torque hydraulic pump factory

... displacement hydraulic motors ensure superior reliability and extended lifetime, supported by their high mechanical efficiency, high starting torque ...

... the motors by Linde Hydraulics: The motors of the Series 02 are capable of transmitting the required torque even at low speed and make it possible to start smoothly ...

... piston fixed displacement hydraulic motors, with unique fluid column technology, have been specifically engineered for high mechanical and volumetric efficiency over a wide range of ...

... series of fixed displacement radial piston hydraulic motors. Available in a wide range of displacements, 100cc-8000cc, it offers very high volumetric efficiency and is ideal for motors requiring high torques ...

... withstand both high mechanical and high hydraulic shock loads offering excellent life and continuous high power use. Speed and power ratings are significantly higher ...

Technically, hydraulic motors are mechanical actuators; they convert pressure into rotational hydraulic energy and torque. They are also the rotary counterpart of hydraulic cylinders. Because hydraulic motors are driven by engines, they may also be called hydraulic drive motors.

Broadly, hydraulic motors serve the construction, automotive, agriculture, forestry, manufacturing, military, waste management and recycling, aerospace, marine, and oil and energy industries.

Hydraulic motors, for example, help raise the wing flaps of airplanes and power the lifting of industrial cranes. Some other of the many machines with which customers use hydraulic motors include agitator and mixer drives, crane drives and self-driven cranes, conveyor and feeder drives, drilling rigs, cars and trucks, drum drives for digesters, high-powered lawn trimmers, the wheel motors of military vehicles, shredders, trench cutters, trommels, kilns, excavators, marine winch drives, and plastic injection machines.

The first hydraulic motors were born during the Industrial Revolution, when industrialist William Armstrong started working on ways to make hydraulic power more efficient. One of the first results of his efforts was his invention of the water powered rotary engine. While his contemporaries did not make much use out his engine, it did serve as an example of a working hydraulic powered rotary actuator upon which later inventors could build. Later, Armstrong designed the hydraulic motor used to the power the Swing Bridge positioned over the River Tyne. His oscillating, single action engine featured three cylinders. Over the years, Armstrong designed many different hydraulic motors, used to power machines like hydraulic cranes and applications related mainly to bridges and docks.

Many of Armstrong’s designed wasted water because they used the same amount of water no matter the load size. This is because they featured fixed strokes and valves with cut-offs operators could not control. To remedy this, engineers such as Arthur Rigg began designing variable stroke hydraulic motors. Generally, operators were able to control water consumption and engine power by adjusting stroke. Arthur Rigg patented his engine design in 1886. It featured a three-cylinder radial engine, the stroke length of which operators could control using a double eccentric mechanism.

Since the Industrial Revolution, engineers have learned ways to use hydraulic power more efficiently and to achieve greater feats. Modern hydraulic systems power hydraulic equipment and products like bulldozers, cranes, kilns, hydraulic lifts, metalworking machines, and much more.

For the best results, manufacturers build the interior hydraulic motor components and main hydraulic motor enclosure from a durable metal, like steel or iron, that can weather both high operating speeds and pressure.

In order to build the best hydraulic motor possible, manufacturers must take a number of factors into consideration, including the state of the relief valves, fluid reservoir, and hydraulic pump. All of these components must all be endowed with levels of strength, capacity, and power that matches the needs of the fluid that will go through them. This fluid, in turn, must be chemically stable and compatible with the metals with which the motor is made, and it must be a good lubricant.

Some of the motor components that manufacturers can customize include torque (starting torque, torque output, breakaway torque, running torque, etc.), motor size, motor range, presence of pistons and shafts, pressure fluid level, and resistance rating.

Hydraulic motors are constructed with a fair amount of simplicity. Its three main parts are the hydraulic pumps, reservoir, and cylinder. Of course, a hydraulic motor, or hydraulic pump motor, would be nothing without the addition of pressurized fluid, usually a type of oil. This hydraulic component creates motion by pushing against it so that the motor’s rotating components spin all the more quickly and generate mechanical energy. Hydraulic motors often also feature input shafts and output shafts. Shafts assist in operation by applying fluid energy to the load.

To work, a small pneumatic engine pumps oil from the reservoir, where it goes from an inlet valve to an outlet valve and through a series of gears and cylinders or turning vanes, depending on the motor’s design.

There are a few different types of hydraulic motors. The main ones, which are each named for the rotating component they use, are vane, gear, and piston hydraulic motors.

Gear motors, or hydraulic gear motors, consist of a driver gear and an idler gear. To generate power in a gear motor, high pressure fluid is forced into one side of the gears, where it flows around outskirts of the gears to the outlet port, where the gears then interlock and disallow the oil from flowing back out. Here, the gears rotate, generating energy.

Piston motors may use an axial piston pump or a radial piston pump. An axial piston motor pump consists of an odd number of pistons, arranged in a circle around a cylinder block, to regulate fluid pressure and flow. A radial piston motor pump, on the other hand, use pistons mounted around an eccentrically-balanced center shaft, which either radiate inward or outward.

In addition to the basic motor types, there are a few different types of specialized motors, modified for semi-specific applications. These include hydraulic wheel motors, high speed hydraulic motors, high torque hydraulic motors, and gerotor motors.

Hydraulic wheel motors are built directly into wheel hubs, where they contribute the power the wheels require to rotate. Depending on the size of the machine and the power of the motor, a hydraulic wheel motor can control just one or multiple wheels.

High speed hydraulic motors provide higher than normal amounts of power by converting hydraulic pressure fluid into force with an elevated number of rotations per minute.

High torque hydraulic motors, on the other hand, achieve increased torque by running at low speeds, which is why they are often called low speed-high torque (LSHT) motors.

Gerotor motors, or generated rotor motors, are motors that consist of an inner and outer rotor. These hydraulic motors can also work as pistonless rotary engines.

Hydraulic motors offer their users a wide a range of benefits. These benefits include improved power transmission, efficiency, improved power transmission safety, and increased ease and simplicity of power transmission.

In addition, hydraulic motors are much more powerful than electric motors of comparable size. They can also achieve high quality results even in a tight space; manufacturers are able to design compact hydraulic motors that use stroke lengths of less than an inch. A byproduct of this is the fact that they are very versatile.

Examples of hydraulic motor accessories you may require include motor seal kits, pump seal kits, check valves, tubing, pumps, and hydraulic fluid. To find out what accessories are best for your application, talk to your hydraulic motor supplier.

First, check your hydraulic motor regularly for issues like motor input shaft or output shaft misalignment, motor displacement, dirty hydraulic fluid and internal leaks (check motor feed lines and the like).

Second, treat your motor well by never operating it outside of its designed limitations. For example, do not push it beyond its designated load, speed, torque, temperature, and pressure. Exceeding your motor’s designed limits puts it at risks for issues like diminished internal lubrication (associated with excessive heat), single displacement reactions, and general malfunctions.

Finally, for your own safety, always handle your hydraulic motor components with proper care. For example, never make direct physical contact with active hydraulic fluid. Not only could it burn you, but if it is under pressure, it could release with a damaging amount of force. Look to organizations like OSHA to guide you when it comes to handling of hydraulic motors.

As we mentioned in the section above, you should always use hydraulic motors according to the guidelines of OSHA, or the Occupational Safety and Health Administration. OSHA puts out standard guidelines designed to keep you and your workers safe when operating machinery. You should also make sure your manufacturer builds your hydraulic motors in a way that supports OSHA requirements.

In addition to OSHA guidelines, your hydraulic motors likely need to meet the standards of a variety of other organizations. The answer to the question of which organizations and guidelines depends on your industry, application, and location. For example, in the United States, some of the standards organizations most influential in the hydraulics motor industry include the NFPA (National Fluid Power Association), SAE (Society of Automotive Engineers), and ANSI (American National Standards Institute). The premiere organization used internationally is the aptly named ISO, or International Standards Organization. All industries and applications either have their own standards or, most commonly, adapt standards from organizations like these. To find out which standards you should make sure your hydraulic motors meet, talk to your industry leaders.

If you are in the market for a hydraulic motor, you need to partner with a supplier that will drive you to success. Such a supplier will not only be experienced with a proven track record but will also offer you tangible advantages such as the ability to deliver high quality products within your budget, the assurance that they will work within your timeframe, the assurance that they will produce a product that meets your standard requirements, the ability to deliver to you, and the agreement to meet any post-delivery services you require (parts replacement, hydraulic repair, etc.).

Find a supplier like this by checking out the hydraulic motor manufacturers we have listed on this page. All of those we have listed are highly capable hydraulic service providers that have proven themselves many times over. Their information is dispersed evenly throughout the page, wedged in between our industry info paragraphs. For the best results, we recommend you pick three or four you believe have the potential to best meet your specifications, and then reach out to each of them individually to discuss said specifications. Once you have done that, compare and contrast those conversations, and pick the right one for you.

Parker is a global manufacturer of hydraulic pumps, transmissions, gear pumps and motors, engineering superior products for a wide variety of applications. Delivering unsurpassed quality and performance, Parker’s extensive line of hydraulic pumps and motors helps you select the right product for your hydraulic application. Achieve easier, safer, and more efficient operation. The Pump & Motor Division assures consistent quality, technical innovation, and premier customer service.

Features Z-Class high-efficiency pump design; higher oil flow and bypass pressure, cooler running and requires 18% less current draw than comparable pumps

From inflatable jacks, hydraulic pumps, cylinders and valves to clamping components and hydraulic accessories, Power Team brand high-force tools and equipment are used wherever strong, concentrated force is required ― on construction sites, in power plants, on rail lines, in shipyards, in mining operations and more.

Located in the United States in Rockford, Illinois, the Power Team brand is marketed by SPX FLOW Inc. in 155 countries. Global sales and manufacturing offices are located in the United Kingdom; the Netherlands; Shanghai and Suzhou, China; and Singapore. The Power Team brand is sold through a worldwide network of stocking industrial distributors. Service is available throughout the world at authorized Power Team Hydraulic Service Centers.

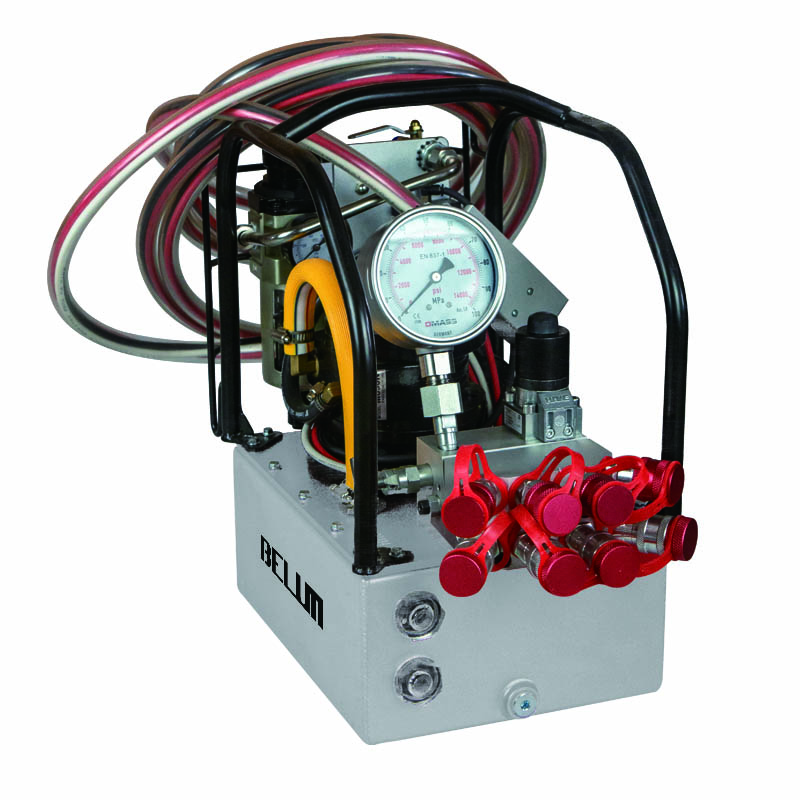

Enerpac offers a wide range of hydraulic torque wrench pumps, with electric or air motors to power single or double-acting hydraulic torque wrenches. Safe and efficient new Enerpac Z-Class ZU4T-series pumps with universal electric motor made especially for repetitive bolting tasks.

Enerpac electric torque wrench pumps feature Z-Class high-efficiency pump design; higher oil flow and bypass pressure, cooler running and requires 18% less current draw than comparable pumps

Auto cycle feature provides continuous cycle operation of the torque wrench as long as the advance button is pressed. (Pump can be used with or without auto cycle feature)

Enerpac electric torque wrench pumps feature Z-Class high-efficiency pump design; higher oil flow and bypass pressure, cooler running and requires 18% less current draw than comparable pumps

Auto cycle feature provides continuous cycle operation of the torque wrench as long as the advance button is pressed (Pump can be used with or without auto cycle feature)

On the design of a new machine which is to be run with a hydraulic motor, a determination of required speed and horsepower must be made so a model with suitable ratings can be selected. This issue describes several methods of making such a determination.

Designers who are experienced only in selecting electric motor drives need to be careful in designing hydraulic drives because of important differences between these two motors.

This is not true of a hydraulic motor. It is selected on the basis of torque and speed rather than horsepower. It cannot be selected without also considering the pressure and flow of the pump which will supply it with fluid. If it is inadvertently selected oversize for the job, its performance will not be as good as if it were correctly sized. Hydraulic pump and motor must work as a team. For optimum performance, the pump and motor must be correctly matched.

An electric motor is relatively easy to select because, at any given horsepower, there are only a few fixed speeds from which to choose, and it does not have to be matched to the alternator which supplies the power. On an induction type electric motor, starting torque is always greater than running torque, so this type motor can start any load which it can run. It can start under a full torque load, or even an overload, although if started too frequently, there will be an excessive heat build-up in the windings.

The reverse is true of a hydraulic motor. Starting torque is uncertain, but nearly always is less than running torque, so this type motor cannot necessarily start under full load but it can run any load it can start. Usually, it cannot start a full torque load unless it has been oversized to gain starting torque. If purposely selected oversize, then it will likely have poor speed regulation with the result that it cannot cover as wide a speed range with acceptable performance.

Torque, not horsepower, is the basis for proper selection of a hydraulic motor. In nearly every application the desired speed is already known, leaving only the torque to be determined.

Torque is always the most significant factor in any hydraulic motor system - much more significant than either speed or horsepower. Unless the motor has sufficient torque to start the load or to run it at maximum speed, the system can never work properly no matter how much horsepower is available.

After a hydraulic motor has been tentatively selected, the horsepower can be computed from speed and torque. If this turns out to be more than is available from the pump, then some of the speed must be sacrificed, but never the torque

Load torque is the twisting or turning effort which must be exerted on the load shaft to start the load and/or to run it at maximum rated speed. This torque must be supplied by the hydraulic drive motor. The amount of torque which will be required from the motor can be estimated in one of several ways:

It is essential that characteristics of the load be considered when attempting to estimate hydraulic motor torque for starting and/or running. Some loads require more torque to break them away from a standstill than to run them after they have started. Other loads require only a small amount of breakaway torque but torque requirements increase in proportion to speed.

Breakaway Torque. Figure 1. Breakaway, or starting torque can be measured with a torque wrench on small machines, or by using a long lever loaded with weights until the load shaft breaks away and starts to rotate. Torque is calculated by multiplying lever arm length, in feet, times the weight necessary to break the shaft away. Torque will be in foot-lbs. On this type load, if the hydraulic motor can supply breakaway torque, it can also run the load at any speed.

Electric Motor Substitution. The running torque can be determined by temporarily coupling an electric motor to the load shaft and measuring the motor line current while it is running. By referring to a torque/current performance curve for the motor, the running torque can be determined with a fair degree of accuracy. Then, a hydraulic motor can be selected and the system PSI can be established which will give the required running torque. Of course the electric motor speed should approximate the maximum running speed of the load.

This is the easiest method where applicable. The proposed new machine can be compared with an existing machine which does essentially the same job, and on which the torque and speed, or horsepower, are known.

But perhaps the new machine is to produce twice as many parts per hour as the existing machine. Then basically the new machine will require twice the horsepower. Perhaps the new machine will manufacture parts of the same size but twice as fast; hence twice the horsepower. Or perhaps larger parts are to be manufactured which will require twice the torque but at the same production rate. Again, twice the horsepower will be required. Suppose the new machine is to manufacture the larger parts and at twice the rate of the existing machine. Then four times the HP is needed.

Caution! If the existing machine is powered with an electric motor and the new machine with a hydraulic motor, and if high starting torque is required, the hydraulic motor must be selected by comparing its starting torque with the starting torque of the electric motor on the existing machine. An induction type electric motor can produce about 3 times the starting torque of most hydraulic motors of the same horsepower rating.

On machines of new design- where there is no way to measure input torque, nor to compare performance with an existing machine, torque and HP must be calculated.

After HP output is determined, work backwards toward the input shaft of the machine, one step at a time, adding sufficient HP at each step to make up for friction losses in gear boxes, bearings, etc. This will give the estimated HP required from a hydraulic motor coupled to the input shaft.

In a similar manner start with the output speed and work back toward the input, adjusting for speed changes through chain drives, gear boxes, etc., finally arriving at the speed of the input shaft to which the hydraulic motor will be coupled.

Vehicle Wheel Motor. Calculate the total drawbar pull (horizontal thrust) to overcome all road and operating conditions. Using the wheel radius, calculate wheel torque with Formula (C) in the box below. Convert travel speed into wheel RPM. Select hydraulic wheel motor to meet these conditions. Information for estimating drawbar pull and making calculations is given in "Industrial Fluid Power - Volume 3" published by Womack Machine Supply Co.

we are manufacturing hydraulic gear pumps which is widely used in hydraulic power packs and machineries, our product quality is very superior and max pressure is 250bar, we have wide range from 1cc/rev to 66cc/rev as per dowty 0P, 1P and 2P series mounting

Avoid any downtime at your construction site with the range of hydraulic pump torque from Alibaba.com. You can check out the fully-stocked parts at Alibaba by manufacturer and model and affordable wholesale prices. The wholesale hydraulic pump torque collection of spare parts from China’s wholesaler, Alibaba, fits well with a wide range of heavy-duty equipment, from bulldozers, excavators, and hammers, among others. Plus, you can find parts for your tractors, skid steer loaders, wheel loaders, backhoe loaders, and crawler dozers.

If you have a limited cash allocation, the used or remodeled parts will go a long way in accommodating your budget. Alibaba’s hydraulic pump torque and tools make it easy to replace, modify and enhance your equipment for their optimal performance. For electrical and mechanical applications, you can find your match at Alibaba.com for everything you need to make your vehicle perform better. Get engine oils, batteries, hydraulic parts, transmissions, injectors, hoses, and starters from the hydraulic pump torque at Alibaba.com.

The new parts from manufacturers have warranties, and you can buy them by matching the part numbers. Such parts, including hoses, plugs, or filters, will help you quickly deal with downtime on site. The used parts, on the other hand, sell for a lower price. Remember, Alibaba partners with sellers who have certificates of operation. So, you can use these second-hand hydraulic pump torque to get your heavy machine running. You can also get rebuild models from the collection at Alibaba.com. These are sustainable choices that use recycled materials and perform as well as the new parts. And depending on your seller of choice, you might get a warranty to accompany them.

Hydraulic motors (sometimes incorrectly spelled as “hydrolic” motors) convert hydraulic pressure into force that is able to generate great power. They are a type of actuator that converts the pressure of the moving hydraulic fluid into torque and rotational energy.

Hydraulic motors are an important component overall in the field of hydraulics, a specialized form of power transmission that harnesses the energy transmitted by moving liquids under pressure and converts it into mechanical energy. Power transmission is a general term denoting the field of translating energy into usable, everyday forms. The three main branches of power transmission are electrical power, mechanical power, and fluid power. Fluid power can further be divided into the field of hydraulics and the field of pneumatics (translating the energy in compressed gas into mechanical energy).

Arguably, hydraulic power traces back to the beginnings of human civilization. For thousands of years, humans have harnessed the power of moving water for energy. (The most basic “hydraulic” application is harnessing moving water to turn wheels.) For a brief survey of hydraulic history, please refer to our article on Hydraulic Cylinders.

In terms of hydraulic motor development, the middle of the Industrial Revolution proved to be a notable turning point. During that year, English industrialist William Armstrong started developing more efficient applications of hydraulic power after observing inefficiencies in water wheel usage on a fishing trip. One of his first inventions was a rotary, water-powered engine. Unfortunately, this invention failed to attract much attention, but it provided an early model for a rotary actuator based on hydraulic power.

The use of hydraulic systems in general offer several advantages within the overall field of power transmission. Some of those advantages include efficiency, simplicity, versatility, relative safety, etc. These and other advantages are further elaborated on in our article on Hydraulic Pumps.

Hydraulic motors are able to produce much more power than other motors of the same size and for this reason are used for larger loads than electric motors.

When space constrictions are an issue, small hydraulic motors are used. Small hydraulic motors have small stroke lengths; they may be less than an inch.

A major disadvantage of using hydraulic motors is inefficient usage of the actual energy source. Power systems with hydraulic motors can consume large amounts of hydraulic fluid. For example, it is not uncommon for hydraulically-driven machines on construction sites to require 100 or more gallons of hydraulic oil to operate.

Since they are often confused in everyday language, it is important to distinguish between hydraulic motors and hydraulic power packs or hydraulic power units. Technically speaking, an enclosed mechanical system that uses liquid to produce hydraulic power is known as a hydraulic power pack or a hydraulic power unit. These packs, or units, generally include a reservoir, a pump, a piping/tubing system, valves, and actuators (including both cylinders and motors). It is not uncommon, however, to hear a hydraulic motor described as consisting of these components – a reservoir, a pump, etc. However, it is more accurate to describe a hydraulic motor as a part of an overall hydraulic power system that works in sync with these other components. Hydraulic motors are a type of actuating component within an overall hydraulic power system – a component responsible for actually translating hydraulic energy into mechanical energy.

Liquids represent a “median” state between gases and solids on the matter spectrum. Despite this, liquids represent solids far more than gases in an important aspect: they are virtually incompressible. One consequence of this is that force applied to one point in a confined liquid can be transmitted quite efficiently to another point in that same liquid. This reality forms the basis of the mechanical energy that hydraulic systems are able to produce. For a fuller explanation of how hydraulic power works, please refer to our article on Hydraulic Pumps.

It has previously been noted that “Pascal’s Law” applies to confined liquids. Thus, for liquids to act in a hydraulic fashion, it must function with some type of enclosed system. As noticed in the introduction, these “systems” are known as hydraulic power packs and share three main parts—a reservoir, a pump and an actuator—that work together to convert hydraulic energy into mechanical energy.

Hydraulic motors are an integral part of machines that rely on hydraulic power for operation because they actuate and “complete” the process of converting hydraulic energy into mechanical energy. Since hydraulic motors are fairly simple machines that are composed of rotating machinery, they specifically translate hydraulic energy into rotational mechanical energy. The main enclosure and interior components of the motor are made from metal such as steel or iron so they can withstand high pressures and operating speeds. In a sense, motors can be thought of as hydraulic pumps working “backward” or in reverse.

Overall, a hydraulic power unit pumps fluid (usually a type of oil) via a small pneumatic engine from a reservoir and sends it to the motor while regulating fluid temperature. Oil is pumped from the reservoir through an inlet valve to an outlet valve through a series of gears, turning vanes or cylinders, depending on what specific type of hydraulic motor it is. Pressurized fluid creates mechanical energy and motion by physically pushing the motor, causing the rotating components to turn very quickly, and transferring energy to the machinery that the motor is linked to. Typically, not every rotational component is directly connected to producing mechanical energy; for example, in a typical gear motor, only one of the two gears is connected to and responsible for turning the motor shaft. This type of operation directly contrasts with electric engines, in which electromagnetic forces produced by flowing electric current are the response for rotating the motor shaft.

Hydraulic motors, rotary or mechanical actuators which is operated by the conversion of hydraulic pressure or fluid energy to torque and angular displacement.

Driveshaft, a part of the hydraulic motor that delivers or transfers the torque created inside the motor to the outside environment where it is used for lifting loads and other applications.

Vane hydraulic motors have a hydraulic balance that prevents the rotor from sideloading the shaft, with the pressure difference develops the torque as the oil from the pump is forced through the motor.

There are three basic kinds of hydraulics motors: gear, vane and piston type. Each is identified by the design of the rotating component inside. Collectively, the various types of hydraulic motors are optimal for a wide range of specific applications, conditions or usages.

Another common type of hydraulic motor. Radial piston hydraulic motors have pistons mounted around a center shaft that is eccentrically balanced. Fluid causes the pistons to move outward, causing rotation. Axial piston hydraulic motors derive their name from the fact they use axial instead of radial motion, despite their similar design to radial piston motors.

Built into wheel hubs to supply the power needed to rotate the wheels and move the vehicle. A hydraulic wheel motor can operate a single wheel or multiple wheels, depending on the power of the motor and the size of the machine.

Other motors focus on the rotational speed and torque. High speed hydraulic motors convert hydraulic pressure into force at elevated rotations per minute thereby generating large amounts of power. High torque hydraulic motors run at low speeds while operating with increased torque, thus earning the name low speed-high torque (LSHT) motors.

Advances are still being made to hydraulic motors and their various applications. One example is the development of hybrid hydraulic automobiles, which are being developed as an alternative to gas/electric hybrid cars. Hybrid hydraulic vehicles are particularly efficient at reclaiming energy when braking or slowing down.

A type of orbital hydraulic motor, have rollers that are hydro-dynamically supported to minimize friction, ensuring maximum durability and high output at high pressure.

A type of orbital hydraulic motor, are particularly suited for long working cycles at average pressure. Rotor motors are operated by lobes that are fixed and set directly on the stator.

Hydraulic systems and their use are abundant in a wide variety of fields including construction fields, agricultural fields, industrial fields, transportation fields (e.g. automotive, aerospace), various marine work environments, etc. Hydraulic motors are commonly used in machinery that requires strong pressurized actions such as aircraft for raising the wing flaps, heavy duty construction vehicles such as backhoes or crane industrial lifting or for powering automated manufacturing systems. Hydraulics motors are also used in trenchers, automobiles, construction equipment, drives for marine winches, waste management and recycling processes, wheel motors for military vehicles, self-driven cranes, excavators, forestry, agriculture, conveyor and auger systems, dredging and industrial processing.

While hydraulic power transmission is extremely useful in a wide variety of professional applications, it is generally not recommended to use only one form of power transmission. Although it is somewhat counter-intuitive, the maximum benefit of each form of power transmission (electrical, mechanical, pneumatic, and hydraulic) occurs when each form is integrated into an overall power transmission strategy. As a result, it is worthwhile to put in an effort to find honest and skilled hydraulic manufacturers / suppliers who can assist you in developing and implementing an overall hydraulic strategy.

Despite the apparent simplicity of hydraulic systems, engineers and manufacturers must take into account certain variables in order to build an efficient and safe device. The fluid used in the motor or system must be a good lubricant, first and foremost. It should also be chemically stable and compatible with the metals inside the motor. The pump, fluid reservoir and relief valves should be of appropriate power, capacity or strength to allow the motor to perform at optimum levels.

Problems with hydraulic motors can often be traced to poor maintenance, the use of improper fluid within the motor, or improper usage of the motor itself. Some not uncommon causes of motor failure are:

It is important to keep in mind that hydraulic motors are designed to function within certain limits which should not be exceeded. Those limits mainly include torque, pressure, speed, temperature, and load. To give one example, operating a hydraulic motor at excessive temperatures thins hydraulic fluid, negatively affects internal lubrication, and decreases overall the efficiency of the motor. Staying within a motor’s operational limits will preempt unnecessary and needless malfunctions.

In terms of safety, the relative simplicity of hydraulic systems and components (when compared to electrical or mechanical counterparts) does not mean they should not be handled with care. A fundamental safety precaution when interacting with hydraulic systems is to avoid physical contact if possible. Active fluid pressure within a hydraulic system can pose a hazard even if a hydraulic machine is not actively operating.

A container that stores fluid under pressure. Accumulators, the common types of which are piston, bladder and diaphragm, are used as an energy source or to absorb hydraulic shock.

The amount of fluid that passes through a pump, motor or cylinder in a period of time or during a single actuation event, such as a revolution or stroke.

As a way to ideal meet up with client"s desires, all of our operations are strictly performed in line with our motto "High Top quality, Competitive Cost, Fast Service" for Hydraulic Pump Torque, Hydraulic Pump Jack, Hydraulic Fluid Pump, Electric Hydraulic Pump For Dump Truck 4 Ton Lift,Discount Hydraulic Oil Pump. We are one of the largest 100% manufacturers in China. Many large trading companies import products from us, so we can give you the best price with the same quality if you are interested in us. The product will supply to all over the world, such as Europe, America, Australia,Austria, Las Vegas,Costa rica, Croatia.Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

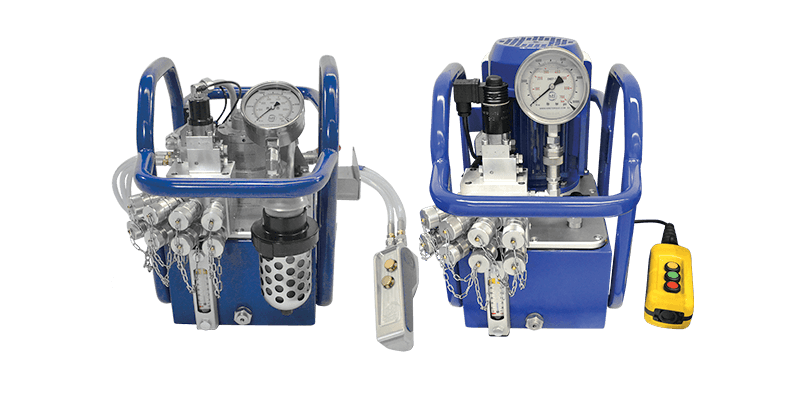

HYTORC HY-EX 3-Stage Electric Pumps are the backbone of an intrinsically safe bolting system. The pump is licensed to EU-Directive 2014/34/EU (Atex 100a) class: 2014/34/EU. These pumps are equipped with a calibrated gauge with certificate and a 15-ft (5m) remote control. An optional 4-tool adapter is also available.

8613371530291

8613371530291