scag tiger cat hydraulic pump rebuild kit for sale

MakeABGAcuraAdlyAeonAg-ChemAgcoAifoAIRMANAJSAlfa RomeoAllis ChalmersAmerican MotorsApriliaArctic CatAriensAston MartinASVAtalaAtlas CopcoAudiAusaAustin HealeyAustin WesternAutocarAVANT TECHNOAYPBad BoyBajajBakerBarber GreeneBelarusBenelliBenfraBentleyBetaBimotaBlue Bird BusBluebirdBMWBobcatBolensBPMBransonBriggs & StrattonBSABuellBuickBukhBuntonBush HogCadillacCagivaCan-amCan-AmCarrier TransicoldCase/International HarvesterCaterpillarCCMCF-MotoChallengerChampionCheckerChevroletChevrolet/GMCChryslerClaasClarkClassenClimaxClub CarCompac EquipmentConstruction Equipment Co.CorniverCountry ClipperCraftsmanCrusaderCub CadetCumminsCummins MercruiserCushmanDaelimDaewooDaihatsuDerbiDeutzDiamond TDitch WitchDixie ChopperDixonDodgeDolmarDresserDrott Mfg.DucatiE-Z-GOEagleEagle TugsEchoEdselElgin SweeperEuclidEvinrude JohnsonExmarkFanticFarmtracFarymannFendtFerrariFerrisFiatFiat-AllisFordFord/New HollandFrank HoughFreightlinerFuchsGalionGas-GasGehlGeneracGileraGMCGodwinGrasshopperGravelyGreat DaneGrove Mfg.Harley DavidsonHarvest ProHatzHesstonHillmanHiltiHinoHitachiHomeliteHondaHoughHuskeeHusqvarnaHustlerHyosungHysterHyundaiICSIndianInfinitiIngersoll RandInternationalIsuzuItaljetIvecoJacobsenJaguarJCBJeepJensenJialingJohn DeereJonseredKawasakiKawataKeewayKenworthKHDKiaKiotiKohlerKomatsuKTMKubotaKymcoLamborghiniLanciaLand RoverLandiniLaverdaLawn-BoyLe TourneauLexusLeylandLiebherrLincolnLincoln WelderListerLittle WonderLombardiniLongLotusLynxMacDonMackMahindraMakitaMalagutiMaruyamaMassey FergusonMazdaMBKMcCormickMcCullochMelroe Spra CoupeMercedes-BenzMercruiserMercuryMGMillerMinneapolis-MolineMitsubishiModenasMotecMoto GuzziMoto MoriniMoto RomaMTDMTD GoldMTD ProMultiquipMurphy DieselMurrayMustangMV AgustaMZNew HollandNew IdeaNissanNortonOldsmobileOliverOnanOpelPartnerPerkinsPeterbiltPeugeotPGOPiaggioPleasurecraftPlymouthPolarisPontiacPorschePoulanPoulan ProPrairie StarPremierRanch KingRed MaxRed-D-ArcRenaultRenault CouachRiejuRigmaster PowerRolls RoyceRoyal EnfieldRuggeriniRyanRyobiSaabSaboSameSamsungSatohSaturnScagScat TrakScionScottsSea-DooShindaiwaSimcaSimplicitySki-DooSlanziSnapperSnapper ProSole DieselSpra-CoupeSteigerSteinerSterlingSteyrStihlSubaruSuzukiSYMTakeuchiTCM EquipmentTecumsehTeledyneTerexThermo KingThomas EquipmentTimberjackToroTowmotorToyotaTriumphTroy-BiltTugUniversalValtra-ValmetVermeerVersatileVespaVetusVictoryVM MotoriVolkswagenVolvoVolvo PentaWabcoWackerWalbroWalkerWaukeshaWesterbekeWestern StarWestwardWhiteWhite OutdoorWillmarWKWoodsWorldlawnWright Mfg.YamahaYanmarYard MachinesYardmanYugoZamaZetor

Heavy-duty hydraulic drive system includes dual 12cc Hydro-Gear hydraulic pumps and large capacity Parker wheel motors for reliable, zero turn maneuverability.

Compact mower size enables you to take the Tiger Cat II into tight places. The Tiger Cat II occupies less space on your trailer without sacrificing performance.

12cc hydraulic pumps equipped with cooling fans provide smooth and reliable power. Built in pressure relief valves reduce internal pressure spikes and add to hydraulic component life.

"Split-Steel" pulleys are used on load-carrying areas like the cutter deck spindles and pump drive systems. Split steel pulleys are stronger than cast-iron or stamped pulley designs. Our pulleys are strong for long life and lightweight for reduced inertia and decreased wear on the cutter deck drive system.

No plastic pulleys - Some [other brands] actually use plastic pulleys on their mowers. Not Scag. All Scag pulleys are made from metal. Plastic is for toys.

Multi-point steering dampers are designed and located for smooth operation and minimal fatigue. Mount the dampers in one of three mounting locations for a customized feel.

Operator friendly instrument panellocated just to the left of the operator. It includes Tiger Eye: Advanced On-Board Monitoring System, ignition switch, mower engagement switch, and separate choke and throttle controls.

High quality electrical components such as switches, wiring, sealed fuses and harness looms are used throughout the Scag mower line for dependable service.

There are many productive accessories for the Tiger Cat II like the Tiger Striping kit, the 16 bushel spindle driven grass catcher, the 12 bushel dump-from-the-seat catcher system, and many more.

Scag Motor Wheels are the perfect choice for anyone looking for a reliable and durable wheel for their Scag mower. They are designed to provide a smooth and consistent ride, even in tough terrain. They are made from high-grade materials to ensure long-lasting performance and are available in a variety of sizes to fit your specific mower. Scag Motor Wheels are easy to install and highly resistant to wear and tear. Get your Scag mower the best wheels for the job and purchase your Scag Motor Wheels today!

When it comes to buying parts for your Scag motor, it"s important to buy only genuine Scag parts. With genuine Scag parts, you can be sure that you"re getting the highest quality parts that will last longer and work better than imitation parts. Genuine Scag parts are designed specifically for Scag motors and are made with the same materials and processes used in the original manufacturing process. With genuine Scag parts, you can trust that you"re getting the best parts for your motor, so you can enjoy many years of reliable performance.

If you are looking for the highest quality Scag wheel motor rebuild kit, then look no further than www.scagpartsonline.com. With unbeatable prices and expert customer service, you can trust that you are getting the best value for your money here. We offer the widest selection of top-of-the-line products, with the upmost precision for perfect fit and function. All our products are backed by a comprehensive warranty and come with the assurance of lasting reliability. Shop with confidence knowing you are getting the best price and quality from www.scagpartsonline.com.

If you do not find here the Scag motor wheel you need look for the parts manual of your equipment or check our Fast Moving Parts Section and get your mower back up and running in no time.

The Scag Turf Tiger features dual Hydro-Gear 16cc hydraulic pumps. 16cc pumps feature a 60% larger displacement than the 10cc pumps used by some other "commercial" mowers on the market today.

That means with every revolution of the pump, the 16cc pump moves 60% more fluid when compared to a 10cc pump. This extra hydraulic displacement means more productivity and more power to the drive wheels.

Diesel and larger horsepower gas models (12mph ground speed units) feature a cooling fan mounted directly to each hydraulic pump, providing additional cooling for added pump life.

Auxiliary oil coolers are standard equipment on every Scag Turf Tiger. They keep oil temperatures within a safe operating level and add to system life.

When ordering and replacing a hydro pump, always replace the wheel motor and lines, flush the tanks and install a new oil filter. Not doing so could cause the hydro pump to fail due to contamination

I have watched a couple videos and while it doesn"t look too difficult none of the videos are of my exact pump and don"t cover every aspect in detail.

I do all the maintenance on our vehicles, tractor, mowers and boat so I"m comfortable doing most things but this is something new somewhat complicated.

he took apart the hydraulic pump on a big ass genie type lift or excavator or something, I think...then couldn"t put it back together. so here comes the whole crew of a few construction guys, the owner and mechanic with a pump in a bunch of pieces and a bunch of parts.

it was a big ass 6 piston hydraulic pump. I put the seals on it, and had to hang it from the lift arm while I lifted the housing onto the pistons to get them all in there.

A variable displacement piston pump is a little more challenging than a simple gearrotor pump, but if the exact parts are available it shouldn"t be too big of a deal.

It shouldn"t be to bad. Make sure you have plenty of clean rags available and plenty of bench space to spread your parts out on as you disassemble. If you have a schematic and the correct seal kit it should be a breeze.

There generally aren"t to many tricks or special tools needed. Can you get the specific number off of the pump and look it up on the net and get an assembly breakdown? I wouldn"t even start unless I had that in hand. I am sure many of the ZTR mowers use standard pumps, or worse yet one big drive unit. On one that I worked on, one side ran the hydraulics for the deck lift and the other didn"t so they were slightly different.

There generally aren"t to many tricks or special tools needed. Can you get the specific number off of the pump and look it up on the net and get an assembly breakdown? I wouldn"t even start unless I had that in hand. I am sure many of the ZTR mowers use standard pumps, or worse yet one big drive unit. On one that I worked on, one side ran the hydraulics for the deck lift and the other didn"t so they were slightly different.

My first step would torque the pump assembly bolts to spec. See if any move and if so does the leak stop. Clean the housing up real good and mow the yard to see if new oil shows up. I"d try it before I even unbolted the pump from the mower....if you can get to said bolts. Check the pump housing for cracks. If the pump was over torqued during assembly or took a hit one of the tapped assembly bolt holes could have cracked and fatigued so the bolt has insufficient threads to hold torque.

View QuoteClean it off, run it like normal for a day, then examine for leak location. Usually it becomes easy to find the leak because all the dirt sticks to the freshly leaked oil.

Clean it off, run it like normal for a day, then examine for leak location. Usually it becomes easy to find the leak because all the dirt sticks to the freshly leaked oil.

Clean it off, run it like normal for a day, then examine for leak location. Usually it becomes easy to find the leak because all the dirt sticks to the freshly leaked oil.

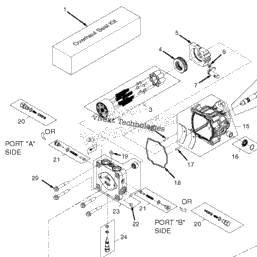

Most likely the failure point is #13 which looks to be a standard shaft oil seal. If you are careful you should be able to get the seal out without dissembling the pump. Often we will drill a small hole in the seal and use a screw in slide hammer to extract it. You can probably find the oil seal at your local Motion Industries for like 5 bucks

If you’re asking how hard it’ll be you probably aren’t experienced enough to do it. Not trying to be use but this is a piston pump and there are quite a few moving parts. Hell I could be wrong but as a dude that’s been repairing hydraulic shit for a long time I’d trust the pro or buy a new pump.

About half of the pumps and cylinders that we get into our shop (mostly high pressure, 10,000 psi) have been "worked on" by the customer before we get them

PLEASE make sure you run the proper hydraulic fluid for the cylinder. I have seen a lot of pumps messed up running "cheap" alternatives to factory oil, it eats seals and bushings in a lot of case.

About half of the pumps and cylinders that we get into our shop (mostly high pressure, 10,000 psi) have been "worked on" by the customer before we get them

PLEASE make sure you run the proper hydraulic fluid for the cylinder. I have seen a lot of pumps messed up running "cheap" alternatives to factory oil, it eats seals and bushings in a lot of case.

View QuoteThe shop I talked to said that 9 times out of 10 it was the O ring. He said that if it was a seal that the pump would likely need to be replaced.

Timely thread. I have a scag turf tiger that is about 12 years old with about 750 hours on it. I replaced the wheel motor on the left side last year because it was leaking. The hydraulics on that side are now weak...it struggles to get up hills, and the other side can easily overpower it if I push the levers all the way forward.

If #13 is the leak just replace it and roll on and see what happens. It could have a piece of trash wrapped around the shaft causing it to leak. No pump disassembly required. Remove the snap ring, drill hole in seal and pull It out, install new one.

#5 is the only one that you should have to disassemble the pump to replace. If any of the other screw in fittings and valves are leaking just remove, replace seal and reinstall.

If you"re asking how hard it"ll be you probably aren"t experienced enough to do it. Not trying to be use but this is a piston pump and there are quite a few moving parts. Hell I could be wrong but as a dude that"s been repairing hydraulic shit for a long time I"d trust the pro or buy a new pump.

View QuoteIf you do have to take the pump apart just make sure everything stays super super clean and protected from any dings or scratches. And don"t force anything, possibly marring it. This is way more important than on something like changing that impeller.

Most likely the failure point is #13 which looks to be a standard shaft oil seal. If you are careful you should be able to get the seal out without dissembling the pump. Often we will drill a small hole in the seal and use a screw in slide hammer to extract it. You can probably find the oil seal at your local Motion Industries for like 5 bucks

If you do have to take the pump apart just make sure everything stays super super cleanand protected from any dings or scratches. And don"t force anything, possibly marring it. This is way more important than on something like changing that impeller.

View QuoteIf it were a gear, vane or gerotor pump I"d tell you to give it hell but a variable piston pump is not where I"d suggest getting your feet wet in hydraulics. There are small parts, things that need to be perfectly lined up and add to that the back plate is under some spring pressure. It makes it hard to tell if you"ve got it going together right. If you screw up putting it back together it may still work just long enough to send shrapnel into every other part of the hydraulic system.

Seriously, after removing the pump, wash the pump exterior absolutely clean before disassembly. Have a clean area prepped to lay out the parts when they are cleaned. The blue shop towels in the box are fairly lint free. I"d also have some crocus cloth handy to polish the seal surfaces on the shaft. Take some hydraulic fluid and mix 1:1 with STP oil additive for build up lube.

Its not hard at all but i have rebuilt a few variable displacement piston pumps. The hardest part is getting the piston and slippers back in. I usually wrap some 550 cord around them to hold them as i install the rotating assembly.

If you have no mechanical experience then a simple error will cause major problems. If it was a gear or vane pump, those are very basic and easy to repair.

If it were a gear, vane or gerotor pump I"d tell you to give it hell but a variable piston pump is not where I"d suggest getting your feet wet in hydraulics. There are small parts, things that need to be perfectly lined up and add to that the back plate is under some spring pressure. It makes it hard to tell if you"ve got it going together right. If you screw up putting it back together it may still work just long enough to send shrapnel into every other part of the hydraulic system.

8613371530291

8613371530291