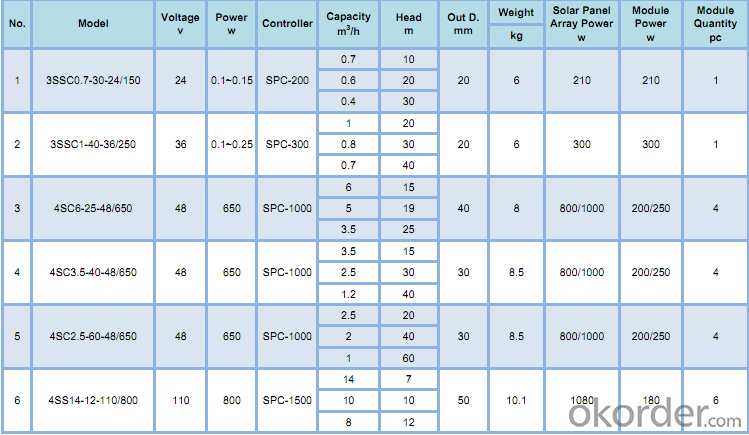

solar hydraulic pump pricelist

Explore a wide variety of solar hydraulic pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These solar hydraulic pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these solar hydraulic pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right solar hydraulic pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of solar hydraulic pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Explore a wide variety of solar hydraulic motor pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These solar hydraulic motor pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these solar hydraulic motor pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right solar hydraulic motor pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of solar hydraulic motor pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

The pricing for solar pumps varies. Advances in technology have made low cost systems possible and readily available. One of the major advances making this possible are solar cells and panels. A basic, but complete solar water pump kit, will cost around $2,000. This baseline system will pump water from a few hundred feet deep at a few gallons power minute flow rate. Often solar pumps systems will replace the high costs of electric pumps and generators, high maintenance costs of windmills, and the inconveniences of hauling water. With Solar Pumps there are no ongoing operating costs as you are relying on the sun to power your pump.

The cost of a solar pump depends on the size of the pump and the number of solar panels you require. The following costs are inclusive of the pump, solar panels, controller, solar wiring, splice kit and hose barb connectors BUT NOT the mounting for the solar panels, which will run you as little as $200 to $2,000 or more depending on the number of solar panels. RPS provides direct to consumer pricing, meaning you don’t pay multiple distributor or re-seller markups. We manufacture the pump and components, and then pass that savings onto you as a DIY install kit.

If your well is on the shallow side, measuring up to 150 feet in depth, then a solar pump will cost around $1,600 to $2,000. For a well up to 300 feet, expect a price closer to $2,5000 to $3,000.

If your well is officially a “”deep well””, 300-1100 in depth, then you’re looking at a cost between $3,500 all the way up to $10,500. If you just drilled a deep well and *gulp* already had to pay $15,000 (we’ve heard higher!), then consider a few additional steps. We understand this is a big investment so you’ll want to protect it! Any well pump being placed past 400 feet typically requires the customer to hire a team with a boom truck to lower the pump down safely. This is because when a pump, with heavy copper wiring and larger diameter pipe is all lowered hundreds of feet into the Earth, gravity starts adding additional weight onto an already VERY heavy line.

We love this question. Solar pumps on amazon are referred to as “”trash pumps””, for more than one reason. Typically made of cheap plastic that breaks or melts under stress, these Amazon and Ebay pumps work for 6 months to 1 year and then summarily die on the customer. We’ve heard stories through the years of ranchers and farmers buying pumps every 3 months, for years on end and they’re fed up with replacing the thing. Trash pumps use brushed motors, imagine a pencil nib that wears down with each use, that’s the brush (and once the nib is gone, you can’t replace it, your only option is to chuck the entire pump in the garbage).

RPS provides systems for NRCS farmer and rancher projects, which means our products are bought and paid for by the federal government and deployed on American farms all over the country. We have to provide documentation on the pumping mechanisms, lab approval on our solar panels efficiency, permanent magnet motors, rust proof stainless steel housing(we’ve got people using these pumps in salt water- which isn’t recommended, but they haven’t come back for a replacement yet) and wind ratings for solar panel mounts.

Cheap brushed motors, flimsy plastic diaphragm pumps, and fake warranties are making a bad name for solar. RPS has stayed strong and maintained our high quality knowing that integrity, quality and reliability win in the end. Our reputation for our commitment to our quality products, warranty and honest, friendly and respectful support is why more customers continue to trust RPS. We started development of our first solar pumps in 2012 and after much testing and refinement, we launched our first pump for purchase in 2014. With all our pumps still in the field, and four major winter upgrades from our engineering team, we are confident we have the highest quality pump that you can install yourself on the market, and the only comprehensive kit designed to make it easy. We believe our customers’s actions speak more loudly, with the majority of sales this past year coming from happy returning customers and their referrals.

We maintain a healthy relationship with FedEx, UPS, DHL and USPS. This provides us with discounted rates that we pass on to our customers, making it possible to expedite shipments of our 12v Micro DC Pumps at a lower cost to our customers worldwide.

Take a look at our full catalog of pumps. There’s a pump for almost anything you need. If you don’t find the specific model you need or you are looking for some other characteristics in a solar water pump please let us know. We might not have it in stock but can get it in for you or suggest a good replacement pump for a product that is no longer available on the market.

Mechanical pumps have a lot of uses nowadays. They are common in pumping water from wells, aquarium filtering, pond filtering and aeration. When it comes to water pumps, the main use of this device is the exchange of fluids such as water.

From agriculture to the energy industry, pumps are found in a wide range of applications. The main working principle of a water pump basically depends upon the positive displacement principle and kinetic energy which helps pushing the water.

Solar water pumps are a relatively new concept in mechanics. A solar water pump system is commonly seen in residential and commercial uses, as well as for irrigation of agricultural land. Through solar panels, the pump can eliminate the cost of energy and provide a more feasible option that uses energy from the sun (and not fuel-burning mechanisms) for pumping water.

In times when the entire world is switching to solar, using the sun’s energy in water pumping systems can significantly help and accelerate the development of agriculture in African countries and many other poor remote areas. This concept is known as solar-powered irrigation and is used in many regions nowadays.

The truth is, solar energy might be the easiest way for farmers to produce energy, especially for those living off the electricity grids with poor infrastructure around their homes. Therefore, the use of solar water pumps in agriculture is becoming increasingly popular. The concept of solar irrigation represents a virtuous circle—when the sun shines, it feeds the irrigation system and feeds the crops which are dependant on water in sunny weather. Therefore, a large quantity of energy is being released right at the time when it is needed the most.

As we discussed before, solar pumps present a clean, simple and energy-efficient alternative to traditional electric and fuel-driven pump sets. They are part of an environmentally friendly approach in agriculture and can be used to exploit every region, whether its developed or poor.

Due to their immense potential for productive use and agricultural productivity, solar water pumps are now powering more and more agriculture projects. Knowing that 40% of the global population relies on agriculture as its main source of income, access to water remains an ongoing struggle for many people. This is what solar aims to change and introduce a cost-effective future for around 500 million small-scale farmers all around the world.

The main components in a solar pumping system include a photovoltaic (PV) array, an electric motoranda pump. Solar water pumping systems, on the other hand, are classified as either direct current (DC) or alternating current (AC) systems based on their motor’s ability. Recently, the concept of brushless DC (BLDC) motors for solar pumping water applications was presented as well.

When it comes to stand-alone solar pumping systems, the main types include rotating and positive displacement pumps. Centrifugal pumps are the common choice for rotation and are designed for fixed head applications. Their output increases in proportion to their speed of rotation.

All in all, the main aspect related to the efficiency of a solar water pump is based on three variables including pressure, flow and input power to the pump. Wire-to-water efficiency is the commonly used metric that determines the overall efficiency of a solar water pump (as the ratio between the hydraulic energy that comes out of the pipe and the energy coming over the electrical wires through solar panels).

A solar-powered water pump is a concept that is environmentally-friendly. More importantly, it is a concept that gets rid of any power grids or fossil fuels used to pump water out of the ground. Below, we are listing the advantages and disadvantages of their use.

The first advantage of solar pumps is that they are reliable in regional and remote areas. A perfect example of this is Africa, which is one of the poorest remote regions in the world with an abundance of water—but also the most dominant region when it comes to most days of sun in the year. On the flip side, Africa is thought to possess 9% of the world’s freshwater resources which translates to around 4,000 km3 of water per year. Deploying solar water pumps in Africa is, therefore, the perfect alternative to any other fuel-based sources—and an alternative which can stimulate life in every part of this continent.

Easy to transport and relocate, solar water pumps can be organized as per the needs of the farm and have extremely low operating costs. Both of these are major advantages, paired with their cost-efficiency in the long run, show that a solar water pumping system is the perfect solution for regions with sunny days and plenty of water on their grounds.

The main disadvantage of deploying a solar-powered irrigation pump for agriculture is its cost (initial investment). Even though it depends on the power of the specific pump, one 120 Watt solar pump which promises to produce 2,100 gallons of water per day can be found on online marketplaces from around US$235. An entire system for a solar-powered irrigation pump based on one pump can also be found for around $498. Other sites like eBay, the prices for kits like these are relatively the same.

Obviously, there is a major difference between deploying a solar water pump for your home and one for an agriculture project. With different types, sizes and needs come different costs. There are cheaper and more expensive models but the average cost of solar water pumps is generally high, considering the fact that many of them need to be deployed for effective irrigation. All in all, compared to the cost of fossil fuels and other types of energy, solar is still a winner in the long run.

In addition to this, solar energy in agriculture is also very weather-dependent. Even though solar energy can still be collected during cloudy and rainy days, the efficiency of a solar system drops. This is why solar irrigation systems are best used in regions with a lot of sunlight.

One important thing to note when it comes to solar pumps and irrigation systems is the fact that their costs have dropped significantly in the past few years. According to new research from the International Renewable Energy Agency (IRENA), there will be a 59% cost reduction for electricity generated by solar PV by 2025 compared to the 2015 prices.

As such, the economic viability of these systems varies for different regions and areas, mostly depending on site conditions, crops and markets. An infographic from The World Bank shows that in 1997, the average price of deploying solar energy per watt was $76. In 2015, that price was $0.3 which clearly showcases the drop in prices. Now, a solar panel has an average lifespan of 25 years and compared to diesel pumping, it lacks any fuel and presents less operation and maintenance. The only disadvantage is its initial cost which is around two times higher compared to diesel water pumping systems.

Price is also a key differentiator when it comes to returns on investment (ROI). The key aspect that determines the economic viability (the factor associated with the worth of solar water pumps as an investment) is how the solar-powered systems compared with other forms of energy.

Generally speaking, diesel pumps have low initial investment costs but are also associated with high operation and maintenance costs, not to mention their negative impact on the environment and ecology. In contrast to this, a solar water pumping system has higher investment costs but lower maintenance and operational costs.

If you are based in a region with plenty of sun and a lot of groundwater, a solar water pumping system is definitely recommended. Despite the initial installation costs, lower maintenance costs and a higher lifespan will give you an up-and-running system set in no time, clean water and many benefits in the long run.

As we mentioned above, the investment costs associated with buying solar water pumps are coming down in the past few years. However, the factors which influence the efficiency of a solar water pump are numerous and include:

Considering these factors, we can say that solar water pumping can provide significant environmental and socio-economic benefits at the farm and national levels. At the farm level, the technology can present a reliable source of energy in remote areas—and especially areas that are not connected to the electricity grid or lacking a regular supply of liquid fuels. On a national level, solar water pumping can help stabilize, increase and diversify agricultural production, which is the foundation of most African countries’ economies.

By definition, an efficient solar-powered water pumping system is one that receives plenty of sunlight and is installed specifically to the needs of the farm.

In a world where there is a current energy crisis, there is a strong drive towards renewable energy. Despite the costs which are relatively higher, the real efficiency of solar systems is seen in their use over the years. As a renewable energy option, the exploitation of solar energy is a valuable option.

The focus of deploying solar water pumping is obviously set to South Africa and regions with poor economic development but plenty of sunlight. Paired with the right environmental conditions, the right amount of PV panels and controllers and the right installation setup of energy storages, converters, inverters, pumps and motors—the solar water pumping system can present a farm and a nation with numerous benefits.

If you are thinking or considering the applications of solar energy for agriculture, the benefits are numerous. With the ability to pump water for irrigation during dry and sunny weather in regions that need it most, panels like these can be easily installed and enable the pumps to work in wells of very low yields, offering a longer lifespan and plenty of energy in the long run. comment↓

In this writing we will explain these questions? What is a submersible water pump? What is the price? What are its applications and features? Stay with us to know the answers. A submersible pump is a sort of sealed pumping equipment that pushes water through the pumping process rather than pulling it. As the name suggests, the pump may work this way because it is totally submerged in the liquid to be pumped. Due to this, the pump may be lowered into a deep pit without experiencing issues like pump cavitation, which can harm moving parts and produce steam bubbles. There are many industrial and commercial uses for submersible pumps.

The whirling impeller and rotating vanes of centrifugal pumps are typically composed of metal. These vanes help the propellant fluid receive energy from the engine. The fluid accelerates when it enters the impeller because of the rotation of the impeller. High speed fluid finally leaves the impeller blades, where the kinetic energy is often transferred to pressure.

There are single-stage and multi-stage submersible pumps. A motor is housed in each stage"s housing, which is mechanically sealed to stop leaks. The body of the motor extends into a tube or hose heading to the surface, and it is connected to a cable that produces electrical power to run the motor. Submersible pumps can be linked to various pipes, hoses, or wires depending on the task and the liquid being pumped. Housings for submersible pumps can be constructed from a variety of metals, including polymer, stainless steel, and chrome. The fact that the cover is hermetically sealed is its most crucial feature.

The electric submersible pumping principle underlies the operation of many submersible pumps (ESP). This is accomplished by lowering the flow pressure, which lowers the pressure at the submersible pump"s location at the bottom of the shaft. Since ESP system motors must function at high temperatures (up to 300°F) and pressures, particularly deep wells like oil wells are frequently employed. In more recent advances, coiled tubular umbilicals may be used to power deep-well motors; but, because special electrical cables are required, their operation may be relatively expensive. Additionally, compared to other submersible pump motors, the power consumption is significantly larger, and the pump operates to a great extent that prevents particles and sand from entering.

A device with a sealed motor linked to the water ump body is referred to as an electric submersible pump (ESP). The fluid that will be pushed is submerged beneath the entire system. This kind of pump"s key benefit is that it doesn"t suffer from pump cavitation, a problem brought on by significant height differences between the pump and the fluid surface. Submersible pumps force the fluid to the surface as opposed to jet pumps, which generate a vacuum and rely on atmospheric pressure. In heavy oil applications, where a liquid under pressure from a surface is utilised to drive the bore of a hydraulic motor and hot water is used as the driving fluid, floats are employed in place of electric motors. Electric submersible pumps are multistage centrifugal pumps that run vertically. The diffuser, where kinetic energy is transformed into pressure, is where the impeller-accelerated fluid loses kinetic energy. This is how radial and mixed flow pumps operate primarily. Instead of being an electric motor, the motor in HSP is hydraulic, and it can either be closed cycle (keeping the power fluid and generated fluid apart) or open cycle (mixing the power fluid and generated fluid cavity and surface separation). A mechanical coupling located at the pump"s base connects the pump shaft to the gas separator or protector. The pump stage raises fluid that enters through the input plate of the pump. Radial bearings (bushings), which are dispersed throughout the shaft and support the pump shaft radially, are among the additional components.

In order to produce a sort of "artificial lift" that can function over a wide variety of flow rates and depths, submersible pumps are utilized in the oil industry. In comparison to natural production, the well can produce much more oil by lowering the pressure at the bottom of the well (by decreasing the flow pressure in the bottom hole or raising the drawdown). When discussing hydraulic power, ESP (Electric Submersible Pumps) or HSP are meant (Hydraulic Submersible Pumps).

A mechanical tool called a pump is used to transfer fluid like water from one location to another. New pumps for new applications such as submersible pumps, maintenance, and repairs are all offered by Pump Service. We are aware that in some circumstances, our clients may require a submersible pump. Here, we delve deeper into the definition, operation, and applications of submersible pumps. A submersible pump is what? Submersible pumps, as their name suggests, are pumps that are fully submerged in the fluid they are moving. This differs from a pump that is outside the fluid being pumped. The pump motor of Lethbridge"s submersible pumps is linked to the hull and sealed, making them entirely submersible. How are submersible pumps operated? Submersible pumps operate by pushing the fluid, as opposed to exterior pumps, which must bring the fluid to the surface. The impeller inside the pump body begins to rotate as soon as the submersible water pump is turned on. Water is drawn into the pump body by this rotation. The water is subsequently forced toward the surface by the impeller through the diffuser. What benefits can submersible pumps offer? Due to their numerous potential advantages over external pumps, Lethbridge"s submersible pumps are used in specific circumstances. The fact that totally submersible pumps don"t need priming is one of its many benefits. Since the water pressure helps transport the fluid into the pump, submersible pumps are more energy-efficient than external pumps. Submersible pumps also have the critical benefit of having a longer lifespan than external pumps due to the absence of mechanical issues.

Due to its benefits, submersible pumps have a wide range of possible uses in residential, commercial, and industrial settings. In Lethbridge, submersible pumps are most frequently used for, but not limited to:

The septic tank is used to pump out sewage. Electricity supply for irrigation systems used in industry and agriculture. Pumping water out of sections of construction sites that are waterlogged. It moves oil from underground to a facility for refining and storing it on the surface. In order to fill above-ground storage tanks, it pumps water from deep underground wells.

You may rely on Pump Services to identify the best pumping solution for your requirements if you require a submersible pump. At Lethbridge, we provide a broad selection of pumps from renowned brands like Jacuzzi, Monarch, Armstrong, Bell & Gossett, including submersible pumps. Inform us of the application you desire. We are delighted to suggest the ideal submersible pump for your requirements.

To achieve this independence, electricity must be on-site and powered by renewable energy sources if possible, such as solar, wind or geothermal. Backup/emergency power via generators and fuel reserves should also be on hand. Many people simply do without electricity. However, doing without water is not an option. Those living off the grid must have a water source such as a well, spring, stream or nearby lake. The means to extract/pump the water for its intended use is vital.

Lever-operated manual well water pumps are an option for established communities that makes transferring the water into a portable container relatively easy.

The manual water pump is a device that works thanks to a piston or plunger, a lever attached to a moving point, a connecting rod and a washer. As the hand pump lever is raised, the piston goes down and the water enters through the holes or tubes in the pump body and the washer is lifted by the pressure of the water. A suction effect is created by this action. When the lever is lowered, the washer does the same, cutting off the flow of water and causing it to accumulate inside the pump. When the process is repeated a few times, the amount of water that accumulates in the pump increases and eventually flows out of the outlet valve with each stroke.

The manual water pump is typically dependable and durable. It is operated with minimal strength or effort and is easy to service. It is also inexpensive and self-priming.

A well is needed for operation. The pumps work best with an extraction pipe diameter of 4 inches with a depth based on underground water level. Depending on the area and cost, a well may not be a viable option. Also, hand-operated water pumps are not portable in most cases.

Solar-powered water pump usage is becoming increasingly popular. The cost of a low-maintenance solar pumping system may make sense compared to the cost of a generator to run a typical water pump, with continual fuel and maintenance costs. A good solar pumping system is often more economical, which is why many nonprofits use solar pumping to provide clean water to remote communities around the world.

Solar-powered photovoltaic solar panels produce electricity from sunlight using silicon cells, with no moving parts. Low volume pumps use positive displacement (volumetric) mechanisms that seal water in cavities and force it upward. Lift capacity is maintained even while pumping slowly. These mechanisms include the types used in diaphragm, vane and piston pumps.

These pumps are becoming more affordable. Modern systems are reliable and most are easy to service. Many options are available depending on required flow rates, and the technology continues to improve.

They are not easily portable in most cases, especially with required solar panels. Cost can still be prohibitive depending on the system required. Solar pumps work best in full sun. As a result, performance will decrease significantly in low light before turning off. With use in low-light, a battery may be required, further impeding portability and raising costs.

Portable impeller pumps in various forms have been used for years to handle everything from small jobs around the house to fluid transfer in an industrial setting. They are available with alternating current (AC) or direct current (DC) motors and can also be operated with a variety of different drills, including rechargeable, depending on how remote the application may be.

A flexible impeller with five or more impeller blades applies pressure to the inside of the pump housing. A shaft with a key runs through the center of the impeller. The shaft is powered via drill or remote power source. The positive displacement rotating impeller transfers the liquid from the inlet to the outlet port of the pump.

These pumps are designed to be portable. The compact lightweight pump and a rechargeable drill can be carried anywhere the user chooses/is able to travel via a tool belt or carry case. The pump can be carried in a user’s pocket. Depending on the model, they are able to self-prime with water up to 14 vertical feet and develop pressures high enough to move water over 100 feet through hose if needed. This is useful when transferring water from a creek with a steep embankment or to a larger container on a bank uphill from a water source.

They are durable and easy to service depending on the brand, and the most cost-effective remote water pump option listed in this article. They can be powered by most standard rechargeable drills and are the most straightforward way to provide potable water without cumbersome equipment in a variety of circumstances.

There is an increasing need worldwide for off-grid pump systems. The reasons for this range from economic factors and population growth to those who want to purposely reduce their carbon footprint and remove themselves from risks involved with living in more densely populated areas. The requirement for clean water has also increased due to the need for proper sanitation in today’s world. Remote communities are at higher risk of disease transmission without an accessible clean water supply.

The pump options listed only consider the ability to transfer water. They do not include filtration that may be required based on the water source and its intended use.

In many parts of the world, including New Mexico (NM), water and energy availability are growing concerns. In areas where connection to an electric utility is not available, the primary technologies for water access—surface sources or pumping—have remained fairly constant for decades. As demands for higher quantities and quality of water, lower costs, improved reliability, and environmental concerns have increased, many livestock and agricultural producers are investigating an alternative technology for remote water pumping: direct-coupled solar photovoltaic (PV) powered systems.

Since the process to design and implement such a system may be a challenging task, New Mexico State University"sEngineering NM program initiated a project to provide the Cooperative Extension Service (CES) with a demonstration module, an interactive design spreadsheet, and literature related to solar water pumping to better inform NM water users about the benefits and methodology of implementing this technology. Available through NMSU multimedia and the CES statewide Extension agent network, these tools serve to educate interested constituencies (primarily farmers and ranchers) in using solar energy to pump water.

This publication provides a general discussion of how to design a photovoltaic-powered solar water pumping system for livestock. A companion publication, Circular 671, Designing Solar Water Pumping Systems for Livestock: User Manual(https://pubs.nmsu.edu/_circulars/CR671.pdf), provides step-by-step instructions for using a Microsoft Excel spreadsheet to perform necessary calculations for designing a solar pumping system.

Livestock, crops, and people often depend upon surface sources of water (streams, ponds, catch tanks, etc.) or wells accessing underground aquifers1. Because of a variety of benefits, and increased regulations in some states, it is often desirable to move water from a surface source to a different location, elevation, or “drinker,” or to pump water from a remotely located well.

For surface sources, a well-vegetated riparian zone establishes a buffer that filters and purifies water as it moves across the zone, reducing sediment loads, supporting soil stability, improving water quality, and enhancing wildlife habitat. Excessive livestock pressure on surface sources often causes nutrient loading, streamside vegetation damage, erosion, pollution, and decreased animal growth and health. One approach is to remove or limit access to these areas; however, often this is the only viable water source for producers. Fortunately, research shows that in many cases pumping water to a different location, combined with a managed rotational grazing plan 2, optimizes animal performance, pasture use, water quality, and wildlife in these zones (Buschermohle and Burns, n.d.; Morris and Lynne, 2002).

Calves require higher-quality water and will not fight cows or mud to obtain it. Increases of 50 pounds/head in weaning weight have been reported when water in sufficient quantity and quality is provided. Studies have shown that, when given a choice, cattle drank from a water trough 92% of the time rather than from a nearby stream (Bartlett, n.d.). Research also shows that yearling steer performance increased 23% when supplied with an alternate water source rather than dugouts (earthen dams or reservoirs). In addition to increased livestock and resource performance, by routing the livestock away from riparian zones, very large reductions (50–90%) in streptococci and coliform fecal organisms, waterborne diseases (foot rot, red nose, TB, mastitis, etc.), nitrogen, phosphorous, suspended solids, and surrounding erosion are realized. By pumping water to drinkers, ranchers can better utilize pastures, get superior animal growth and health, and provide higher-quality water (Pfost et al., 2007; Surber et al., n.d.).

Costs, reliability, and environmental concerns often influence a producer’s choice of surface water pumping system. When producers do not have economical access to grid electric power 3, they generally look to options such as ram, sling, diesel, wind (Figure 1), or solar powered pumps. When these choices are compared, solar pump systems are often the best choice due to the operational conditions inherent to New Mexico, which allows them to function effectively and economically (Foster et al., 2010).

Solar pumping systems for surface sources or wells can be portable, which is appealing because more and more producers want systems that can move among various locations. Some users are even powering broken windmill pump jacks with portable photovoltaic (PV) systems.

For pumping water from underground aquifers via wells, access to existing AC electric connections (closer than one-half kilometer or 0.3 mi) is again the best option. In remote locations, though, PV water pumping systems represent a very attractive, long-term, cost-effective alternative to hauling water, diesel pumps, and even traditional windmills for drinking water and many irrigation applications (drip/trickle, hose/basin, and some channel irrigation–although typically not for very high flow rates such as might be used in flood irrigation). The abundant and varied benefits of PV systems make them attractive in many situations.

A solar pumping system involves calculations and concepts that may make it difficult to determine a design if one is unfamiliar with the technology and terminologies. With this in mind, NMSU developed the following tools to aid and educate a potential user:

1. Two portable demonstration devices that illustrate the concepts and major system components for a solar pumping system. Each module is portable and therefore available for displays and presentations.

2. Literature and educational multimedia materials related to PV water pumping systems (https://www.youtube.com/playlist?list=PL89870B418A514D27), including comparisons between three main remote water pumping technologies (Table 1) used in New Mexico today, contrasting two different ways to mount PV modules (fixed-angle mounting vs. single-axis tracking systems), and a simple cost analysis for each of the three technologies and mounting systems (Foster et al., 2010).

3. A Microsoft Excel spreadsheet to provide an easy and visual educational tool to present concepts behind PV technology and system design methodology (available to download at https://pubs.nmsu.edu/_circulars/CR671/CR671.xlsm). This tool allows the user to follow the basic step-by-step design process, and offers sample components and simple economic analysis for a user-defined scenario. For the sake of organization and ease of use, the spreadsheet follows the design approach outlined in this publication. A companion publication, Circular 671, Designing Solar Water Pumping Systems for Livestock: User Manual (https://pubs.nmsu.edu/_circulars/CR671.pdf), covers the step-by-step instructions for using the Excel spreadsheet to design a solar water pump system.

In order to design and successfully implement solar water pumping systems, you need an understanding of several concepts as well as information specific to how you will use your system. This includes:

With no moving parts, the PV panel takes energy from sunlight and generates DC electricity, which is then directed through a controller to the pump/motor in what is termed a “direct-coupled system” (Figure 2). The pump/motor combination (hereafter referred to as the pump) moves water from the source through a pipe to a discharge point, commonly a storage tank that feeds a trough-drinker (Figure 3). This direct-coupled system is intended to operate only during the day when sunlight is present, thus eliminating the expense and complexity of batteries 4. In a properly designed direct-coupled system, extra water must often be pumped into a storage tank. By providing storage, a producer can still provide their daily water requirements from the storage tank at night or on cloudy days. The amount of water pumped depends primarily on the amount of sunlight hitting the PV panels, the type of pump, and a few other factors. The amount of available sunlight is predictable by location, but there are always variations in weather (e.g., cloudy days 5). By using a simple direct-coupled approach, the operation, maintenance, costs, and complexity of the system are greatly reduced.

Modules are sized as DC power (watts [W]) and come in all sizes, from a few watts to over 250 W. Rated power is determined by the output voltage and current under standard sun intensity. A module rated at 50 W may have an operating voltage up to 17.4 volts (V) and a maximum current of 3.11 amps (A). Modules can be wired in series to increase output voltages and in parallel to increase current while also increasing total power. If sunlight changes (clouds), output current will fall and thus power will fall at a relative level (e.g., if sunlight is halved, current and power will be halved while voltage remains about the same). PV modules are sized and configured (series/parallel combinations) to power the second major component of the system: the pump.

Pumps move water from wells or surface sources. It is important to analyze the system properly in order to make it as efficient and economical as possible while still meeting the watering requirements. Choosing and matching PV modules and pumps to meet the design constraints is vital. In designing an efficient system, one should minimize the amount of work required of the pump, which minimizes the amount of energy needed to operate the pump and thus the size and cost of components. By understanding these basic concepts beforehand, the designer will be able to determine the appropriate pump (and PV modules) for a system.

Figure 3. PV-powered pump systems often discharge to a storage tank to provide the daily water requirement even under lowlight conditions. (Photo from National Renewable Energy Labs, 1997.)

Once each parameter is clearly addressed, a pump can be selected. Pumps are classified as either positive-displacement or kinetic/centrifugal, and each has advantages. The list of available pumps (and manufacturers) is very extensive, and many will be capable of pumping from a surface source or a well. A pump for a “well application” is most commonly a DC submersible pump with a range of 12 V to more than 36 V, but may be much higher for very deep wells or high flow rates. The current is typically in the 3 to 5 A range, which equates to a rough operating power up to (though typically much less) around 1 horsepower (or 746 W). DC pumps use one-third to one-half the energy of AC pumps and are specifically designed to use solar power efficiently even during low-light conditions at reduced voltages without stalling or overheating. Solar pumps are low volume, pumping an average of 1 to 5 gallons per minute (gpm). A majority of pumps are positive displacement pumps (centrifugal-type pumps are also common), which enables them to maintain their lift capacity all through the solar day at varying speeds that result from changing light conditions 8. A good match between the pump, PV array, and system parameters is necessary to achieve efficient operation (Morris et al., 2002).

Most PV applications will be pumping at low flow rates (1–5 gpm), and these low flow rates will not have sufficient water velocity through a large pipe to keep suspended solids from settling out into the bottom of the piping.

The first step in a design is to determine the total amount of water needed per day. Many producers are used to thinking of pumping lots of water in a short time frame with large-capacity pumps. Solar pumping, like windmills, will pump water at slower flow rates (gpm) over a longer time.

Household water use demand is variable and depends on climate, usages, and other factors, but is typically around 75 gallons/person/day for drinking, cooking, and bathing. Irrigation water demand depends on local conditions, season, crops, methods of delivery, and evapotranspiration 11. Agriculture watering is usually greater in summer seasons when solar radiation is at its highest.

Once the daily water requirement is calculated, the solar resource—“insolation,” or total sunlight reaching a specific location—is determined. Sunlight will provide the energy, via the PV modules, to run the pump, and sunlight value is determined by the nearest latitudinal coordinate of the well location (between 31 and 37° in New Mexico). When you insert this value, the spreadsheet determines the solar insolation for winter, summer, or a yearly average. It is recommended to use winter values since winter has the least amount of sunlight per day and it is best to design for the worst-case scenario. Nevertheless, you can choose to use the summer insolation value if you plan to water a summer-only pasture. A good rule of thumb is that the solar resource must be greater than 3.0 kWh/m2 per day (3,000 watt-hours per square meter of area in one day) for choosing a solar 12.

Total dynamic head (TDH) is the total “equivalent” vertical distance that the pump must move the water, or the pressure the pump must overcome to move the water to a certain height. Water pressure is expressed in pounds per square inch (psi) and is defined as the force caused by the weight of water in a column of a certain height, also known as “head.” Head is a term relating feet of water in a column that exerts a certain pressure; for example, a column of water 10 ft high would exert 10 ft of head, or 4.3 psi (pressure). Knowing head, you can determine pressure and vice versa. Head is important to determine how hard the pump must work to move water from the source to a discharge point (i.e., to overcome the equivalent pressure of that water).

Pumps may be submersed in a well as deep as necessary to ensure reliable water supply (taking into account drawn-down levels, seasonal variations, and recharge rates). The water level variable in Equation 2is measured from the water surface to the level of the water in the source—not the depth location of the pump. Placing the pump lower in the well (increasing its submergence) will NOT cause it to work harder or to pump less water, nor will it increase stress or wear on the pump. However, there are reasons to NOT set the pump too close to the bottom of the well:

The pump must move the water from the well to an elevation, but it must also overcome friction losses in the system. These losses depend on the type of pipe (its roughness), total length of pipe including any horizontal runs, flow rate (speed) of the water in the pipe, fittings and joints, and pipe diameter. These friction losses, which are expressed in equivalent lengths of vertical pipe distance, are added to the static head to yield an equivalent TDH—i.e., what equivalent height would the pump need to move water given these values.

Oftentimes, we may work in units other than gallons and feet. One U.S. gallon is equal to about 0.0037854 cubic meters, while 1 foot of distance is equal to about 0.3048 meters. If we convert TDH from feet to meters and the daily water volume from gallons to cubic meters, then we can calculate something called the hydraulic workload (Equation 6), which is an excellent indication of the power that will be required to meet the designed system constraints.

If the hydraulic workload is less than 1,500 m4, then the project is a good candidate for solar PV. If it is between 1,500 and 2,000 m4, it will be borderline. If the hydraulic workload is greater than 2,000 m4, you may need to consider other options.

In the Pump Selection tab of the spreadsheet, you are shown the calculated Q and TDH. Using these two key values, you must manually choose a specific pump (from an initial limited selection) that will be capable of pumping water at the necessary Q and TDH. Once a pump is selected, we determine at what voltage this pump will operate (12 V, 30 V, etc.) and how much power (watts) is required to run this pump assuming standard pump efficiency (η ~35%). This is the power that de-rated 14 PV modules must supply to operate the pump. Pump power can often be looked up in pump tables, but it can also be determined by Equation 8.

The Array Sizing spreadsheet tab involves the automatic sizing of the PV array given the calculated and manually selected pump parameters. The first calculation performed is to determine the number of PV modules in series—a string. Each PV module has an operating output current and voltage. Connecting modules in series increases the total voltage to match or exceed the required pump motor voltage (determined earlier). Equation 9 illustrates this, while Equation 10 describes how the PV strings may be connected in parallel to increase total current and thus total power to match or exceed the required pump’s power (also determined earlier). Voltage multiplied by current determines total power provided by the PV array in watts (or converted to horsepower, HP). NOTE: It is possible that there will only need to be a single module or modules only in series and not in parallel.

Because we round up the number of strings and parallel combinations to whole numbers, the total amount of energy and therefore water pumped will be greater than our daily requirements on any full sunny day. This is typically not an issue when float switches are incorporated into storage systems, which will stop the pumping when the tank is full. Excess power produced by solar panels can be used for cathode protection, to aerate a dugout, or to power an electric fence.

The Design Specification spreadsheet tab summarizes the design values obtained through the use of the spreadsheet and lists the key components and materials for this scenario’s direct-coupled solar water pumping system. The description and quantities for specific items are obtained from calculations or specified by you. The cost for each itemized component is calculated by multiplying the quantity of each item by a representative retail price, but prices will of course vary over time. The necessary length of UF wire is roughly determined by the length of pipe plus an extra 25%. The market price for the UF wire is for 250-ft rolls. Pipe is assumed to be PVC and the price is calculated by dividing the total length of needed pipe by 10 (PVC pipe is typically sold in 10-ft lengths) and multiplying by its market price. The grand total of the entire system (not including the well, labor, storage, etc.) is calculated by adding up all the itemized totals. This will reflect an approximate cost to construct the system plus the costs of other materials, labor, sales taxes, shipping, etc. Federal and state tax incentives may lower the initial costs by up to 40% (as of 2012).

Using the spreadsheet allows you to test various design scenarios and demonstrate the design method and terminology for a direct-coupled solar water pumping system. It is important to consider the limits of this spreadsheet because it is only able to calculate for flow rates up to ~4 gpm and TDH values no greater than ~230 ft due to the very limited PV and pump selection options within this version. In the case of design values outside these limits or for pumps or PV module choices not available within the spreadsheet, you should reference alternative performance data provided by other pump or PV manufacturers. We hope that later versions of this spreadsheet will address several of these issues.

Photovoltaic-powered water pumping systems are attractive for livestock and agricultural producers with remote water sources and limited access to AC power. Even though wind has been in use for decades and will continue to provide effective solutions for water pumping, solar power has made significant steps toward becoming the system of choice for these situations. Solar systems’ low maintenance and simple operation, lack of fuel (transportation or storage) costs, environmental friendliness, and competitive life-cycle economics place them at the forefront of choices for supplying water to livestock or agriculture. The technology for solar water pumping is exceeding all expectations, and will continue to be a viable choice for more and more users as its capabilities, reliability, and versatility increase while costs decrease.

The spreadsheet, documentation, and demonstration modules provide you with terminologies, knowledge, and skill sets that can be the foundation for informed choices relating to alternative water pumping systems. For additional information, contact your county

Buschermohle, M., and R. Burns. n.d. Solar-powered livestock watering systems [Online]. Available from https://utextension.tennessee.edu/publications/documents/pb1640.pdf

Foster, R., and A. Ellis. 2003. Renewable energy for water pumping applications in rural villages [Online; NREL/SR-500-30361]. Available fromhttps://www.nrel.gov/docs/fy03osti/30361.pdf

Morris, M., and V. Lynne. 2002. Solar-powered livestock watering system [Online]. Available from https://www.clemson.edu/sustainableag/IP217_solar_livestock_watering.pdf

Pfost, D., J. Gerrish, M. Davis, and M. Kennedy. 2007. Pumps and watering systems for managed beef grazing [Online]. Available from https://extension.missouri.edu/p/EQ380

12 All areas of New Mexico meet this limit with values well above 5 kWh/m2 per day. New Mexico climate website (https://weather.nmsu.edu) has good historical solar, wind, and temperature data.

13Draw-down is the level of water that may drop in the well as pumping occurs—the well pipe is refilled at a recharge rate. The low flow rates of solar systems have less negative impact on draw-down.

This non-electric water pump is a patented product of MWI and is used around the world in communities without electricity. The SolarPedalFlo™ uses a minimum of 350 watts of solar power to provide 12,000 liters of filtered (down to 1 micron) chlorinated and pressurized water daily. The water that is produced is free of waterborne and airborne diseases and is protected in an overhead tank. Safe water, such as that provided by SolarPedalFlo™, is proven to result in healthier babies, significantly lower infant mortality rates, and when used in combination with simple hygienic practices, it can dramatically reduce incidences of diarrhea and cholera.

Due to its unique linear current booster, the SolarPedalFlo™ can even operate in low-light conditions, such as the early morning and early evening hours. When there is very low to no light, this pump can be powered by the body’s most powerful muscles—the legs—to rotate pedals connected to the Borehole Reciprocating Piston Pump. Pedaling is always smooth and uniform, so even young children can pedal with ease. The pump’s design also uses a flywheel for consistent power conversion. In addition, this pump has been shown to outperform the flow of four combined handpumps when it comes to providing safe drinking water to entire rural communities.

Compared to most hand pumps that become difficult to use at water depths of more than 45M, the SolarPedalFlo™ can effectively operate at water depths down to 55M. This non-electric water pump is now in operation in twelve African countries and has freed women and children from the arduous daily chore of trekking long distances to fetch contaminated water. This pump thereby allows women to be more productive in their daily tasks and permits children precious time to go to school.

8613371530291

8613371530291