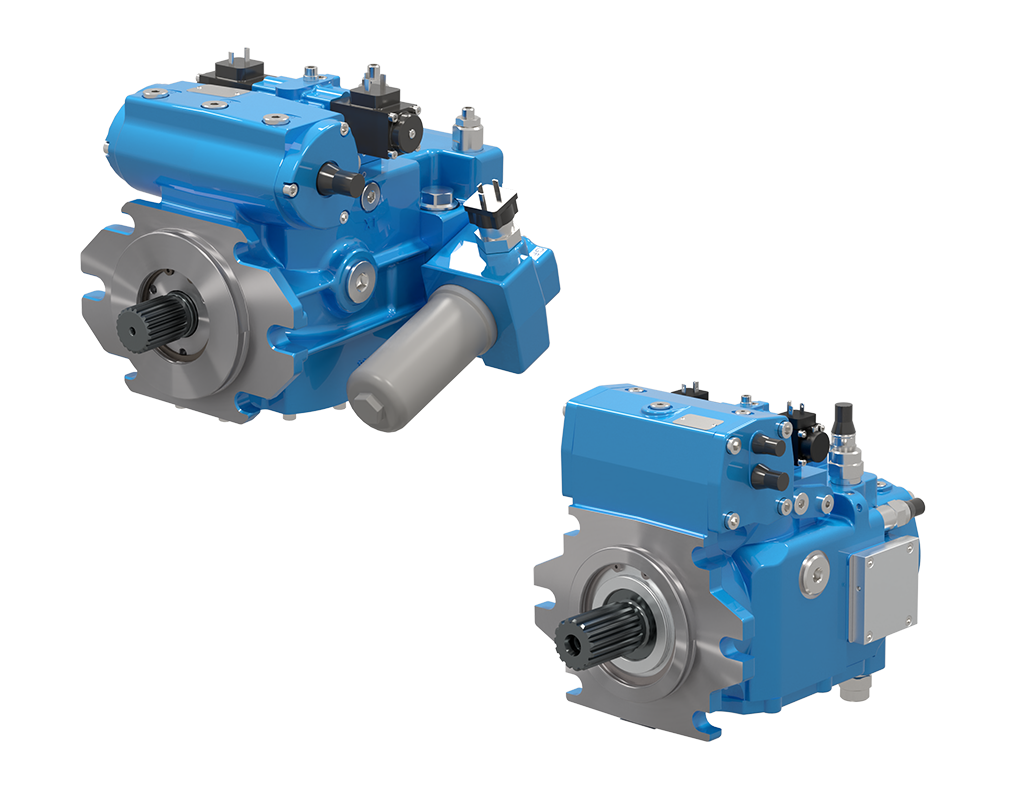

variable delivery hydraulic pump in stock

6431 hydraulic pump variable displacement products are offered for sale by suppliers on Alibaba.comAbout 80% % of these are hydraulic pumps, 6%% are pumps, and 3%% are hydraulic motors.

A wide variety of hydraulic pump variable displacement options are available to you, such as new, used.You can also choose from piston pump, gear pump and vane pump hydraulic pump variable displacement,as well as from 1 year, 6 months, and 1.5 years hydraulic pump variable displacement, and whether hydraulic pump variable displacement is hydraulic power units, fittings, or hydraulic accumulators.

Boasting high pressure, low noise and energy saving technology in a compact package,the Nachi PZH is a variable-displacement axial-piston pump, designed to take on all demanding applications.

The PZH manages to save energy and reduce operating noise by utilising low friction engineering on all sliding surfaces. Pressure pulsation is also reduced, therefore providing a smoother pressure flow within the hydraulic circuit (which is incredibly important in any extrusion/forming process to reduce ripple in the finished manufactured part.)

For customers looking to specify a high performance a reliable 70cc/rev pressure compensated, axial piston pump capable of 350 bar, the PZH-3B makes a first-class substitute to the following pump models in the same pressure and flow class:

Zeus Hydratech fully supports the Nachi PZHpump product line and is the only valid source for OEM parts in the South of the UK. All Nachi repairs are machined and tested per our original factory specifications.

The displacement of a pump is defined by the volume of fluid that the gears, vanes or pistons will pump in one rotation. If a pump has a capacity of 30 cm3, it should treat 30 ml of fluid in one rotation.

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

... rev. displacements, these pumps are designed to operate in both directions of rotation (clockwise or counter-clockwise). Only one reference regardless of direction of rotation. The TXV indexable pumps ...

... needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump ...

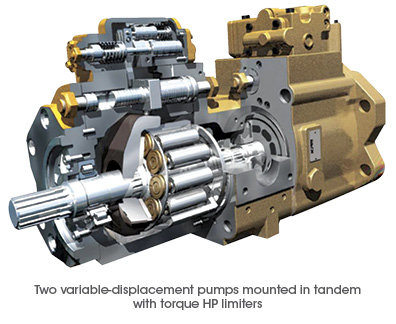

Axial piston twin flow pump. With a very high performance in all job conditions. Due to its twin flow configuration this pump allows a great variety of solutions in different job applications.

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable ...

... PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design ...

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

In a hydraulic system, fluid is conveyed through the various components by the activity of a pump. Pumps work by converting mechanical energy—e.g., the turning of a gear—into hydraulic (i.e., fluid) energy. Hydraulic pumps may be either fixed displacement (conveys a precise, unchangeable amount of fluid during each rotation) or variable displacement (can be altered to change the amount of fluid conveyed). Of these two types, variable displacement pumps are more complicated in design and, therefore, tend to be more expensive.

Hydraulic pumps are used in a wide range of industrial equipment and, for this reason, they exist in a broad assortment of designs, including the following:

Vane pumps – Vane pumps feature a rotating shaft with a number of thin vanes protruding from it. The vanes effectively separate the housing into distinct compartments, each of which conveys fluid from the input to the output as the central rotor turns. Because the rotor is positioned eccentrically, its motion first steadily increase the volume of space in each compartment as the compartments fill and then decreases them as they empty when the fluid is forcefully expelled through the output.

Gear pumps – The typical gear pump has two interlocking gears, one of which is connected to a drive shaft. As the shaft turns, the two gears are put into motion, conveying the hydraulic fluid around the outer perimeter of the housing and finally through the outlet.

Piston pumps – A piston pump is characterised by the presence of one or more pistons, consisting of a cylinder inside a cylinder. The up-and-down motion of the piston conveys hydraulic fluid to the output. These pumps are available in axial and radial designs.

In addition to supplying all types of hydraulic pumps, from stock White House Products can also manufacture piston gear and vane pumps to order. For gear pumps consult the Tailor Made gear pump section of our catalogue. For Vane pumps see the available options in the Vane pump and mtors section of the catalogue. For Piston pumps see the available options in the Standard Piston Pumps section.

If your hydraulic pump requires new parts or to be repaired White House Products can assist with a wide range of spare parts and full repair and test facilities for all types and styles of hydraulic pump. So if you need to replace the entire system, a component or need a component repair, you can count on White House Products for the exact part numbers. Parts for Cessna, Kayaba, Saeur Danfoss, Vickers, and other pump brands are available from stock.

Sometimes, it is a challenge to find an exact match to your application. If a particular hydraulics system manufacturer does not produce a pump for your requirements, we can help. You can have one built to your own specifications, which sets our operation apart from other hydraulic pump suppliers. Register to access this feature, but not before conducting a complete search of our catalogues, as this is the world’s largest selection of hydraulic pumps.

Search filters and the “Quick Find” feature simplify the process of browsing thousands of products from a leading pump system supplier. Your search can be as simple as entering a keyword or part number. By registering, instantly see stock availability and hydraulic pump pricing, and use instant online ordering; for help, our technical support team is always standing by.

When you need to choose a hydraulic pump solution for a hydraulic system, it is important to decide what type of pump you will require. You must also understand the basics of how pumps work and hydraulics.

All hydraulic systems rely on pressurized fluid to create force in order to perform work that is accomplished by transforming mechanical energy into hydraulic energy inside hydraulic pumps and creating a positive displacement downstream. For example, a forklift needs to raise and lower pallets—which would be the desired work.

You must also choose between a ‘closed-loop’ or ‘open-loop’ system. In a ‘closed-loop’ system, the fluid passes from the pump directly to the motor before returning to the pump. In an ‘open-loop’ system, the pump draws the fluid from a reservoir or tank, and then pumps it to a control valve from where it is directed to the services being operated before returning to the tank.

Fixed-displacement pumps are well suited to a wide range of functions where the amount of pressure required to perform work is the same each and every time. For instance, if the pump is rated as a 30 cc pump, it will pump 30 ml of hydraulic fluid through the system for every single rotation.

The pressure and flow rate will not change, no matter how the pump is operated or what occurs elsewhere in the system. If you need a lower flow rate, then you will have to divert the excess flow or use a variable displacement pump.

Two common types of fixed-displacement pumps you can use are the bent axis piston pump and the gear pump. The bent axis piston pump provides the added benefit of normally having a higher pressure capability than a gear pump.

Aside from flow rates being directly proportional to pump drive speeds, fixed-displacement hydraulic pumps have several key benefits over variable displacement pumps, including:

Unlike fixed-displacement pumps, variable displacement pumps are able to increase or decrease the fluid flow rates electronically, manually, or hydraulically. The method used will depend on the flow required and the type of pump being used, such as a vane pump, axial piston pump, etc.

Furthermore, the method of displacement changes based on the pump’s internal structure. For example, a variable displacement piston pump is determined by the bore area of the pistons and the stroke length. The stroke length can vary to help regulate the flow rates as shaft rotation turns and moves the pistons inside the pump.

The control piston inside the pump also helps regular pressure and, essentially, functions as a relief valve. When pressure increases above the desired pressure compensator setting, the control piston moves outwards and slows the travel distance of the other pistons.

As can be seen, fixed-displacement pumps and variable displacement pumps have their own benefits, depending on your specific needs. For further assistance in choosing the right pump or for other hydraulic system solutions, please feel free to contact White House Products, Ltd. at +44 (0) 1475 742500 today!

Hydraulic Pumps are any of a class of positive displacement machines used in fluid power applications to provide hydraulic flow to fluid-powered devices such as cylinders, rams, motors, etc. A car’s power-steering pump is one example where an engine-driven rotary-vane pump is common. The engine’s gear-type oil pump is another everyday example. Hydraulic pumps can be motor-driven, too, or manually operated. Variable displacement pumps are especially useful because they can provide infinite adjustment over their speed range with a constant input rpm.

Pumps produce flow. Pressure is resistance to flow. Whereas centrifugal pumps can run against blocked discharges without building up excess pressure, positive-displacement pumps cannot. Hydraulic pumps, like any positive-displacement pump, thus require overpressure protection generally in the form of a pressure-relief valve. Over-pressure relief is often built into the pump itself.

Hydraulic systems are used where compact power is needed and where electrical, mechanical, or pneumatic systems would become too large, too dangerous, or otherwise not up to the task. For construction equipment, hydraulic power provides the means to move heavy booms and buckets. In manufacturing, hydraulic power is used for presses and other high-force applications. At the heart of the hydraulic system is the pump itself and the selection of a correct hydraulic pump hinges on just what the hydraulic system will be expected to do.

Axial piston pumps use axially mounted pistons that reciprocate within internal cylinders to create alternating suction and discharge flow. They can be designed as variable-rate devices making them useful for controlling the speeds of hydraulic motors and cylinders. In this design, a swashplate is used to vary the depth to which each piston extends into its cylinder as the pump rotates, affecting the volume of discharge. A pressure compensator piston is used in some designs to maintain a constant discharge pressure under varying loads.

Radial piston pumps arrange a series of pistons radially around a rotor hub. The rotor, mounted eccentrically in the pump housing, forces the pistons in and out of cylinders as it rotates, which cause hydraulic fluid to be sucked into the cylinder cavity and then be discharged from it. Inlets and outlets for the pump are located in a valve in a central hub. An alternative design places inlets and outlets around the perimeter of the pump housing. Radial piston pumps can be purchased as fixed- or variable-displacement models. In the variable-displacement version, the eccentricity of the rotor in the pump housing is altered to decrease or increase the stroke of the pistons.

Rotary vane pumps use a series of rigid vanes, mounted in an eccentric rotor, which sweep along the inside wall of a housing cavity to create smaller volumes, which forces the fluid out through the discharge port. In some designs, the volume of the fluid leaving the pump can be adjusted by changing the rotational axis of the rotor with respect to the pump housing. Zero flow occurs when the rotor and housing axes coincide.

External Gear pumps rely on the counter-rotating motion of meshed external spur gears to impart motion to a fluid. They are generally fixed-displacement designs, very simple and robust. They are commonly found as close-coupled designs where the motor and pump share a common shaft and mounting. Oil travels around the periphery of the pump housing between the teeth of the gears. On the outlet side, the meshing action of the teeth decreases the volume to discharge the oil. The small amount of oil that is trapped between the re-meshing gears discharges through the bearings and back to the pump’s suction side. External gear pumps are very popular in fixed-displacement hydraulic applications as they are capable of providing very high pressures.

The internal gear pump uses the meshing action of an internal and external gear combined with a crescent-shaped sector element to create fluid flow. The axis of the external gear is offset from that of the internal gear, and as the two gears rotate, their coming out of and into mesh create suction and discharge zones. The sector serves as a barrier between suction and discharge. Another internal gear pump, the gerotor, uses meshing trochoidal gears to achieve the same suction and discharge zones without needing a sector element.

This article presented a brief summary of some of the common types of hydraulic pumps. For more information on additional topics, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

Continental Hydraulics are at the forefront of engineering hydraulic solutions for over 50 years-a testament to a long-standing reputation built upon your challenges and opportunities. A worldwide leader- a one-stop-shop for valves, pumps, power units and proportional products-all assembled in the USA.

Continental Hydraulics PowrFlow™ PVR Vane Pumps deliver the rugged, reliable performance and value you’ve come to expect in all our products. They outperform sensitive piston pumps in harsh environments. PVR Vane Pumps deliver faster response, and require less external compensation compared to fixed displacement designs.

8613371530291

8613371530291