solar hydraulic pump free sample

Explore a wide variety of solar hydraulic pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These solar hydraulic pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these solar hydraulic pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right solar hydraulic pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of solar hydraulic pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

![]()

The project assembles a deep well of 32 m, equipped with a solar lift system and a UV decontamination and sterilization plant to promote accessibility to drinkable water and contribute to the improvement of sanitation conditions in the area. Accessibility to primary services and infrastructure is absent, leading to the majority of the population drawing on contaminated water resources. 88% of the region’s inhabitants live in dwellings that dispose of household waste in the street, in the wild, or illegal dumps, while life expectancy is below the national average, with 2 out of 3 children being at risk of entering a stage of malnutrition resulting in mortality and morbidity. About 80% of children under 5 years old are at risk of contracting diarrhea, giardia, and cholera, also, due to the absence of vaccines and inaccessibility to medical care. The construction of the well is set to reduce 60-70% of diseases due to contaminated water, and as the structure becomes fully operational and sanitary conditions stabilize the project’s social impact will be greatly evident.

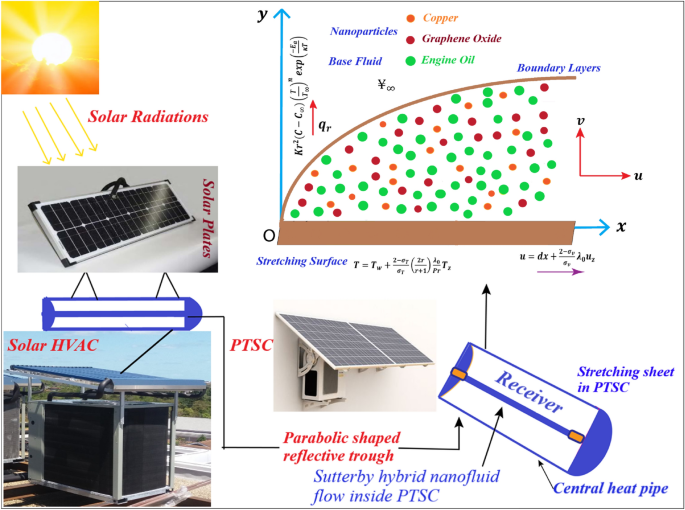

The deep well reaches the water table at a depth of up to 32 m after the excavation process with drilling machines. After protecting the site from erosion and collapses, cylinders are suitably arranged inside the ground pit in which the hydraulic pump descends. Inside the pit, a strong pressure for water extraction is then stimulated by the solar lifting pump. Due to the water pressure of the underground aquifer, the trench fills with water and will be recharged seasonally depending on the rainfall cycle. Much deeper than traditional wells, the infrastructure provides water less polluted with a lower amount of fixed residues. The well installs a submersible pump powered by solar energy through a photovoltaic station, equipped with solar panels and batteries allowing energy to be stored and reused at any time of the day. The station is regulated by a solar controller and inverter.

The hydraulic ram pump – commonly referred to as a hydram – pumps water from its source to a community. It utilises the natural power of falling or rapidly moving water, meaning the hydram requires zero external energy supply to operate. This process works on a principle called ‘water hammer’, where a large amount of quickly moving water is pushed through a small opening to create pressure. As pressure builds within the system it reaches a critical point that then lifts a fraction of the water flow. These smaller amounts of water are repeatedly lifted and ultimately collected in a storage tank placed above a community. The storage tank then feeds water back down to the community using gravity. A single hydram can lift water up to 200 vertical metres and supplies roughly 20,000 litres of water per day (enough to fill 250 baths) to a community.

Hydrams are particularly useful in remote mountainous regions where communities live high above their nearest water source. This allows people to save valuable time since they no longer have to go on faraway journeys to water sources via dangerous mountain paths. Most importantly, hydrams require a high-volume water source to operate effectively. This is because the hydram only lifts a small fraction – roughly 10% – of the water that flows through the pump. It therefore does not make sense to install a hydram at a small stream. In cases of lower-volume water sources, a SolarMUS system makes more sense!

Did you know that we have installed hydrams in 13 communities in Nepal? This means convenient, reliable water for more than 2,500 people. These pumps continue to lift more than 260,000 litres of water (the equivalent of filling 3,250 baths) per day. Families no longer spend hours fetching water. This means more time for business, school, and play.

– The pump is placed below a water source and connected to it with a pipe, called a drive pipe. Gravity feeds the water down the drive pipe to a chamber in the pump.

One of the more challenging aspects of developing pasture and grazing land is providing access to a reliable water supply for livestock. In some cases, existing streams, creeks, or ponds provide drinking water for the livestock. When a surface water source is not available, wells can be drilled and pumps installed to provide water for the animals. In some instances, surface water may be available, but not accessible to the livestock due to water quality issues, steep access slopes, or fencing issues.

Providing an electrical power source to such a location for a pump can be cost-prohibitive. Utilizing a pump powered by an internal combustion engine can require inspection and attention several times each day and regular fuel supply runs. Nose pumps and sling pumps may be used effectively in some of these situations, but these pumps will not work if the elevation difference between the water source and grazing area is greater than twenty feet. Solar-powered pumps are an excellent option but can be expensive depending on the flow rate and pressure needs of the system.

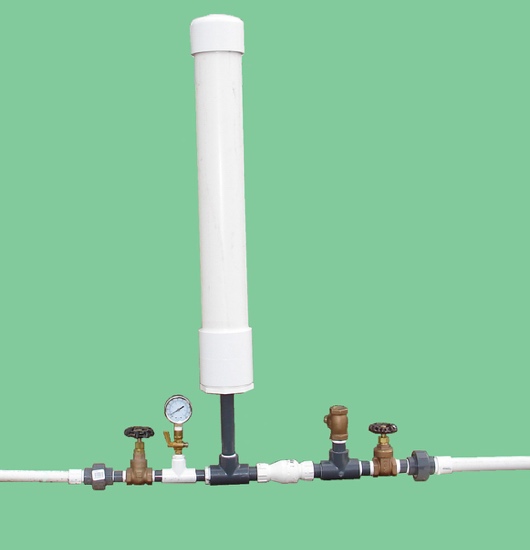

Figure 1. A 3/4-inch homemade hydraulic ram pump made with PVC fittings. Water flows from right to left during operation. Image credit: W. Bryan Smith, Clemson University.

One possible solution to providing livestock drinking water in remote locations is the hydraulic ram pump. The first development work of the hydraulic ram is reported to have been completed by John Whitehurst in 1772, with the first automatic version of the hydraulic ram developed by Joseph Montgolfier in 1796.1 Various companies in England and the United States have been producing cast-iron versions of the hydraulic ram since the early 1800s. Hydraulic ram pumps can lift water over a considerable elevation, and do not require any external power source.

Commercially sold hydraulic ram pumps last for decades but are quite expensive. A simple, homemade PVC (polyvinyl chloride) hydraulic ram pump (figure 1) may be constructed for $150 to $200 depending on material costs in your area and size of pump constructed. These homemade pumps will last for several years if not longer and can allow a farmer to see how such a pump would work before investing in a more expensive commercial unit.

Hydraulic ram pumps operate by utilizing pressure developed by a “water hammer” shock wave. Any object in motion has an inertial force. Energy is required to place the object in motion, and energy will also be required to stop the motion, with more energy being required if the motion is started or stopped quickly. A flow of water in a pipe also has inertia (or momentum) that resists sudden changes in velocity. Slowly closing a valve allows this inertia to dissipate over time, producing very little pressure increase in the pipe. Closing a valve very rapidly will create a pressure surge or shock wave as the flowing water stops, which moves back up the pipe – much like a train stopping, with individual train cars hitting the coupling in front of them in rapid succession as the brakes are applied. The more quickly the valve is closed, the larger the shock wave produced. A faster water flow will also produce a larger shock wave when a valve is closed, since more inertia or momentum is involved. A longer pipe will also produce a larger shock wave for the same reason.

A hydraulic ram relies on a non-pressurized flow of water in a pipe placed from the water source to the pump (called a “drive” pipe). This flow is produced by placing the hydraulic ram some distance below a water source and running the drive pipe from the water source to the pump. The hydraulic ram employs two check valves, which are the only moving parts in the pump.

Figure 6. Step 5: When the low-pressure wave reaches the drive pipe inlet, a normal pressure wave travels down the drive pipe to the valves. Normal water flow due to the elevation of the source water above the ram follows this pressure wave, and the next cycle begins. Image credit: W. Bryan Smith, Clemson University. The hydraulic ram pump cycle described in figures 2-6 may repeat from forty to ninety times per minute depending on elevation drop to the hydraulic ram pump, drive pipe length from the water source to the ram pump, and drive pipe material used. Image credit: W. Bryan Smith, Clemson University.

Figure 7. A typical hydraulic ram pump installation, with (a) drive pipe, (b) delivery pipe, and (c) hydraulic ram pump placement noted. Image credit: W. Bryan Smith, Clemson University.

In its simplest form, a hydraulic ram pump installation includes a drive pipe to bring water from the water source to the pump, the hydraulic ram pump, and a delivery pipe to take water from the pump to the water trough or site where water is needed (figure 7).

The drive pipe size determines the actual pump size and also determines the maximum flow rate that may be expected from the pump. Since the pump efficiency depends on capturing as much of the water hammer shock wave as possible, the best drive pipe material for a hydraulic ram pump installation is galvanized steel pipe. Most livestock producers use PVC pipe instead due to the lower cost and the difficulty in placing and assembling galvanized steel pipe. Hydraulic ram pump installations using a PVC drive pipe will work well, but the elasticity of the pipe will allow some of the water hammer shock wave to dissipate slightly with pipe wall expansion. If PVC pipe is used for the drive pipe installation, choose PVC piping with a thicker wall. Schedule 80 PVC pipe would be the better choice, with Schedule 40 PVC pipe being a secondary choice.

The best drive pipe installation would place the pipe on a constant slope from the water source to the hydraulic ram pump, with no bends or elbows, and anchor it with bolts and/or galvanized tie-downs to large rocks or concrete pads to prevent movement. This would allow the most efficient shock wave development. The Gravi-Chek Company suggests the optimum drive pipe slope is one foot of drop for every five feet of length, which corresponds to a 20% slope.2 However, this is not always practical in livestock water supply installations. The ram pump will work with piping that is not installed on a constant slope, as long as all piping slopes are either level or downward toward the pump (figure 8). There can be no “humps” or up-and-down installation points in the drive pipe, since this will allow air to be captured in the pipe, which will allow shock wave dissipation.

Figure 8. A PVC drive pipe placed in a stream bed. Galvanized steel was not an option due to the bed topography and geometry. The hydraulic ram pump worked well, but each bend allowed a tiny portion of the shock wave to dissipate. A straight, galvanized steel pipe would have captured a larger shock wave and provided more pressure. Image credit: W. Bryan Smith, Clemson University.

If a choice must be made between installing the drive pipe on a constant slope and using a more rigid drive pipe (such as galvanized steel), choose the more rigid drive pipe. This will have a larger impact on pump performance than the drive pipe slope.

There is a range of allowable drive pipe lengths for each pipe size used. If the drive pipe is too short or too long the pressure wave that allows the pump to cycle will not develop properly.

The publication Hydraulic Rams for Off-Stream Livestock Watering gives the following equations developed by N. G. Calvert for minimum and maximum drive pipe length.3

Rife Ram Company literature offers a different method of drive pipe length selection.4 The Rife method does not consider pipe size but is based solely on vertical elevation drop or fall from the water source to the hydraulic ram pump. Values are presented in table 2.

Figure 9. A hydraulic ram pump installation with a (a) standpipe and (b) supply pipe to allow a longer piping solution from water source to ram pump location. Image credit: W. Bryan Smith, Clemson University.

The Rife recommendations in table 2 maintain a given pipe slope for each range of elevation falls. Either method (table 1 or table 2) may be used to determine mainline length; satisfying both methods may provide the best ram pump performance.

There are installation solutions if the maximum drive pipe length allowed is not long enough to reach the water source from the hydraulic ram pump placement. One option is to install a “standpipe” at the maximum drive pipe distance from the ram pump (figure 9). This standpipe should be three pipe sizes larger than the drive pipe and should be open at the top to allow the water hammer shock wave to dissipate at that point. The standpipe should be installed vertically, with the top of the standpipe a foot or so above the level of the water source. Supply piping, which should be at least one pipe size larger than the drive pipe, is then run from that point to the water source.

Figure 10. Use of a carpenter’s level and a measuring stick to determine elevation drop from the water source to the proposed hydraulic ram pump location. Image credit: W. Bryan Smith, Clemson University.

Hydraulic ram pumps operate based on an amount of elevation drop or fall from the water source to the site where the ram pump is placed. The amount of drop will determine the performance of the ram pump. The amount of drop or fall available at a given location can be measured using a measuring stick and a carpenter’s level. Start at the site where the hydraulic ram pump will be placed. Hold the measuring stick vertically, placing one end on the ground. Place the carpenter’s level on the measuring stick, holding it level, with the top even with the top of the measuring stick. Look along the top of the carpenter’s level at the slope going up to the water supply, and sighting along the top of the level, pick a spot on the slope (figure 10). That point is the height of the measuring stick above the starting point. Move to that spot and repeat the sighting process, continuing up the slope after each sighting until the water supply is reached. Count the number of times the measuring stick was placed on the ground, multiply that number by the measuring stick’s length, add any partial stick measurement for the last sighting (see figure 10), and the result will be the elevation drop or fall from the water source to the ram pump location.

Hydraulic ram pumps are very inefficient, generally pumping only one gallon of water for every eight gallons of water passing through the ram. They will, however, pump water up ten feet (or more in some cases) of vertical elevation for every foot of elevation drop from the water source to the hydraulic ram. For instance, if there is an elevation drop of seven feet from the water source to the hydraulic ram, the user can expect the hydraulic ram to pump water up to seventy feet or more in vertical elevation above the ram. Higher delivery elevations do decrease the pump flow – the higher the elevation difference between the hydraulic ram and the delivery pipe outlet, the smaller the delivered water flow will be.

In this equation, Q is the available drive flow in gallons per minute, F is the fall in feet from the water source to the ram, E is the elevation from the ram to the water outlet, and D is the flow rate of the delivery water in gallons per minute. 0.6 is an efficiency factor and may differ somewhat between various ram pumps. For example, if a flow rate of twelve gallons per minute is available to operate a ram pump (Q), the pump is placed six feet below the water source (F), and the water will be pumped up an elevation of twenty feet to the outlet point (E), the amount of water that may be pumped with an appropriately-sized ram pump is:

The same pump with the same drive flow will provide less flow if the water is to be pumped up a higher elevation. For instance, using the data in the previous example but increasing the elevation lift to forty feet (E):

The pump inflow rate, Q, will always be determined by the drive pipe size, drive pipe length, and the elevation of the water source above the hydraulic ram.

Table 3 uses the Rife equation to list some flow rate ranges for various sizes of hydraulic ram pump based on the friction loss found in Schedule 40 PVC pipe. The pump flow ranges in the chart are based on a fall (F) of five feet of elevation and an elevation lift (E) of twenty-five feet. Changing the values of E or F will change the expected performance of the ram pump.

Some of the delivery flow rates listed in table 3 are quite small, but even the 3/4-inch ram pump will deliver a considerable amount of water over time. Hydraulic ram pumps operate twenty-four hours per day, seven days per week, so even at the minimum pump inflow the 3/4-inch ram pump will provide (0.10 gpm x 60 minutes x 24 hours =) 144 gallons of water per day, which would supply the daily water need of four to five 1,200 pound cattle.

If more flow is desired, either a larger hydraulic ram may be used, or another hydraulic ram may be installed with a separate drive pipe, and then plumbed into the same delivery pipe to the water trough as long as there is sufficient water flow in the water source to supply this demand.

Figure 11. A schematic diagram for homemade hydraulic ram pump Design 1. Table 4 contains item descriptions. Image credit: W. Bryan Smith, Clemson University.

There are a number of designs for a homemade hydraulic ram. The University of Warwick has some excellent designs developed for use in developing countries where standard plumbing parts may not be readily available.5

This publication will address two similar designs. The first design was developed by Mark Risse of the University of Georgia and was presented by Frank Henning in University of Georgia Extension Service publications #ENG98-0023 and #ENG98-003.6 Figure 11 provides a schematic of the design, and table 4 provides a parts list for a 1 1/4-inch hydraulic ram pump.

This is a very simple design that only requires assembly of basic plumbing fittings. The air chamber (#14–16) acts like a pressure tank for a well, using compressible air captured in the tank to buffer shock waves and provide a steady outlet pressure. The air initially captured in this air chamber, however, will be absorbed by the water flowing through the pump over time. When this happens there will be a much more pronounced shock to the pump and piping during each cycle (this condition is described as a water-logged pump), and material fatigue and failure will follow. In order to keep air in the chamber over time, a bicycle or scooter inner tube may be filled with air until it feels “springy” or “spongy,” and then folded and inserted into the pressure chamber before the cap (#16) is glued on to the pipe. This will retain air in the chamber and prevent pump failure.

Fittings 1–4 in the diagram must be the same size as the drive pipe in order for the pump to work properly. The spring-loaded check valve (#5) and the pipe nipple (#12) should also be the same size as the drive pipe, but the pump should work if they are reduced to the same size as the delivery pipe.

Figure 12. A brass swing check valve. Note the free-swinging flapper in the outlet port. The swing check valve should be placed vertically for best pump performance. Image credit: W. Bryan Smith, Clemson University.

Valve #1 in figure 11 is used to stop or allow flow to the pump and can be used to turn off water flow if the pump needs to be removed or serviced. Valve #7 is turned off while the pump is started, then gradually opened to allow water to flow after the pump is operating. The pump will operate for thirty seconds or more with this valve completely closed, and if the valve is left in the closed position the pump will reach some maximum pressure and stop operating. The ram pump requires approximately 10 psi of back pressure to operate, so if the delivery pipe outlet is not at least twenty-three feet above the ram pump, valve #7 can be used to throttle the flow and maintain the required back pressure.

The pressure gauge (#11) is used to determine when valve #7 may be opened during pump start-up and can be used to determine how much valve #7 should be closed during normal operation if throttling is needed. The pipe cock (#10) is optional but can be turned off to protect the gauge from failure over time due to repeated pulses.

The air chamber size is dictated by the expected flow rate of the hydraulic ram pump. University or Warwick documentation suggests the optimum pressure chamber volume is twenty to fifty times the expected volume of water delivery per cycle of the pump.5 Table 5 provides some minimum lengths of piping required for a pressure chamber based on this information. The table is based on a hydraulic ram that will operate sixty pulses or cycles per minute.

The second design presented in figure 13 is one commonly found on the internet in YouTube videos.7 It is very similar to the first design, but this design incorporates a homemade “snifter” valve that allows a small amount of air to be added to the air chamber with each pumping cycle, which eliminates the need for an inner tube in the air chamber.

Figure 13. A schematic diagram for homemade hydraulic ram pump Design 2 with air snifter. Tables 4 and 6 contain item descriptions. Image credit: W. Bryan Smith, Clemson University.

The size of the snifter hole is critical to pump operation. The University of Warwick has an extensive discussion concerning this property in their hydraulic ram pump documentation.5 Their information suggests drilling a 1/16-inch hole and increasing the size slightly if necessary. A 1/8-inch snifter hole or smaller with an appropriately sized cotter pin inserted may be a good option instead as a starting point. If the hydraulic ram should become waterlogged, a slightly larger snifter hole may be needed.

The advantage of this design is that if the snifter hole is sized correctly, the pump should never become waterlogged due to a leaking inner tube in the air chamber. The disadvantages are the trial-and-error approach to obtaining the correct hole size, the need for additional support for the pump’s increased vertical height, and the possibility that the snifter hole, being very small, may freeze over and close in cold weather.

Figure 14. A 3/4-inch hydraulic ram pump (Design 1) in operation. The image was taken just at waste valve closure. The concrete block is in place to support the air chamber. Image credit: W. Bryan Smith, Clemson University.

Both pump designs are started using the same steps. Attach the assembled ram pump to the drive pipe, close valve #7, then open valve #1 to allow water flow. The waste valve (#4) will almost immediately forcefully close. The flapper in the waste valve must be pushed down manually a number of times to initially start automatic pump operation. This process purges air from the system and builds up the pressure in the air chamber required for the pump to operate. Pressing the flapper down twenty to thirty times is expected to start a ram pump. If the pump does not start operating after pressing the flapper down more than seventy times, there is an issue somewhere in the system. The flapper on a smaller pump (1/2-inch, 3/4-inch, etc.) can be pressed down with a thumb fairly easily, but larger pumps may require the use of a metal rod of some type to push the flapper down, especially if there is considerable elevation drop between the water source and the hydraulic ram pump.

After the pump has started operating (figure 14), gradually open valve #7 to allow water to flow uphill to the water trough. The pump must have 10 psi or more back pressure to operate, so gradually open valve #7 while watching the gauge to maintain 10 psi of back pressure. Pressure will build as the water fills the delivery pipe as it is pumped uphill.

The pump will operate continuously after starting as long as water flows freely to the pump and is flowing out of the delivery pipe. If water flow is stopped at the water trough, the ram will pump up to some maximum pressure and stop, and then must be manually restarted. The pump will not restart itself. This means that if water is supplied to a single water trough, a float valve cannot be used. Some provision must be made to drain overflow away from the trough after it fills, since the water must flow continuously for the pump to remain in operation. A simple gravel-filled trench or another method may be used to direct the excess water away from the water trough.

Since water continuously flows out of the pump’s waste valve, some consideration must also be given to water drainage at the pump site. If the pump is placed near a stream downstream of a pool or other water source, this will not be an issue. If, however, it is placed on dry ground away from the water source, drainage must be considered.

There are no restrictions on the size or type of delivery pipe used beyond normal piping design practice. Galvanized steel pipe, PVC pipe, rubber hose, or a simple garden hose may be used to deliver water to the water trough, provided it is sized to deliver the anticipated flow rate. Some ram pump installation guidelines indicate the delivery pipe should be one half the size of the drive pipe, but this has no bearing on the pump performance. The delivery pipe should be sized based on flow rate and friction loss.

Table 7 provides some maximum recommended flow rates for various pipe sizes. These flow rates are based on a maximum flow velocity of five feet per second in the delivery pipe, which will help prevent water hammer development in the delivery pipe. Smaller flows than those listed will allow the water to be piped longer distances or to higher elevations within reason, since less pressure will be lost to pipe friction. Pipe friction loss charts for the appropriate pipe material used may be utilized to determine the actual friction loss for a given installation.8 Larger delivery pipes will reduce friction losses but will also increase costs. Smaller delivery pipes will cost less but can decrease the ram pump flow rate. If friction losses are not calculated, use half the allowable flow rates (or less) listed in table 7 to select a delivery pipe size.

Water will run continuously through a hydraulic ram pump since the pump runs constantly. If the water source for the pump is a shallow pool in a flowing stream or creek this will not be an issue, since water flows continuously in those water bodies. There may be a problem, though, if a small pond is used as a water source for a hydraulic ram pump.

For example, say that a farmer decides to use a small, 1/2-acre pond to supply a hydraulic ram. The pond history shows that it seems to stay fairly full except during times of severe drought. The farmer wants a flow rate of 1 gpm (gallons per minute) to his livestock water trough, and therefore places a 1 1/2-inch hydraulic ram pump behind the pond. The ram pump requires a flow of approximately 9 gpm to produce the desired 1 gpm flow to the water trough.

The ram pump runs twenty-four hours per day, seven days per week, withdrawing 9 gpm from the pond. This flow rate will remove (9 gpm x 60 minutes x 24 hours =) 12,960 gallons of water per day from the pond. That is the equivalent of approximately one inch of water removed from the pond each day. If the stream or spring that fed the pond was just adequate to keep the pond full before the ram pump was installed, the pond water level will begin to fall one inch each day. Over a month’s time the pond level could fall as much as thirty inches.

There are methods described in the next section that allow the use of a hydraulic ram pump using a pond as a water source without breaching the dam. The farmer, though, must first determine if the springs or streams supplying the pond will be adequate to maintain the pond’s water level before installing a ram pump. This may prevent draining a good pond to non-useable levels.

If a hydraulic ram pump is installed behind a pond dam, the farmer should also consider drainage requirements to remove the expelled drive water from behind the pond. This will prevent the development of a wet area or possible soil erosion over time.

Some type of siphon assembly may be used to draw water from a pond and deliver it over the dam to a hydraulic ram pump. However, this siphon cannot be directly connected to the drive pipe without some provision for pressure and siphon release. The siphon will interfere with the development of the pressure wave in the drive pipe. If a siphon is used, the water may be delivered by the siphon pipe to a trough or barrel open to the atmosphere behind the pond dam, with a ram drive pipe plumbed directly into the trough or barrel. This will prevent the siphon action from affecting pressure wave development.

There are only two moving parts in the home-made hydraulic ram pump – the waste valve and the spring-loaded check valve (#4 and #5 in figures 11 and 13). Over time one or both of these valves may fail simply due to wear. The wear will be more extensive in rams utilizing sandy or silty water, and in rams that have a more rapid cycle time. Farmer reports indicate that home-made hydraulic ram check valves seem to last between three months and two years depending on these two factors. The two unions in the figures 11 and 13 (#1 and #8) are there to allow pump removal for maintenance if needed.

If there is detritus in the water source and an inlet screen is not used, there may be an issue with a small stick or twig becoming caught between the waste valve flapper and the valve seal, preventing proper valve closure. In some cases, this might make it miss a cycle and then the stick may be flushed away, but in other cases the stick may become lodged. If the hydraulic ran pump is the only source of water for your livestock it should be checked daily – in most cases the farmer can simply drive near the site, roll down a window (or turn the tractor off), and listen for the regular “click” to confirm the pump is operating. The best inspection is always to visit the operating pump, but a second option is simply to visit the water trough to make sure water is flowing.

If a ram pump is used during winter months, care should be taken to insulate as much of the pump and above ground piping as possible. The constant flow of water through the pump should help prevent freezing, but ice may still build up around the waste valve outlet in colder temperatures and might stop the pump. If Design 2 is used, inspection of the snifter hole is a must in cold weather to ensure it has not frozen closed.

If a hydraulic ram pump is installed in or near a small stream bed, care should be taken to make sure the pump is anchored sufficiently to a concrete pad or other heavy, non-moveable items to prevent loss during a major storm event. Some type of shield or shelter from branches or other detritus flowing downstream during such an event should also be considered. A better placement would be to position the ram pump on dry ground near the stream, but out of the potential flood plain for average storm events, with drainage provisions for the waste or drive water to return to the stream.

There are two methods that may be used to “tune” or adjust a hydraulic ram pump to increase or decrease pump pressure and flow rate. The first tuning method is to simply change the position of the waste valve (#4 in figures 11 and 13). This valve should normally be placed vertically for best pump performance. If the grower desires to lower the pressure, the tee the valve is attached to (#2 in figures 11 and 13) may be rotated slightly to one side, which will allow the waste valve flapper to drop slightly into the valve body. The valve body should be oriented as shown in figure 12 to allow the flapper to descend into the water flow path. Rotating the valve slightly will allow the flapper to close at a slower water velocity, which will create a smaller water hammer shock wave and result in a lower pump pressure. Rotating the valve too far, as illustrated in figure 12, will cause the pump to stop operating, since the water velocity in the drive pipe will be too slow when the valve closes to create a useful water hammer shock wave.

The second tuning method can be used to increase the pressure developed by the ram pump, and in doing so increase the flow rate. The waste valve flapper (shown in figure 12) will close when a certain water velocity is reached in the pipe. The weight of the valve flapper determines the water velocity needed to close the flapper. If weight is added to the flapper, a higher water velocity will be necessary to close the flapper. The University of Warwick’s “How Ram Pumps Work” publication provides a detailed description on flapper weights and closing water velocities.9

Common methods of increasing flapper weight include using screws or epoxy to attach washers or other small weights to the flapper. Care must be exercised to attach weights so that they remain firmly attached and they do not interfere with normal valve closure. The grower must also consider how much pressure may be obtained by tuning the pump in this manner. It is possible to increase the water velocity in the pipe to where the increased water hammer shock wave may cause actual damage to the piping or the pump.

The Ram will not start: (a) In most cases this is due to the fact that the correct size check valve for the waste valve was not installed. That valve and tee must be the same size as the drive pipe. Using a PVC check valve or a metal check valve that is spring-loaded instead of a free-swinging check valve will also cause this issue; (b) Another problem could be a lack of elevation difference between the ram pump and the water source. While some commercially made ram pumps will operate with as little as twenty inches of elevation fall, these home-made units are less efficient and require approximately five feet of vertical elevation drop to operate dependably; (c) the air has not been purged from the system. Pushing the waste valve flapper down twenty to fifty times is normal to start a hydraulic ram pump; (d) a flexible hose was used for the drive pipe. The drive pipe must be made of a rigid material.

The ram pumps for a few cycles and stops: (a)This is usually due to a drive pipe that is too long or too short for the hydraulic ram pump size. A drive pipe that is too long or too short can interfere with or prevent the development of the shock wave pulse in the pipe; (b) valve #7 on the outlet side of the pump is not closed when starting the pump. This valve must be closed during start up for the pump to develop some back pressure and start operating.

We tested it with a garden hose, but it would not start. Sliding a garden hose inside the drive pipe to supply water to test the ram will partially pressurize the water in that pipe, which will interfere with the water hammer shock wave and keep the waste valve closed. The best way to test a hydraulic ram pump is to plumb the drive pipe to the bottom of an open bucket and keep the bucket filled with water from the garden hose. The bucket should be a minimum of five feet in elevation above the ram.

Henning F, Risse M, Segars W. Hydraulic rams for off-stream livestock watering. Agricultural Engineering Department, University of Georgia. 1998; ENG98-002.

School of Engineering. Technical release: TR12 – DTU P90 hydraulic ram pump. Design technical unit (DTU) ram pump programme. Coventry (UK): University of Warwick. [updated 2008 July 25; accessed 2019 July]. https://warwick.ac.uk/fac/sci/eng/research/grouplist/structural/dtu/pubs/tr/lift/rptr12.

Henning F, Risse M, Segars W, Calvert V, Garner J. Hydraulic ram made from standard plumbing parts. Agricultural Engineering Department, University of Georgia. 1998; ENG98-003.

School of Engineering. Technical release: TR15 – How ram pumps work. Coventry (UK): University of Warwick. [updated 2008 July 25; accessed 2019 July]. https://warwick.ac.uk/fac/sci/eng/research/grouplist/structural/dtu/pubs/tr/lift/rptr15.

Sound crazy or impossible? Don"t worry, it does obey the laws of physics, but I"ll try to explain the operation later. This instructable shows how to build a fairly simple water pump that needs no energy input other than water flowing from a higher point to a lower point. Most of the pump is constructed from PVC, with a couple of bronze pieces thrown in for flavor. I was able to source all of the parts from a local hardware store (Lowes) for a bit under $100.

To function, the pump does require a reasonable amount of water that will drop at least 3"-5". The level that the pump can raise water to depends on the water"s head (total drop the water will make).

Old Bicycle InnertubeThis parts list comes directly from the Clemson website. I recommend you look there for help in identifying what each of the pieces look like, if you"re unsure. I"m also not convinced that the 100 PSI gauge, or all of the things that make it possible, are necessary. This will probably drop the price a good bit, and I haven"t found a need for it on my pump. The associated pieces are: 100 PSI gauge, 3/4" Tee, 3/4" x 1/4" bushing, the 1/4" pipe cock. Four things not needed. But have them if you like.

Now that you"ve bought lots of goodies, lay them out on the table (or floor) so that you can start to see how the pump goes together. See the pictures for a visual on this.

While you"re at it, you might as well clean up the edges on the other sections of pipe, though it will be less critical for the other parts. Now that you"ve got all the connecting segments, you can actually test fit the first part of the pump together, just for fun.

Once you"ve got cement where you want it (and hopefully only a little where you don"t) fit the pipe into the fitting. It should slide in without too much resistance. When working on my pump, I felt that it was best to clamp up each piece after I had assembled it, that way the pipe couldn"t slip back at all. It may not be necessary, but I figure it helps.

I began at one end of the pump, with the 1-1/4" valve to the 1-1/4" union. You can choose to start with other pieces, but I found that setting up the main line gave me something easy to clamp up. After the 1-1/4" to 3/4" bushing is on this tee, you can glue up the end assembly separately, and then connect it to the main assembly with the threaded 3/4" pipe.

Now you need to put together the pressure chamber. Gather up your big pipe section, cap, adapter, bike tube, and bike pump. Using the pump, partially inflate the bike tube. Don"t pump it up all the way, just enough that the tube is squishy. We need the air in the pressure chamber to act like a spring.

Some may choose to omit the bike tube, and just drain the pump out every once in a while. That"s totally possible. It"s also possible to either mount a schrader valve onto the end cap of the pressure chamber to recharge it. Whatever suits your fancy, but this setup worked fine for me so far.

If you haven"t done it already, install the brass swing check valve. Make sure that the flapper (I just like calling it that) is hanging down, when the pump is held upright (everything pointing upwards). The whole thing should just thread onto the bushing that you"ve cemented to the end of a 1-1/4" pipe. Simple enough.

After that, you may break out the flapper dress, cut your hair short, and swing dance the night away celebrating the reckless spirit of the Jazz Age (and completion of your pump). You party animal you.

Now that you"ve got a rather aggressive looking collection of PVC bits, it"s time to make it do something. You"ll need to attach the stand pipe (the long section of 1-1/4" pipe) to the 1-1/4" union with cement, and then decide how you want to hook the other end to your water source. My first method was a chopped up milk jug. Honestly, I just wanted to see this thing pump some water.

Gather up a garden hose, your stand pipe, and your pump, then drag all of this out to your waterfall or what have you. Bring a friend or two. They help in the setup, and maybe you can win the bet that "you can pump water above the source without electricity, gasoline, diesel, a bicycle, or a bucket while they watch."

At this point you can probably figure it all out on your own, but you"ll need to get the water flowing down the stand pipe, which you"ve connected to the main pump, and then up through the swing check valve. On to the next step for theory of operation, troubleshooting and tuning.

When you install this permanently (or semi-permanently), you"ll want to find a good place to anchor it to, probably not in the stream. Place it as low as possible, but keep in mind that if the stream were to flood and / or a tree to wash down it, it would take your nice little pump off with it.

Also, for those in the northern (or far southern) latitudes, you won"t want this to be running during the winter. Water could potentially collect inside the pressure chamber and freeze, causing you problems (untimely death of pump). But experiment as you feel fit.

The video here is playable using Quicktime. Presently, you have to save it to your computer, and change the extension (bit after the long strange file name) from .tmp to .3gp. I"m sorry it"s being difficult, maybe someday I"ll set it up with an embedded player, but right now I"m short on time. It shows the pump working, with narration by yours truly. Gives you an idea of what it sounds like standing in the water right next to it, and also has a close up of the swing check valve working.

As the pump cycle begins, water flows down the stand pipe, and up through the swing check valve. Water begins to flow faster and faster around the flapper in the check valve, until friction draws the flapper up, slamming it closed. This causes a pressure spike in the pump body, as the water flowing down the stand pipe at some speed no longer has anywhere to go. This pressure is relieved by some of the water flowing across the spring check valve, over onto the pressure chamber side of the pump. Once past the swing check valve, it cannot return, and has to stay there. When the pressure difference across the spring check valve drops, the valve will close and water will stop flowing through it. The lower pressure will allow the swing check valve to open again, beginning the cycle all over again.

Sometimes water will flow out of the swing check valve, then the valve will slam closed, but nothing will happen. If this occurs, tap on the flapper in the check valve to open it up again, and let the cycle begin again. In theory these pumps need some back pressure (coming from the pressure tank side) to operate, but I"ve never had any trouble getting mine going with just some basic tapping and fiddling.

Now that it"s working, can you make it work better? You"ll find that there"s a maximum height that the pump can deliver water to. Be patient when trying to find this, as it takes a little while for the pump to achieve the pressure required to raise the water up higher and higher. There are formulas that will tell you how high you can theoretically pump water based on the source water head. Feel free to look them up.

Tuning ram pumps mostly involves varying the water velocity that results in the swing check valve closing. A higher water velocity will generate a larger pressure spike, allowing you to pump to greater heights. But it will also cause a slower cycle, so you pump more slowly. If the valve closes at a lower water velocity, it will take less time for the water to reach that velocity, so the pump will cycle faster, and the water pumped faster, but you will not be able to pump as high. So that"s the trade off. Keep in mind though, that this will work without interference 24 hours a day, so combining it with a holding tank, you can get a decent supply of water built up.

To tune this specific design, you take advantage of how gravity acts on the flapper. When the check valve is pointing straight up in the air, the full force of gravity holds the flapper down, so the water must flow past the flapper faster to generate enough drag to raise the full weight of the flapper. By rotating the pump about the main line, you put the flapper"s degree of freedom at an angle to the force of gravity, so that less drag is required to move the flapper. You could work out all of this fairly easily with a bit of trig, but I feel it would serve you little use out in the field. Just play around with it, you should find a position that works well for your application.

Well, no. This pump derives its power from the potential energy of the water uphill, and by wasting (not in a bad sense) the majority of the water that flows through the stand pipe. It only pumps a small fraction of the water that actually travels down that pipe. But that"s fine if you have a stream already flowing down a hillside. Before, you weren"t doing anything with all that potential / kinetic energy. Now you are. Hooray for you!

Hi Guys Can any one tell me what the sizes are when I make a 40mm (1./12") ram pump. mainly the size of the pressure chamber and how long. A complete list would be appreciated.0

The power for a ram pump comes from the head pressure, how far the water drops before reaching the pump. The flow of a stream, unless it can lift water up a pipe won"t be sufficient; however, a dam can be constructed if you can"t find or make a spot lower than the water level in the stream. Ponds and lakes typically have dams (natural or man-made). Below the dam is the best place for the pump. If you can put the drive pipe through the dam this would be ideal, otherwise, getting the water to flow over the dam is as simple as drawing water through the drive pipe until it is below the level of the water held back by the dam using a process known as siphoning. Yes, sometimes your mouth is the best tool to draw the water through the pipe, just be ready to get a mouthful of water (and possibly muck or scum).

The lift of a ram pump is 6 times the head pressure, so if the feed water drops 1 unit (feet, meters, whatever) it can be pumped uphill 5 units above the level of the feed source.0

I have a small creek behind my house and want to know if this 1 1/4” ram pump will be large enough to furnish enough water to supply a small waterfall?0

you need to use a actual spring check valve. A low pressure spring will suffice. if what im seeing in the photo is correct the swing check that is being used will only give you grief. they are designed for a horizontal install with the "flapper" always hanging down. A spring check will make sure you have the back pressure to close the valve when needed so your pump is able to work its magic. good luck everyone. I hope this helps. If I have repeated anyone please forgive me, i caught this in passing. these pumps are great. thanks for sharing the build1

My guess - You probably don"t have enough back pressure. Either you need much faster moving water, or you need a larger diameter hose feeding the pump. If you take a look at this similar ram pump, it says it requires 8 gpm and a 1-1/4" prive pipe.0

Hi further to my previous comment my husband ha finished making the ram pump. He made a few minor adjustments and it is working like a dream. It hasn"t missed a beat. We installed anew 11,200 litre water tank and it filled it in just over 4 days. Your instructions and photos are invaluable and anyone that has the means to utilise water in this way, don"t hesitate. It puts us another step closer in self sufficiency. Great work and thank you for sharing.

Thank you for sharing your amazing ram pump. Very impressed. We are using a Billabong brand which is Australian made. Having a few issues so we are going to give yours ago. Off to Bunnings tomorrow to get some fittings. They are an amazing concept and they sound good also. Thanks again0

The spiral pump (also known as water wheel pump) is a hydraulic machine that pumps water without electricity. With the global efforts toreduce carbon emissions, the increased focus on renewable energy is making the spiral pump a viable option for pumping water, especially in rural areas and developing countries. Simple installation and low maintenance costs make the spiral pump a favorable, environmentally-friendly alternative.

A spiral pump is constituted of a pipe wrapped around a horizontal axle, generating a spiral tube that is fastened to a water wheel. The water wheel is in flowing water, so that the water in the river provides the energy necessary for the rotation of the wheel. Hence, the spiral tube also rotates. When the inlet surface of the tube (the tube’s external extremity) passes into the river, water enters into the tube. This water volume moves toward the outlet of the tube (the internal extremity), at the center of the wheel, where a straight tube is connected to the end-user.

Several water columns are generated inside the spiral tube, separated from each other by columns of compressed air trapped between the water columns. These columns of compressed air push against the water columns, so that at the outlet (the center of the wheel) the water achieves energy and velocity. In this way, it can be pumped at a higher elevation or at a certain distance from the river.

The possible users are irrigation consortia and civil people, in both developing and developed countries, especially for drip irrigation and partially for drinking water in developing nations. The largest application of the pump, and in general of water withdrawal, is irrigation. Although there have been past attempts to build such pumps in an artisanal way, aQystadeveloped a patent that allows to manufacturer this pump cost-effectively and as a commercial product. aQysta says that spiral pumps are able to pump to a maximum height of at least 20 meters and a maximum flow rate of at least 43.6 m3/day. As of October 2016, aQysta installed over 40 pumps worldwide in countries like Nepal, Indonesia, Turkey, Zambia and Spain.

Spiral pumps work without fuel or electricity, since the needed energy is supplied by flowing water (preferably a flow velocity faster than 1 m/s). The spiral pump saves up to 70% of overall lifetime costs compared to diesel pumping. The spiral pump requires no operation costs and it is environmentally friendly.

Therefore, spiral pumps can represent an interesting technology, especially for irrigation. This is the motivation that has encouraged Politecnico di Torino (Polytechnic University of Turin, Italy) and Southampton University (UK) to start scientific research on spiral pumps, in collaboration with the industry.

Emanuele Quaranta is project officer (scientific research) at the Joint Research Center of the European Commission (Water Directorate), while previously was post Ph.D. researcher at Politecnico di Torino (Turin, Italy) in hydraulic engineering, hydropower (expert in water wheels), eco-hydraulics (focus on fish passages) and fluid mechanics (CFD simulations). Emanuele was hydropower expert for European Commission in 2017.

Such a system is an unregulated system as the power output from the modules changes due to change in the sunshine hours and no backup battery arrangement is made to supply energy demand during night-time operation. Such a system is more suitable for domestic applications such as pumping of water using a DC motor water pump.

As stated, such a system can be used for pumping of water especially in the application of irrigation. If we need water at night, then we can use the stored energy in the battery to pump the water during night time. But as we know that batteries can only be charged during the day sun-shine hours.

So why should we charge batteries if we can utilize that available solar energy to pump the water right away during sunshine hours? On the other hand, we know that batteries are not cheap and would also require a power electronics circuit like a charge controller which would add to the cost. So, by utilizing the available solar energy right away during sunshine hours to pump the water we can eliminate the cost and space required for the battery and charge controller in this standalone application.

The design of such a system is very simple as we have to match the power and voltage rating of the PV module to that of the DC pump motor so when the module receives the solar radiation the pump will draw the water and store it in the tank. Such a system can also be designed for an AC motor of different power ratings which is available in the market.

But the AC motor pump will require an inverter (DC – AC) circuit to invert the DC power generated by the PV module into AC power to run the motor. Also, the inverter power rating should be properly matched with that of the AC motor and PV module.

Now before we begin with the design of the system for water pumping it is important to understand some terms which are closely related to design such a standalone system.

Total Dynamic Head (TDH) (meters): This is the most important parameter for the design of the pumping system. It is the effective pressure at which the water pump must operate and it is measured in meters. It has two sub-parameters first one is the total vertical lift and the other one is the total frictional losses. Now further, the total vertical lift is the summation of three parameters shown in figure 3 below as; elevation, standing water level, and Drawdown.

Frictional losses (meters): This is the pressure that is required to overcome the friction in the pipe present between the water pump outlet to the point of water exit. It is added in the total vertical height to obtain the value of Total Dynamic Head (TDH) and is measured in meters. Multiple factors contribute to the cause of the frictional losses such as the size of the pipe, type of fittings, air present in the pipe, number of bends, flow rate, etc. If the water discharge point is close to the well than an approximation value of the frictional loss is used for the calculation. For example, if the discharge point is within 10 m of the well, 5 % of the total vertical lift is taken as the frictional loss.

All the above parameters are very useful for the design of the system for water pumping using solar PV modules. Now let us see how these parameters and different steps can be useful to design such a standalone system. The system design can be done in five steps as follows;

Water density is 2000 kg/m3 and acceleration due to gravity (g) is 9.8 m/s2. The peak power rating of the solar module is 36 WP, as the modules do not operate at its rated peak power capacity so the operating factor is 0.75. The pump efficiency is around 40 % and the mismatch factor is 0.85 as the modules do not operate at the maximum PowerPoint.

Note that the mismatch factor should be taken as 1 if we are using an MPPT along with the charge controller, but in our case mismatch factor is 0.85 as we are directly connecting the PV modules to the DC pump motor.

We studied a simple and economical approach to design a solar PV powered based DC water pumping which requires limited components, no requirement of batteries and controller. We briefly studied basic terms related to water pumping and detailed design calculations to pump the required level of water for irrigation purposes. Such a system can also be designed using an AC motor and can be implemented at domestic, residential, and commercial levels.

The spiral pump (also known as water wheel pump) is a hydraulic machine that pumps water without electricity. With the global efforts toreduce carbon emissions, the increased focus on renewable energy is making the spiral pump a viable option for pumping water, especially in rural areas and developing countries. Simple installation and low maintenance costs make the spiral pump a favorable, environmentally-friendly alternative.

A spiral pump is constituted of a pipe wrapped around a horizontal axle, generating a spiral tube that is fastened to a water wheel. The water wheel is in flowing water, so that the water in the river provides the energy necessary for the rotation of the wheel. Hence, the spiral tube also rotates. When the inlet surface of the tube (the tube’s external extremity) passes into the river, water enters into the tube. This water volume moves toward the outlet of the tube (the internal extremity), at the center of the wheel, where a straight tube is connected to the end-user.

Several water columns are generated inside the spiral tube, separated from each other by columns of compressed air trapped between the water columns. These columns of compressed air push against the water columns, so that at the outlet (the center of the wheel) the water achieves energy and velocity. In this way, it can be pumped at a higher elevation or at a certain distance from the river.

The possible users are irrigation consortia and civil people, in both developing and developed countries, especially for drip irrigation and partially for drinking water in developing nations. The largest application of the pump, and in general of water withdrawal, is irrigation. Although there have been past attempts to build such pumps in an artisanal way, aQystadeveloped a patent that allows to manufacturer this pump cost-effectively and as a commercial product. aQysta says that spiral pumps are able to pump to a maximum height of at least 20 meters and a maximum flow rate of at least 43.6 m3/day. As of October 2016, aQysta installed over 40 pumps worldwide in countries like Nepal, Indonesia, Turkey, Zambia and Spain.

Spiral pumps work without fuel or electricity, since the needed energy is supplied by flowing water (preferably a flow velocity faster than 1 m/s). The spiral pump saves up to 70% of overall lifetime costs compared to diesel pumping. The spiral pump requires no operation costs and it is environmentally friendly.

Therefore, spiral pumps can represent an interesting technology, especially for irrigation. This is the motivation that has encouraged Politecnico di Torino (Polytechnic University of Turin, Italy) and Southampton University (UK) to start scientific research on spiral pumps, in collaboration with the industry.

Emanuele Quaranta is project officer (scientific research) at the Joint Research Center of the European Commission (Water Directorate), while previously was post Ph.D. researcher at Politecnico di Torino (Turin, Italy) in hydraulic engineering, hydropower (expert in water wheels), eco-hydraulics (focus on fish passages) and fluid mechanics (CFD simulations). Emanuele was hydropower expert for European Commission in 2017.

8613371530291

8613371530291