roper hydraulic pump supplier

We’ve spent more than a century and a half developing innovative pumping solutions for clients in a wide range of industries. Thousands of our pumps are currently in the field delivering superior performance every day.

At Liquid Handling Equipment, Inc. in Charlotte, NC, we are pleased to offer pump equipment from the Roper Pump Company, which is recognized worldwide as a leading provider of innovative fluid handling solutions including external gear pumps & flow dividers and progressing cavity power sections & pumps. Roper was established in 1857, and they leverage unsurpassed fluid dynamics expertise to deliver engineered offerings in the most challenging applications. Call us to help you configure the right Roper pump for your needs.

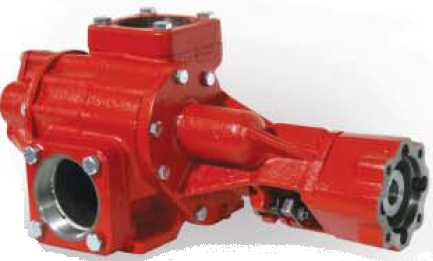

Rubber gear pump specifically designed for handling liquids with high solid content and abrasives. Often used for oilfield service, hydro-seeding, waste oils, tallow and sludges.

These pumps operate smoothly and with equal efficiency in either direction of rotation. They effectively handle heavy, viscous materials such as asphalt, molasses, roofing compounds, and printing inks, as well as fuel oils, gasolines, and similar thin liquids. Pumps can be supplied in several materials of construction, with or without built-in relief valves. Pumps can be assembled either hi-drive or low-drive, and are available with conventional packed box or lapped-face mechanical shaft seal. They can be direct driven or driven through a built-in gear reduction with a wide range of ratios. These pumps operate equally well regardless of the mounting configuration or the direction of rotation.

The pricing offered on our website for this pump model includes the standard options. Click Here to see the other options available, call us at 1-800-433-8831 for assistance and pricing.

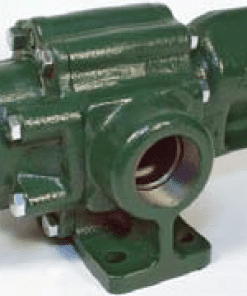

The Roper 1AP21 is a Cast Iron pedestal Gear Pump, bare shafted pump end, with Upper Drive shaft configuration, Ductile Iron Gears, 1-1/2 inch NPT by 1-1/2 inch NPT Ports, replacement pump end only without a Motor. This pump is a pump end only, for close or long coupling to motors, and is designed to operate at standard motor speeds, with provisions for flange or foot mounting. The internal bearings are lubricated by the fluid being pumped, and with only two moving parts, and idle gear and a drive gear, the pumps run quietly. They are manufactured and assembled with close tolerances, and regularly tested to insure dependable performance. The pump is factory assembled for clockwise rotation (facing the pump drive shaft end), most may be reassembled for operation with equal efficiency in a counter-clockwise rotation. All pump body castings are cast iron, for a precise, rugged, maintenance-friendly design. This gear pump has bi-directional rotation, with quiet-running helical gears precision machined to insure proper meshing, reduced friction and vibration, quiet efficient operation and long life. Four heavy duty sleeve bearings give positive support to pumping gears and insure long, efficient service. The 4 pump bearings are special wear-resistant, high-lead bronze with long-lasting bearing surfaces. (Iron and carbon bearings are available.) Large, hardened steel dowel pins insure positive alignment between the faceplate, case, and backplate. This pump end does not include a motor and is just the bare shafted pump end only. Complete pump and motor assemblies can be close coupled with a motor bracket and electrical motor, or fabricated with a pump, coupling, coupling guard, motor, and baseplate. The maximum temperature for this pump is 250 F.

The Roper 2AM16 Series A pump is adaptable to a wide range of applications, pumping clean fluids such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer. The precise manufacturing tolerances provide minimum clearances for maximum pumping efficiency. Typical applications for the 2AM16 include Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer. This pump has an internal pressure relief valve with a factory setting that is not the same as the pressure setting required in your application. The relief valve must be positioned as shown in instructions for direction of rotation otherwise the valve will be inoperable, and the discharge pressure will not be working against the relief valve. If the builtin relief valve is used, it is mandatory that the relief valve be set BY THE USER, since maximum relief valve pressure depends upon the viscosity and specific gravity of the liquid, the flow rate pump RPM, and also the initial relief valve setting. A builtin relief valve should not be used on applications where the discharge must be closed for more than a few minutes. Prolonged operation with the relief valve fully bypassing will cause heating of the liquid circulating thru the valve, thus resulting in possible damage. This pump has a Mechanical seal shaft seal. Mechanical seals do not require adjustment. Leakage developed at the seal may be due to one of the following conditions worn, marred, or cracked rotating or stationary seal face, or bellows that have become hard, soft, cracked, expanded or extruded.

Roper Pumps are recognized worldwide as a leading provider of innovative fluid handling solutions including external gear pumps & flow dividers and progressing cavity power sections & pumps.

Roper Gear Pumps have been sold in New Zealand by Pump & Valve for over 20 years. Simple, reliable and very robust these gear pumps have been manufactured in the United States since the late 1940’s. Ideally suited for pumping thick lubricating liquids they are in service all over New Zealand pumping bitumen, emulsion, molasses, waste oil and resin.

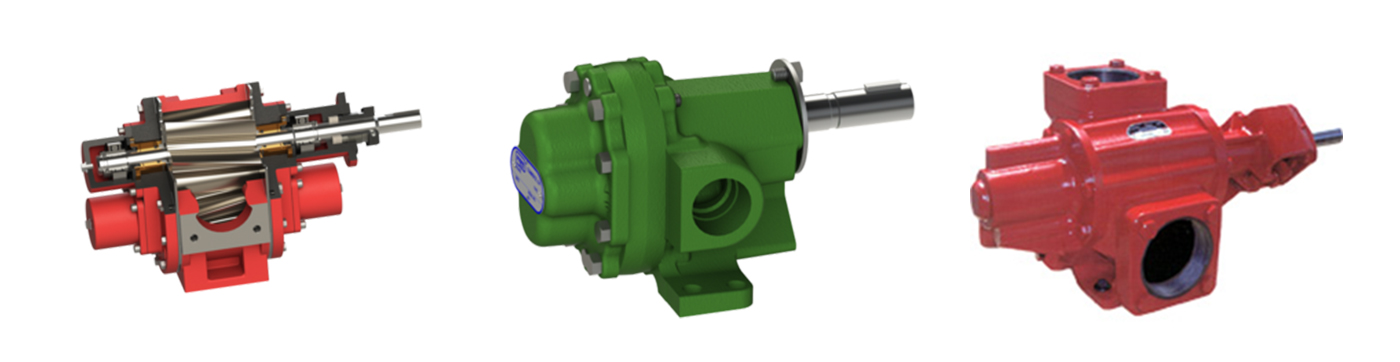

The Roper Gear Pump range features a complete line of helical gear pumps from the workhorse 3600 and A Series through a wide variety of Bulk Liquid Handling, High Pressure and Severe Duty Pumps.

Roper Pump Co. boasts a complete line of helical gear pumps for the industrial, transport and oil & gas marketplaces. It is a product line with broad capabilities – from the workhorse 3600 and A series to a wide variety of Bulk Liquid Handling, High Pressure, and Severe Duty Pumps.

Today, Roper Pump is recognized worldwide as a leading supplier of industrial pumps including helical gear pumps, progressing cavity pumps, pumping systems, and solutions. As an ISO 9001:2000 certified designer and manufacturer, Roper Pump Company is setting the standard for premium quality products.

Roper A Series pumps are adaptable to a wide range of applications pumping clean ?uids, such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer.

These pumps are designed to operate at standard motor speeds, with provisions for ?ange or foot mounting. The internal bearings are lubricated by the ?uid being pumped. With only two moving parts, the pumps run quietly.

8613371530291

8613371530291