sae hydraulic pump mount dimensions supplier

For many years the only standardization on pump and motor shafts and mounting flanges had been the SAE (Society of Automotive Engineers) Standard J744a. It was widely accepted by other industries as well as the automotive and is still a valid standard. The NFPA (National Fluid Power Association) started work in 1962 on a set of standards which would more directly apply to industrial fluid power pumps and motors, and would be more complete. This set of standards was unanimously approved by the NFPA Board of Directors and issued in 1965 as NFPA Recommended Standard T3.9.65.1. In 1966 it was also adopted by the ANSI (American National Standards Institute) and issued as B93.6-1966. It has since been revised and now carries the numbers ANSI B93.6-1972 and NFPA T3.9.2 R1. Copies are available from the NFPA.

The purpose of the standard is to encourage manufacturers to use interchangeable dimensions on both mounting flanges and shafts as far as possible to simplify dimensional interchangeability. No standards presently exist for foot mounting dimensions. No performance specifications exist although recommended methods of testing pumps and motors and the manner of presenting test data are given in NFPA Recommended Standard T3.9.17-1971.

The new NFPA and ANSI standards are similar to the SAE standards but differ in these respects: Additional shaft diameters and an alternative long length shaft have been added to the straight-shaft-without-thread listings. Additional mounting flange sizes have been added to provide a wider selection for the designer. NFPA has not assigned any horsepower ratings, making it the responsibility of the pump designer. However, the SAE horsepower ratings are shown for mounting flanges.

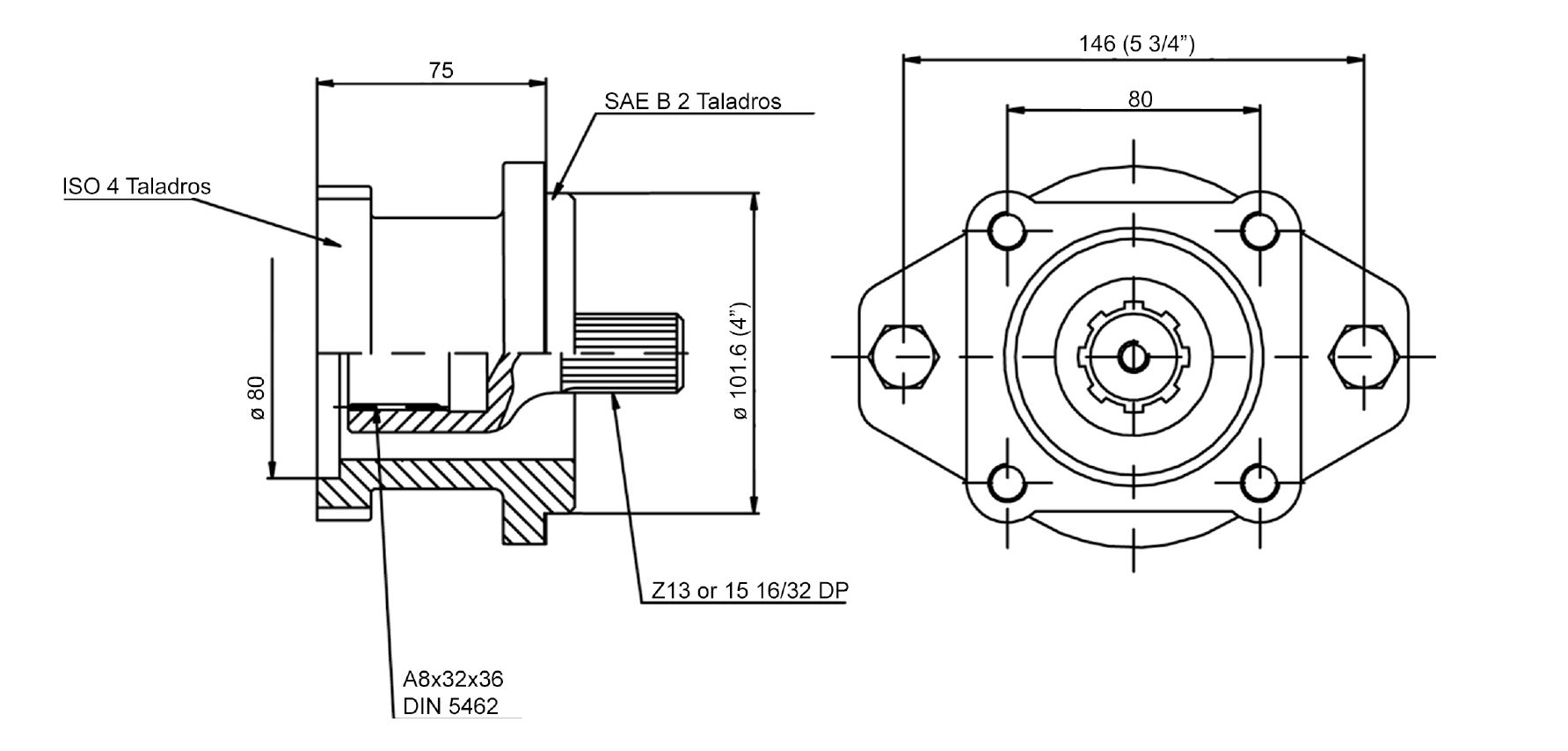

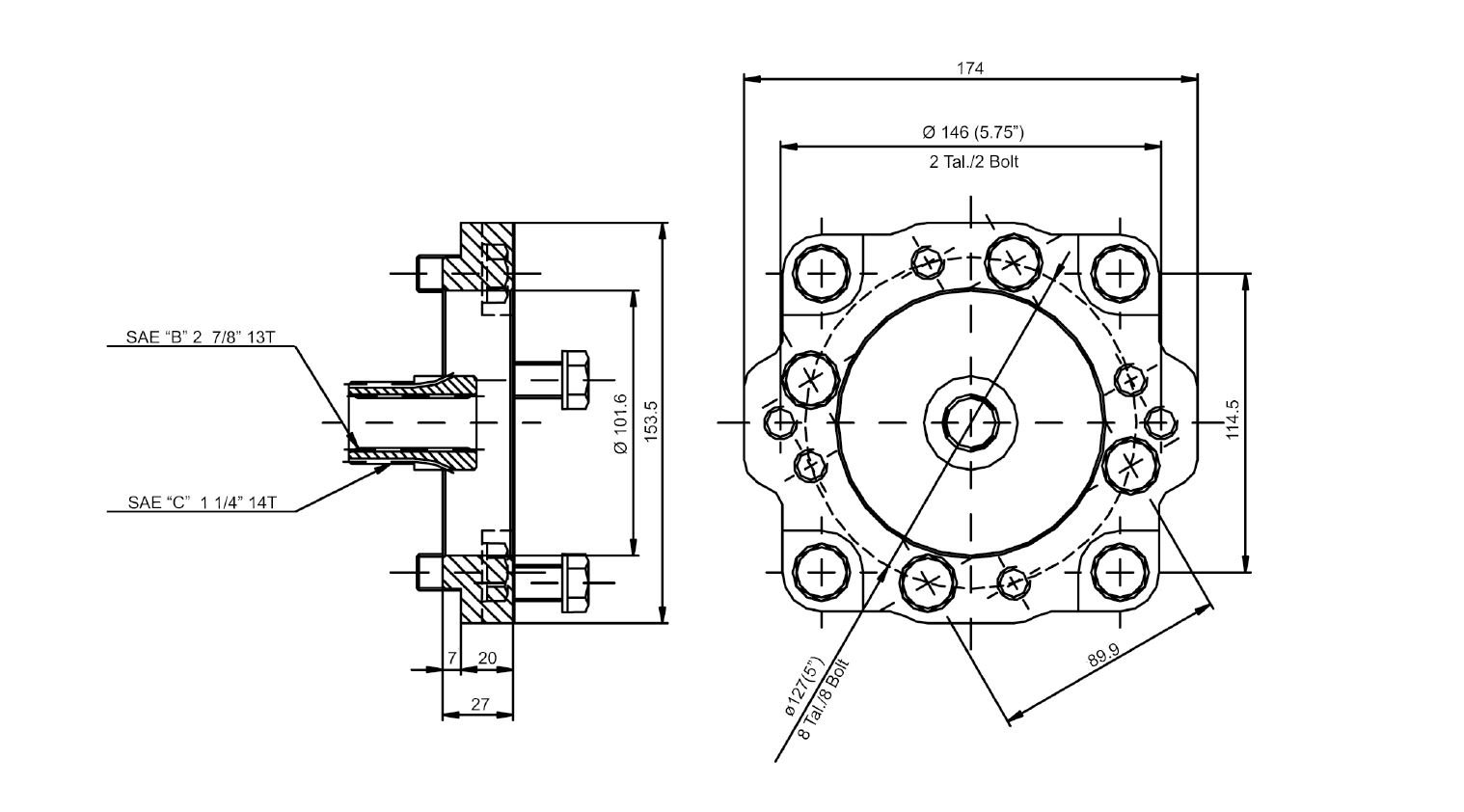

The pump mounting flanges are made of steel and cast iron for hydraulic pumps with flange connections according to SAE-A, -B, -C, -D and-E in a design with 2 holes and 4 holes.

Pump connection housings made of cast iron of our portfolio are suitable for direct mounting to the back plate of the engine. Our pump mounting flanges are also availabe with surface coating as well as special flange dimensions on request.

It is not uncommon that we will need to couple pumps, motors and/or engines together. Jaw-style couplers help with joining shafts together. With the use of these couplers, we can adapt and fit many different types of shafts together, but interestingly, there are so few choices! Granted, there are lots of choices in the catalogue, but it seems that there should be many more shaft sizes, spline cuts and keys to choose from. Why aren’t there more? Also, what about the outside of the parts? They look like they were designed to be mated with something.

Your questions are not unfounded. There was a standardization that took place years ago. SAE led the way with standardized shafts and mounting flanges in SAE J744. The standard takes a seemingly infinite number of combinations and boils it down to a manageable number of combinations. The fewer the choices, the easier it is on engineers. Plus, manufacturers can often bring a product to market quicker since there aren’t many custom options.

The Society of Automotive Engineers (SAE) has standardized the mounting flanges for hydraulic pumps and motors using a letter codes and the number of bolts used. The sizes are already designed to be able to properly carry the load with medium strength fastener (Grade 5 or equivalent)

SAE J744 specifies the flanges by a letter and a bolt count. In a two bolt pattern, the two bolts and center pilot are all in line. Two bolt flanges (black) come in AA, A, B, C, D and E configurations. Each one gets successively larger. The four-bolt ones have the center pilot surrounded by four bolts arranged in a square around it. These four-bolt (blue) configurations are available in B, C, D and E configurations. These flanges are constructed so that the center pilot will take the main x-y loads and the bolts only take the torque load. Below, is a table for the two bolt configurations. It contains the pitch circle diameter, PCD, which is the diameter of a circle drawn centered at the pilot and intersects the center of the bolt holes. It also has the size of the bolt holes and the pilot diameter.

Keeping your pump and motors on the same center and parallel is critical and often difficult to do. It can mean the difference between a long-lasting system and one that constantly needs maintenance. The example here, a log splitter, is almost exactly how notto do this. Let’s take a look at several problems:

This is not ideal and will definitely wear out the spider coupler faster. However, there are three options to get great alignment with a pump or motor.

Many times you can buy a pre-machined cast aluminum coupler if you are coupling an electric motor or gas engine to a hydraulic pump. Grainger, McMaster Carr and many others have these products online. They are wonderful because they ensure that the shafts will lineup perfectly and have an added safety feature. They usually shield all the way around except for a small opening so that you can tighten set screws in the jaw coupler. Some even have options for a plastic or rubber plug to fill this hole. I always opt for this option. Be sure to mount with the opening on top so that the plug does not fill with water and debris or the vibrations cause it to fall out.

SAE has standardized shaft configurations to use keyways and splines to attach components. This limits the number of choices for each shaft size to one key and one spline. This makes it easy for the customer to specify mating components and the manufacturer to minimize component configurations.

You may have noticed that I skipped over close coupled arrangements. I did that because I wanted to discuss SAE shafts first. We will address that later in this section.

A splined shaft is much different. The full description is SAE 30° involute spline shaft, but in practice if you say splined shaft everyone will know what you are talking about. In appearance, they look like gears and essentially that is what they are. As you can guess, they do not have any mechanism to deal with over torque like a keyed shaft does. So these also have the same SAE letter codes available as a keyed shaft. A sizing table will have the spline details, nominal diameter and total length. Spline detail are displayed as 11T 16/32 DP. This is similar to how a gear is specified. In this example, the spline has 11 teeth and 16 teeth per inch of diameter (DP, diametric pitch). I’ll be honest; I do not know why the 32 is there. It seems redundant to me. The bottom line is this; if the teeth and diametric pitch match, the shaft and hub will fit together.

Yes, finally to the close coupling. This is when we fit our pump or motor to have either a splined or keyed hub instead of a shaft. This allows us to eliminate the entire issue of shaft alignment and jaw couplers by inserting the electric motor shaft inside the pump. In the image here, you can see that the pump is directly connected to the motor and there is no housing or coupler. This is a great option if you are driving multiple pumps from the same power source. In this case, you can have the pump that attaches to the motor with a hub on one side and a shaft on the other. You can then attach your second pump. Granted, having a hub instead of a shaft is more expensive on the front end, but it may end up paying for itself quickly if you can eliminate jaw couplers, machined framework and the time it takes to assemble.

In figuring out the specifications of our parts, SAE has helped by laying out the information for us. A very quick web search will provide you with the tables of all the shaft and mounting information. All that needs to be done is to answer these questions:

One last word of advice when working with couplers and shafts: Remember to always use anti-seize between the two faces in order to prevent any rust or corrosion. It is more than likely that you will need to remove or separate these parts at some point. If these components rust together, you might as well throw them away. You can try to pry them apart or use heat, but it is more than likely you will damage the internal components of your pump and motor in the process. Please, use the anti-seize. It is inexpensive and available in any auto parts store.

Vertical Pump/Motor MountsLovejoy Hydraulics Vertical pump/motor mounts are a cost-effective, space-saving solution that allows mounting the pump through the tank lid top or from underneath. The pump and mount assembly is enclosed inside the tank, which is a safe, quiet, compact way of mounting the pump/motor assembly. Vertical mounts are available in NEMA C-Face motor frame sizes from 56C to 256TC for most SAE and Metric 2 and 4 bolt pump flanges. Two mounting options are available to give additional flexibility in Vertical Power Unit Design.Included HardwareA Motor Mount kit and Pump Mount kit is included. Each includes all the required bolts and washers to mount the pump and motor to the pump/motor mount. The kit does NOT contain hardware required to mount the pump/motor mount to the tank lid top.

string(741) "We understand the importance of quality brakes and supply a range with exceptional holding power for both wet and dry conditions, for a variety of applications and industries. Designed and built for the harshest conditions, our range of brakes are utilised on a arrange of equipment including loaders, cotton harvesters, oil rig equipment, cranes, serial work platforms and boom lifts. We supply multi-disc brakes and torque lock brake systems from leading manufacturers including Ausco and Fairfield. Our hydraulic brake range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic brake range please fill out a form, call or email us using the links below."

string(741) "We understand the importance of quality brakes and supply a range with exceptional holding power for both wet and dry conditions, for a variety of applications and industries. Designed and built for the harshest conditions, our range of brakes are utilised on a arrange of equipment including loaders, cotton harvesters, oil rig equipment, cranes, serial work platforms and boom lifts. We supply multi-disc brakes and torque lock brake systems from leading manufacturers including Ausco and Fairfield. Our hydraulic brake range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic brake range please fill out a form, call or email us using the links below."

string(673) "Coolers and heaters work to maintain an ideal working temperature of hydraulic fluid to prevent fluid damage or system failures. We source a range of hydraulic coolers and heaters from well-known suppliers including Olaer. Our range of Olaer coolers and heaters includes: Air/oil heat exchangers including LAC Series, LDC Series, LHC Series Water/oil heat exchangers including PWO Series Air/water coolers Our hydraulic coolers and heaters range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic coolers and heaters range please fill out a form, call or email us using the links below."

string(673) "Coolers and heaters work to maintain an ideal working temperature of hydraulic fluid to prevent fluid damage or system failures. We source a range of hydraulic coolers and heaters from well-known suppliers including Olaer. Our range of Olaer coolers and heaters includes: Air/oil heat exchangers including LAC Series, LDC Series, LHC Series Water/oil heat exchangers including PWO Series Air/water coolers Our hydraulic coolers and heaters range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic coolers and heaters range please fill out a form, call or email us using the links below."

string(884) "Hydraulic gearboxes are a reliable and effective solution for power transmission and motion control, suitable for many types of off-road, mobile vehicles and equipment. We source a complete range for light duty industrial automation applications from well-known brands such as Fairfield and Bonfigioli. Our range of Fairfield gearboxes includes: Torque-hub wheel drives Torque-hub shaft output drives Excel Series including 7000, 11000, 18000 Series Torque-hub planetary final drives including CT and CW Series Our range of Bonfiglioli gearboxes includes: Industrial gearboxes including 300 Series Multipurpose Gearbox Planetary gearboxes Our hydraulic gearbox range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic gearbox range please fill out a form, call or email us using the links below."

string(884) "Hydraulic gearboxes are a reliable and effective solution for power transmission and motion control, suitable for many types of off-road, mobile vehicles and equipment. We source a complete range for light duty industrial automation applications from well-known brands such as Fairfield and Bonfigioli. Our range of Fairfield gearboxes includes: Torque-hub wheel drives Torque-hub shaft output drives Excel Series including 7000, 11000, 18000 Series Torque-hub planetary final drives including CT and CW Series Our range of Bonfiglioli gearboxes includes: Industrial gearboxes including 300 Series Multipurpose Gearbox Planetary gearboxes Our hydraulic gearbox range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic gearbox range please fill out a form, call or email us using the links below."

string(722) "Berendsen sources a large selection of hydraulic hoses and fitting sizes such as braided, spiral and multi-purpose hydraulic hoses. These ultimate fluid conveyance solutions are equipped with wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities. We supply hydraulic hose, fittings, adapters, couplings and fluid connectors from well-known suppliers including Eaton Aeroquip. Our hydraulic hose and fitting range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic hose and fitting range please fill out a form, call or email us using the links below."

string(722) "Berendsen sources a large selection of hydraulic hoses and fitting sizes such as braided, spiral and multi-purpose hydraulic hoses. These ultimate fluid conveyance solutions are equipped with wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities. We supply hydraulic hose, fittings, adapters, couplings and fluid connectors from well-known suppliers including Eaton Aeroquip. Our hydraulic hose and fitting range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic hose and fitting range please fill out a form, call or email us using the links below."

string(750) "Instrumentation and gauges are essential elements of hydraulic systems and include pressure gauges, pressure switches, flow meters, pressure sensors, temperature sensors, turbine flow meters, gear flow meters, speed sensor infrareds and mini test fittings and hoses. We source a large range of instrumentations and gauges from MP Filtri, Hystar and The Hydraulic Warehouse. Our range of MP Filtri instrumentation and gauges includes: ICM particle counter LPA2 particle counter Our instrumentation and gauges range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic instrumentation and gauges range please fill out a form, call or email us using the links below."

string(750) "Instrumentation and gauges are essential elements of hydraulic systems and include pressure gauges, pressure switches, flow meters, pressure sensors, temperature sensors, turbine flow meters, gear flow meters, speed sensor infrareds and mini test fittings and hoses. We source a large range of instrumentations and gauges from MP Filtri, Hystar and The Hydraulic Warehouse. Our range of MP Filtri instrumentation and gauges includes: ICM particle counter LPA2 particle counter Our instrumentation and gauges range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic instrumentation and gauges range please fill out a form, call or email us using the links below."

string(1167) "Manifolds regulate the fluid flow between pumps, actuators and other components in a hydraulic system, allowing the operator to control how much fluid flows between the different components. Berendsen is proud to have developed our own range of standard manifolds and custom designed and manufactured manifolds to meet the needs of a range of industrial applications. Our standard range of manifolds includes station manifolds, CETOP 3 manifolds, CETOP 5 manifolds and sub-plates. Custom Designed and Manufactured Manifolds Manufactured to the highest quality at our ISO certified manufacturing hub in Newcastle, our range includes steel, aluminium and stainless steel manifolds. Our world class CAD manifold design software and the latest technologies applied in our manufacturing process make us the first choice supplier of custom and standard manifolds. Click here for more information on our custom manifold manufacturing capabilities. Our manifold range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our manifold range please fill out a form, call or email us using the links below."

string(1167) "Manifolds regulate the fluid flow between pumps, actuators and other components in a hydraulic system, allowing the operator to control how much fluid flows between the different components. Berendsen is proud to have developed our own range of standard manifolds and custom designed and manufactured manifolds to meet the needs of a range of industrial applications. Our standard range of manifolds includes station manifolds, CETOP 3 manifolds, CETOP 5 manifolds and sub-plates. Custom Designed and Manufactured Manifolds Manufactured to the highest quality at our ISO certified manufacturing hub in Newcastle, our range includes steel, aluminium and stainless steel manifolds. Our world class CAD manifold design software and the latest technologies applied in our manufacturing process make us the first choice supplier of custom and standard manifolds. Click here for more information on our custom manifold manufacturing capabilities. Our manifold range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our manifold range please fill out a form, call or email us using the links below."

string(674) "Power steering products, such as control units, steering wheels, pumps and steering columns, assist with controlling and directing fluid pressure. Berendsen source innovative power steering pumps from Eaton Char-Lynn. Our range of Eaton Char-Lynn power steering products includes: Power steering pumps including the VTM Series Steering control units including Series 3, 6, 10, 12 and 20 Steering accessories including wheels and columns Our power steering range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our power steering range please fill out a form, call or email us using the links below."

string(674) "Power steering products, such as control units, steering wheels, pumps and steering columns, assist with controlling and directing fluid pressure. Berendsen source innovative power steering pumps from Eaton Char-Lynn. Our range of Eaton Char-Lynn power steering products includes: Power steering pumps including the VTM Series Steering control units including Series 3, 6, 10, 12 and 20 Steering accessories including wheels and columns Our power steering range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our power steering range please fill out a form, call or email us using the links below."

string(1324) "Hydraulic Power Units and Power Packs Hydraulic power units, also referred to as hydraulic power packs, are used to provide hydraulic power through liquid flow and pressure. Our hydraulic power units are suitable for applications such as mining, lubrication systems, industrial, defense, automotive, manufacturing, cardboard waste compactors, marine hook lock systems, agricultural, rotary dairies, grain stackers, produce sorting systems, emergency brake systems for cranes and personal lift systems. Berendsen is proud to supply both a standard range of power units and a custom designed and manufactured power units. Standard Power Units Our standard range of power units are supplied by The Hydraulic Warehouse (THW) and Eaton. Our standard range of THW power units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. The THW range of Power Units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. Each power unit can be built and tested within three working days. Custom Designed and Manufactured…"

string(1324) "Hydraulic Power Units and Power Packs Hydraulic power units, also referred to as hydraulic power packs, are used to provide hydraulic power through liquid flow and pressure. Our hydraulic power units are suitable for applications such as mining, lubrication systems, industrial, defense, automotive, manufacturing, cardboard waste compactors, marine hook lock systems, agricultural, rotary dairies, grain stackers, produce sorting systems, emergency brake systems for cranes and personal lift systems. Berendsen is proud to supply both a standard range of power units and a custom designed and manufactured power units. Standard Power Units Our standard range of power units are supplied by The Hydraulic Warehouse (THW) and Eaton. Our standard range of THW power units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. The THW range of Power Units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. Each power unit can be built and tested within three working days. Custom Designed and Manufactured…"

string(857) "Tools and equipment are an essential part of hydraulic activity and include products such as general purpose cylinders, centre hole cylinders, double acting cylinders, high tonnage cylinders, hydraulic hand pumps, air hydraulic pumps, electric hydraulic pumps, high pressure hoses and quick couplers, sourced from SPX Power Team. Our tools and equipment range includes products such as: Electric operated pumps Pneumatic operated pumps Mechanical operated pumps Hoses Gauges Nut splitters Hydraulic punches Spreaders Jaw type pullers Push pullers Tire removers Hydraulic testers Torque wrenches Our hydraulic tools and equipment range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic tools and equipment, please fill out a form, call or email us using the links below."

string(857) "Tools and equipment are an essential part of hydraulic activity and include products such as general purpose cylinders, centre hole cylinders, double acting cylinders, high tonnage cylinders, hydraulic hand pumps, air hydraulic pumps, electric hydraulic pumps, high pressure hoses and quick couplers, sourced from SPX Power Team. Our tools and equipment range includes products such as: Electric operated pumps Pneumatic operated pumps Mechanical operated pumps Hoses Gauges Nut splitters Hydraulic punches Spreaders Jaw type pullers Push pullers Tire removers Hydraulic testers Torque wrenches Our hydraulic tools and equipment range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic tools and equipment, please fill out a form, call or email us using the links below."

8613371530291

8613371530291