scag hydraulic pump rebuild made in china

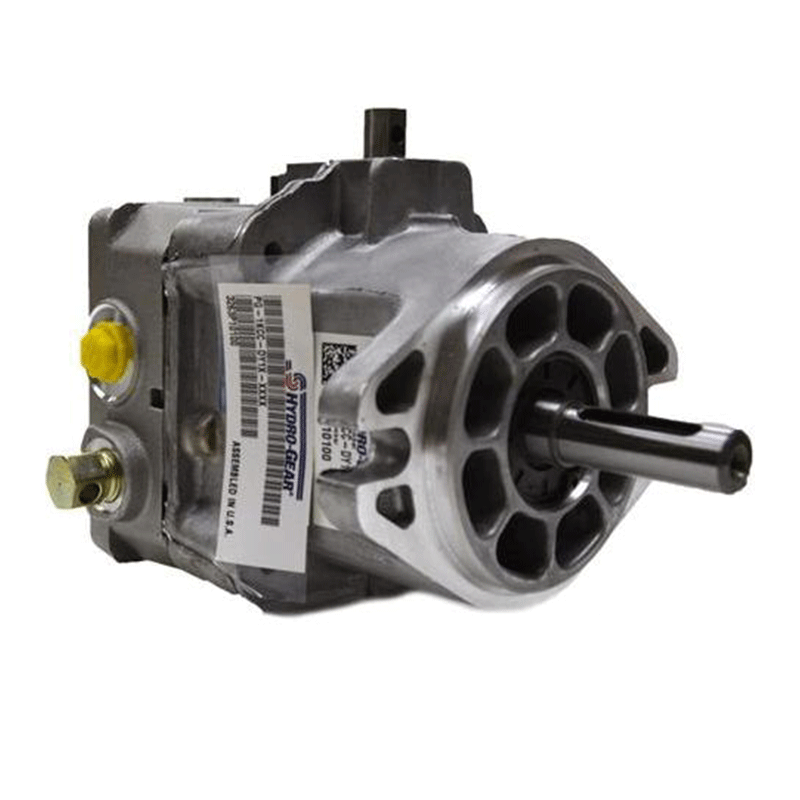

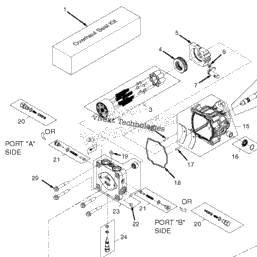

Replacement Hydro Pumps for your Scag Mowers. Hydro pumps are known as the world leader in the lawn and garden industry. This pump has a 6 month parts and labor warranty from date of Professional Installation. Shown in the chart below are the Hydro Gear.

When ordering and replacing your hydro pump always replace the wheel motor if equipped and lines, flush the tanks and install a new oil filter. Not doing so could cause the new hydro pump to fail due to contamination in the system.

All Scag Hydraulic Pumps and Transaxles discounted with fast delivery. These high quality pumps and transaxles are made by Hydro Gear, the world leader in the manufacturing of precision drive systems for the turf industry.

Scag Hydraulic Pump, 485574 Made by Hydro Gear .... the leading manufacturer of precision hydraulic drive systems for outdoor power equipment. Please order by part number Pictures shown for illustration purposes Prices subject to change...

Scag Hydraulic Pump, 485573 Made by Hydro gear is the leading manufacturer of precision hydraulic drive systems for outdoor power equipment. Please order by part number Pictures shown for illustration purposes Prices subject to change...

Scag Hydro Gear pump 484760 Pictures shown are for illustration purposes only. Please order by part number. Hydro Gear is the leading manufacturer of precision hydraulic drive systems for commercial and residential lawn mowers.

Scag Hydro Gear pump 484761 Pictures shown are for illustration purposes only. Please order by part number. Hydro Gear is the leading manufacturer of precision hydraulic drive systems for commercial and residential lawn mowers.

Scag Hydraulic pump Made by Hydro Gear # 482643 Hydro Gear is the World Leader in the manufacturing of Precision Drive Products for the Lawn and Garden Industry Hydro Gear is the OEM supplier for many top turf equipment manufacturers Picures...

In this article I would like to throw in my modest opinion about non-original spare parts - a frequent discussion topic among folks involved in the business of hydraulic pump and motor overhauling.

Although workshops can"t repair pumps without spare parts, they can choose where to buy the spares, and this choice is the key factor that defines how much money they make and how much "overhauling quality" they deliver. With so many suppliers and resellers of non-genuine replacement parts for hydraulic pumps and motors popping up every day, choosing the right "economic" supplier has become all but an easy task involving trial and error overhauls, pissed-off mechanics, pissed-off customers and even forever lost contracts and clients.

A mechanic, for example, being the person who shoves the parts into them pumps and motors, will always prefer genuine replacement parts over any aftermarket ones for one simple reason - they are easy to work with, they always fit and require no "finishing touches" - ergo his work is faster and simpler. Genuine parts last long and are hardly ever faulty, which makes the testing and adjustment procedures safer and reduces the risk of having to re-open overhauled units to a minimum. A mechanic doesn"t care about how much they cost because he"s not the one paying for them.

The truth lies, as always, in the golden middle, and I, personally, came to the conclusion that although most of the times you do get what you pay for, this doesn"t mean that you can"t get a bargain for a penny every once in a while, so a sound overhauler keeps his eyes and mind open and uses both genuine and aftermarket parts in a combination defined by his trial an error experience and the pump/motor application demands. This approach is sound because even in pre-recession years there were hydraulic equipment owners who actually preferred aftermarket to genuine in the pursuit of cutting down overhaul expenses. So, some clients will want the genuine quality, and some will want the lower price - and in order to satisfy both you, naturally, have to be able to serve both, but - if your goal is to deliver quality repairs, aftermarket part suppliers should be chosen with a cool head and on the basis of quality, not price!

OK, you say, so I am a hydraulic equipment owner, and I"ve got this excavator pump to repair, how do I know if I am going to be scammed with them Chinese spares? Well, there is no simple answer to this question...There is an opinion that if an overhaul is backed up by warranty than you"re on the safe side, no matter what parts were used - this, unfortunately, is not entirely true, because if you"re the unlucky hydraulic pump owner caught in the "error" stage of the new supplier trial and error validation process, you can get two different answers and two very different bills depending on how honest the company you are dealing with is. An honest workshop will admit their fault and try to correct the mistake as fast as they can, and if you are not the first-time customer you might even get the - "sorry about that, dude, the parts"re all **cked up..." confession, while a less candid workshop will give you the standard "commission errors committed by non-qualified personnel plus hard particle contamination in conjunction with the inappropriate oil temperature and deficient system design" excuse, and make you pay for their poor part supplier choice. So I"d say that warranty alone isn"t a guarantee, and would cast my vote for warranty combined with transparency - if a workshop has good experience with their non-genuine spare parts supplier - they won"t be ashamed to admit that the parts are not original.

Now, a separate word must be said about Chinese suppliers of spare parts for hydraulic pumps and motors. There are hundreds of companies in China that will sell you spare parts for almost any existing brand, with the quality ranging from superb to unacceptable and even ridiculously unacceptable. However with most suppliers (and especially resellers) the fact that you have received a batch of supreme quality spares doesn"t guarantee that you will get the same quality in the next batch. So if you ever decide to "go oriental" - be prepared for nasty surprises! (At least that was the situation at the moment of writing - December 2011).

My calling is more technical than commercial, therefore I am mainly interested in the quality of the spares rather than their price or where they come from - so please, don"t bother asking me for a list of "unofficially approved" Chinese suppliers of cheap yet extremely high quality spare parts for hydraulic pumps and motors - I won"t provide it because I frankly don"t have it! We do use some aftermarket spares from China, we did have our share of mishaps and disappointments with Chinese made parts, and our initial "Hurrays" got eventually replaced by "Boos" for most of them. Since our policy has always been to never let a client pay for a breakdown caused by a low quality part, a couple of lessons "learned the hard way" taught us that in most cases (not all, though) using Chinese spares in hydraulic pumps and motors is like using bathroom soap for filling cakes - looks and smells nice, yet still tastes like crap...

The pump whether manual, air or electrically driven takes longer to start actuating the cylinder -All the pumping before the cylinder moves is the time it takes for the air in the system to be compressed enough to start moving the actuator.

Air being introduced into a hydraulic system can causeCavitationand in turn possibly cause severe damage to moving parts and potentially a dangerous situation to the user and anybody else around the hydraulic system or related machinery. This would most likely be an issue with high flow type systems, not with manually operated tools and jacks and hydraulic press set-ups that don’t operate at high RPMs. If you suspect that damage has occurred it’s best to stop using the equipment before more damage can happen, possible rendering the equipment beyond economical repair.

Manually operated devices like hand pump and cylinder set-ups, most jacks, hydraulic knock-out sets, crimpers and cutters, being over-filled or under-filled usually isn"t as damaging to the tool like Cavitation as described above. None the less can cause problems resulting in a potentially dangerous situation – Never attempt to work on any kind of hydraulic equipment that is under load or has pressurized lines.If you aren’t sure – STOP - find out. It’s not worth an accident!

There are many variations in designs of hydraulic jacks, tools and systems. Some may have special bleeding procedures specific to them – Don’t hesitate to call us if you need help getting the correct service instruction or parts manuals for your equipment! Work Safe!

Well, short version of a long story I bought a "new" w/o box Haldex 22gpm pump off Ebay for a great price. It looked new but it had clearly been installed before. Seller buys and sells distressed merchandise and didn"t know any of the history about the pump, but did knock a large chunk off the price rather than a return.

Anyway there is little to no info I can find on repairing these pumps. Northern sells some repair parts, but my main concern is what is the very thin plastic?? material that serves as a gasket between sections? Or what should I use as a substitute?

Getting the right transmission or replacement pump can be tricky, so please call us or email us if you have any questions about ordering a large replacement component like this. We would be happy to look up your model and serial number to find the exact replacement part your mower needs. From the filter head to the complete pump assembly, we have every transmission or pump part you could need to fix your mower and keep cutting.

8613371530291

8613371530291