief valve must be positioned as shown in instructions for direction of rotation otherwise the valve will be inoperable, and the discharge pressure will not be working against the relief valve. If the builtin relief valve is used, it is mandatory that the relief valve be set BY THE USER, since maximum relief valve pressure depends upon the viscosity and specific gravity of the liquid, the flow rate pump RPM, and also the initial relief valve setting. A builtin relief valve should not be used on applications where the discharge must be closed for more than a few minutes. Prolonged operation with the relief valve fully bypassing will cause heating of the liquid circulating thru the valve, thus resulting in possible damage. This pump has a Mechanical seal shaft seal. Mechanical seals do not require adjustment. Leakage developed at the seal may be due to one of the following conditions worn, marred, or cracked rotating or stationary seal face, or bellows that have become hard, soft, cracked, expanded or extruded.

THE LEADING FORCE behind liquids™ since 1857 A Series General Purpose Pumps General Purpose Pumps for Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer

The Roper Pump Family of Gear Pumps ■ Industrial applications requiring a special mechanical seal ■ ANSI Flanges ■ Many parts interchangeable with 3600 Series ■ Direct drive or built-on gear reducers ■ Bi-directional rotation* ■ Congurations available for close coupled drive and close coupled hydraulic drive ■ Oilelds including light & heavy crude oil ■ Kerosene mixtures, condensates and hot oils ■ Sealed ball bearings ■ Quadruple grease purged lip seals ■ Helical gears for quiet operation ■ Bi-directional rotation* ■ Fuels, solvents, petrochemicals ■ Residual fuel oils, molasses, resins ■...

A Series General Purpose Pumps General Purpose Pumps for Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer Up to 59 GPM Roper A Series pumps are adaptable to a wide range of applications pumping clean uids, such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer. These pumps are designed to operate at standard motor speeds, with provisions for ange or foot mounting. The internal bearings are lubricated by the uid being pumped. With only two moving parts, the pumps run quietly. They are manufactured and assembled with close tolerances,...

Pump Seals SIZE 06 THROUGH 40 Flange Mounted Foot Mounted PACKED BOX The packed box seal is suited for general purpose applications. The standard packing has a temperature limit of 250ºF (121ºC), with special tting available for higher temperature applications. The gland should be adjusted to allow slight seepage. Foot Mounted Flange Mounted Baseplate Mounted Close Coupled to NEMA “C” Motor LIP SEAL The lip seal is suitable for low pressure sealing of lubricating uids. The standard seal has a temperature limit of 212ºF (100ºC). Special tting is available for higher temperature applications....

A Series Performance Charts SIZE If there is any question concerning these charts or the recommended operating conditions, please consult your Roper distributor, district representative, or the home ofce. [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] [l/min] [kW] Performance gures show maximum horsepower requirements for minimum rated gallons per minute at the various speeds, viscosities and pressures. The charts are intended as a guide for conditions at the pump. In determining the proper...

NOTE: Consult your Roper Area Sales Manager for operation in the ranges indicated by the yellow colored areas. NOTE: An outboard ball bearing is recommended for viscosities below 40 ssu.

A Series Dimensions SIZE 005 THROUGH 02 (ange mounted) THREE HOLES 1/4-20 UNC THREAD EQUALLY SPACED ON 2-3/4 DIA. B.C. SIZE 06 THROUGH 16 (foot mounted) PUMP 1-1/4 DIA. N.P.T. PORT EACH SIDE [32] SIZE 21 THROUGH 40 (foot mounted) PUMP S (N.P.T. PORT EACH SIDE) R (RELIEF VALVE) ROPER PUMPS - THE LEADING FORCE behind liquids™ since 1857

SIZE 003 (ange mounted) SIZE 003 (foot mounted) THREE HOLES 1/4-20 UNC THREAD EQUALLY SPACED ON 2-3/4 BIA. B.C. 1-9/16 [40] SIZE 06 THROUGH 16 (ange mounted) R (RELIEF VALVE) 7-1/2 DIA.[191] SIX HOLES 9/16 DIA.[14] EQUALLY SPACED ON 6-7/16 [164] DIA. BOLT CIRCLE 1-1/4 N.P.T. PORT EACH SIDE [32] SIZE 21 THROUGH 40 (ange mounted) PUMP S (N.P.T. PORT EACH SIDE) 1 DIA. [25.4] 3/16 [5] SIX HOLES 9/16 DIA.[14] EQUALLY SPACED ON 6-7/16 DIA.[164] BOLT CIRCLE

AE Series Pumps Low Pressure ● Capacities to 130 GPM Pressures to 300 PSI Roper AE Series pumps are well suited to applications where a compact and quiet unit is required, such as hydraulic lift applications. Bearings and wear-plates are special wear-resistant, high lead bronze. The pumping gears are accurately machined to run quietly and smoothly. SIZE Pump NOTE: Consult your local Roper Pump Company representative for operation in the range indicated by the yellow colored areas. ROPER PUMPS - THE LEADING FORCE behind liquids™ since 1857

THE LEADING FORCE behind liquids™ since 1857 Roper Pump Company is a global supplier of high quality positive displacement pumps, designed to handle a broad range of industrial applications. In addition to helical gear pumps and progressing cavity pumps, we design and develop numerous custom pumps for customers with unique and demanding applications. From a small pump company founded in 1857, Roper Pump Company has grown into a technological leader. With a large installed base, we have both the knowledge and experience to help you solve your most challenging pumping problems…and our strong...

Roper Pump Company’s pioneering work in developing and manufacturing positive displacement pumps dates back to 1857, and more than 150 years later it is recognized as the leading manufacturer of external gear pumps. With a large installed base, Roper Pump has both the expertise and experience to help you solve your most challenging pumping problems.

Roper Pumps provides a variety of pumps for the industrial market, from the popular 3600 Series cast iron gear pump to the magnetic coupled stainless steel ROC Pumps.

The Roper 2AP21 Series A pump is adaptable to a wide range of applications, pumping clean fluids such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer. The precise manufacturing tolerances provide minimum clearances for maximum pumping efficiency. Typical applications for the 2AP21 include Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer. This pump has an internal pressure relief valve with a factory setting that is not the same as the pressure setting required in your application. The relief valve must be positioned as shown in instructions for direction of rotation otherwise the valve will be inoperable, and the discharge pressure will not be working against the relief valve. If the builtin relief valve is used, it is mandatory that the relief valve be set BY THE USER, since maximum relief valve pressure depends upon the viscosity and specific gravity of the liquid, the flow rate pump RPM, and also the initial relief valve setting. A builtin relief valve should not be used on applications where the discharge must be closed for more than a few minutes. Prolonged operation with the relief valve fully bypassing will cause heating of the liquid circulating thru the valve, thus resulting in possible damage. This pump has a packing ring type shaft seal. Operate the pump under normal conditions and, after a short runin period, examine the packing for leakage. If leakage is excessive, stop the pump and follow the procedure described below. A slight leakage is a necessary and normal condition for packing and allows for expansion and proper seating.

These pumps operate smoothly and with equal efficiency in either direction of rotation. They effectively handle heavy, viscous materials such as asphalt, molasses, roofing compounds, and printing inks, as well as fuel oils, gasolines, and similar thin liquids. Pumps can be supplied in several materials of construction, with or without built-in relief valves. Pumps can be assembled either hi-drive or low-drive, and are available with conventional packed box or lapped-face mechanical shaft seal. They can be direct driven or driven through a built-in gear reduction with a wide range of ratios. These pumps operate equally well regardless of the mounting configuration or the direction of rotation.

The pricing offered on our website for this pump model includes the standard options. Click Here to see the other options available, call us at 1-800-433-8831 for assistance and pricing.

These pumps operate smoothly and with equal efficiency in either direction of rotation. They effectively handle heavy, viscous materials such as asphalt, molasses, roofing compounds, and printing inks, as well as fuel oils, gasolines, and similar thin liquids. Pumps can be supplied in several materials of construction, with or without built-in relief valves. Pumps can be assembled either hi-drive or low-drive, and are available with conventional packed box or lapped-face mechanical shaft seal. They can be direct driven or driven through a built-in gear reduction with a wide range of ratios. These pumps operate equally well regardless of the mounting configuration or the direction of rotation.

The pricing offered on our website for this pump model includes the standard options. Click Here to see the other options available, call us at 1-800-433-8831 for assistance and pricing.

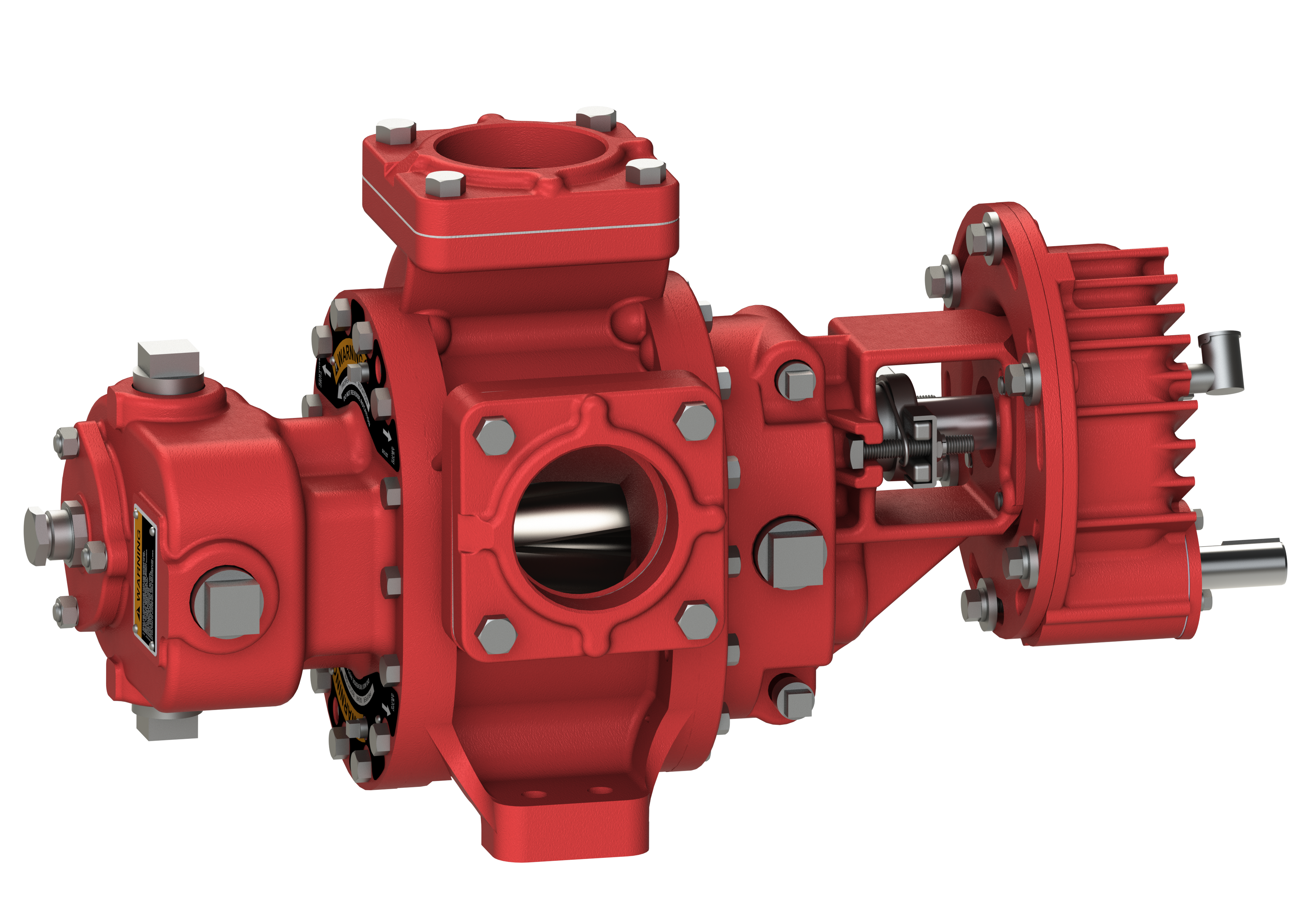

The Roper 3600 series pump has been the industry leader for decades. Rugged, versatile and dependable the 3600 is the gold standard of tank truck pumps. These pumps operate smoothly and with equal ef?ciency in either direction of rotation

The 3600 series is the industry standard for pumping fuel oils and gasoline. They also effectively handle heavy, viscous materials such as asphalt, molasses, roo?ng compounds, and printing inks.

All Pumps listed below come with a built in relief valve and an outboard drive shaft bearing to supports external radial loads and absorb thrust loads.

8613371530291

8613371530291