variable swash plate hydraulic pump manufacturer

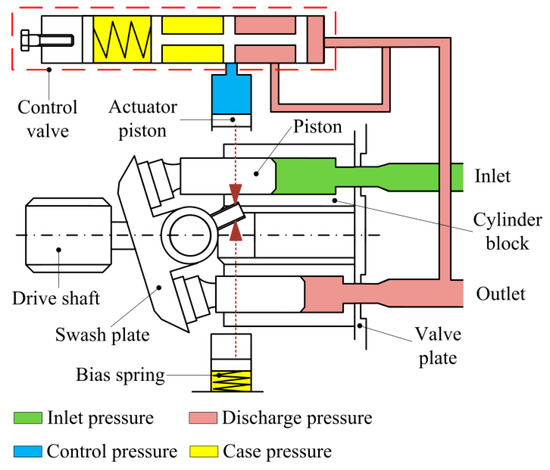

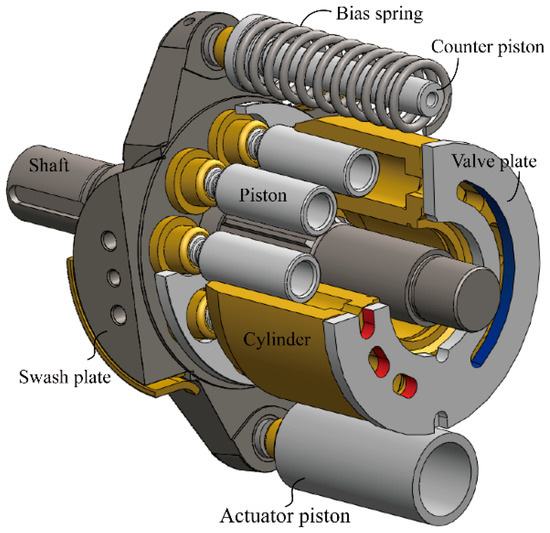

Swashplate hydraulic pumps have a rotating cylinder containing pistons. A spring pushes the pistons against a stationary swash plate, which sits at an angle to the cylinder. The pistons suck in fluid during half a revolution and push fluid out during the other half. The greater the slant the further the pump pistons move and the more fluid they transfer.

Electro-Hydraulic Controls for Model (A)A4VSO (Sizes 40...1,000), Model A4VSH (Sizes 40...250), Model (A)A4VSG (Sizes 40...1000) and Model (A)A4CSG (Sizes 250...750) Swashplate pumps

The displacement of a pump is defined by the volume of fluid that the gears, vanes or pistons will pump in one rotation. If a pump has a capacity of 30 cm3, it should treat 30 ml of fluid in one rotation.

In axial piston variable pumps, the flow is proportional to the drive speed and the displacement. The flow can be steplessly changed by adjusting the swivel angle. Axial piston variable ...

... axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

... piston pump type V30D is designed for open circuits in industrial hydraulics and operate according to the swash plate principle. They are available with the option of a thru-shaft for operating additional ...

... circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

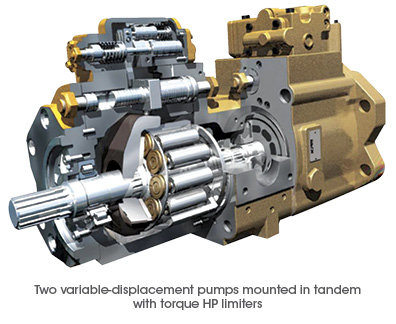

Axial piston twin flow pump. With a very high performance in all job conditions. Due to its twin flow configuration this pump allows a great variety of solutions in different job applications.

Air hydraulic pump, double pneumatic motor, double effect, foot operated with lock-up function, lever distributor valve (4/3), 10L tank, oil flow 8.5 / 0.26 l / min

... customer system options for mechanical, hydraulic and electric input solutions are available. Further special regulating features like torque control and pressure cut-off are also available. The reliable ...

... needs of truck hydraulics, the TXV variable displacement pumps with LS (Load Sensing) control allow flow regulation to suit the application requirements. The pump ...

... rev. displacements, these pumps are designed to operate in both directions of rotation (clockwise or counter-clockwise). Only one reference regardless of direction of rotation. The TXV indexable pumps ...

... PVG is a variable-displacement axial-piston pump designed to take on your most demanding applications. It offers high-pressure, superior performance in a compact design ...

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

The axial piston pump type V60N is designed for open circuits in mobile hydraulics and operate according to the swash plate principle. They are available with the option ...

Variable displacement axial piston pumps operate according to the bent axis principle. They adjust the geometric output volume from maximum to zero. As a result they vary the flow rate ...

The K3VG series are swash-plate type axial piston pumps which give excellent performance in high flow industrial applications in a compact and cost-effective package.

Closed circuit axial piston pumps are used as hydrostatic transmission components in self-propelled machines and for rotary drives in both fixed and mobile equipment of all kinds.

Twin flow axial piston pumps offers two different flows. In addition, we find several advantages such as lower weight or standar system solutions. BZT are available in ISO and SAE version.

Our variable volume, pressure compensated axial piston pumps continuously match output flow to the system demands. They’re designed to closely match the Eaton-Vickers PVB and PVQ and ...

The PFBA is a fixed displacement pump, axial-piston pump. It’s proven itself in a variety of operations—including die casting and injection molding machines, high-pressure ...

PMH high pressure axial piston pumps for closed loop are specifically designed to be used on heavy duty machines for traction and auxiliary functions, providing efficiency and durability.

Variable displacement pumps in closed loop; 3 basic design units and 8 max. displacement sizes of 14, 18, 21, 28, 35, 46, 56, 64 cc/rev; various control options; max. nominal pressure 300 bar, 350 bar peak; driving speed: ...

"C"" Axial Piston Pumps for high accuracy fluid metering with precision flow controls and high-pressure capability. Specifically designed for the Polyurethane Industry. Capacities from ...

Rotork offers a range of high quality hydraulic pumps for applications in the upstream and downstream oil and gas industries. These include an extensive range of axial piston ...

... Parker’s hydraulic truck pump series F1 featuring high self-priming speed and high efficiency and is one of the leading truck pumps in the market. The F1 pump provide ...

Parker P2/P3 High Pressure Axial Piston Pumps are variable displacement, swashplate piston pumps designed for operation in open circuit, mobile hydraulic ...

... Series pump offers variable displacement axial piston pumps for open-circuit applications. Featuring a compact footprint and continuous operating pressure ...

All control is achieved by the proper positioning of the swash plate. This is achieved by a servo piston acting on one end of the swash plate working against the combined effect of the off-setting forces of the pistons and centering spring on the other end. The control spool acts as a metering valve which varies the pressure behind the servo piston. The amount of flow produced by the Parker Piston Pump is dependent upon the length of stroke of the pumping pistons. This length of stroke, in turn, is determined by the position of the swash plate.

Maximum flow is achieved at an angle of 15-17 degrees. The rotating barrel, driven by the prime mover, moves the pistons in a circular path and the piston slippers are supported hydro statically against the face of the swash plate. When the swash plate is in a vertical position, perpendicular to the center line of the piston barrel, there is no piston stroke and consequently no fluid displacement. When the swash plate is positioned at an angle, the pistons are forced in and out of the barrel and fluid displacement takes place. The greater the angle of the swash plate, the greater the piston stroke.

All control is achieved by the proper positioning of the swash plate. This is achieved by a servo piston acting on one end of the swash plate working against the combined effect of the off-setting forces of the pistons and centering spring on the other end. The control spool acts as a metering valve which varies the pressure behind the servo piston. The amount of flow produced by the Parker Piston Pump is dependent upon the length of stroke of the pumping pistons. This length of stroke, in turn, is determined by the position of the swash plate.

Maximum flow is achieved at an angle of 17°. The rotating piston barrel, driven by the prime mover, moves the pistons in a circular path and the piston slippers are supported hydrostatically against the face of the swash plate. When the swash plate is in a vertical position, perpendicular to the centerline of the piston barrel, there is no piston stroke and consequently no fluid displacement. When the swash plate is positioned at an angle, the pistons are forced in and out of the barrel and fluid displacement takes place. The greater the angle of the swash plate, the greater the piston stroke.

The centerline of the pumping piston assembly is offset from the centerline of the swash plate. Therefore, as shown on the accompanying Figure 1A, the pistons’ effective summation force tends to destroke the swash plate to a vertical (neutral) position. This destroking force is balanced as the swash plate is angled by the force of the servo piston.

Piston pumps are typically much more complicated and are often available in wither fixed or, commonly, variable displacement configurations and with pressure compensation. These are big words that mean that piston pumps can usually adapt to the system pressure, providing maximum efficiency and flexibility. They are often used in “closed center” systems where the pump displacement varies to meet the needs of the work being done. Piston pumps use a “swashplate” to move the pistons and the angle of the swashplate & bore of the pistons determines the displacement. Pressure compensation regulates outputs in response to variations in the system. Piston pumps are typically the most efficient type of hydraulic pumps.

In an axial-piston pump, the pistons and cylinder rotate around the center, longitudinal axis. The pistons and shoes move in and out of the cylinder because they are sliding upon a stationary, variable angle, swashblock.

Kawasaki’s new medium duty pump, the K3VLS, has been developed for machines and equipment that use a load sensing control system and/or electric displacement control systems. Its launch follows extensive research and development as our engineers combined efficiency with simplicity to deliver the most technologically advanced pump on the market.

A4FO40/71/125/250 series axial piston hydraulic pump, products with high pressure rating, high volume efficiency, strong anti-pollution impact ability, compact structure. It is widely used by smelting steel mills, Marine equipment, mining machinery,...

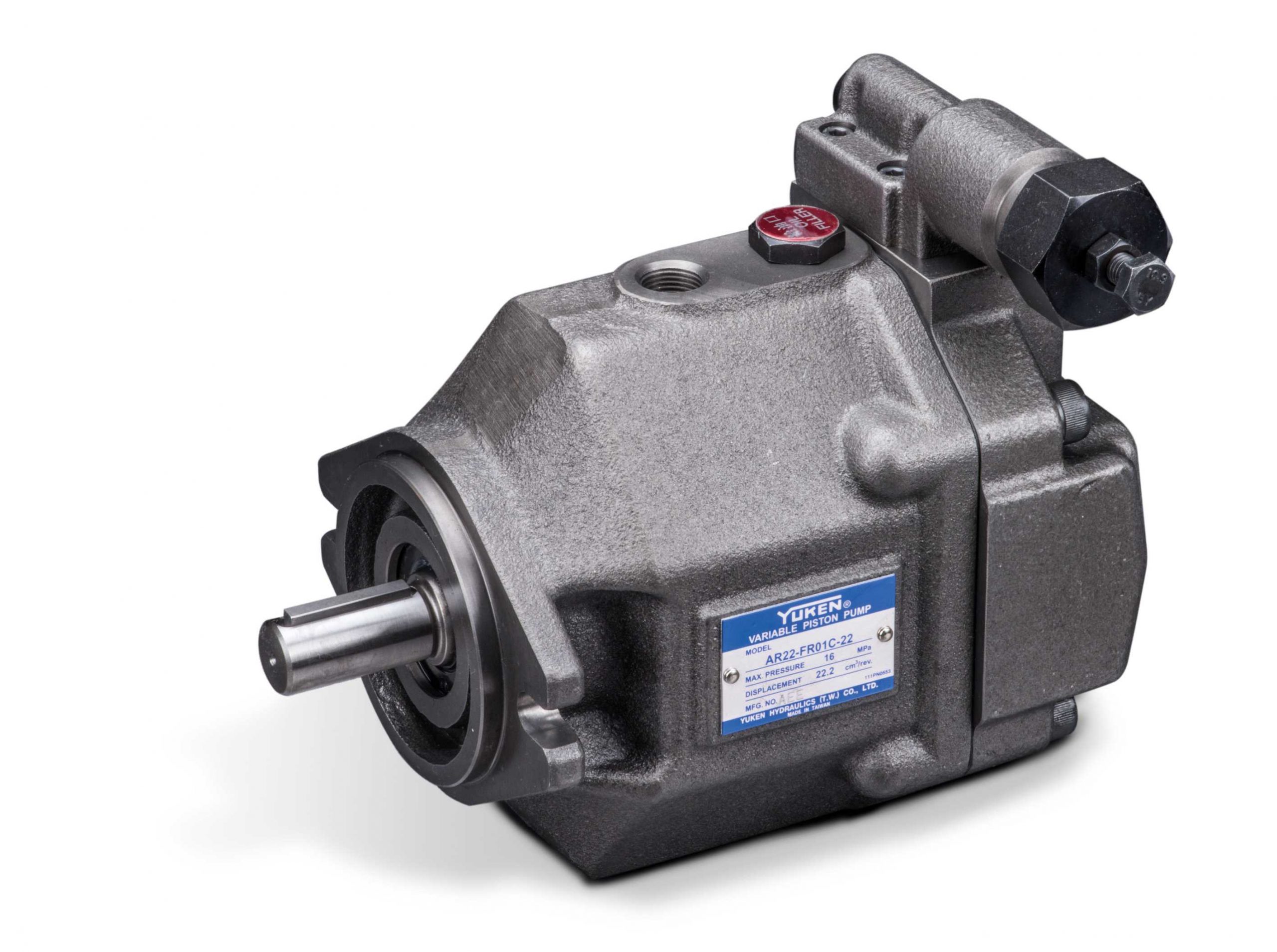

Hydraulic PumpsOur range of products include yuken piston pump ar 16, daikin piston hydraulic pump, axial piston hydraulic pump, tokimec hydraulic pump, hawe hydraulic pump and boss rexroth hydraulic pumps.

We are offering Yuken Piston Pump to our clients.Yuken offers low noise/high efficiency, swash plate type variable displacement piston pumps. These pumps have been developed by Yuken"s leading hydraulic engineers and provide a diverse lineup to meet a wide range of application requirements.

* High-density media discharge: Due to the use of a supporting swash plate, it is small, lightweight, and high-pressured, thereby increasing the output power per unit weight.

* Low working noise: While improving the rigidity of the swash plate structure, the frame designed with the latest measurement and analysis technology is used to greatly reduce the running noise.

An axial piston pump has a number of pistons (usually an odd number) arranged in a circular array within a housing which is commonly referred to as a cylinder block, rotor or barrel. This cylinder block is driven to rotate about its axis of symmetry by an integral shaft that is, more or less, aligned with the pumping pistons (usually parallel but not necessarily).Mating surfaces. One end of the cylinder block is convex and wears against a mating surface on a stationary valve plate. The inlet and outlet fluid of the pump pass through different parts of the sliding interface between the cylinder block and valve plate. The valve plate has two semi-circular ports that allow inlet of the operating fluid and exhaust of the outlet fluid respectively.

Protruding pistons. The pumping pistons protrude from the opposite end of the cylinder block. There are numerous configurations used for the exposed ends of the pistons but in all cases they bear against a cam. In variable displacement units, the cam is movable and commonly referred to as a swashplate, yoke or hanger. For conceptual purposes, the cam can be represented by a plane, the orientation of which, in combination with shaft rotation, provides the cam action that leads to piston reciprocation and thus pumping. The angle between a vector normal to the cam plane and the cylinder block axis of rotation, called the cam angle, is one variable that determines the displacement of the pump or the amount of fluid pumped per shaft revolution. Variable displacement units have the ability to vary the cam angle during operation whereas fixed displacement units do not.

We are offering Boss Rexroth Hydraulic Pumps to our clients.Vane pumps are available in a wider range of sizes. They are used in applications requiring medium operating pressures and low noise emissions.

We are offering Open Circuit Piston Hydraulic Pump to our clients.Open circuit axial piston pumps are used to operate services (hydraulic motors and cylinders) on mobile agricultural and construction machinery, also for lifting and for cleaning applications. Wide range of units, modular solutions and controls.

We are offering the reliableHydac Fix Displacement Pump to our clients.HYDAC supplies fixed and variable displacement pumps with various designs and setting ranges. They range from 0.25cm³/rev. to 560cm³/rev. with setting ...

8613371530291

8613371530291