schematic lippert hydraulic pump diagram brands

ABLE OF ONTENTS SYSTEM……………………………………………..….….. Warning…………………………………..……..Description………………………………..…….. Prior to Operation……………………..……… Preventative Maintenance………..……….. OPERATION…………………………………..…………… Warning............Extending Slideout Room….....…………. Retracting Slideout Room…….....……... Auxiliary Operation..…………....………. SERVICE…………………………..………………..……… Filling Procedures........Adjustment Instructions………..………….. Syncronizing System........Replacing Actuator........Troubleshooting……………………..……… Wiring Diagram…………………….…..……… LIMITED WARRANTY………………..……..…………. Warranty Registration.........

SYSTEM MAINTENANCE The Lippert Hydraulic Slideout System has been static tested to over 4,000 continuous cycles with out any noticeable wear to rotating or sliding parts. It is recommended that when operating in harsh environments (road salt, ice build up, etc.) the moving parts be kept clean and can be washed with mild soap and water.

AUXILIARY OPERATION The Lippert Hydro-Sync Slideout System can be run with auxiliary power devices like electric drills, ratchet wrenches or cordless screwdrivers. In the event of electrical or system failure, this manual method of extending and retracting the slideout room can be used. A standard handheld drill is all that is required. A standard 38"...

Fig. 4 Breather Cap The Lippert Hydraulic Slideout System uses automatic transmission fluid (ATF). Any ATF can be used. A full synthetic or synthetic blend works best such as Dexron III or Mercon 5. For best operation, fill system within ½” of the top when all slideouts are completely retracted.

TABLE OF CONTENTS System System Description Component Description LCI Hydraulic Jacks Steel Jacks - Bi-rotational Power Unit Aluminum Jacks - Unidirectional Power Unit Leveling System Controls Leveling Features System Wiring Requirements Air and Auxiliary Features Touchpad Schematic Level Zero Point Calibration "Latched Out" Warning Air and Auxiliary Feature Configuration Error Mode User Alarm Mode Miscellaneous Prior to Operation Operation Selecting A Site Automatic Leveling

System Failure to act in accordance with the following may result in death or serious personal injury. The use of the Lippert Electronic/Hydraulic Leveling and Slideout System to support the coach for any reason other than which it is intended is prohibited by Lippert"s Limited Warranty.

Component Description The Lippert Electronic/Hydraulic Leveling and Slideout System consists of the following major components: Lippert jacks are rated at a lifting capacity appropriate for your coach. Each jack has a 9” diameter (63.5 square inch) shoe on a ball swivel for maximum surface contact on all surfaces. (12” dia. - 113 sq. in. shoe also available).

Touchpad Schematic Fig. 5 A C B E O J D N K L F G H P M I Callout A B C D E F G H I J K L M N O P Rev: 07.14.2014 Description Manual Operation - Places control panel in manual operation mode. Manual Operation LED - Indicates control panel in manual operation mode. Automatic Operation - Places control panel in automatic operation mode. Automatic Operation LED - Indicates control panel in automatic operation mode. Wait LED - Indicates to the operator to pause operation until the LED turns off.

Prior to Operation The leveling system should only be operated under the following conditions: 1. The coach is parked on a reasonably level surface. 2. The coach “PARKING BRAKE” is engaged. 3. The coach transmission should be in the neutral or park position. 4. The ignition is in the run position, or engine is running. 5. Be sure all persons, pets and property are clear of the coach while Lippert Leveling System is in operation.

Manual Leveling Procedure Note: When leveling your coach, the coach should be leveled from FRONT TO REAR first (steps 2-4). When the coach is level from FRONT TO REAR, then level the coach from LEFT TO RIGHT (step 5). NOTE: Coach must be running for LCI Electronic/Hydraulic Leveling System to operate. 1. Push ON/OFF (Fig. 5O) button on control panel. The system is now operational and the ON/OFF (Fig. 5O) light will be lit. If ON/OFF (Fig. 5O) light is not lit, see PRIOR TO OPERATION, page 9. 2.

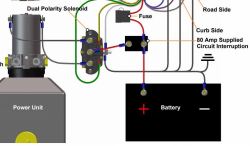

Wiring Diagram - Bi-Rotational Power Unit Harness Fig. 18 B A E D C Fig. 18C Fig. 18A Wire Color White White w/ Black Blue Green Yellow Red Brown Purple Grey Wire Color Purple Pink Red Blue Green Function 12v DC Power Pump Retract Curbside Rear Valve Roadside Front Valve PSI Switch Roadside Rear Valve Plug Curbside Front Valve Pump Extend Fig. 18D Wire Color White Black w/ White Brown Grey Black Fig.

Wiring Diagram - Unidirectional Power Unit Harness Fig. 31 A C B Fig. 31A Wire Color White White w/ Black Blue Green Yellow Red Black Purple Grey Rev: 07.14.2014 Function 12v DC Power Pump Retract Curbside Rear Valve Roadside Front Valve PSI Switch Roadside Rear Valve Ground from solenoid Curbside Front Valve Pump Extend Wire Color Green Green Orange Purple Tan Fig. 31B Function LF Valve Isolator Valve Main Room Slide Curbside Front Valve Kitchen Slide Fig. 31C Wire Color Lt.

Troubleshooting Chart - HLG Problem Jacks will not extend to ground, pump is running. Probable Cause Little or no fluid in reservoir Leg valve is inoperative Electronic signal is lost between switch Hose damaged or disconnected. Return valve inoperative. Any one or two jacks will not retract. Electronic signal is lost between switch and solenoid. Corrective Action Fill reservoir with DEXRON III Clean, repair or replace Trace wires for voltage drop or loss of signal and leg valves.

The contents of this manual are proprietary and copyright protected by Lippert Components, Inc. (“LCI”). LCI prohibits the copying or dissemination of portions of this manual unless prior written consent from an authorized LCI representative has been provided. Any unauthorized use shall void any applicable warranty. The information contained in this manual is subject to change without notice and at the sole discretion of LCI. Revised editions are available for free download from www.lci1.com.

8613371530291

8613371530291