single acting vs double acting hydraulic pump made in china

Hydraulic cylinders provide the unidirectional force required to power your industrial equipment for heavy lifting. Telescopic hydraulic cylinders, which are ideal for dump trailers and platform truck trailers, give the extended stroke lengths required for a range of versatile purposes. When purchasing telescopic hydraulic cylinders, consumers are frequently faced with the decision between single-acting and double-acting hydraulic cylinders. Learn what distinguishes the two types of telescopic cylinders to determine which cylinder is appropriate for your high-power hydraulic requirements.

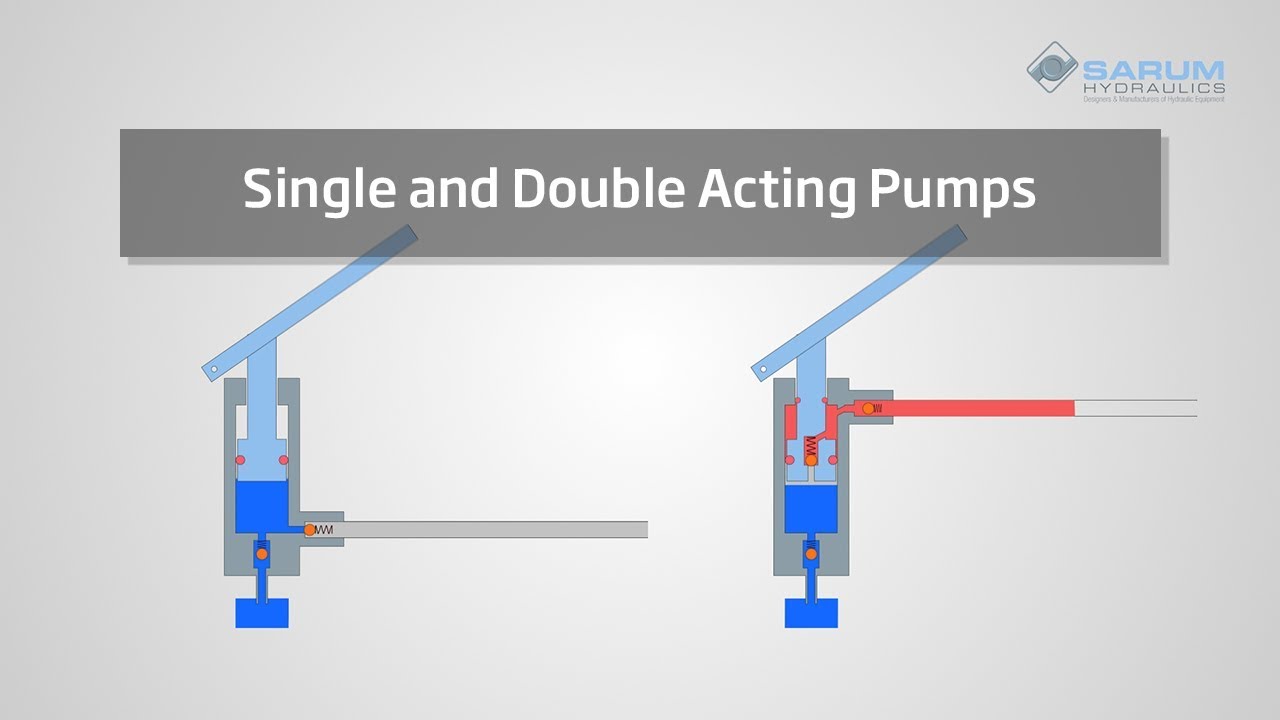

The hydraulic cylinder is the industrial world’s workhorse. Learn about the benefits and drawbacks of single and double-acting hydraulic cylinders. The function of your cylinder decides whether you should choose a single-acting or double-acting hydraulic cylinder.

Single-acting cylinders generate force exclusively in one direction, whether it is a push or pull action. These are also referred to as “plunger” cylinders. They are utilized in lifting operations where hydraulic pump pressure stretches the hydraulic cylinder and a mass or spring retracts it. Single-acting cylinders contain only one port through which the hydraulic pump’s pressurized oil passes. This causes the piston to extend in one direction, compressing the piston’s spring. After releasing the air via the cylinder port where it entered, the spring or associated mass will retract the piston rod.

Single-acting cylinders are classified into two types: push and pull cylinders. The push-type, as the name implies, will allow the air entering to push the piston out of the cylinder. The pull-type hydraulic cylinder allows the oil entering the cylinder to pull the piston inside the cylinder. For one-way linear movement, single-acting cylinders are ideal. They are commonly seen in hydraulic jacks and forklifts.

The lower manufacture, installation, and repair costs of single-acting hydraulic cylinders are an advantage. With only one port to operate instead of two, both piping and valve costs are significantly reduced.

The spring mechanism in single-action cylinder interiors necessitates venting, which provides the unit with an outlet to the outside world. Particles, on the other hand, can enter the cylinder and create potential malfunctions or a slow loss in performance if not adequately monitored.

Single-acting hydraulic cylinders are ideal for use with smaller equipment due to their single port and compact structure. Most of the time, if a smaller equipment design allows for ports, fluid transmission, and venting, then this cylinder will be extremely suitable.

Pressure flows from two ports in double-acting hydraulic cylinders. The “advance” hydraulic hose fitting connects to one of the ports. The pump’s hydraulic power forces the cylinder to extend via the first port. The “retract” hydraulic hose fitting is connected to the second port. Hydraulic power is used to extend and retract the cylinder in a double-acting hydraulic cylinder. In contrast to the single-acting cylinder, which produces force in only one direction, force is generated in both directions. As a result, the cylinder may both push and pull.

The piston rod moves due to the push and pulls forces created by the pressurized fluid that alternates between both sides of the piston. These hydraulic cylinders have more control over their movement in the application where they are installed. Using 2-, 3-, or 4-way position valves, different levels of movement can be produced. Double-acting hydraulic cylinders are utilized in mobile applications such as a TLB’s boom or to control the steering of an excavator.

Though this hydraulic cylinder is not appropriate for small places, double-acting hydraulics are extremely versatile. Two ports provide hydraulic power in both directions and are readily operated with a push-and-pull motion. As a result, they are the most popular hydraulic cylinder.

Unlike single-acting variants, double-acting cylinders are sealed from the outside world. As a consequence, you will not require repairs as a result of particles invading inside pipes and valves.

Precision work that needs hydraulic pistons to stop at specific lengths regularly can stretch and deform the hydraulics over time. However, double-acting hydraulic cylinders are constructed with exact, very precise dual ports, enhancing the product’s longevity.

The choice between a double-acting and a single-acting cylinder is frequently a matter of control. How precisely do you need to be while exerting force in your hydraulic system? A single-acting cylinder may be sufficient if you need to produce a large force to move a load in a single direction, such as in heavy lifting applications. However, if you need to direct a load in two directions or have more control over the cylinder’s movements, a double-acting cylinder will provide you with more control.

Ningbo Target Hydraulics is your reliable hydraulic components supplier. We offer you high-quality dc12v hydraulic pump single acting and double acting. There are many different industrial applications for hydraulic pump unit systems.

dc12v hydraulic pump motor combo is the most common electrical hydraulic pump system. They come with dc motor, hydraulic gear pump, and some other hydraulic components such as a hydraulic oil tank ,hydraulic manifold blocks, some hydraulic valves.

Hydraulic AC power packs are widely used in industrial applications. They are designed with AC voltage electric power supply, so, they can work with AC motors. Some of them are designed with standard B14 flange mounted AC motors, It is easy to find flange type AC motors from your local market.

Dump trailers and forklifts are very common applications of DC12 voltage hydraulic pumps. Most of them are designed and manufactured with single-acting hydraulic pump schematics. They work Power up/gravity down.

DC voltage hydraulic pump packs are designed for mobile hydraulic applications. So, they are also called mobile hydraulic power packs. Some of them are double acting hydraulic pumps, Power Up/power down hydraulic systems.Some of others are single acting,power up/gravity down hydraulic pumps.

Target Hydraulics products are used in different hydraulic applications. Electric dump pump is the most popular application. They complete with a dc motor, hydra-gear pump, and some valves that are assembly in center hydraulic block manifolds, also a button remote and cable.

DC hydraulic pumps are most work with mobile hydraulic applications, so, the mounting size is very compact. That is why compact size power packs are designed with such small sizes. They are designed and manufactured for mini and compact mounting size.

Our hydraulic cartridge valves and hydraulic valve manifold blocks are widely used in DC hydraulic power units, AC hydraulic power units, and hydraulic manifold designs.

The weight of a car is heavy, and it is very difficult to lift a car by muscle power alone, let alone to repair it while suspended in the air. This is the reason why hydraulic systems exist. When you want to work with dump trucks, RVs, boat lifts, lift gates, etc., a hydraulic pump is a must-have tool that allows you to easily complete jobs that are difficult to reach with human power. For some light work, we recommend choosing a 12 volt hydraulic pump, which is a tool of both size and power. Then before buying you"d better choose the type of hydraulic pump you need according to your needs. Next I will give you information about hydraulic pumps you should know.

A hydraulic pump is a machine that works with liquid fluid power, using an incompressible fluid, usually a derivative of petroleum and additives, as the working fluid to convert mechanical energy into hydraulic energy. Should hydraulic pumps be non-sparking due to potentially explosive environments? Keep in mind that most operating fluids are derivatives of petroleum, but there are non-sparking options available. Fluid selection should be determined by the operating environment/temperature.

This hydraulic energy can make a relatively small device very powerful and versatile. In the automotive industry, hydraulic pumps are used in combination with jacks and engine hoists to lift vehicles, platforms, heavy loads and pull engines. They can also be used in production facilities for conveyors, mixers, forklifts, etc.

Electric hydraulic pumps are generally divided into single-acting and double-acting. The most obvious difference is the number of couplers or connection ports. Single-acting hydraulic pumps include only one port. This port is where the hydraulic fluid is allowed to enter and force the plunger to extend in one direction. Double-acting hydraulic pumps have two such ports. The difference is that the first port is where the "push" (extension) hydraulic hose fitting will connect, and the second port is where the "retract" hydraulic hose fitting will connect.

When high pressure hydraulic fluid is pumped into a hydraulic pump, the plunger in the single acting hydraulic cylinder extends. When the cylinder needs to be retracted, depending on the cylinder design, the plunger is retracted by either a load weight or a built-in spring. Single-acting hydraulic pumps have fewer components and less potential for error, which facilitates maintenance of the hydraulic pump. Single-acting is ideal for this simple task when fast or controlled retraction is not required.

In a double-acting hydraulic pump, the plunger retracts as the hydraulic fluid is pumped into the top port at high pressure, forcing the plunger back to its original position. The double-acting principle of operation enables hydraulic oil to be pumped to both sides of the plunger. Connection ports located near each end allow the piston rod to move back and forth. The additional ports also allow for more fine control of the plunger during retraction. Faster and predictable retraction makes double-acting hydraulic pumps a better choice for projects requiring repeatable accuracy.

For lightweight applications, such as rear fender lifts on commercial passenger vehicles, where a low power output is required, a 12v miniature hydraulic power unit is a good choice because the 12v motor can be connected to a standard vehicle circuit for the rear fender lift function. There are other application scenarios such as dump trucks, RVs, boat lifts, lift gates, trailers, clearance trucks, car porters, agricultural equipment, snow plow equipment, and a variety of other applications that require powerful and compact hydraulic pumps.

A compact lightweight pump, the Power Team 60 series is designed for rugged applications and low voltage starting. Experiencing a long, trouble-free life in the most demanding work environments, the 60 ...

... P-Series hand pumps come in a variety of configurations to meet the requirements of your application. Along with various oil capacities and flow rates, you can choose from the following options:

A two-speed pump, the Power Team PA60 series pumps are designed for rapid oil delivery at low pressure to quickly advance cylinder or tool. Equipped with air pressure regulator, air filter and lubricator. ...

The EPA series hand pumps are compact and easy to carry around the job site. To get the job done faster, these powerful dual speed pumps offer some of the best flow rates in the industry. ...

... : industrial tools, lifting systems, car repair, clamping systems, hydraulic equipment (presses, jacks, …), tire changers, bead breakers, automotive.

The HP-AP pump, like all HP Series pumps, can be installed in any hydraulic applications which requires high working pressures and moderate and controllable oil flow. Our HP Series air-hydraulic ...

... manually operated pumps have a proven track record industry wide and offer excellent value for money in portable hydraulic power. A full range of system components suitable for use with HP manually operated ...

... for use with either single or double acting cylinders and tools. The HP range offers the ideal solution for applications where completely independent, portable hydraulic power is required. ...

Single-acting, single-stage air-powered compact pump. Standard with a 3/8” NPT female thread and compressed air connector. Excluding coupler, hoses and ...

The hand pump type CH is single acting. It draws oil in when the hand lever is moved in one direction and discharges it when the hand lever is moved in the opposite direction.

Air hydraulic pumps, working pressure 700 bar, using a pressure multiplicator. Recommanded solution to replace hand pumps. For single and double acting ...

... socket and etc. hydraulic lifting tools include: double acting jacks, single acting jacks, hollow jacks, big tonnage jacks.hydraulic pulling tools include: ...

Hand Operated Hydraulic Pump Model: HHB-700F Characteristics: Made of aluminum alloy One-way pump for single-acting cylinders or tools Supplied with high pressure hose 1.8 meters and R2 3/8 quick coupler with dust cap. Working pressure 700 bar ●Lightweight, robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Reduced handle effort and…

Hand Operated Hydraulic Pump Model: HHB-1000 Characteristics: Made of aluminum alloy One-way pump for single-acting cylinders or tools Supplied with high pressure hose 1.8 meters and R2 3/8 quick coupler with dust cap. Working pressure 700 bar ●Lightweight, robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Reduced handle effort and ergonomic…

Hand Operated Hydraulic Pump Model: HHB-2000 Characteristics: Made of aluminum alloy One-way pump for single-acting cylinders or tools Supplied with high pressure hose 1.8 meters and R2 3/8 quick coupler with dust cap. Working pressure 700 bar ●Lightweight, robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Reduced handle effort and ergonomic…

, Hand Operated Hydraulic Pumps Model: HHB-7000,HHB-7000S Characteristics: Working pressure 700 bar HHB-7000 is one-way pump for single-acting applications. HHB-7000S is two-way pump for double-acting applications. Supplied with high pressure hose 1.8 meters and R2 3/8 quick coupler with dust cap ●HHB-7000 and HHB-7000S feature extra large reservoirs and high first-stage flow rate. These…

Hand Operated Hydraulic Pump Model: HHB-700 Characteristics: Working pressure 700 bar One-way for single-acting applications. ●Robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Lower handle effort to minimize operator fatigue. ●Large and comfortable release knob for improved control of pressure release. ●Internal pressure relief valve for overload protection. ●Supplied with 1.8-meter…

Hand Operated Hydraulic Pump Model: HHB-700A Characteristics: Working pressure 700 bar One-way for single-acting applications. ●Robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Lower handle effort to minimize operator fatigue. ●Large and comfortable release knob for improved control of pressure release. ●Internal pressure relief valve for overload protection. ●Supplied with 1.8-meter…

Hand Operated Hydraulic Pump Model: HHB-700B Characteristics: Working pressure 700 bar One-way for single-acting applications. ●Robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Lower handle effort to minimize operator fatigue. ●Large and comfortable release knob for improved control of pressure release. ●Internal pressure relief valve for overload protection. ●Supplied with…

Hand Operated Hydraulic Pump Model: HHB-700E Characteristics: Working pressure 700 bar Square and large oil tank HHB-700E is one-way pump for single-acting hydraulic application. ●Robust and durable construction. ●Handle lock for easy transport. ●Two-speed hydraulic system for fast and easy operation. ●Reduced handle effort and ergonomic grip for less operator fatigue. ●Internal pressure relief…

Hand Operated Hydraulic Pump Model: HHB-700S Characteristics: Working pressure 700 bar Square and large oil tank HHB-700S is two-way pump for double-acting hydraulic applications ●Robust and durable construction. ●Quick grip handle for easy transport. ●Two-speed hydraulic system for fast and easy operation. ●Reduced handle effort and ergonomic grip for less operator fatigue. ●Internal pressure relief valve…

Hand Operated Hydraulic Pump Model: HHB-700C Characteristics: Working pressure 700 bar ●Robust, durable and compact. ●Two-speed hydraulic system for fast and easy operation. ●Lower handle effort to minimize operator fatigue. ●Large and comfortable release knob for improved control of pressure release. ●Internal pressure relief valve for overload protection. ●Supplied with 1.2-meter length high pressure…

The Power Team P-Series hand pumps come in a variety of configurations to meet the requirements of your application. Along with various oil capacities and flow rates, you can choose from the following options:

Compact design ensures that the Power Team PA6 series pump is lightweight and portable. The PA6 series consists of single-speed pumps designed to drive single-acting cylinders. The power unit of choice for major manufacturers of auto body, frame straighteners and other equipment. Operates at 40-100 psi (3-8 bar) shop air pressure at the pump, dBA 85 at 10,000 psi (700 bar). Serviceable pump motor is not a “throwaway”, providing economical repair. Permanently vented reservoir cap. Internal relief valve protects circuit components, air inlet filter protects motor.

Compact, lightweight and portable the Power Team PA6D series pumps are single-speed pumps for driving double-acting cylinders. The PA6D series pumps operate at 40-100 psi (3-8 bar) shop air pressure at the pump. Designed with longevity in-mind the PA6D series feature internal relief valve protects circuit components, air inlet filter protects motor. Serviceable pump motor is not a “throw away”, providing economical repair. Permanently vented reservoir cap. dBA 85 at 10,000 psi (700 bar) for all PA6 pump.

Ideal for powering single-acting cylinders and portable hydraulic tools, the Power Team PA9 series pumps are easier to operate than a hand pump, designed for efficiency. Built to be economical in service; the PA9 series is not a “throwaway” unit. Unique bladder design for all-position operation and storage. Operates on 40-120 psi (3-8 bar) shop air, at 20 cfm (570 l). Hard-coat anodized aluminum housing. Oil filler with integral safety relief minimizes chance of damage to reservoir bladder if overfilling occurs.

A two-speed pump, the Power Team PA60 series pumps are designed for rapid oil delivery at low pressure to quickly advance cylinder or tool. Equipped with air pressure regulator, air filter and lubricator. Serviceable air motor for economical repair. Internal relief valve protects circuit components. Permanently vented reservoir cap.

Focused on single-speed and low pressure the Power Team PA50 series pump outputs 3,200 PSI / 220 BAR, fitting serviceable requirements for air motor for economical repair. Integrated air inlet filter protects motor. The PA50 series also features a filter in outlet port protects against contaminated systems Assorted reservoirs to suit your application"s requirements.

Rotary-Style Air Motor. Use where air is the preferred source of energy. 3 hp motor starting under full load. Two-speed operation for rapid cylinder advance. Models available with full remote control over advance and return, except PA554. Tandem center valve holds the load when pump is shut-off.

Compact, Portable, Cordless Hydraulic Pump for MRO Applications. Compact, Li-ion 18VDC, 9.0 Ah battery-powered pump provides extended run-time. Two-stage, high-pressure hydraulic pump offers quick tool advancement in the first stage. Extremely compact, lightweight with an ergonomic handle grip and transport strap to ease portability. Self-contained, rubber bladder reservoir allows pump usage in most positions with an impressive capacity of 70 cu. in. usable. Quiet, smooth-running, serviceable brushed 18VDC motor. High-impact, fiberglass reinforced shroud protects your investment in the most demanding and harsh applications. Interchangeable valve configuration accommodates a vast array of applications. CSA rated for intermittent duty, CE compliant.

The 10 series Power Team hydraulic pumps are designed to have a maximum of 690 bar (10,000 psi) at a flow rate of 164 cc/min (10 cu. in/min). All Power Team pumps come fully assembled, and each with the ability to be valved for either single- or double acting cylinders. Designed to be compact can easily mobile, the power team 10 series includes a portable power source is included for hydraulic cylinders, and tools. The permanent magnet motor is strategically constructed to easily start under load, even with reduced voltage conditions. Battery-operated models have 8 foot (2,4 m) power cord with alligator clips to connect to any 12 volt battery, optional rechargeable battery pack with shoulder strap are alternatives for maximum portability. The Power Team 10 series pump typically delivers 15 minutes of continuous operation at 10,000 psi (700 bar) on a single battery. Built to withstand High-impact, shielded with a flame retardant construction.

The Power Team 17 series pump is delibertly designed for maintenance and construction applications up to 55 Ton. For use with single-acting or double-acting cylinders at operating pressures to 10,000 psi (700 bar). For intermittent duty; starts under full load. Equipped with 1⁄2 hp (0,37 kW), 3,450 rpm, single-phase, thermal protected induction motor; 10 ft. remote control cord (PE172S has 25 ft. (7,6 m) cord) Low amperage draw; small generators and low amperage circuits can be used as power source. Extremely quiet noise level (67-81 dBA).

Vanguard Jr. + Power Team 18 series pumps provide two-speed high performance in a light-weight, compact package. Designed to provide a gauge port and metal reservoir on all pump models. Equipped with a 1⁄2 hp (0,37 kW), 115 volt, 60/50 Hz single phase motor that starts under load, even at reduced voltage. Low amperage draw permits use with smaller generators and low amperage circuits. All pumps have a 10 foot (3 m) remote control. CSA rated for intermittent duty. Noise level of 85-90 dBA. For operating hydraulic crimping, cutting or other tools: No. PE184C - Allows you to alternately operate a spring-return cutting and/or crimping tool without disconnecting either tool. Select a port connection with a manual 4-way valve, start the pump with a remote control hand switch and extend the connected tool. When the hand switch is switched to off, the pump stops and the automatic valve opens, allowing the tool to return. In the center (neutral) position, a manual control valve holds the tool in position at the time valve is shifted.

The 21 series Power Team pump and RD5513 cylinder used in a special press that produces pharmaceutical-grade extracts for herbal medicines. Totally enclosed, fan cooled induction motor: 1 hp (0,75 kW), 1,725 rpm, 60 Hz, single phase. Designed intentional for thermal overload protection. Remote control, with 10 foot (3,1 m) cord is standard on pumps with solenoid valves. Manual valve pumps have “Stop”, “Start” and “Run/Off/Pulse” switches. Pump controls are moisture and dust resistant. Motor drip cover with carrying handles and lifting lug. Low noise level of 70 dBA@ 10,000 psi (700 bar). In the event of electrical interruption, pump shuts off and will not start up until operator presses the pump start button. 24 volt control circuits on units with remote controls provide additional user/operator safety.

Ideal for running multiple tools or cylinders from one power unit. Recommended for cylinders up to 75 tons. Two-speed pumps have the same low pressure and high pressure flows from both valves. Flows and pressures of each pump are independent. Delivers 300 cu. in./min. of oil at 100 psi (4,8 liter/min of oil at 7 bar) and 25 cu. in./min. at 10,000 psi (0,4 liter/min at 700 bar) from each pump. 1 1/2 hp, 110/115 volt, 60 Hz (1,12 kW, 220 volt, 50 Hz) induction motor, 10 foot (3,1 meter) remote control and 5 gallon (19 liter) steel reservoir. Models available for operating single-acting or double-acting cylinders. Each power unit contains two separate pumps and two separate valves allowing operator to control multiple processes with one power unit. Both pumps on each power unit are equipped with an externally adjustable pressure relief valve. Not recommended for frequent starting and stopping.

The Power Team 30 series pump is intently ideal for maintenance and construction applications. Operating both single-acting or double-acting cylinders. A dynamically built, Integral roll cage protects the 30 series pump from many forms of damage. 1 hp (0,75 kW), single phase, permanent magnet motor. High performance to weight ratio. Starts under full load even when voltage is reduced to 50% of nominal rating. Quit operations: 82 dBA @ 10,000 psi (700 bar) and 87 dBA @ 0 psi (0 bar). CSA rated for intermittent duty. Remote controls and/or solenoid valves feature 24 volt controls.

The Power Team 46 series is best suited for under the roof maintenance and production applications. Equipped with two-speed high-performance pump, for use with single- or double-acting cylinders at operating pressures to 10,000 psi (700 bar) the 46 series pump is versitile. With a 1 1⁄2 hp (1.12 kW), 3,450 (2,875) rpm single-phase, 60 (50) Hz thermal protected induction motor that starts under full load. Noise level of 77-81 dBA. All equipped with a 10 foot (3,1 m) remote control except PE462S which has a 25 foot (7,6 m) remote control. 24 volt control circuit on all units with remote control. CSA rated for intermittent duty.

A powerful multifaceted pump, the Power Team 55 pump excels at multiple applications. From heavy construction to concrete stressing this pump series is designed for intensity. With low voltage starting possible, the 50/60 Hz universal motor; draws 25 amps at full load, and can start at reduced voltage. CSA rated for intermittent duty. 10 foot (3,1 m) remote motor control (except PE552S which has a 25 foot (7,6 m) remote motor and valve control). True unloading valve achieves greater pump efficiency, allowing higher flows at maximum pressure. Reservoirs available in sizes up to 10 gallons (38 liter). Lightweight and portable. Best weight-to-performance ratio of all Power Team pumps. “Assemble to Order” System: There are times when a custom pump is required. Power Team’s “Assemble to Order” system allows you to choose from a wide range of pre-engineered, off-the shelf components to build a customized pump to fit specific requirements. By selecting standard components you get a “customized” pump without “customized” prices. All pumps come fully assembled, add oil and ready for work.

A compact lightweight pump, the Power Team 60 series is designed for rugged applications and low voltage starting. Experiencing a long, trouble-free life in the most demanding work environments, the 60 series is durable.. Powered by 1 1⁄8 hp, 115 volt, 60/50 Hz (0,84 kW, 220 volt, 60/50 Hz) single phase motor. Starts under load, even at the reduced voltages at construction sites. Optional fan-driven external oil cooler includes rollover guard. Insulated carrying handle. Integral 4" (102 mm) diameter fluid-filled pressure gauge with steel bezel complies with ASME B40.1 Grade A. 0 to 10,000 psi (0 to 700 bar) pressure range in 100 psi (7 bar) increments. Sealed 3⁄4 gallon (4,34 liter (usable) reservoir. Reservoir drain port is standard. Standard oil level sight gauge for accurate oil level monitoring. External spin-on filter removes contaminants from circulating oil to maximize pump, valve and cylinder/tool life.

The Power Team PQ60 series pumps are designed specifically for heavy-duty, extended cycle operation. Integrating single- or double-acting cylinders the PQ60 series is versatile. Constructed for longevity by employing a metal shroud keeps dirt and moisture out of motor and electrical components. An electrical shut-down feature prevents unintentional restarting of motor following an electrical service interruption. Internal relief valve limits pressure to 10,000 psi (700 bar). External relief valve is adjustable from 1,000 to 10,000 psi (70 to 700 bar). The Power Team PQ60 pumps operate below maximum OSHA noise limitation (74-76 dBA). Start and operate under full load, even with voltage reduced by 10%.

The Power Team 120 series pump is exactingly designed for heavy duty, extended cycle operation up to 400 Ton. Built in grit, the series 120 pump can start and operate under full load, even with voltage reduced 10%. An electrical shut-down feature prevents unintentional restarting of motor following an electrical service interruption. Internal relief valve limits pressure to 10,000 psi (700 bar) and an external relief valve is adjustable from 1,000 to 10,000 psi (70 to 700 bar). Pump prewired at factory with a 3 hp, 460 volt, 60 Hz (2,24 kW, 380 volt, 50 Hz), 3 Phase motor. Other electrical configurations are available. 24 volt control circuits on units with remote controls for added user/operator safety. 3 hp (2,24 kW) 3 phase motor with thermal overload protection. Motor starter and heater element supplied as standard equipment; with an intentionally designed metal shroud to keep dirt and moisture out of motor and electrical components. Pumps operate below maximum OSHA noise limitation.

With high tonnage double-acting cylinders, the Power Team 400 series offers both single or multiple cylinder applications. Two-speed high output pump delivers up to 5 gpm (16 liter/min) of oil, with a low noise level of 73-80 dBA. Integral electrical shut-down feature prevents unintentional restarting of motor following an electrical service interruption. Over-current protection prevents damage to motor as a result of overheating. “Stop” and “Start” control buttons are 24 volt. PE4004 has a 4-way/3-position manual valve. The PE4004S has a 4- way/3-position solenoid valve with a 24 volt remote hand switch. External pressure relief valve is adjustable from 1,500 to 10,000 psi (100 to 700 bar). Heavy duty 4" (50,8 mm) diameter casters assure easy maneuvering. 20 gallon (3,927 cu. in. usable) / 75,7 liter (62,8 liter usable) reservoir has a low oil level sight gauge. Powered by a dual voltage 10 hp (7,46 kW), 3 phase, 1,725 (1,437) rpm motor. 3 phase motor has all the electrical components necessary to operate the pump.The customer has no hidden charges when making purchase. Deliver 1,200 cu. in./min. (16 liter/min) of oil @ 200 psi (15 bar), 420 cu. in./min. (5,6 liter/min) of oil @ 10,000 psi (700 bar).

Power team synchronized lifting and lowering system, the MCS ( motion controller system ) series can be used in many hydraulic applications where load position is critical, requiring cylinder synchronization. Whether it is a bridge, a building or any kind of heavy load, with the SPX FLOW power team motion control system, lifting, lowering, pushing, pulling, tilting or positioning loads can be carried out automatically with a high degree of accuracy. The PLC-controlled system is a combination of digital actuation and digital control providing significant advantages such as time savings, repeatability, and extremely low internal stress in the object one is moving. The system also provides documentation for the movement performed.

Extremely durable yet lightweight and operable under low-line voltage conditions, the Power Team PE-NUT series pumps are constructed for challenging conditions. A 115V 5/8 hp (0,46 kW) universal electric motor (50/60 cycle), employing a two-stage pump for efficiency and designed for use with spring-returned remote tools. The PE-NUT series pumps also feature high-pressure safety relief valve, remote hand control with 10-foot (3,1 meter) cord, and a pressure matched quick-coupler supplied. The PE-NUT series uniquely utilizes intermittent duty, piston-type high-pressure pump supercharged by a low-pressure pump. CAUTION: DESIGNED FOR CRIMPING APPLICATION ONLY! This system should not be used for lifting.

Gasoline power ideal for remote locations. A logical choice at work sites where electricity or compressed air are unavailable. For single or double-acting cylinders at operating pressures up to 10,000 psi. All gasoline engine/hydraulic pumps feature Posi-Check® valve to guard against pressure loss when valve is shifted from “advance” to “hold.”

PG303 is for single-acting cylinders, has a 9520 valve with separate internal return line which allows oil from running pump to return to reservoir, independently of cylinder return oil, when valve is in “return” position.

A logical choice at work sites where electricity or compressed air are unavailable. For single or double-acting cylinders at operating pressures to 10,000 psi.

PG1200 Series pumps powered by a Honda 4-cycle, 5.5 hp engine with automatic decompression and electronic ignition. Deliver over 0.5 gallon (130 cu. in.) of oil per minute at 10,000 psi.

Rubber anti-skid insulation on bottom of reservoir resists skidding and dampens vibration. PG1200M-4 and PG1200M-4D include a pump cart with 12” wheels.

The Power Team HB series is purposefully constructed to convert low-pressure portable hydraulic pumps or on-board hydraulic systems, into high pressure power sources. HB series applications include utilities, railroads, construction, riggers and others. This product operates single or double-acting cylinders, jacks, and tools such as crimpers, spreaders, cable cutters, or tire tools. Version for use with double-acting torque wrenches available. May be used to operate two separate, single-acting tools (with integral valves) independently, without need for additional manifold. Control valve included. Other Power Team valves available as an option to suit your specific application, if needed; consult factory. Compact and rugged for use inside a utility vehicle aerial bucket or stowing in a vehicle. No reservoir level to maintain; uses low pressure system as oil supply. Has 3⁄8" NPTF ports; compatible with standard fittings for low and high pressure systems.

Portable two-speed pump operated in any position (open or closed-center) providing pressures up to 10,000 psi for the operation of high-pressure tools.

These compact, lightweight boosters do not have reservoirs. The units can be operated in any position on either open- or closed-center (accumulator) hydraulic systems.

“Assemble to Order” means you can choose a basic pump with gas, air or electric motor. Then select the proper valve, gauge, pressure control, motor control and reservoir. You get a two-stage pump that gives high oil volume for fast cylinder approach (and return with double-acting cylinders) in the first stage and high pressure in the second stage.

1-1/8 HP Universal Motor. These motors start under full load and are suitable for operation up to 5,000 or 10,000 psi. The motor is 1-1/8 hp, 12,000 rpm, 115 or 230VAC (specify), 50/60 cycle AC single-phase (25 amp draw at 115VAC). With proper valve they can be used with single or double-acting cylinders. NOTE: Remote control available.

1-1/2 HP Jet Motor, Single & Three-Phase. Feature low noise level, moderate speed for long service and are ideal for fixed applications. Motor is 1-1/2 hp, 3,450 rpm, 115 or 230VAC, 50 or 60 cycle (specify), AC single-phase with thermal overload switch. Can be used with single or double-acting cylinders and equipped with remote control. Also available in 230/460VAC, three-phase (specify). NOTE: These do not start under full load unless valve is in “neutral” (requires open or tandem center valve) and are not recommended for frequent starting and stopping.

3 HP Jet Motor, Three-Phase. Gives low noise level and long life due to its moderate operating speed. Ideal for fixed installations. Consists of basic 10,000 psi pump, jet pump motor: 3 hp, 3,450 rpm, 230/460VAC, 60 or 50 cycle (specify). AC three-phase, with thermal overload switch. Equipped with internal and external relief valve. Will start under load.

or cannot be used. The 5,000 or 10,000 psi pump has a 3 hp air-driven motor at 3,000 rpm (optimum performance based on 80 psi air pressure and 50 cfm at the pump). You can drive single or double-acting cylinders with the correct valve. NOTE: 80 psi air supply required to start under full load.

unavailable. It is capable of continuous operation at full pressure. Consists of basic 10,000 psi pump, 4-cycle Briggs & Stratton “Diamond Edge” gasoline engine, developing 6 hp. As with all these pumps, this unit can be valved for use with either single or double-acting cylinders.

Cylinders can be found in almost all hydraulic systems and combustion engines, and they are among the most common industrial components around. While the shape of a cylinder is always similar, these parts are actually very diverse, and choosing the correct cylinder can make or break a repair job. Whether you"re engaged in motorcycle maintenance, fixing hydraulic doors, or replacing the cylinder on a drilling rig, Alibaba"s wholesale store is the place to search. Finding a hydraulic hand pump double acting cylinder couldn"t be easier, and every cylinder variety is easy to find.

Cylinders come in a massive range of forms, so using the search function at Alibaba is recommended. If you are looking for hydraulic versions, you"ll find cylinder components for doors, drills, pumping systems, bottle blowing machines, mechanical jacks, lifting platforms, passenger elevators and many more commonplace applications. They are in the hoists we use to lift rocks, forklift steering mechanisms and so much more. Match the specs of the machinery being fixed with the ideal cylinder and make whatever alterations need to be made. Refresh the piston on a plunge press, or stock up on hydraulic hand pump double acting cylinder components. Whatever you need, it"s here.

The same goes for automotive cylinders. Alibaba"s wholesale catalogue has all of the parts you need to fix engines and get vehicles back on the road and back to work. There are ignition lock gaskets, brake cylinder components, piston overhaul sets for bikes and autos, and all of the other parts needed. If you run a mechanics workshop or have a fleet of industrial vehicles to manage, Alibaba is the place to look. Find the ideal hydraulic hand pump double acting cylinder and don"t let a blown cylinder derail your plans.

As a foreign trade company with rich experience in hydraulic fittings, Topa is able to deal with various problems. We offer a wide range of fittings to satisfy the needs of different customers.

Whether you are buying a car lift as a car enthusiast looking to work on vehicles as a hobby, or an automotive shop looking for a new lift—buying a car lift is a big decision. There are multiple factors you should weigh when planning on which type of lift to purchase. What kind of vehicles am I hoping to work on? What size lift will I need? What type of lift should I buy? This last question is important in understanding what kind of car lifts are available and what makes them different. For example, some car lifts you see will use chains to pull automobiles upward. However, another way to lift a car is with hydraulic power. This article will help you understand how hydraulic lifts work and the difference between a single-acting and double-acting hydraulic cylinder. This will allow you to have the information to make the best available purchase.

First, it’s important to understand what hydraulic power is and how it works in place of the chain system of other lifts. Car lifts that use hydraulic power will move cars upward when a pump in their structure pushes a liquid from a fluid container to a hollow cylinder. The cylinder then fills with the liquid, forcing the piston component inside to move upward, which creates the movement of the lift. To lower a vehicle, the process is reversed. This is a basic understanding of how car lifts that utilize hydraulic power works. With this understanding, you can now start to look at how this source of power can be more advantageous than a typical chain system for lifting vehicles.

Car lifts that take advantage of hydraulic power and the use of hydraulic cylinders have unique advantages over their chain-powered counterparts. Here are a few reasons why you should consider a hydraulic-powered car lift.

SPACE EFFICIENT- A car lift that uses a hydraulic system takes up less space than its chain counterpart. A chain lift will need room for its beams so the chains can move, so you can operate the lift and move the lift or down. Hydraulic lifts can be more compact because they push from the bottom instead of incorporating the “pulling” motion of the chains.

LESS PARTS- Car lifts that use a chain to lift a vehicle have many moving parts that it utilizes to move a vehicle upward or downward. This exposes more parts and equipment to be strained or to not work correctly, which have you needing to replace parts or your lift. However, a hydraulic lift is simpler in its design and function—making it easier to maintain and less parts to worry about.

SINGLE CYLINDER OR DOUBLE- Lastly, you have the choice with the hydraulic power of a single acting hydraulic cylinder or double acting hydraulic cylinder. Both have different advantages that could work for different types of consumers.

Power and hydraulic cylinders go hand in hand. Hydraulic power has become a staple of the industrial world—with power and reliability that can be counted on. From the biggest movers to car lifts, they are widely used to get multiple jobs done. However, there’s more to hydraulic power than just the science behind it that was discussed above. There are single-acting hydraulic cylinders and double-acting hydraulic cylinders, and both have their advantages. By learning the differences between the two, you will have the information necessary to determine which is best for you to purchase.

A single-acting hydraulic cylinder is less involved than a double-acting hydraulic cylinder, making it easier to maintain. The cylinder’s action is determined entirely by the pressure on one line. Oftentimes they will have a spring to push or retract the piston rod, or they might rely on the force on end to push it back. The simplicity of the operation makes it more reliable, and fewer parts are being tasked with lifting the vehicle. The simplicity of the single-acting hydraulic cylinder makes it easier to manufacture and repair, leading to cheaper costs associated with the product. Lastly, Due to their single port and small housing, single-acting hydraulic cylinders work well with smaller equipment and spaces. While a single-acting hydraulic cylinder may work for some, others will need the benefits of a double-acting hydraulic system.

A double-acting cylinderalternates cycles of pressurized fluid to both sides of the piston, creating the ability to extend and retract forces to move the piston rod, allowing more control over the movement. Due to this, double-acting hydraulic cylinders allow for additional versatility. While a single cylinder may be best if you’re moving in only one direction, a double cylinder can operate in multiple directions and offer additional control. The two ports make hydraulic power available in both directions and are easily controlled with an effective push-and-pull motion. Therefore, the double-acting hydraulic cylinder is the most used for hydraulic power.

Now that you understand the differences between single-acting and double-acting hydraulic cylinders, you can make an educated purchase on which is best for your needs.

Hydro Dynamics is one of the trusted Single Acting Hydraulic CylinderManufacturers In China and offers you the top-class Single Acting Hydraulic Cylinder In China. We have a wide array ofHydraulic Jack, Hydraulic Double Acting Jack, Center Hole Jack, Low Height Jack, Threaded Ram Jack With Safety Lock Nut, Hydraulic Cylinder, Hydraulic Power Pack, Hydraulic Press, and Hydraulic Hand Pump In China. We work beyond the boundaries to supply top-quality products to our clients. We blend innovation and creativity to manufacture high-end performance Single Acting Hydraulic Cylinder In Colombia, Model Town, Bankura. Our advanced knowledge and dedicated service team work their level best to stand apart from the crowd. The versatility, accuracy, and ability to boost productivity make our Single Acting Hydraulic Cylinder the best choice in China.

We have state-of-art-infrastructure equipped with cutting-edge tools, modern machinery, and updated resources. Our strongly dedicated team works on their toes to ensure the best quality Single Acting Hydraulic CylinderIn China. Our professionals supervise every detail during manufacturing, so there is no chance of a mistake being left behind. Our Single Acting Hydraulic Cylinder is available in different sizes and shapes that can cater to your industry needs. We have a wide range of Hydraulic Manual Pumps, Hydraulic Cylinders, Low Height Jack, Industrial Hydraulic Press, Hydraulic Remote Control Jack, Center Hole Acting Jack, Hydraulic Lift Cylinder, and Hydraulic Press Cylinder In China. We also customize the Single Acting Hydraulic Cylinderaccording to the customer demand. Our commitment to serving nothing but the best Single Acting Hydraulic Cylinder In Somalia, Ahmedabad, Crawley makes us the reliable Single Acting Hydraulic Cylinder Manufacturer In China in this cut-throat competitive world. Each product goes through various tests to ensure international grade standards and accuracy.

Are you looking for Hydraulic Press, Hydraulic Power Press, or Industrial Hydraulic Press? We are one of the leading Single Acting Hydraulic Cylinder Exporters And Suppliers In Chinaand are the best-stop solution for you. We design top-notch products and formulate them with utmost precision. We are the industry leader who manufactures distinct models Single Acting Hydraulic Cylinder In Rewari, Kota, Ukraine at the most affordable price. We deliver user-friendly designs to our customers with utmost safety. We have a competitive range of Single Acting Hydraulic CylinderIn China and are ready to cater to your requirements in a call.

Without any further delay, get in touch with our experts. They will guide you in all possible ways about the Single Acting Hydraulic Cylinder. So without any second thought, browse our website to place your order. Drop your requirement via the enquiry form on the website or call the given number now. We are happy to help you in all possible ways.

A hydraulic pump converts mechanical energy into fluid power. It"s used in hydraulic systems to perform work, such as lifting heavy loads in excavators or jacks to being used in hydraulic splitters. This article focuses on how hydraulic pumps operate, different types of hydraulic pumps, and their applications.

A hydraulic pump operates on positive displacement, where a confined fluid is subjected to pressure using a reciprocating or rotary action. The pump"s driving force is supplied by a prime mover, such as an electric motor, internal combustion engine, human labor (Figure 1), or compressed air (Figure 2), which drives the impeller, gear (Figure 3), or vane to create a flow of fluid within the pump"s housing.

A hydraulic pump’s mechanical action creates a vacuum at the pump’s inlet, which allows atmospheric pressure to force fluid into the pump. The drawn in fluid creates a vacuum at the inlet chamber, which allows the fluid to then be forced towards the outlet at a high pressure.

Vane pump:Vanes are pushed outwards by centrifugal force and pushed back into the rotor as they move past the pump inlet and outlet, generating fluid flow and pressure.

Piston pump:A piston is moved back and forth within a cylinder, creating chambers of varying size that draw in and compress fluid, generating fluid flow and pressure.

A hydraulic pump"s performance is determined by the size and shape of the pump"s internal chambers, the speed at which the pump operates, and the power supplied to the pump. Hydraulic pumps use an incompressible fluid, usually petroleum oil or a food-safe alternative, as the working fluid. The fluid must have lubrication properties and be able to operate at high temperatures. The type of fluid used may depend on safety requirements, such as fire resistance or food preparation.

Air hydraulic pump:These pumps have a compact design and do not require an external power source. However, a reliable source of compressed air is necessary and is limited by the supply pressure of compressed air.

Electric hydraulic pump:They have a reliable and efficient power source and can be easily integrated into existing systems. However, these pumps require a constant power source, may be affected by power outages, and require additional electrical safety measures. Also, they have a higher upfront cost than other pump types.

Gas-powered hydraulic pump:Gas-powered pumps are portable hydraulic pumps which are easy to use in outdoor and remote environments. However, they are limited by fuel supply, have higher emissions compared to other hydraulic pumps, and the fuel systems require regular maintenance.

Manual hydraulic pump:They are easy to transport and do not require a power source. However, they are limited by the operator’s physical ability, have a lower flow rate than other hydraulic pump types, and may require extra time to complete tasks.

Hydraulic hand pump:Hydraulic hand pumps are suitable for small-scale, and low-pressure applications and typically cost less than hydraulic foot pumps.

Hydraulic foot pump:Hydraulic foot pumps are suitable for heavy-duty and high-pressure applications and require less effort than hydraulic hand pumps.

Hydraulic pumps can be single-acting or double-acting. Single-acting pumps have a single port that hydraulic fluid enters to extend the pump’s cylinder. Double-acting pumps have two ports, one for extending the cylinder and one for retracting the cylinder.

Single-acting:With single-acting hydraulic pumps, the cylinder extends when hydraulic fluid enters it. The cylinder will retract with a spring, with gravity, or from the load.

Double-acting:With double-acting hydraulic pumps, the cylinder retracts when hydraulic fluid enters the top port. The cylinder goes back to its starting position.

Single-acting:Single-acting hydraulic pumps are suitable for simple applications that only need linear movement in one direction. For example, such as lifting an object or pressing a load.

Double-acting:Double-acting hydraulic pumps are for applications that need precise linear movement in two directions, such as elevators and forklifts.

Pressure:Hydraulic gear pumps and hydraulic vane pumps are suitable for low-pressure applications, and hydraulic piston pumps are suitable for high-pressure applications.

Cost:Gear pumps are the least expensive to purchase and maintain, whereas piston pumps are the most expensive. Vane pumps land somewhere between the other two in cost.

Efficiency:Gear pumps are the least efficient. They typically have 80% efficiency, meaning 10 mechanical horsepower turns into 8 hydraulic horsepower. Vane pumps are more efficient than gear pumps, and piston pumps are the most efficient with up to 95% efficiency.

Automotive industry:In the automotive industry, hydraulic pumps are combined with jacks and engine hoists for lifting vehicles, platforms, heavy loads, and pulling engines.

Process and manufacturing:Heavy-duty hydraulic pumps are used for driving and tapping applications, turning heavy valves, tightening, and expanding applications.

Despite the different pump mechanism types in hydraulic pumps, they are categorized based on size (pressure output) and driving force (manual, air, electric, and fuel-powered). There are several parameters to consider while selecting the right hydraulic pump for an application. The most important parameters are described below:

Speed of operation: If it is a manual hydraulic pump, should it be a single-speed or double-speed? How much volume of fluid per handle stroke? When using a powered hydraulic pump, how much volume per minute? Air, gas, and electric-powered hydraulic pumps are useful for high-volume flows.

Portability: Manual hand hydraulic pumps are usually portable but with lower output, while fuel power has high-output pressure but stationary for remote operations in places without electricity. Electric hydraulic pumps can be both mobile and stationary, as well as air hydraulic pumps. Air hydraulic pumps require compressed air at the operation site.

Operating temperature: The application operating temperature can affect the size of the oil reservoir needed, the type of fluid, and the materials used for the pump components. The oil is the operating fluid but also serves as a cooling liquid in heavy-duty hydraulic pumps.

Operating noise: Consider if the environment has a noise requirement. A hydraulic pump with a fuel engine will generate a higher noise than an electric hydraulic pump of the same size.

Spark-free: Should the hydraulic pump be spark-free due to a possible explosive environment? Remember, most operating fluids are derivatives of petroleum oil, but there are spark-free options.

A hydraulic pump transforms mechanical energy into fluid energy. A relatively low amount of input power can turn into a large amount of output power for lifting heavy loads.

A hydraulic pump works by using mechanical energy to pressurize fluid in a closed system. This pressurized fluid is then used to drive machinery such as excavators, presses, and lifts.

A hydraulic ram pump leverages the energy of falling water to move water to a higher height without the usage of external power. It is made up of a valve, a pressure chamber, and inlet and exit pipes.

A water pump moves water from one area to another, whereas a hydraulic pump"s purpose is to overcome a pressure that is dependent on a load, like a heavy car.

Gaodetec Equipment is100 150 200 250 300 500 1000 ton double acting hydraulic cylinder with electric pump for sale manufacturers and supplier made in China.

double acting hydraulic cylindewith convenient operation and control, which is especially suitable for large-scale projects. In order to protect the safe operation of the jack, the jack has a built-in pressure relief valve to prevent overload, and a safety device is designed. Thecylinderjoint adopts high-pressure rubber hose and threaded joint, which has the advantages of fast operation and overcomes the disadvantage of oil leakage of traditional joint. China"s Prestresseddouble acting hydraulic cylinder with electric pumpis mainly used for concrete post tensioning prestress and tensioning steel strand.

The high pressure 50 100 150 200 250 300 500 1000 tondouble acting hydraulic cylinder with electric pumpis powered by ZB series high-pressure electric oil pump, which has the functions of oil pressure rebound and overflow. The safety protection booster is designed to protect the emergency overpressure, and the special structure can protect the oil cylinder. Thedouble acting hydraulic cylinder with electric pumpcan withstand the eccentric load of 5% of the rated pressure. High pressurehydrauliccylinder is very durable, especially in large projects, it is easy to operate and control. It can be used for hoisting heavy machinery, bridge engineering, water conservancy engineering, port construction and other equipment. It has the advantages of large output, light weight and remote control. It can be matched with our high-pressure oil pump, and can achieve a variety of operation modes such as Jack, push, pull and extrusion.

The50 100 150 200 250 300 500 1000 tonwith electric pumpcan be used for the maintenance of large machinery, the overall hoisting of bridges, the maintenance of hydropower station gates, the hoisting of steel structures and the installation of supporting equipment.

Double acting hollowhydrauliccylinder combines all the design features of single acting and the advantages of double acting design, so as to improve the operation and use speed, especially in the operation of relatively long stroke. The piston center of double acting hollow cylinder has a through hole, which is widely used in nuclear power plants, tunnel engineering, underground engineering, buildings and other occasions to realize the preloading process, and can also be used for other similar needs

Thedouble acting hydraulic cylindersold can be equipped with two-way manual oil pump or two-way electric oil pump. Due to the through hole in the middle, the hollow jack not only has the lifting capacity of the general hydraulic jack, but also has the stretching and tensioning functions that the general Jack does not have. Through holes allow cables, wire ropes and other shafts to pass through. The hollow roof has dual functions and hydraulic retraction function. Double acting hollow cylinder is the first choice for various large projects. It has the characteristics of convenient operation and control. The new technology and structure make the hollow ceiling Jack safer and longer service life.

a). In case of out of control during use, loosen the drainage screw on the pump body first, then lift the pump body vertically and run down, and then tighten the drainage screw to wait for a sense of stress. Continue to use.

d). For new or long-term placed hydraulic jacks, due to more air in the oil cylinder, the piston rod may suddenly jump slightly at the beginning of use. The hydraulic jack can stand upside down and reciprocate 2-3 times without load. Remove air from the cavity.

If you are interested in the price of50 100 150 200 250 300 500 1000 tondouble acting hydraulic cylinder with electric pump, please tell us the tonnage and stroke you need.

We have many standard models for you to choose from, and we can also customizedouble acting hydraulic cylinder with electric pumpaccording to your requirements. If you are interested in our hydraulic cylinders, electric pumps or other hydraulic tools, please contact us! Email: info@gaodetec.com

Electric hydraulic pumps are pray coating, anti-corrosion, pollution-resistant, durable. Lightweight and compact design make it easy to be moved. Double speed pump design, with the high flow in low pressure. The actuator can be fast moved on no-load status.Internal high and low pressure automatic reversing valve and external adjustable pressure valve to make it easy to calibrate the working pressure and avoid the over load. Motor starter has the function of preventing overload, overheat and leakage. The pump can be matched with both double acting and single acting cylinders. Choosing the solenoid valve electric hydraulic pump, remote operation can be realized.

8613371530291

8613371530291