the heil co hydraulic pump manufacturer

We’re excited to bring the show to you and introduce the amazing innovations brought to you by the ESG family – all in the comfort and safety of your home or office. Take a moment to browse our booths and the new products our companies have to offer and be sure to join us for our live, staffed booth events!

McNeilus, the McNeilus logo, and STREET SMART PARTS are trademarks of McNeilus Truck and Manufacturing, Inc. All other manufacturer names and trademarks are the property of their respective owners and are used for reference purposes only. McNeilus is not affiliated with or authorized by any of those manufacturers but provides replacement parts that are designed to fit with equipment from these other manufacturers. Original equipment manufacturer part numbers and product descriptions are provided for reference only and are not intended to suggest endorsement or authorization by the manufacturer.

Highway and Heavy Parts is in no way associated, sponsored, or affiliated with any OEM manufacturer. Products from Highway and Heavy Parts presented on this website are not to be confused with any of the products or trademarks of any OEM company. All parts listed to fit these manufacturers" models are replacement aftermarket parts. In no way is it implied that the products listed to fit these manufacturer’s models are original equipment parts, rather they are replacement aftermarket parts and accessories.

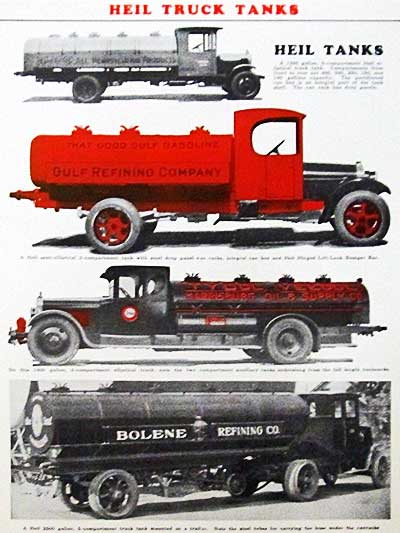

Left to right: Julius P. Heil, Joseph F. Heil, and Joseph F. Heil Jr. Throughout most of its history, Heil Company was under the ownership and direction of three generations of the Heil family. Colorful Julius Peter Heil (1876-1949) founded the company and ran it until 1939, when he took office as the 30th governor of Wisconsin. His son, Joseph Frank Heil (1908-1984), joined the family business in 1923, and took over operation of the company as executive vice president while his father was serving as governor. Joseph Heil was elected president of Heil Company in 1946, while his father stayed on as business director and treasurer until his death in 1949. Joseph F. Heil, Jr. (1925-1996) represented the third generation, and joined Heil in the 1940s. He became chairman and CEO in 1977, and headed the company until it was sold to Dover Industries in 1993.

Years of wear and tear can render your Heil pneumatic and hydraulic cylinders, pumps, or motors useless. This not only hampers your normal course of operations, but also results in costly downtime. When you need performance stability even in the most demanding applications, Motor & Gear Engineering, Inc. is your partner of choice.

Our hydraulic cylinder specialists have more than 40 years of combined experience in repairing and remanufacturing Heil cylinders. The management team and crew are dedicated to giving our customers the best service available. We can repair your obsolete cylinders or design and build you a custom cylinder.

Our hydraulic cylinders are engineered to perform reliably and reduce the chance of mechanical garbage truck breakdowns. Engineered with a performance-built design, our replacement SAT telescopic cylinders are optimized to exceed OEM standards.

Hydraulic Cylinders, Inc. carries an extensive inventory of Heil replacement dump hoist cylinders proven to perform. Demolish downtime with same-day shipping on all orders placed by 12:00 PM CST. If you have trouble finding single-acting dump hoist cylinders that match your specifications, please contact us for assistance. You can also find helpful information on our blog.

Garbage trucks and other refuse equipment are critical to the sanitation and health of our cities and towns. Built to heavy-duty and high-quality standards, we rely on this equipment to keep our communities and streets clean.

When it comes to hydraulics on refuse equipment, it’s all about power and reliability. Hydraulic power is one of the best ways to economically apply force (i.e. lifting and packing) in industrial applications, including all types of refuse equipment.

Hydraulics provide maximum productivity for refuse trucks, not only regarding cycle time, but the quantity and compaction rate of the garbage itself. Compaction rate refers to the density of trash per cubic yard of capacity after the material is compacted. Compaction rate is a measurement of mass per volume of space, rather than a time component. It is dictated by a combination of body strength, hydraulic cylinder force and the surface area of the compactor. A higher compaction rate provides more compacted material per cubic yard, improving collection productivity.

Each refuse packer body is somewhat unique with pumps, valves, controls, filters, and cylinders designed specifically for a given application. On refuse vehicles, the hydraulic pump is often powered through a PTO or directly from the driveshaft (e.g. a front-mount hydraulic pump).

Depending on the refuse equipment design, the hydraulic fluid is conveyed between the various components through rigid pipe or steel-reinforced flexible hydraulic hose.

Most hydraulic oil reservoirs have in-tank filters. The wear of hydraulic system components is dependent on this contamination, and the existence of metal parts in hydraulic system oil (iron and copper are particularly powerful catalysts) accelerates its degradation. A hydraulic filter helps to remove these particles and clean the oil on a continuous basis. The performance for every hydraulic filter is measured by its contamination removal efficiency, i.e. high dirt-holding capacities.

Wastebuilt can supply every component for the packer body hydraulic system including Eaton Aeroquip hydraulic hoses and fittings, as well as hydraulic cylinders.

In many cases, the equipment design envelope doesn’t allow for a simple (i.e. single stage) cylinder and a telescopic or multi-stage cylinder is required due to space constraints.

Outside of the refuse industry, most telescopic cylinders are single acting (push); within the refuse industry, most telescopic cylinders are double-acting cylinders.

Oil leaks are the most common cause of cylinder failure. Usually related to rod damage which in turn damages the seals; rod damage is often a result of objects falling on an extended rod, debris being dragged back through the seal upon retraction, or oil contaminants scoring the rod.

The piston rod is the most vulnerable hydraulic system component. If the rod becomes damaged, leakage and failure follow shortly thereafter. Most cylinder suppliers offer a range of designs based on customer preference – Wastebuilt mirrors the OEM selections.

Hardened steel rods are standard; most rods are hard-chromed. An alternative is black nitride or nitrocarburizing which involves converting the surface of the rod with iron nitride which provides:

The combination of a nitrocarburized rod and steel scraper considerably extends the life of the cylinder, but also adds materially to the cylinder’s cost.

Wastebuilt’s cylinder suppliers include many of the same suppliers used by the OEM’s. Like the refuse body OEM’s, we do not sole-source from any one supplier and have several suppliers for each item to ensure the integrity of supply to our customers.

Wastebuilt works with the world’s leading suppliers (ISO 9001 Certified) to ensure we offer high-quality cylinders to meet the needs of our customers.

Wastebuilt provides a two-year limited warranty for all new hydraulic cylinders and a three-year limited warranty on cylinders with nitrocarburized rods.

If cylinder performance has deteriorated or leakage is evident, action is needed. The question is whether the cylinder can be repaired or if it should simply be replaced.

In the past 5-10 years, cylinder rebuilding has become less common as the cost for new cylinders with longer warranties have become much more competitive when compared to rebuilding.

WARNING — Often what is claimed as a cylinder rebuild is just the replacement of a seal kit; this practice, as much as anything else, may have contributed to the decline in the number of cylinder rebuilds.

Wastebuilt cylinders are sourced direct from the same suppliers as the OEMs, but Wastebuilt has one less level of mark-up than most OEMs who must deliver through a chain of distributors.

All Wastebuilt cylinders are brand new and carry a minimum 2-year (and up to 3-year) warranty; we do not sell rebuilt cylinders because the cost of a rebuilt cylinder is often more than 50% of the cost of a new cylinder despite used components and the lack of a warranty.

Adjustable Fork Cylinder, Arm Cylinder, Arm Lift Cylinder, Arm Reach Cylinder, Arm Swivel Cylinder, Blade Cylinder, Blade Slide Cylinder, Body Raise Cylinder, Bottom Compactor Cylinder, Cart Dump Cylinder, Carriage Cylinder, Compactor Cylinder, Container Arm Lift Cylinder, Container Cylinder, Container Dump Cylinder, Container Fork Cylinder, Container, Grabber Cylinder, Container Tilt Cylinder, Dump Hoist Cylinder, Dumper Cylinder, Dumping Door Cylinder, Ejector Cylinder, Fork Cylinder, Grabber Cylinder, Grip Cylinder, Hoist Cylinder, Holding Panel Cylinder, Hopper Cover Cylinder, Inner Door Swing Cylinder,Inside Blade Cylinder, Inside Packer Cylinder, Lift Cylinder, Lift Arm Cylinder, Lift Tip Dump Cylinder, Link Cylinder, Loading Arm Cylinder, Operating Blade Cylinder, Operating Packer Cylinder, Operating Sweep Cylinder, Outside Packer Cylinder, Outside Blade Cylinder, Overhead Container Cylinder, Packer Cylinder, Packer Blade Cylinder, Panel Cylinder, Partition Door Swing Cylinder, Partition Positioning Cylinder, Push Out Cylinder, Reach Cylinder, Reeving Cylinder, Roll Bar Cylinder, Self Levelling Cylinder, Service Body Lift Cylinder, Slide Cylinder, Slide Shift Cylinder, Sweep Cylinder, Tailgate Raise Cylinder, Tailgate Latch Cylinder, Through Bucket Lift Cylinder, Tilt Cylinder, Top Compactor Cylinder, Top Door Cylinder, Winch Cylinder and others.

Wastebuilt offers a wide variety of hydraulic cylinders for most refuse bodies including EZ Pack, G&H, Galbreath, Galfab, Heil, Kann, Labrie, Leach, Loadmaster, McNeilus, New-Way, Pak-Mor, Pioneer, Wayne, Wittke and others.

To learn more about Wastebuilt hydraulic cylinders, availability and pricing, contact Wastebuilt at 855-927-8328 or online via our Refuse Body Parts page.

Caterpillar is the world’s leading manufacturer of construction and mining equipment, engines, and diesel-electric locomotives. Their hydraulic cylinder assemblies are sold in both separate parts and in kits, with the option to buy new or remanufactured cylinders within any specification desired. They own more than 500 locations around the world and are headquartered from Deerfield, IL.

Eaton Corporation is a global power management company and manufacturer of electrical and mechanical equipment and hydraulics, based out of Beachwood, OH. They manufacture and distribute the world’s largest selection of standard cylinders and provides customized cylinder solutions for interested buyers. Eaton serves the aerospace, building, data center, military, healthcare, mining, oil and gas, rail, residential, utilities, vehicles, and other vital industries.

Parker Hannifin is a worldwide supplier of precision-engineered motion and control technology for the commercial, mobile, industrial, and aerospace markets. Parker is the leading global manufacturer of hydraulic cylinders and actuators for industrial applications, and have an extensive portfolio of accumulators, linear actuators, grippers, stages, and related equipment. They possess around 13000 global locations and are run from their headquarters in Mayfield Heights, OH.

Bosch Rexroth Corp is a global engineering firm and manufacturer of control and motion systems used in industrial and mobile equipment, headquartered from Lohr am Main, Germany. Their products include assembly technologies, electric drives and controls, gears, industrial hydraulics, linear motion devices, molding and casting technology, robotics, and more, and have related services to ensure paired customers succeed in their applications.

SMC Corporation is a Tokyo-based global manufacturer of automatic control equipment, sintered filters, and filtration equipment. They sell full pneumatic control systems and provide gauges, fittings, and control inputs needed to create a state-of-the-art air control system for any need. They provide their products to Japan, the US, Europe, and China and own factories in 30 countries.

HYDAC is a fluid engineering solutions provider, with products ranging from components to complete hydraulic and electronic systems for numerous applications. Their product line includes filtration systems, sensors, controllers, cooling systems, accumulators, hydraulic cylinders, compact hydraulics, and more. They own 100 + branches all over the world and have their head office in Sulzbach, Germany.

Standex International is a global manufacturing company with five segments in electronics, engraving, engineering, hydraulics, and food service equipment. Standex’s hydraulic division manufactures mobile cylinders for standard and custom applications, all made in the US and China to serve the truck, airline, mining, farming, and other industries. Their headquarters is in Salem, NH.

Actuant Corporation, recently renamed to Enerpac Tool Group, is a premier industrial tool service company and manufacturer of hydraulic products around the globe. They create small to high tonnage hydraulic cylinders and related equipment, along with pumps, lifts, pullers, cutters, portable machine tools, and much more from their 28 facilities in 22 countries. They are headquartered in Menomonee Falls, WI.

Weber-Hydraulik is a manufacturer of cylinders, manifolds, steering and suspension systems, valves, aggregates, and more, based out of Güglingen, Germany. Their products include cylinders, hydraulic control systems, valves, rescue equipment, and much more with additional customized options for any desired application. They serve the agriculture, crane, municipal, material handling, machinery, construction, truck, rescue equipment, and general industrial markets.

Marrel is a global manufacturer of high-pressure hydraulics, skip loaders, tipper scissors, and other industrial vehicle-mounted equipment for government, construction, waste management, armed forces, and agricultural applications. Their manufacturing capabilities can create bores from 60 to 350 mm, rods from 32 to 200 mm, and stroke lengths up to 2500 mm, all equipped with built-in position sensors. They are a mainstay in the industrial heavy-duty hydraulics market and are headquartered in Andrézieux Bouthéon, France.

Texas Hydraulics, of Temple TX, is a custom hydraulic cylinder manufacturer for OEMs, utilities, road service, mining, material handling, public service, underground construction, oil, gas, waste, transportation, agriculture, defense, and many more markets. They can walk customers through engineering to manufacturing to value-added services to ensure their standard or custom hydraulic system will fit the needs of their applications, and have an extensive catalog of configurable light-to-heavy duty cylinder options to choose from.

Parker Hannifin, Parker’s Cylinder Division designs and manufactures the largest selection of actuation in North America. Cylinder Division offers a full range of standard NFPA hydraulic and pneumatic cylinders, mobile, compact and telescopic cylinders, helical rotary actuators, tilting couplers and custom cylinders.

RAM Industries Inc. is a leader in hydraulic and pneumatic cylinder design and manufacturing. RAM has served OEMs for over 45 years in a wide range of industries with custom and innovative cylinder solutions. RAM’s success is built on its engineering and technical expertise. RAM designs and builds cylinders that meet your equipment fit and performance requirements. RAM prides itself on its quality products, service and customer support. Contact the RAM team of experts today!

Hader Industries, Inc. We have the knowledge in the hydraulic cylinder industry that allows you to keep running efficiently and effectively for years. We don’t believe in making products that will break easily, and all our products can stand up to the harshest uses. We take the time to ensure that our designs are the best, and everything we make is made right here in the US! Find out more by contacting us today!

A.L.E. Hydraulic Machinery Company LLC was incorporated in 1975. Since then we have been responding to our customers requests for services such as engineering services and fabrication.

Advanced Fluid Systems, Inc. For over thirty years, Advanced Fluid Systems has been manufacturing custom hydraulic cylinders, pneumatic, lubrication, filtration and motion control systems. OEM trained & certified repairs and installation services. Our sales engineers are supported by in-house engineering and highly knowledgeable customer service departments. Contact us today for more information!

Advanced Hydraulics, Inc. At Advanced Hydraulics, we offer heavy duty hydraulic cylinders and medium duty hydraulic cylinders, as well as hydraulic presses, pumps, valves, air cylinders, and more. We also provide a hydraulic cylinder repair service. With over sixty years in the industry, you can count on us for high quality products and service.

Aggressive Hydraulics, Inc. is a leading manufacturer and designer of custom hydraulic cylinders. Since our founding in 2002 we have assembled a team of experienced professionals and talented engineers to assist us in creating the best hydraulic cylinders on the market. The component parts we offer include cylinder heads, end caps, mounts, pistons, ports, valve blocks, and other related accessories. To learn more about our hydraulic cylinders, visit our website.

AiROYAL Mfg. Co. is a manufacturer of medium and heavy duty hydraulic cylinders, custom hydraulic cylinders, welded hydraulic cylinders, telescopic hydraulic cylinders, special hydraulic cylinders, high pressure hydraulic cylinders, small bore hydraulic cylinders and standard hydraulic cylinders. We also have both single- and double-acting cylinders.

Al Xander Company, Inc. is a second generation family business, hydraulics and pneumatics distributor and manufacturer of pneumatic valves, controls and air line accessories. We pride ourselves on our largely stocked quality products. Contact us today for availability and pricing of a variety of components including air and hydraulic cylinders, o-rings, quick disconnect couplings and pressure gauges.

Alkon Corporation is a leading manufacturer of custom hydraulic cylinders, special hydraulic cylinders and low pressure cylinders. Currently, we have 20,000 hydraulic cylinders in stock. Honed brass tubing construction equals longer lasting cylinders. We offer the best in quality, service and delivery.

Anker-Holth™ is a manufacturer of a variety of hydraulic cylinders, including our mill duty cylinders, high-pressure cylinders, rotating cylinders, casting cylinders, torpedo cylinders, tie-rod cylinders and more. We will also build a cylinder according to your system parameters.

Atlas Cylinders, a division of Parker Hannifin, is a manufacturer of heavy duty tie-rod custom hydraulic cylinders with bore sizes from 1” – 48”. Our special hydraulic cylinders and small hydraulic cylinders are used all over the world. Our cylinders are the major source for Boeing.

Aurora Air Products is a family-owned and -operated company specializing in the manufacture of air cylinders, pneumatic cylinders, hydraulic and stainless steel cylinders. You can choose a device from our extensive catalog or receive assistance building your own.

B&H Machine, Inc. A progressive reputation in cylinder manufacturing for over 40 years, B&H means “PRECISION” & “QUALITY” when it comes to heavy duty mill type, Pathon line & special design air & hydraulic cylinders, with a specialty in large bore & long stroke cylinders plus repair, rebuild, refurbish & modify all types & all manufacturers cylinders. Your go-to source for the most difficult cylinder requirements!

Bailey International LLC is recognized for “best in class” hydraulic cylinders of all types and sizes, and settles for nothing less than total customer satisfaction. Our product line includes Bailey brands Chief® and Maxim®, Prince cylinders, telescopic cylinders, surplus and custom cylinders. See what we can ship immediately or how we can customize to your specs. Economically priced for one to thousands!

Bay Hydraulics, Inc. For expert hydraulic equipment & servicing, Bay Hydraulics repairs & sells all brands of hydraulic motors, pumps, valves, cylinders and more. We not only rebuild your hydraulic motor but also do hydraulic testing to 150 HP and 5000 PSI. Our field service offers complete hydraulic trouble-shooting.

Berendsen Fluid Power is one of the largest distributors of pneumatic and hydraulic products in North America. We distribute from quality manufacturers products such as hydraulic cylinders, hydraulic pumps, hydraulic motors, hydraulic valves, filters and more. Visit our website for more information.

Best Metal Products Co. meets exact OEM specifications for custom hydraulic cylinders & hydraulic rams with superior service & turnaround. For the highest quality single, double acting, welded, telescopic & mobile cylinders in a broad range of configurations for high & low duty uses, trust our more than 50 years of expertise. Our continual refining of processes equals the best quality cylinder.

Bimba Manufacturing Company produces air cylinders, stainless steel air cylinders, rodless cylinders and a variety of other cylinders. We provide custom-designed air cylinders, quick delivery and a company-wide commitment to quality. Contact us for your cylinder needs today!

Bosch Rexroth Corporation, Pneumatics Division With 60 years experience manufacturing and distributing innovative air cylinders and valves, Bosch Rexroth offers standard and custom solutions for all industries. Cylinder types include NFPA, rodless, micro and mini, ISO/VDMA, octagon, twin rod, slides and pneumatic cylinders. We offer brass cylinders & stainless steel cylinders. Try our on-line configurators! We strive for customer satisfaction.

Brenner-Fiedler & Associates, Inc. has been a leading automation and pneumatic solution provider for well over seven decades.The company has earned multiple certifications from ISO for their quality. Their panel shop focuses on creating world class material for product line like ABB, Kawasaki etc. If you are looking for good quality and affordable automation/ pneumatic related products then Brenner – Fiedler is the right place for you.

Buffalo Hydraulic – For over 60 years, our company has offered hydraulic solutions to complex high pressure problems. We distribute products such as hydraulic cylinders, hydraulic presses, hydraulic pumps, hydraulic valves (both direction and solenoid), control valves, flow valves and more. We also can custom build pneumatic and hydraulic valves.

C & C Hydraulics, Inc. For 30 years, C & C Hydraulics has been serving the hydraulic system needs of its customers throughout New England. We offer several product lines of hydraulic motors. We also repair hydraulic motors, cylinders and pumps, as well as steering gears and parts. Contact us for free pickup and delivery.

CAL-WEST Machining Inc. Here at CAL-WEST Machining Inc. we offer a comprehensive line of hydraulic cylinders. These quality products can be tailored to your exact needs. There is no project size too big or too small for our company, we promise to supply your needs no matter what. It is our mission to create a lasting relationship with our customers and we will always support your projects. Please give us a call today to learn more information!

Canadian Tool & Die – We have extensive experience in the manufacturing of hubs, spindles, wheels, OEM cylinders and replacement cylinders for agricultural and industrial use. We maintain rigid quality standards through all phases of production, thus, Canadian Tool & Die has built a reputation for quality, dependability and service throughout Canada and the United States.

Carlson Hydraulics, a division of Squires Corp., is a leading manufacturer of welded hydraulic cylinders, heavy duty hydraulic cylinders, custom hydraulic cylinders and high pressure hydraulic cylinders. We can also produce your cylinder in a custom size to suit your particular specifications. Our staff is on hand to assist you with any inquiries. Call Carson and speak to a representative today!

Heil, whose head office and main production plant was in Milwaukee, Wisconsin, USA, was at one stage on the ‘cutting edge’ of earthmoving technology when it introduced its ‘Heiliner’ series of motor scrapers and bottom dump wagons.

Heil also built a lot of the truck bodies fitted to the early Mack AC trucks, many of which were used in the construction of the Hoover dam (Arizona / Nevada border, 1931-36).

A separate Road Machinery division was set up to develop and manufacture earthmoving equipment. This caught the attention of International Harvester who entered into a manufacturing agreement in which Heil became a preferred supplier to International to produce blades and scrapers to be used with IH’s range of track type tractors.

Heil’s bulldozer blades were, however, fairly crude compared to International Harvester’s other major equipment supplier, Bucyrus-Erie, and consequently, Bucyrus blades could be more commonly found fitted to International tractors.

The scrapers loaded well, and part of the secret of their loadability was a low centre of gravity and Heil’s curved bowl floor that imparted a natural boiling action to incoming earth, thus reducing the amount of tractor power required to load it.

Not especially successful, they were interesting machines none-the-less in that the very early models, the “Dig-N-Carry”, were supplied with their own engine mounted on the rear to power a hydraulic pump. This means the pump was not reliant on the tractor to power the setup (very few track tractors of the period had hydraulic pumps on them, let alone having the necessary flow to operate a scraper).

On the other hand, the cable operated “C” and “4C” series were very successful and widely produced, the bowl of the C-14 being used as the basis for the 2H700 motor scraper while the C-12 was used for the 2H500

Spurred on by LeTourneau’s successful Tournapull, Heil tried its hand at manufacturing a three-axle motor scraper and in 1940 introduced the 10 cubic yard Truc-Trailer Scoop. It was powered by a 10 litre 6-cylinder Waukesha gasoline engine.

A larger version known as the High Speed Scoop was introduced in 1941, featuring the same tractor unit but now powered with a 150 horsepower Cummins diesel and pulling a 15 cubic yard scraper.

A two-axle overhung machine powered by a 150 horsepower Cummins HBIS600 diesel, the 2H700, had a Fuller manual transmission and featured hydraulic steering.

In 1948 another smaller Heiliner joined the range, being the 13 cubic yard 2H500 that later became the model 2T-55 in International-Harvester’s catalogue.

Heil’s Heiliners had a tendency to nose dive in a turn and the steering geometry, although hydraulic, was not designed for 90 degree turns, limiting the machine to about xx either side of centre.

It was also easy to lift the rear wheels clear of the ground when push loading due to the location of the bowl’s draft arm pivots, and the scraper’s push block was hard on dozer blades due to its shape.

International was very keen to get its hands on Heil’s two motor scrapers to fill out its own product range and save many, many thousands of dollars in research and development (R&D) costs in the process.

International had also bought Bucyrus-Erie’s construction equipment division to secure once and for all the blades, buckets, rippers and compaction equipment it manufactured and of course this also included Bucyrus-Erie’s towed scrapers as well.

International didn’t need two similar and competing lines of towed scrapers in its product catalogue, so the decision was made to sell off the Heil designs and patents and recoup some money.

Britstand in turn sub-licensed Hewco (Huntly Engineering & Welding Co) of Huntly, New Zealand to manufacture the OC-6 model, eight of which were used as the basis for Hewco’s “Twin-Six” motor scraper, New Zealand’s only indigenous motor scraper.

Today, the commercial division of Heil still exists, manufacturing specialist garbage collection units and dump truck bodies just as they did when the company was set up.

The occasional Heil or Britstand scraper can, however, still be found operating in New Zealand, almost all of them converted to hydraulic operation, a conversion to which the type was ideally suited due to its overall layout.

Genuine Heil motor scrapers (Heiliners) are non-existent but there are a few preserved examples of the type from when International-Harvester manufactured them.

All full-size Heil Environmental refuse collection and recycling vehicles now are equipped with an updated in-tank hydraulic oil filter. Heil says the 3-micron filter is more efficient and captures up to 85 percent more 4-micron contaminants and 50 percent more 6-micron contaminants than its previous filter.

According to the company, the hydraulic oil passing through the filter becomes much cleaner than even new oil, helping to extend the life of the vehicle’s hydraulic pump, valves and cylinders. The new filters have the same dimensions as the company’s previous 5-micron filters, making it easy for customers to upgrade existing vehicles; older vehicles that use 6-micron or 10-micron filters can be retrofitted with simple conversion kits.

8613371530291

8613371530291