scag hydraulic pump rebuild quotation

I have watched a couple videos and while it doesn"t look too difficult none of the videos are of my exact pump and don"t cover every aspect in detail.

he took apart the hydraulic pump on a big ass genie type lift or excavator or something, I think...then couldn"t put it back together. so here comes the whole crew of a few construction guys, the owner and mechanic with a pump in a bunch of pieces and a bunch of parts.

it was a big ass 6 piston hydraulic pump. I put the seals on it, and had to hang it from the lift arm while I lifted the housing onto the pistons to get them all in there.

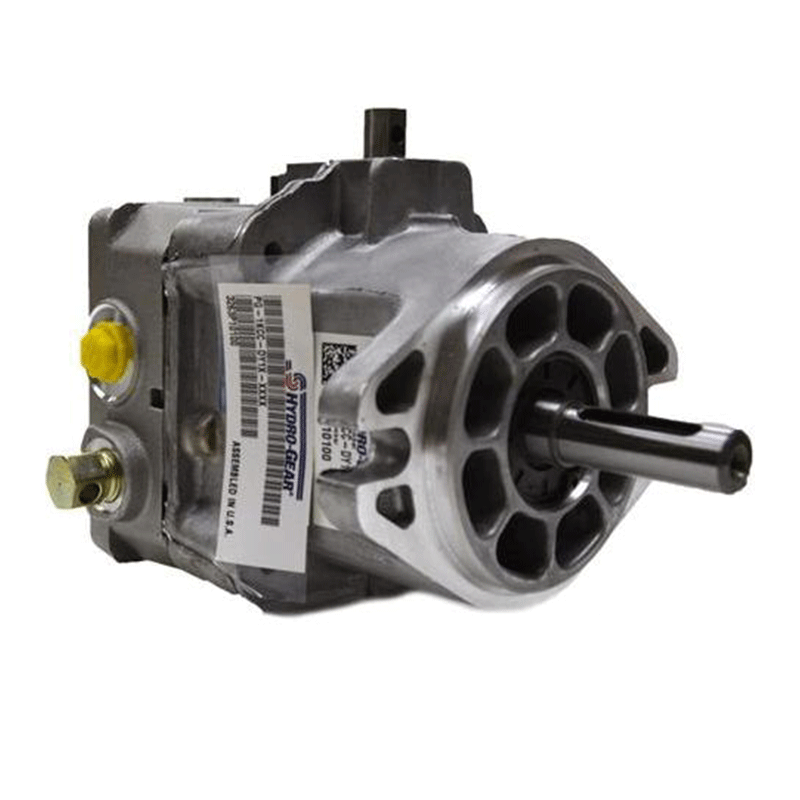

A variable displacement piston pump is a little more challenging than a simple gearrotor pump, but if the exact parts are available it shouldn"t be too big of a deal.

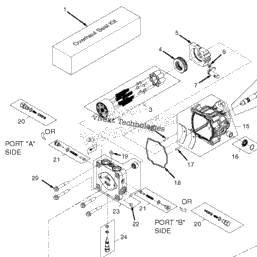

There generally aren"t to many tricks or special tools needed. Can you get the specific number off of the pump and look it up on the net and get an assembly breakdown? I wouldn"t even start unless I had that in hand. I am sure many of the ZTR mowers use standard pumps, or worse yet one big drive unit. On one that I worked on, one side ran the hydraulics for the deck lift and the other didn"t so they were slightly different.

There generally aren"t to many tricks or special tools needed. Can you get the specific number off of the pump and look it up on the net and get an assembly breakdown? I wouldn"t even start unless I had that in hand. I am sure many of the ZTR mowers use standard pumps, or worse yet one big drive unit. On one that I worked on, one side ran the hydraulics for the deck lift and the other didn"t so they were slightly different.

My first step would torque the pump assembly bolts to spec. See if any move and if so does the leak stop. Clean the housing up real good and mow the yard to see if new oil shows up. I"d try it before I even unbolted the pump from the mower....if you can get to said bolts. Check the pump housing for cracks. If the pump was over torqued during assembly or took a hit one of the tapped assembly bolt holes could have cracked and fatigued so the bolt has insufficient threads to hold torque.

Most likely the failure point is #13 which looks to be a standard shaft oil seal. If you are careful you should be able to get the seal out without dissembling the pump. Often we will drill a small hole in the seal and use a screw in slide hammer to extract it. You can probably find the oil seal at your local Motion Industries for like 5 bucks

If you’re asking how hard it’ll be you probably aren’t experienced enough to do it. Not trying to be use but this is a piston pump and there are quite a few moving parts. Hell I could be wrong but as a dude that’s been repairing hydraulic shit for a long time I’d trust the pro or buy a new pump.

About half of the pumps and cylinders that we get into our shop (mostly high pressure, 10,000 psi) have been "worked on" by the customer before we get them

PLEASE make sure you run the proper hydraulic fluid for the cylinder. I have seen a lot of pumps messed up running "cheap" alternatives to factory oil, it eats seals and bushings in a lot of case.

About half of the pumps and cylinders that we get into our shop (mostly high pressure, 10,000 psi) have been "worked on" by the customer before we get them

PLEASE make sure you run the proper hydraulic fluid for the cylinder. I have seen a lot of pumps messed up running "cheap" alternatives to factory oil, it eats seals and bushings in a lot of case.

View QuoteThe shop I talked to said that 9 times out of 10 it was the O ring. He said that if it was a seal that the pump would likely need to be replaced.

Timely thread. I have a scag turf tiger that is about 12 years old with about 750 hours on it. I replaced the wheel motor on the left side last year because it was leaking. The hydraulics on that side are now weak...it struggles to get up hills, and the other side can easily overpower it if I push the levers all the way forward.

If #13 is the leak just replace it and roll on and see what happens. It could have a piece of trash wrapped around the shaft causing it to leak. No pump disassembly required. Remove the snap ring, drill hole in seal and pull It out, install new one.

#5 is the only one that you should have to disassemble the pump to replace. If any of the other screw in fittings and valves are leaking just remove, replace seal and reinstall.

If you"re asking how hard it"ll be you probably aren"t experienced enough to do it. Not trying to be use but this is a piston pump and there are quite a few moving parts. Hell I could be wrong but as a dude that"s been repairing hydraulic shit for a long time I"d trust the pro or buy a new pump.

View QuoteIf you do have to take the pump apart just make sure everything stays super super clean and protected from any dings or scratches. And don"t force anything, possibly marring it. This is way more important than on something like changing that impeller.

Most likely the failure point is #13 which looks to be a standard shaft oil seal. If you are careful you should be able to get the seal out without dissembling the pump. Often we will drill a small hole in the seal and use a screw in slide hammer to extract it. You can probably find the oil seal at your local Motion Industries for like 5 bucks

If you do have to take the pump apart just make sure everything stays super super cleanand protected from any dings or scratches. And don"t force anything, possibly marring it. This is way more important than on something like changing that impeller.

View QuoteIf it were a gear, vane or gerotor pump I"d tell you to give it hell but a variable piston pump is not where I"d suggest getting your feet wet in hydraulics. There are small parts, things that need to be perfectly lined up and add to that the back plate is under some spring pressure. It makes it hard to tell if you"ve got it going together right. If you screw up putting it back together it may still work just long enough to send shrapnel into every other part of the hydraulic system.

Seriously, after removing the pump, wash the pump exterior absolutely clean before disassembly. Have a clean area prepped to lay out the parts when they are cleaned. The blue shop towels in the box are fairly lint free. I"d also have some crocus cloth handy to polish the seal surfaces on the shaft. Take some hydraulic fluid and mix 1:1 with STP oil additive for build up lube.

Its not hard at all but i have rebuilt a few variable displacement piston pumps. The hardest part is getting the piston and slippers back in. I usually wrap some 550 cord around them to hold them as i install the rotating assembly.

If you have no mechanical experience then a simple error will cause major problems. If it was a gear or vane pump, those are very basic and easy to repair.

If it were a gear, vane or gerotor pump I"d tell you to give it hell but a variable piston pump is not where I"d suggest getting your feet wet in hydraulics. There are small parts, things that need to be perfectly lined up and add to that the back plate is under some spring pressure. It makes it hard to tell if you"ve got it going together right. If you screw up putting it back together it may still work just long enough to send shrapnel into every other part of the hydraulic system.

I just called all around my local area asking for quotes to diagnose my issue and see if its a pump vs drive motor issue and what I could expect, ball park, to repair one or both. Its fair to say that it would cost just a $100 to diagnose and an additional $400-$1K to repair. All the shops I"ve talked with said they will not rebuild pumps or motors.

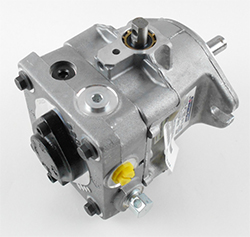

While calling around and talking to people my coworker has a vendor visiting with him and the vendor overheard me talking to these shops. He said he"s serviced commercial Toro hydrostatic systems for years. He said the wheel motors are not serviceable because of the fit-up of all the parts and once its opened up its all lost. He strongly recommended replacing wheel motors. He said the pumps can be rebuilt and are easy, takes about an hour. He said you can get everything you need for the pumps except the barrel cap and if they are bad then you"ll need a new pump.

The issue with my mower is once it gets warmed up the one side becomes weak. He suggested that I change my fluid and swap the wheel drives. If the issue follows the wheel drive then I have a drive motor issue. If the issue remains on the same side I have a pump issue.

The main enemy of any hydraulic system is heat. By properly sizing the hydraulic oil reservoir, efficient hose routing, and the use of oil coolers and fans where needed, Scag drive systems have been designed to have normal operating temperatures well within the safe range of the hydraulic components using “standard” oil. Using larger oil tanks, oil coolers and fans (where needed) does add additional cost to the manufacturing process, however, we feel that this extra attention to performance, longevity and value is one of the many reasons people decide to “step up” to a Scag mower.

The “requirement” to use synthetic oil in a mower is generally the result of producing a machine with a hydro system that has an operating temperature that can exceed the temperature range of the hydraulic components. These systems usually have very small oil reservoirs located in an area without sufficient airflow (due to limited space on the mower) and do not use oil coolers or fans. This is a less expensive way to manufacture mowers, however, the extra cost of the synthetic oil (synthetic oil is normally four to five times the cost of standard oil) is a burden that you, the customer, will have to pay.

Occasionally customers inquire about switching the hydro oil in their new Scag to synthetic. While there is nothing in the drive system that could be damaged from its use, as outlined above, it is certainly not necessary. We do suggest that they wait until after the initial break-in period before making the switch, if desired.

We are recognized worldwide for our expertise in hydraulic pump repair. At our facility in Wooster, Ohio, we have the state-of-the-art technology and years of expertise necessary to repair hydraulic pumps. As a leader in the field of hydraulic repair, we understand the importance of pump technology to your operations, no matter where you are in the world. You can ship your unit to us from anywhere in the United States or worldwide and you can be assured that we’ll fix it right, fix it fast and fix it at a good price. Our experienced, dedicated team is committed to providing our customers and partners with superior hydraulic repair service and consultation. We support a wide range of hydraulic pumps from many manufacturers and brands. We also work on the various types of pumps, including:

An average repair price is established, agreed upon, and approved before the unit is sent to us for repair. Once the unit is received, we inspect it, rebuild it with genuine OEM parts and test it out in our shop during our normal schedule. When it passes testing, we send it back to you.

No matter where you are, or what industry you are in, we can provide you with on-site repair and consultation services. We can send our expert technicians to you to ensure that your hydraulic pumps are working at peak performance. Our team has worked at various locations, including:

Check out our current inventory of new hydraulic pumps and remanufactured hydraulic pumps to see which models can be purchased and shipped out to you today.

If you are looking for reliable service and consultation for your hydraulic pump, look no further than the expert team at Wooster Hydrostatics. Call us today at 800-800-6971 to learn more about the Wooster Way and how we can help you keep your equipment running at peak performance.

Hydraulic power and simple design combine to make the SWZ the most efficient and easy-to-handle walk-behind you can buy. The SWZ has all the features Scag® mowers are famous for: tough, durable components for long life and heavy-duty cutter decks that deliver an unmatched cut.

8613371530291

8613371530291