transfer case pto hydraulic pump for sale

All CategoriesMILITARY VEHICLE PARTSPOWER INVERTERS, CONVERTERS, AND TRAILER VOLTAGE CONVERTERSCOMMERCIAL TRUCK PARTS: PTO"s & PUMPS, ELECTRICAL, TURBOCHARGERS & MOREMILITARY AND INDUSTRIAL SURPLUS ITEMS, ELECTRONICS AND MORECUSTOMER"S VEHICLE PICTURESERIK"S T-SHIRTS

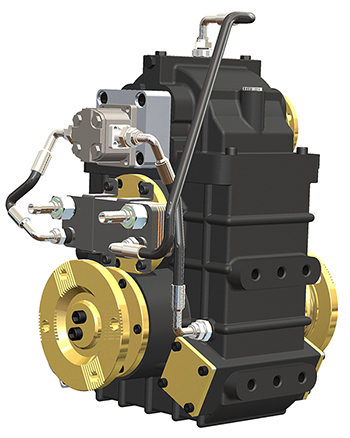

Hydraulic PTO pump P5151A231AAXK25-14, 3000 PSI, 22 GPM at 900 RPM / 55 GPM at 2100 RPM. SAE 4 bolt flange. 7/8 inch - 13 spline shaft. CCW rotation only (compatible with 221 PTO on M939 series truck). Cast iron housing. Doweled construction. Extended rear studs. 1-1/4 inch NPT side and 1-1/2 inch NPT rear ports.

PTO stands for Power Take-Off, which is a common form of mechanical power delivery in the mobile machine market. Here at Flowfit, we are proud to offer industry-leading PTO gearboxes and pump assemblies to transfer high volumes of power and torque from the hydraulic or mechanical systems engine. Typically, these models can be found in high-powered industrial or agricultural machines, including trucks and tractors.

Our PTO gearbox and pump assemblies are available in a wide range of designs and specifications to meet the exact requirements of your system. Typically cast in mechanically-resistant iron or housed in shell-cast aluminium, our models are designed for connecting gear pumps to power take off systems.

For more information on any one of our pump and gearbox assemblies, get in touch with our friendly team of hydraulic and mechanical specialists today on 01584 876 033.

PTO Power Takeoff Mounting Stud, washer and nut kit. Used on M809 and M35 (M44) Series 6X6 Military Trucks with Transmission Mounted PTO. Studs also Used on M37 Dodge for Carburetor Mounting.

Adelman"s has new PTO"s and dump pumps available, along with controls and control towers to help you complete your wetline kit. We carry 8-bolt, air shift, direct mount PTO"s to fit most Eaton Fuller brand, twin counter transmissions. Adelman"s also carries a variety of new hydraulic dump pumps in direct mount and remote mount applications, as well as manual and air shift controlled.

Muncie Pump and Hydraulic Components: remote mounted and engine mounted pump models, geared pumps, clutch pumps, refuse pumps, dump pumps, piston pumps, hydraulic components and valves, hydraulic motors, cylinders and reservoir tanks, snow & ice removal systems, wet kits, drive gear replacement kits, pump mounting kits, idler pulleys and belts, cable, air and leaver controls, control towers, spreader controls as well as throttle and speed control systems.

PTO is one of the most critical components in the truck hydraulic system. It is accountable for transferring mechanical energy from the hydraulic pump to auxiliary parts for executing given applications. However, a slight issue with the truck PTO hydraulic pump can cause system failure resulting in loss of revenue.

If you"re noticing whining or high-pitched sound – it could be because PTO"s gears are not appropriately merged or being too tight, issues with bearings or hydraulics. However, the clattering sound indicates that gears are too loose or have torsional vibrations.

In general, PTO hydraulic pump"s engagement issues could cause due to blocked hoses or bad fittings, connections, or the solenoid. In addition, mechanical engagement could generate from low air pressure, backlash too tight or improper cable deployment.

Once identifying the symptoms, it needs to operate rightly to enhance the vehicle"s life. Routine and scheduled maintenance is essential to ensure the PTO tool functions trouble-free. In this blog, we"ve outlined the maintenance steps for helping the end-users.

The PTO maintenance is divided primarily into three stages. The initial stage, short-term and system stages. The maintenance process needs adequate planning, operational expertise and thorough system knowledge. So, keep that in mind before the initiation of the process of vehicle maintenance.

The first step should be carried out within 24 to 48 hours of use or after experiencing symptoms of PTO hydraulic system damage. It would be best to analyse drive train sound if it seems louder than usual – it means further investigation may be required.

Further in the process, after cooling down the engine, look for potential damage such as leaks. These leaks could impact the transmission fluid level and affect the system performance over time. The PTOs must be checked within a week of installation for making sure that its mounting bolts have been torqued appropriately.

After the initial check-up, the truck operator needs to think about the next maintenance schedule based on the duty cycle. Usually, the duty cycles are divided into normal or severe duties. When the PTO operates five minutes extra out of every 15 minutes, it is defined as a severe duty. Lower than that compared as a normal duty. You can choose which duty cycle is ideal for long-term maintenance based on PTO performance.

The more complex a truck PTO hydraulic pump works, the more it needs to be inspected. Based on previous maintenance, the normal duty cycle inspects which items need replacement, checks the fluid level, or verifies that the equipment is tight and secure.

Long-term PTO maintenance is essential, suggested by vehicle manufacturers. It can help improve the performance of the hydraulic pump. Check fasteners are torqued rightly, and no fluid is leaking around the seal. If you find any leak source, seals need replacement.

Keeping the vehicle in optimal condition and PTO functioning requires periodic maintenance. When regular maintenance is carried out on the vehicle chassis (frame), it will be good to inspect the PTO of the hydraulic system.

During a weekly or monthly maintenance schedule, along with other components, PTO is checked for cleaned shaft proper lubrication. The application of lube simplifies parts engagement and disengagement issues. Applying an anti-seize grease helps smoothen parts movement in high-temperature cases. Also, make sure to clean off the grease fitting once the lube is applied.

Visual Inspection – To make the equipment run smoothly, the PTO inspection needs to be performed weekly or monthly. The inspections include checking for leaks, wear or tear, making sure the hose and wire are not rubbing against the transmission. Through visual inspections, you can prevent many issues immediately.

Physical Inspection –When it comes to checking the condition of PTO – physical inspection is equally important. It is suggested to perform after 100 hours of use. If you have removed the PTO from the hydraulic system for inspection, check the wear patterns and bearings. The periodic physical inspection could reduce the amount of downtime and expenses.

Surya Truck Parts – Your Trusted Online Supplier for Heavy Truck PartsWe are one of the best market leaders in Power Take-Off (PTO) products for the truck and mobile vocational markets. We are an establishedsupplier,having years of experience serving customers with the best and most affordable products.

We offer a complete range of PTO hydraulic system parts to match your needs. At Surya Trucks, you can enjoy cost benefits and get crucial components like PTO wet kit for sale.

The Gear Centre offers the complete line of Parker Chelsea Power Take-Off units and parts. Chelsea has been serving the auxiliary power market since 1945 with the broadest coverage in the industry. Parker Chelsea PTOs are designed with a wide range of internal speeds, torque capacities and output options to match up with virtually all driven equipment requirements.

Offering a complete line of Power Take-Offs for North America, Asia Pacific, Australia, China, India and Europe, including cast iron 6-Bolt, 8-Bolt, 10-Bolt, counter shaft, split-shaft and front engine mount applications, Chelsea PTOs can fit any application you need. Features include mechanical shift, power shift, constant engaged shift options, over speed controls and flanges for direct or remote mounting of hydraulic pumps, blowers, water pumps, product pumps and generators.

In an industrial capacity, the need for heavy-duty components that can handle transmitting the power required for machinery to operate translates into one specific part: the power take-off. The Power Take-Off (PTO) is an essential element that transfers an engine’s power to another mechanical device. However, there isn’t just a single type of engine driven PTO, and each unit is uniquely suited for various, specific industrial applications.

Parker Chelsea is a market leader in Power Take-Off products for the truck and mobile vocational markets. Our PTOs are designed with a wide range of internal speeds, torque capacities and output options to match up with virtually all driven equipment requirements. We offer a complete line of Power Take-Offs for North America, Asia Pacific, Australia, China, India and Europe, including cast iron 6-Bolt, 8-Bolt, 10-Bolt, countershaft, split-shaft and front engine mount applications. Features include mechanical shift, powershift, constant engaged shift options, overspeed controls and flanges for direct or remote mounting of hydraulic pumps, blowers, water pumps, product pumps and generators. Bottom line is if you need a reliable and rugged performer, think Parker Chelsea.

8613371530291

8613371530291