schematic lippert hydraulic pump diagram free sample

Lippert’s Ground Control system allows for the electronic stabilization and leveling of travel trailers. This is a 5-point system (including tongue jack) that is compatible with I-beam frames and travel trailers with a GVWR (Gross Vehicle Weight Rating) of up to 10,000 pounds.

Lippert’s Ground Control 3.0 system is designed specifically for fifth-wheel RVs. The system makes leveling your fifth wheel easy. It even has auto-hitch memory to make your life easier.

Lippert’s Ground Control 3.0 system is available in 4-point and 6-point configurations and gives the rig two additional jacks and rounded jack footpads to increase the stability of the RV.

Lippert’s systems are complete and easy to operate. The only additional components you’ll want would be items for the landing gear such as utility blocks or SnapPads (which are like shoes for your jacks).

If you ever have an issue with the smooth operation of your Lippert Leveling System, troubleshooting is quite easy. The following steps are likely to help you to sort out the issue.

A great feature of Lippert leveling systems is that the monitor displays error messages when the system needs to be reset or requires some other type of attention.

If you contact Lippert for assistance with an issue, the technician is likely to ask if you’ve restarted the system. This is one of the first things you should do when you encounter any type of problem.

Hydraulic leveling systems require proper fluid. Otherwise, the entire hydraulic system can experience difficulties. For example, you might not be able to raise or lower your jacks or open and close your slides.

There will be times when you’ll need to manually level your RV. Following are the steps to take to manually operate the level-up jacks when using a Lippert Leveling System.

Obtaining replacement parts for your Lippert leveling system is easy. Lippert has an online store where you can purchase whatever you need, and their customer service is reportedly excellent.

There are great automatic systems like Lippert’s that will make your leveling life much easier. But no matter how you level your rig, learning how to do it well consistently is key.

My LCI leveling system was working fine earlier this year. In fact I got home from a trip and went to level and discovered the motor was burnt out (pn 414850 ). I did not want to spend $1,000 for an $80 motor from Lippert so I rebuilt the motor. Motor works great now but jacks don"t move when the system operates.

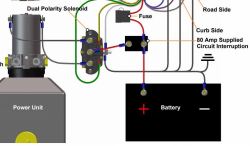

I could really use a hydraulic diagram to aid me in troubleshooting. Not the simple line diagram as found in the Lippert manual but an actual hydraulic diagram showing how the pump/jack valves/return valve/ are piped within the system. Anyone know where I might find this?

In the LCI manual it describes manually retracting the jacks. Manual opening the left/right or front/back pair of solenoids and then running the motor with an electric drill in the COUNTER CLOCKWISE direction. Question: when the system is in normal operation from the controls, does the pump motor run in a CLOCKWISE direction? I ask this as my rebuild may have resulted in the motor operating in the other direction.

Level Up ™ Installation and Owner’s Manual (For Aftermarket Application) 4. Install hydraulic fittings to leveling jacks. See (Figs.4-7) 7. Mark the needed modifications on the jack brackets for details of fitting placement. This example assumes the (Fig.8). power unit is closest to the driver’s side (roadside) of the trailer.

(For Aftermarket Application) Notes Manual information may be distributed as a complete document only, unless Lippert Components provides explicit consent to distribute individual parts. All manual information is subject to change without notice. Revised editions will be available for free download at lci1.com.

I gave up and took it to the dealership. $700 and a battery compartment full of hydraulic fluid later they pronounced the whole system kaput. Said I would need new hydraulic cylinders, valves- the whole works. They claimed this was based on advice from Lippert.

I declined and took my rig home. I got out my multimeter and just started tracing stuff. I found that the iNCommand BCM sends a low amperage signal to the trombetta solenoid, which in turn sends the high amp current to the hydraulic pump to power the slides. The BCM would send the low amp signal to my meter all day long, but would disappear when connected to the trombetta solenoid.

Just to be clear- my wiring only carries the signal from the BCM- not the current to power the pump. The pump still pulls power from the trombetta solenoid just like when it left the factory.

8613371530291

8613371530291