truck front mount hydraulic pump manufacturer

Offering a complete line of Power Take-Offs for North America, Asia Pacific, Australia, China, India and Europe, including cast iron 6-Bolt, 8-Bolt, 10-Bolt, counter shaft, split-shaft and front engine mount applications, Chelsea PTOs can fit any application you need. Features include mechanical shift, power shift, constant engaged shift options, over speed controls and flanges for direct or remote mounting of hydraulic pumps, blowers, water pumps, product pumps and generators.

Built for high-torque and heavy-duty requirements, the 82 Series PTO features a lever or air shift cast iron housing and a single or dual optional hydraulic pump mount.

A constant drive power take-off, the CD05 Series PTO is designed to fit tight mount applications. Without loss of torque or horsepower, the CD05 uses the same components as the CD10 but is approximately 15 percent smaller.

Designed as a functional alternative to front, crank shaft driven hydraulic pump applications, the CD10 Series PTO boasts an ample capacity for heavy duty applications without obstructing service areas of the truck engine and cooling system.

Constructed with large gears, the CS10 Series PTO is built for heavy duty applications. The CS10 features a drag brake and an output shaft designed around popular hydraulic pumps. For a more compact installation, the CS11 is a remotely mounted solenoid option.

Designed with the same technology as the CS10 Series, the CS24 Series PTO is 20 percent smaller. CS PTOs are engaged by means of a direct mounted solenoid, which activates an internal wet clutch pack. With this feature, installation is made simple with a single hose connection

Designed to work on Allison 1000 and 2000 series automatics and many other current manual transmissions, the CS6/8 Series PTOs offer direct mount pump options and a drag brake. Upgrading to a multi-disk clutch brake allows for absolute shaft stoppage.

The EX Drive is designed to fit on Allison 3000 and 4000 series transmissions with retarder or cooler, and allows for large gear or piston pumps to be direct mounted, eliminating the need for timely driveline installations.

A solution for limited clearance applications, the HS24 Series PTO features a sculptured housing designed to clear mounting obstructions and a direct mount solenoid for a clean and simple installation.

The two position, two way valve provides a simple means of directing oil flow into two separate hydraulic circuits or can be used as a low pressure bypass back to the reservoir.

The Optimum X Series gear pumps/motors offer premier performance for a wide variety of applications across several industries. Featuring the innovative OPTI-Grip® technology, the Optimum X Series exemplifies strength, endurance, and rigidity making for long lasting units even in the most extreme conditions. The X Series is the middle range of the Optimum group, providing nine displacements to cover light to heavy flow and pressure requirements.

Ultimate power and performance in a small package best describes the F4 Series gear pumps. The pressure balanced bushing blocks and sleeve bearings provide both long life and high performance.

Muncie clutch pumps provide hydraulic power at the flip of a switch. Clutch pumps can be used in situations where a PTO aperture is unavailable or difficult to access. Although normally belt driven, clutch pumps may also be shaft driven from the engine crankshaft.

Muncie’s PTO shaft extensions for the Allison 3000 and 4000 Series transmission provide easier hydraulic pump installation by moving the hydraulic pump mount to the rear of the transmission. Shaft Extensions are available for most Allison 3000 & 4000 Series transmission applications and popular pump mounts.

Parker Chelsea is a market leader in Power Take-Off products for the truck and mobile vocational markets. Our PTOs are designed with a wide range of internal speeds, torque capacities and output options to match up with virtually all driven equipment requirements. We offer a complete line of Power Take-Offs for North America, Asia Pacific, Australia, China, India and Europe, including cast iron 6-Bolt, 8-Bolt, 10-Bolt, countershaft, split-shaft and front engine mount applications. Features include mechanical shift, powershift, constant engaged shift options, overspeed controls and flanges for direct or remote mounting of hydraulic pumps, blowers, water pumps, product pumps and generators. Bottom line is if you need a reliable and rugged performer, think Parker Chelsea.

Have a Hydraulic component and not sure exactly what it is, or where to have it fixed? Look no further put out extensive hydraulic knowledge to use and let us help you with your Hydraulic system needs.

Performance - Speed - Accuracy - Capacity - Long Life Reliability - Robustness - Ease of Use are all well known features for Hydreco Hydraulics pumps and motors even in the harshest of environments.

Responsiveness, Accuracy, Reliability and Robustness are all design features of the range of Hydreco Hydraulic valves which will continue to perform as specified in the most challenging arenas.

The Hydreco Group offers a range of products for agricultural machinery composed of hydraulic cylinders, gear pumps, control valves, joysticks and machine control systems, offering customers the optio...

The Hydreco Group offers a comprehensive range for the construction of machines used for forestry: gear pumps, control valves, joysticks and machines control systems.

Garbage trucks and other refuse equipment are critical to the sanitation and health of our cities and towns. Built to heavy-duty and high-quality standards, we rely on this equipment to keep our communities and streets clean.

When it comes to hydraulics on refuse equipment, it’s all about power and reliability. Hydraulic power is one of the best ways to economically apply force (i.e. lifting and packing) in industrial applications, including all types of refuse equipment.

Hydraulics provide maximum productivity for refuse trucks, not only regarding cycle time, but the quantity and compaction rate of the garbage itself. Compaction rate refers to the density of trash per cubic yard of capacity after the material is compacted. Compaction rate is a measurement of mass per volume of space, rather than a time component. It is dictated by a combination of body strength, hydraulic cylinder force and the surface area of the compactor. A higher compaction rate provides more compacted material per cubic yard, improving collection productivity.

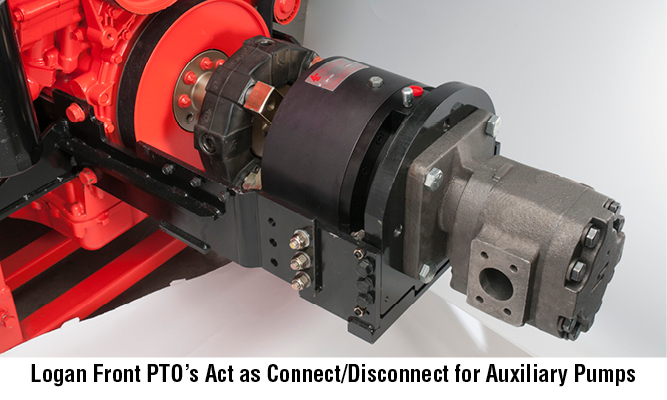

Each refuse packer body is somewhat unique with pumps, valves, controls, filters, and cylinders designed specifically for a given application. On refuse vehicles, the hydraulic pump is often powered through a PTO or directly from the driveshaft (e.g. a front-mount hydraulic pump).

Depending on the refuse equipment design, the hydraulic fluid is conveyed between the various components through rigid pipe or steel-reinforced flexible hydraulic hose.

Most hydraulic oil reservoirs have in-tank filters. The wear of hydraulic system components is dependent on this contamination, and the existence of metal parts in hydraulic system oil (iron and copper are particularly powerful catalysts) accelerates its degradation. A hydraulic filter helps to remove these particles and clean the oil on a continuous basis. The performance for every hydraulic filter is measured by its contamination removal efficiency, i.e. high dirt-holding capacities.

Wastebuilt can supply every component for the packer body hydraulic system including Eaton Aeroquip hydraulic hoses and fittings, as well as hydraulic cylinders.

The piston rod is the most vulnerable hydraulic system component. If the rod becomes damaged, leakage and failure follow shortly thereafter. Most cylinder suppliers offer a range of designs based on customer preference – Wastebuilt mirrors the OEM selections.

Wastebuilt provides a two-year limited warranty for all new hydraulic cylinders and a three-year limited warranty on cylinders with nitrocarburized rods.

Wastebuilt offers a wide variety of hydraulic cylinders for most refuse bodies including EZ Pack, G&H, Galbreath, Galfab, Heil, Kann, Labrie, Leach, Loadmaster, McNeilus, New-Way, Pak-Mor, Pioneer, Wayne, Wittke and others.

To learn more about Wastebuilt hydraulic cylinders, availability and pricing, contact Wastebuilt at 855-927-8328 or online via our Refuse Body Parts page.

8613371530291

8613371530291