roper hydraulic pump brands

We’ve spent more than a century and a half developing innovative pumping solutions for clients in a wide range of industries. Thousands of our pumps are currently in the field delivering superior performance every day.

Our product line boasts broad capabilities – from the workhorse 3600 and A series to a wide variety of Bulk Liquid Handling, High Pressure, and Severe Duty Pumps. Every Roper Pumps product is backed by expert technical support and customer service dedicated to getting the right pump at an economical price for every application.

Roper Pumps are recognized worldwide as a leading provider of innovative fluid handling solutions including external gear pumps & flow dividers and progressing cavity power sections & pumps.

Rubber gear pump specifically designed for handling liquids with high solid content and abrasives. Often used for oilfield service, hydro-seeding, waste oils, tallow and sludges.

These pumps operate smoothly and with equal efficiency in either direction of rotation. They effectively handle heavy, viscous materials such as asphalt, molasses, roofing compounds, and printing inks, as well as fuel oils, gasolines, and similar thin liquids. Pumps can be supplied in several materials of construction, with or without built-in relief valves. Pumps can be assembled either hi-drive or low-drive, and are available with conventional packed box or lapped-face mechanical shaft seal. They can be direct driven or driven through a built-in gear reduction with a wide range of ratios. These pumps operate equally well regardless of the mounting configuration or the direction of rotation.

The pricing offered on our website for this pump model includes the standard options. Click Here to see the other options available, call us at 1-800-433-8831 for assistance and pricing.

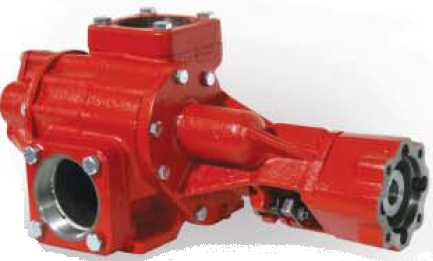

The Roper 3600 series pump has been the industry leader for decades. Rugged, versatile and dependable the 3600 is the gold standard of tank truck pumps. These pumps operate smoothly and with equal ef?ciency in either direction of rotation

The 3600 series is the industry standard for pumping fuel oils and gasoline. They also effectively handle heavy, viscous materials such as asphalt, molasses, roo?ng compounds, and printing inks.

All Pumps listed below come with a built in relief valve and an outboard drive shaft bearing to supports external radial loads and absorb thrust loads.

Progressive cavity pumps come are used in precision applications, so they come with tight tolerances. This type of positive displacement pump consists of two very important parts. Generally, there will be a helical rotor inside of a double helical hole. As the rotor spins inside of the pump body, cavities are left behind. This is where the fluid will reside as the helical rotor turns. These cavities maintain a constant shape as the rotor turns and moves the fluid through the pump. That being said, it is very important that these pumps are manufactured with precision to ensure efficient operations.

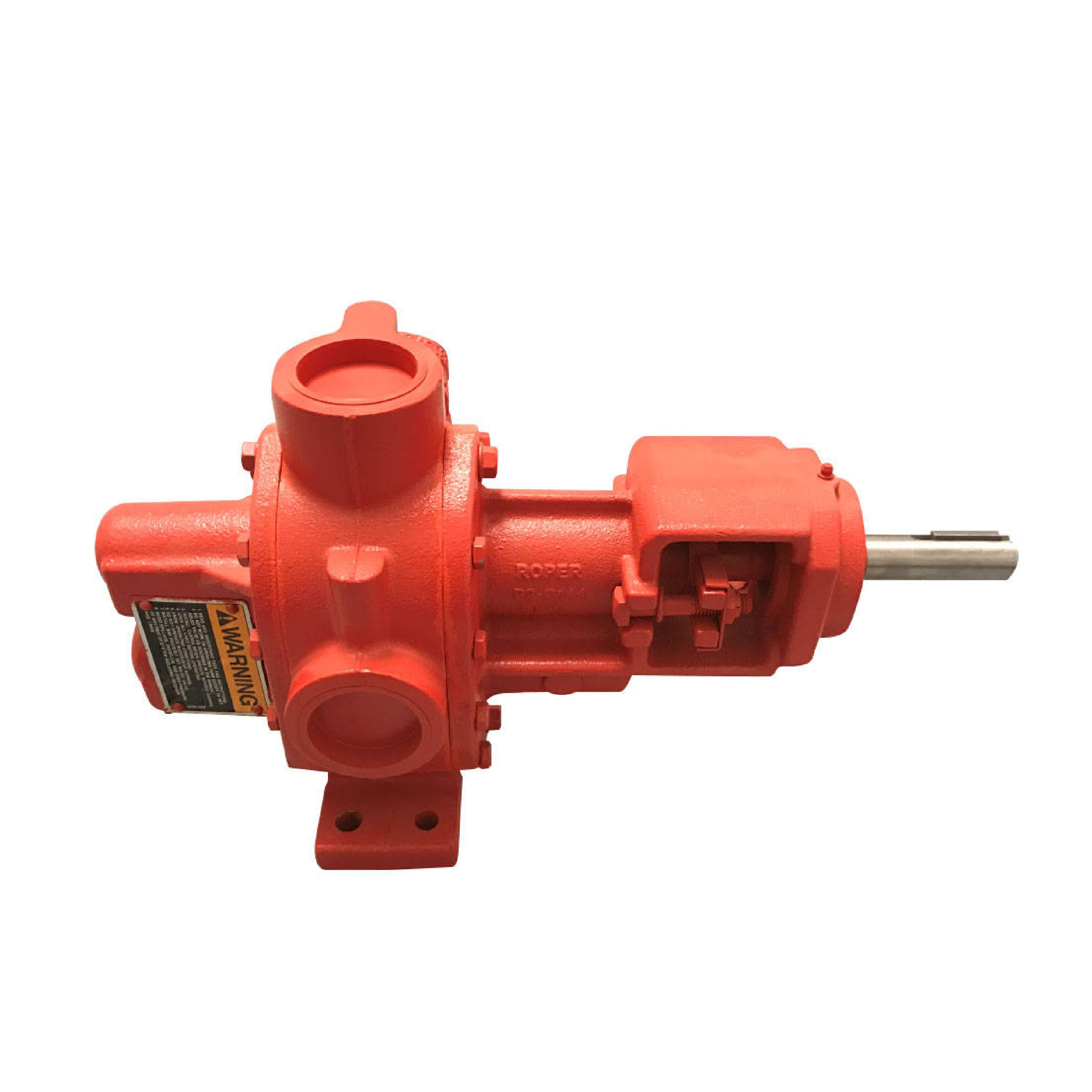

This is a general purpose Roper A series Pump for Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer. The Roper A Series pumps are adaptable to a wide range of applications pumping clean fluids, such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer. These pumps are designed to operate at standard motor speeds, with provisions for flange or foot mounting.

They are manufactured and assembled with close tolerances, and regularly tested to insure dependable performance. Accurate machining insures proper meshing, reduced friction and vibration, quiet, efficient operation, and long life. Factory assembled for clockwise rotation (facing the pump drive shaft end), most may be reassembled for operation with equal efficiency in a counter-clockwise rotation.

Large, hardened steel dowel pins insure positive alignment between the faceplate, case, and backplate. Four heavy duty sleeve bearings give positive support to pumping gears and insure long, efficient service. These internal bearings are lubricated by the fluid being pumped. The Bearings are special wear-resistant, high-lead bronze. (Iron and carbon bearings are available.) With only two moving parts, being the gears, the pumps run quietly.

The Roper 3600 series pump has been industry leader for decades. Rugged, versatile and dependable the 3600 the gold standard of tank truck pumps. These pumps operate smoothly and with equal effciency in either direction of rotation

The 3600 series is the industry standard for pumping fuel oils and gasoline. They also effectively handle heavy, viscous materials such as asphalt, molasses, roofng compounds, and printing inks.

8613371530291

8613371530291