variable delivery hydraulic pump factory

The displacement of a pump is defined by the volume of fluid that the gears, vanes or pistons will pump in one rotation. If a pump has a capacity of 30 cm3, it should treat 30 ml of fluid in one rotation.

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

... rev. displacements, these pumps are designed to operate in both directions of rotation (clockwise or counter-clockwise). Only one reference regardless of direction of rotation. The TXV indexable pumps ...

... needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump ...

Axial piston twin flow pump. With a very high performance in all job conditions. Due to its twin flow configuration this pump allows a great variety of solutions in different job applications.

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable ...

... PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design ...

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

ISO 9001:2000 certified custom manufacturer of variable displacement axial piston pumps. Specifications of pumps include 3600 rpm maximum speed & 350 psi maximum pressure. Optional electronic control units provide proportional control, automotive control, control with feed-back for speed, displacement & steering angle, power limiter & customized software. Also available are hydraulic, mechanical & electric servo controls. Optional pump features include front & rear lever bypass, electrical bypass with brake release, reinforced roller bearings, suction filter, SAE flanges, UNF threads, cut-off pressure valve, pressure inlet & purge valve. Other products include gearboxes, drivelines, axles, electric wheel drives, hydraulic motors & pumps.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

With fast control response and superior performance, the PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design — while thriving on low-viscosity fluids.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

When you need peak performance from a variable-displacement axial-piston pump, the Oilgear pump PVV line is ready. No matter what pressure and flow demands you face, these pumps rise to the challenge.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Quiet operation, high efficiency and compact design — all available at a competitive price. That’s what Oilgear PVWC closed-loop, hydrostatic axial-piston hydraulic pumps bring to the table. All designed around our proven rotating group.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids—and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Designed to be cost-effective, stable and low-maintenance, PVWJ is a variable-displacement axial-piston pump with a medium control response. Like all Oilgear pumps, it thrives on low-viscosity fluids — and comes in a variety of frame sizes and available displacement rates.

Extremely effective across numerous industrial applications that require quick response in extreme environments, the XD5 series of pumps offer lightning-fast control response on both low-viscosity fluids and standard hydraulic oil. Engineered to handle the most challenging environments, they have been designed to be a high-performance solution for demanding mobile applications.

Designed for power and speed, the Oilgear PVV open-loop axial-piston hydraulic pumps can handle large, heavy-duty systems. Manufactured with advanced engineering and computer-optimized, the PVV pump range delivers up to 450 Bar / 560 horespower which equates to four times the horsepower at less than half the cost of other manufacturers pumps.

With it"s compact design available in several displacements, the PVV pumps offer a large selection of readily interchangeable controls. With improved response controls and reduced noise levels, its rugged cylinder design enhances performance.

The patented, pressure lubricated swashblock design offers high performance for high-cycling operations. It also contributes to the pump’s ability to run on low-viscosity fluids, including high water content, fire-resistant and other special fluids.

Zeus Hydratech fully supports the Oilgear PVV pump product line and is the only valid source for OEM parts. All Oilgear repairs are machined and tested per our original factory specifications.

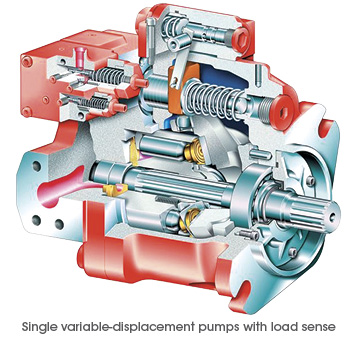

Another option is to utilize a load sense compensator. With a load sense compensator, this compensator will include a lighter spring setting to control the swash plate. Upstream pressure is ported into a load sense port on the pump, as the pressure requirement increases, the pressure acts against the load sense piston. Once the pressure requirement is higher than the offset, the pump swash plate angle changes and the pump begins to increase flow, by increasing the swash plate angle, until we have enough pressure to balance the piston. Once balanced, the flow remains steady until the load changes.

The offset pressure is normally 200-300 PSI. With a load sense compensator, the pump produces what the load requires plus the spring offset, normally 200-300 PSI.

With a standard pressure compensator, you would have to set the pump at 2600 PSI to accomplish the work. When the work only requires 1500 PSI, the pump will be trying to produce 2600 PSI. Fifty percent of the time, your system will be operating at 1100 PSI of inefficiency, which means heat. With a load sense compensator, when the load requires 1500 PSI, the pump will actually produce about 17-1800 PSI. Yes, this is 300 PSI inefficient, but that is much better than 1100 PSI inefficient.

With a varying load, the load sense is a much better system. For additional control, you can utilize an electronic proportional flow control or throttle. You can use an electrical signal to vary the hydraulic signal which is received by the pump’s load sense line. This would give you full electronic control of the amount of flow the pump produces.

There are additional control options which allow you to remotely control the pressure compensator. With this remote compensator control, you can set 2 or more different system pressures. With the ability of a variable piston pump to build 5,000 or more PSI; the additional setting can be used when operating components with a much lower pressure requirement.

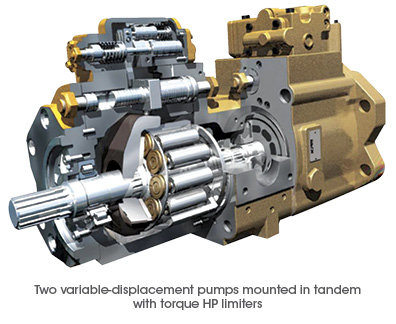

The next control is a torque limiting or HP limiting control. By adding an additional spring and piston, you can set a pump to always maximize its allowable input torque, therefore, maximizing output flow and pressure at a defined setting.

Our pump has an output of 15 CIR, a maximum flow of about 113 gallons at 1750 RPM. Our prime mover is an electric motor, 75HP with a 1.15 service factor. I want to keep my cylinder moving as fast as possible, but I also want to ensure that I never exceed a power demand 82 HP.

At 82 HP, the pump can produce 1254 PSI at full output, 113 GPM. As the load requires more pressure, the pump will begin to reduce flow and increase pressure. At 90 GPM flow, the system will produce about 1560 PSI; at 60 GPM we can get almost 2350 PSI. At 4500 PSI, the pump flow will be reduced to about 31 GPM. The advantage of this pump is that the internal controls of the pump are adjusting to maximize flow and pressure at all times without exceeding the available HP.

If I wanted to use a pump which could produce 113 gallons of flow at 4500 PSI, I would need 296 HP. If I choose a 75 HP motor with a pressure compensated variable piston pump, the motor would stall before the pressure compensator could kick in and reduce the pump flow. Depending on the load, a load sense pump could also stall the 75 HP motor if the load pressure is high enough to use up the HP before the pressure compensator kicks in. With a torque limiting (HP) control, we utilize the full limits of the prime mover and maximize power usage.

In the variable displacement pump category, customers can find this variable displacement axial piston pump that is mainly used as a stand-alonepump. The other type of axial piston pump is constant pump. This type of pump can be identified by parallel arrangement of many pistons to the drive. It is possible to adjust the flow rate of fluid when using such pump. The variable flow rate is possible as the pump can adjust its geometric output volume. This type of pump finds use in hydraulic motors and cylinders for controlling their speed.

BI pumps are axial piston pumps with single and double fixed displacement. They are available from 25 to 172 cm3/rot. and with a maximum pressure of 400bar. They can be assembled directly into the PTO´s, with the exception of the PTO’s of two shafts without support.

6431 hydraulic pump variable displacement products are offered for sale by suppliers on Alibaba.comAbout 80% % of these are hydraulic pumps, 6%% are pumps, and 3%% are hydraulic motors.

A wide variety of hydraulic pump variable displacement options are available to you, such as new, used.You can also choose from piston pump, gear pump and vane pump hydraulic pump variable displacement,as well as from 1 year, 6 months, and 1.5 years hydraulic pump variable displacement, and whether hydraulic pump variable displacement is hydraulic power units, fittings, or hydraulic accumulators.

Products, people performance, expertise and passion are the underlying strengths of the business as is the ability to listen to the needs and requirements of our customers. Distribution and engineering services are built on a foundation of market leading brands and products, technical support and service delivery.

Variable Displacement Pumps Market was valued at $3,322 million in 2016, and is projected to reach $4,478 million in 2023, growing at a CAGR of 4.4%. The substantial growth in automotive and manufacturing sector fosters the demand for variable displacement pumps. Variable displacement pump is a type of hydraulic pump that makes positive displacement. Variable displacement pumps are energy-efficient as compared to fixed displacement pumps as the pumps doesn"t require manual control and can control the amount of flow via valves that control speed of hydraulic actuators. Growth in construction industry is the major driver for the incremented demand for variable displacement pumps, which are used to have better control over large machine activities. Rising population and rapid urbanization would further contribute to the blooming construction industry, thus, the market for variable displacement pumps would also grow.

The global variable displacement pump market is segmented based on type, application, end-user and geography. Based on type, the market is categorized into vane pump and piston pump. Piston pumps would dominate the market throughout the analysis period owing to its wide volumetric & pressure efficiency range. Market by application comprises hydraulic and IC engine. Hydraulic pumps accounts for maximum market share due to increasing usage of hydraulic pumps in the manufacturing industry. The end-user segment include construction, agriculture, mining, automotive, material handling, oil & gas, water & waste water management, and others.

Variable displacement piston pumps market share is expected to grow at a considerable growth rate during the forecast period. It is a type of positive displacement pump in which number of pistons are arranged in a certain manner. It could be used as a stand-alone pump, an automotive air conditioning compressor, or a hydraulic motor.

Variable displacement pumps market for construction and water & waste water management industries is expected to grow at the significant growth rate during the forecast period. Water & waste water management is one of the crucial task of a city or a town, for which high-pressure, high torque, and highly efficient motors and pumps are required. Increase in innovations, high demands for high-performance, and efficient high-pressure pumps are expected to offer numerous growth opportunities for market expansion. Furthermore, the demand for hydropower energy and tidal energy is expected to drive the market growth. Increase in need for planned cities and towns and rise in standards of living in the developing countries are expected to fuel the market growth in this sector.

The Asia-Pacific variable displacement pumps market is expected to show significant growth in the near future, owing to development in infrastructure, availability of multiple manufacturing facilities, increase in population, significant growth in GDP in the developing countries, and increase in construction activities.

Technological advancements, increase in process automation, growth of oil & gas industry, and design upgradation of pumps & motors are expected to drive the market growth. Deep water and ultra-deep water reserves in Asia-Pacific are expected to contribute toward oil & gas production, and is expected to increase the sales of hydraulic pumps.

The key players profiled in this report are Bosch Rexroth AG, Parker Hannifin Corp., Danfoss A/S, Eaton Corporation, The Oilgear Company, Kawasaki Heavy Industries, Ltd., Yuken Kogyo Co., Hawe Hydraulics, Casappa SPA and Ranger Caradoc Hydraulics Ltd.

The study provides an in-depth analysis of the global variable displacement pumps market and current & future trends to elucidate the imminent investment pockets.

Variable Displacement Piston Pumps – A Series – Yuken offers low noise/high efficiency, swash plate type variable piston pumps, these have been developed by Yuken’s leading hydraulic engineers and provide a diverse lineup to meet a wide range of application requirements. Variable Displacement Piston Pumps – A Series.For other products visit Products

Yuken: Hydraulic specialist and its products are recognised as an industry leading brand, utilised in various regular and specialist applications around the world.

We supply standard, off-the-shelf products but at Yuken, we will always go the extra mile to understand your needs and provide Hydraulic solutions,which will allow you to meet the increasingly tough challenges that we all face.

Our company dates back to 1929 in Japan and in 1980 Yuken Europe Ltd. was founded. During this time Yuken: Hydraulic specialist has accumulated a wealth of practical and technical expertise and our enduring success lies in the fact that our history is filled with examples of how we have met and exceeded the needs of machine and system builders.

Our Hydraulic products are used by original equipment manufacturers operating in a diverse variety of sectors including shipping, construction, subsea operations, chocolate-makers and contact lens manufacturing equipment.

The demanding requirements of those machine, system builders and hydraulic power pack, who need improved productivity, and performance to gain technical edges over their competition, means that we have built ourselves a reputation for quality and cutting edge innovation and design, developing a range of products which will enhance any system they are used in.

8613371530291

8613371530291