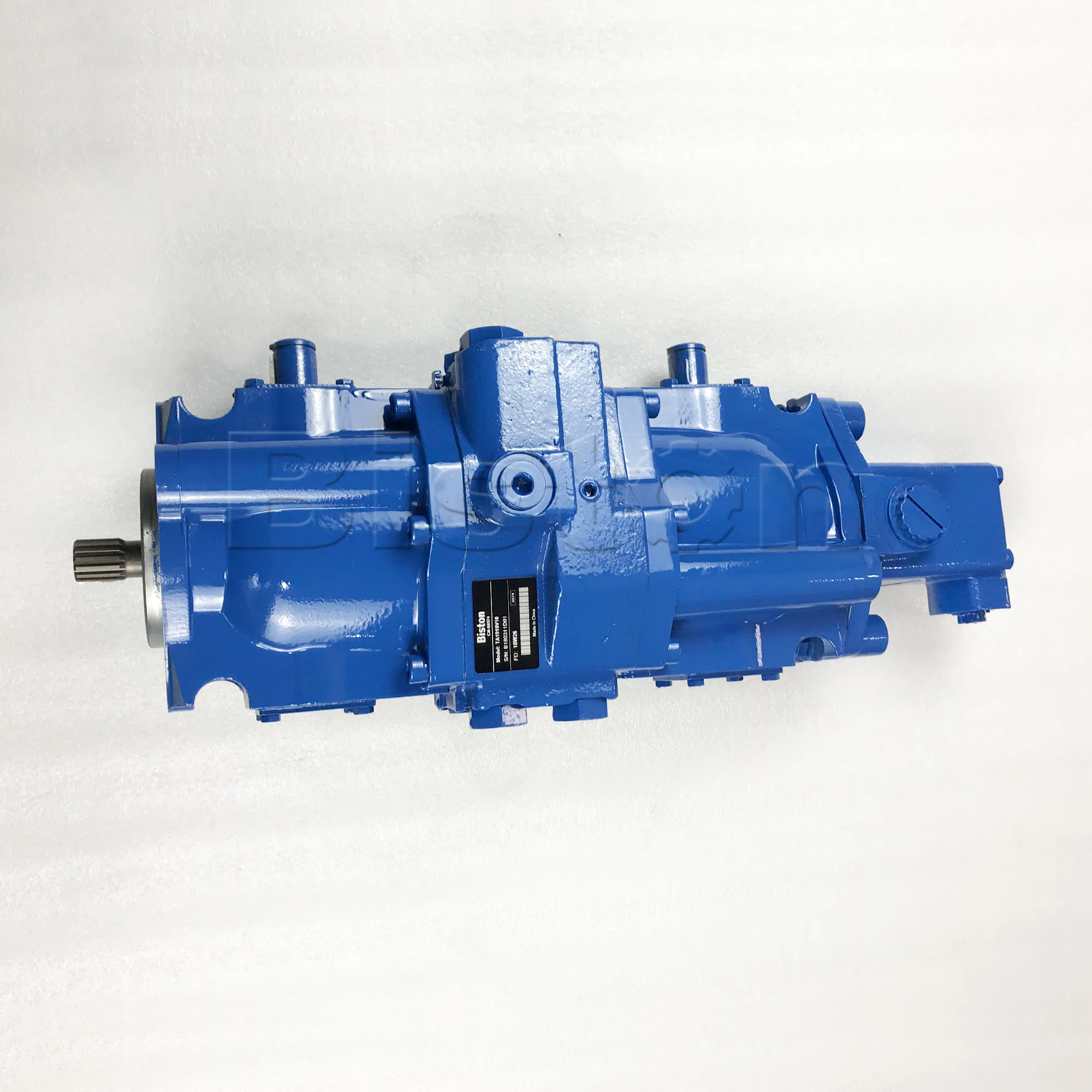

transmission hydraulic pump made in china

Linde Hydraulics is a global developer and supplier of modular drive systems consisting of hydraulics, power transmissions and electronics. As a leading technology provider in the field of high pressure hydraulics, the systems produced by Linde Hydraulics set the standard in terms of significantly reducing fuel consumption and CO2. The product range comprises hydraulic pumps and motors, valves, electronic controls, peripheral devices, rotary drives and electric motors. Linde Hydraulics is the development partner and supplier of a number of reputable manufacturers of mobile work machinery, including construction, mining, agricultural, forestry and municipal utility machines, as well as manufacturers of industrial machinery.

The company, which was founded in 1904, is based in Aschaffenburg. Around 1300 employees work at four production sites in Germany, at a fifth production site in China and at the subsidiaries in Europe, the US, South America and China. Linde Hydraulics is represented in more than 50 countries by a strong network of around 80 sales and service partners.

Gear pumps are commonly used for hydraulic fluid power applications in machines like forklifts. With a simple design, they’re a cost-efficient solution that’s easy to use and easy to maintain. Our product range includes both internal and external gear pumps.

An external gear pump has two identical gears that typically turn towards each other. Displacement chambers form between the gear tooth profiles, the internal walls of the housing, and the surfaces of the bearing blocks. The oil is transported from the suction side to the pressure side within these chambers. The flow of a gear pump is fixed per rotation.

An internal gear pump operates in the same way. It has two interlocking gears of different sizes. The larger gear (rotor) is the internal gear. The smaller external gear, also known as the idler, rotates inside the large gear. When the two gears interlock, the liquid is pushed forward under pressure.

l Protect drive shaft seal during pump painting. Check if contact area between seal ring and shaft is clean: dust could provoke quicker wear and leakage.

Use specific mineral oil based hydraulic fluids having good anti-wear, anti-foaming, antioxidant, anti-corrosion and lubricating properties. Fluids should also comply with DIN51525 and VDMA 24317 standards and get through 11th stage of FZG test.

The YOC marine hydraulic coupling transmission box offers the advantages of on-load starting, overload protection, torsional vibration isolation, impact mitigation, stepless speed regulation, quick and steady clutch, and others. It is a perfect substitute for the traditional mechanical reduction gearbox of engineering ships, improving transmission performance and eliminating the problems existent in the traditional transmission devices. Therefore, the power transmission device is an ideal choice for the power unit of engineering ships.

In view of the special working conditions of such engineering ships as dredgers, sand pumping vessels, etc., our company has designed and manufactured a line of marine hydraulic coupling transmission boxes with transmitted power ranging from 100kW~8000 kW. The products provide superior performance, high reliability, and easy operation and maintenance.

The speed-adjustable hydraulic coupling gravel pump assembly is a brand new product designed based on the characteristics of the working conditions of dredgers, sand pumping vessels and gravel pumps. The hydraulic transmission device offers optimized construction in terms of the hydraulic coupling transmission box structure and shafting.

The hydraulic transmission product comes with integrated pump and transmission box. The head of the gravel pump, by means of the connector panel, is connected to the transmission box, and the rotor (impeller) is directly fitted onto the output shaft of the transmission box. Comparing to an original gravel pump, there are no brackets or bearing housing in the integrated structure. This hydraulic coupling gravel pump assembly has advantages of low manufacturing cost, compact structure, small size, and flexible, smooth drive.

We provide a complete line of market-oriented products which can meet any need of medium and small sized dredgers and sand pumping vessels ranging from 300 to 2000KW.

Following the evaluation of the risk, Hengli has taken measures to protect personal data against accidental or unlawful destruction or accidental loss, alteration, unauthorized disclosure or access, in particular where the processing involves the transmission of personal data over a network, and against all other unlawful forms of processing.

30 years focusing on innovation, Hengli Hydraulic (stock code 601100) has reached the forefront of the world’s hydraulic industry in terms of both production scale and technical level. Meanwhile Hengli is now a widely recognized benchmarking enterprise in the domestic hydraulic industry. Headquartered in Changzhou, Hengli has founded four hydraulic R&D centers in China, Germany, the United States and Japan, and eight manufacturing bases worldwide.

The even stronger Hengli. After the acquisition of Shanghai Lixin Hydraulics and Hawe InLine Hydraulik GmbH, the establishment of a high-precision foundry and a pump & valve factory, Hengli has mastered the key of developing and manufacturing more advanced hydraulic transmission and control components to supply high-pressure cylinders, hydraulic pump valves, motors, precision castings, pneumatic components, and the complete hydraulic system. Well sold in over 20 countries and regions, the products are widely applied in various fields as engineering vehicles, port vessels, mining machinery, tunnel machinery, metallurgy machinery and industrial manufacturing industries.

Hengli is committed to providing customers with efficient hydraulic technology solutions and products, maintaining strong partnerships with customers, and leading the development of China’s hydraulic industry. Through more scientific solutions, Hengli aims to make more contributions to the sustainable development of society, the construction of green cities and building a better future.

8613371530291

8613371530291