slurry tanker hydraulic pump in stock

Fruitland Manufacturing RCF500 Vacuum Pumps are designed to work in all types of liquid waste handling markets including the Oil and Gas Fracturing Industry, Industrial, Environmental, Grease and Septic.

Fruitland RCF500 Vacuum Pumps have an approximate air flow of 396 CFM and pressures to 35 PSI. They have a maximum vacuum of 28.5″ Hg at 44 BHP and require 23 BHP power at 27″Hg. The RCF500 vacuum pump has an operating speed of 1400 RPM and a 3″ port size. These are automatically lubricated with an included oil pump and have 8 Kevlar vanes. The 500 series pumps use less oil than any other rotary vane pump in the industry. Applications for the 500 pump are universally used throughout oil & gas fracturing, environmental, industrial and septic industries.

The RCF500LUFH is a RCF500 vacuum pump with the following options. (L) Left hand or Counter-clockwise rotation (when looking at the pulley or drive shaft). (U) The four-way diverter valve is installed on top of the pump. (F) This pump includes the filter option. (H) This pump includes the hydraulic drive adapter.

Phil’s Pumping & Fab proudly offers top fill slurry tankers by Calumet and Balzer with their smooth-riding, heavy-duty hydraulic suspension and available automatic rear steerable axle technologies. These durable, hard-working manure spreader tankers come in multiple sizes and configurations to meet any liquid manure application need.

Littlejohn offers the largest selection of tank trailer pumps including Blackmer Pumps, Roper Pumps and Ranger pumps. We stock pumps, repair kits, and repair parts at all 6 locations for same day shipping. Coast to Coast tanker trailer pumps from Littlejohn since 1936.

Wide range of Slurry Parts, Ranging from Slurry Tanker Parts, Side Spreader Parts And Slurry Mixing Pump Parts. We also stock a wide range of Abbey Slurry Tanker Parts. | Buy Online | In-Stock Parts next day Delivery To Northern Ireland. All Other Parts available to order 3 to 5 Days Delivery To UK and Ireland.

The reliability and strength of the MEC is the result of continuous design and manufacturing improvements accomplished during 40 years of deployments. Its light and compact design made MEC 1000/1600 the best vacuum pump for portable sanitation services and small vacuum tank for liquid applications.

RME0MGKF–Apr. 04, 1955 - Previews of the British industries fair at Birmingham. One of the exhibits at the B.I.F at Birmingham is this Simon Mobile hydraulic platform. This machine dispenses with ladders, scaffolding, block and pulley rigs, and other time wasting tackle. It can put a man - or men - heights of 40 feet or more. Operations is entirely hydraulic and all movement are controlled from the platform by means of pedals for rasing and lowering and a Knee operated rotation control. Duplicate controlled are provide on the tunatable should the pump or motor fail. photo shows Miss Wendy Adshead

Located outside the village of Kilmacthomas, Co Waterford, brothers Noel and Ger Hickey are the men behind the patented Safeshaft System. For those unfamiliar with Safeshaft, it’s essentially a hydraulic drive system which replaces the conventional PTO shaft used to power vacuum pumps on slurry tankers.

Noel is an agricultural mechanic running his own business while Ger runs his own metal fabrication shop. In 2015, the brothers were approached by a neighbour to see if they could design a solution to replace the standard PTO shaft on his slurry tanker. The duo got to work.

What you see with the Safeshaft is what you get. The concept is to remove the PTO shaft, transferring the drive from the tractor’s PTO to the tanker’s pump.

Obviously, this is the most dangerous part of the slurry tanker, which is due to its high speed of rotation (nine revolutions per second) and close proximity to people.

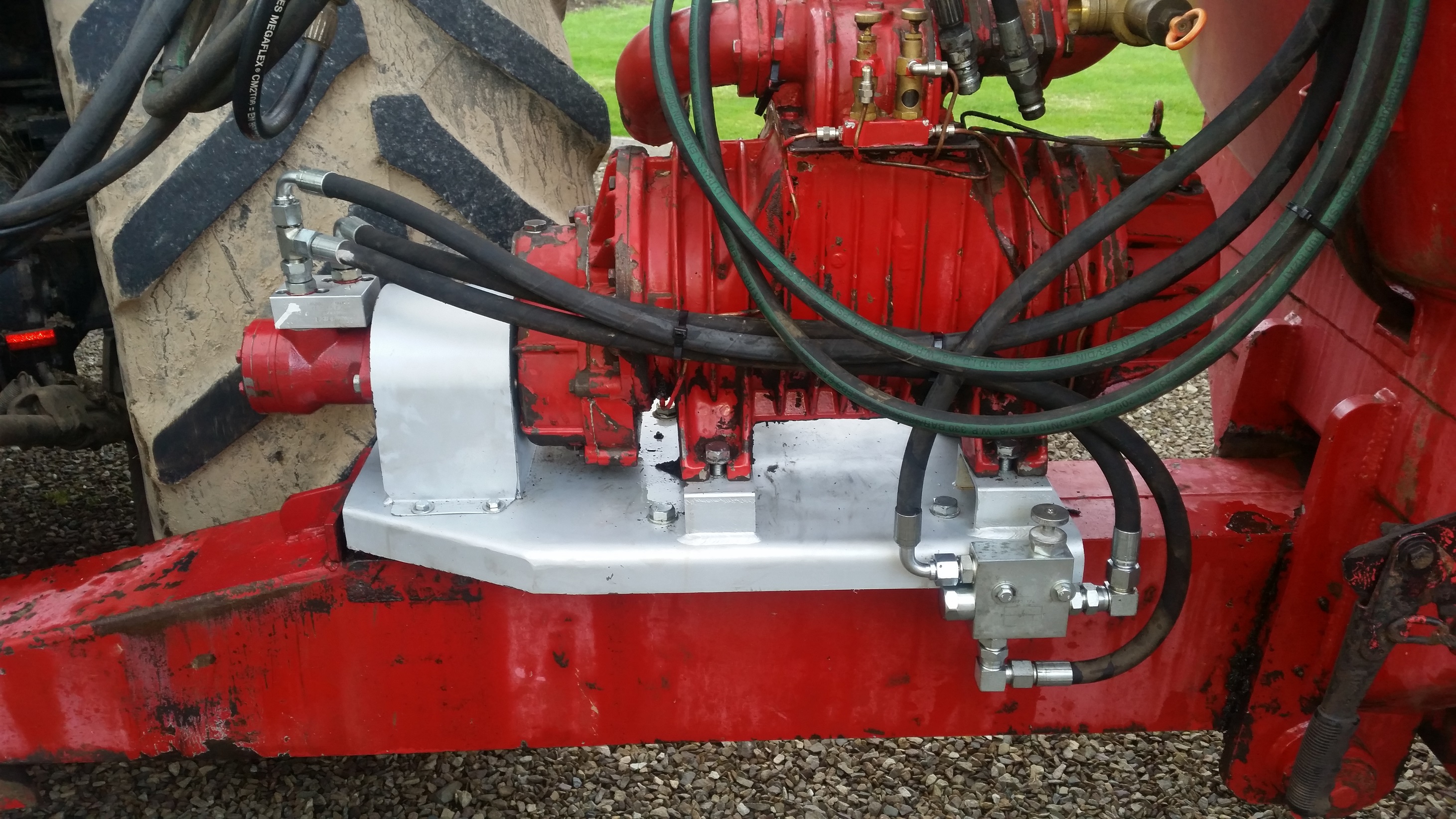

The Hickey brothers have fitted a hydraulic motor in place of the PTO shaft. This is powered by the tractor’s hydraulic system through a double-acting spool valve. The return line is fitted with a non-return valve to stop the pump being run in reverse accidentally. To allow the pump to start slowly and to prevent shock engagement and disengagement, an anti-cavitation block is fitted which alters the oil flow on start-up and stopping, making it smoother.

The power is transferred from the motor to the pump via a steel coupler with a shock absorber that can allow for up to 4° of misalignment and is fully guarded for safety.

Depending on the brand of slurry tanker and pump, the pump may need to be moved rearwards or mounted crossways so that the hydraulic motor is out of reach of the tractor’s lift arms.

1 For starters, the PTO shaft and PTO cover need to be removed. Next, the four bolts securing the vacuum pump to the tanker chassis need to be removed. Once these bolts are removed, the pump needs to be lifted upwards using a loader or similar.

2 Once there’s enough clearance, the new galvanised base plate specific to the particular pump needs to be slid into place and bolted down to the original mounting plate on the tanker’s chassis. Most base plates are also designed to be mounted crossways on the drawbar if desired. Either way, these bolts need to be tightened correctly.

3 The next step is to seat the pump in position on the new base plate. Fasten the bracket to the face of the pump using the holes in the bracket which correspond with the holes on the face of the pump previously used for mounting the PTO guard. Longer bolts than the previous PTO guard bolts may be needed.

4 Next up, the hydraulic motor and coupler needs to be placed on to the pump shaft and mounted to the front plate with the anti-cavitation valve facing upwards. Once the motor has been fastened to the front plate, square the vacuum pump up on the new base plate and fasten the pump via the four bolts.

5 When the pump and base plate is fastened, tighten the coupler’s hex bolts on both the vacuum pump and hydraulic motor side. At this stage the parking brake will need to be fitted which will involve drilling the base plate to suit the particular bracket.

6 Although the pipe work comes readymade, it needs to be plumbed. Where a hose arm is fitted, try to route the flow and return pipes so that they are alongside existing hydraulic hoses. If fitted with the shut-off valve, make sure pipe work is plumbed according to the diagram provided. It is essential that the one-way valve is fitted on the return line to prevent the pump being operated in reverse.

The manual shut-off lever is designed to stop the vacuum pump at ground level. Once engaged, oil is diverted back through the return causing the pump to cut out. When the spool has been re-engaged, the lever will automatically return to its working position.

Secondly, it cuts out the possibility of damaging an expensive wide-angle PTO shaft with the lift arms. This also means the tractor can turn tighter against the tanker’s drawbar.

The brothers currently have over 70 units to date working throughout Ireland and the UK. It’s worth noting that this design isn’t solely limited to slurry tankers, but can also be fitted to PTO powered implements which do not require huge amounts of power to drive. One such example is sprayers, which the Hickeys have a number of hydraulic drives fitted too.

The big question some readers will have is what is the hydraulic requirement, and will I have enough capacity to simultaneously run both the hydraulic pump and the macerator on a low-emission slurry spreading (LESS) system. According to the Hickeys, when filling the tanker, the system needs 28 l/min, while to spread it needs 20 l/min.

In terms of running a macerator, most will work on 30-35 l/min. This means total oil flow will be in the region of 50-60 l/min, which would be within the capability of the vast majority of tractors which are given the task of operating a tanker and LESS system.

The Hickeys explained that they cater for all tanker manufacturers, with kits on the shelf ready for delivery. Depending on the tanker, there are numerous options available to suit individual requirements, such as manual or electric flow control valves, in-cab speed display and in-line filters.

Depending on brand, a new standard shaft will cost in the region of €250-280 while a wide-angle shaft will cost somewhere in the region of €650. Most slurry tankers will require at least one replacement shaft throughout their lifetime.

Brothers Noel and Ger Hickey from County Waterford, Ireland, have designed a retrofit system for vacuum-type slurry tankers that swaps the pto drive for a hydraulic motor.

Installation involves bolting a 10mm thick baseplate between the existing vacuum pump and tanker chassis, before slotting in a hydraulic motor that provides the necessary rotational force required to replace the original mechanical pto drive.

Some clever hydraulic plumbing and valve work allow for a soft-start function to protect the vacuum pump and gearbox, and also avoid damaging the components by accidentally driving it in reverse.

8613371530291

8613371530291