vertical shaft hydraulic pump supplier

Distributor of vertical pumps. Vertical mounting & discharge type pumps include centrifugal submersible, split case & sump pumps & vertical turbine universal transfer pumps. Vertical pumps are available in various configurations & drive types including hydraulic, single & multi stage, end & double suction, non-clogging, single & three phase & auto & manual operation types suitable for liquid handling applications. Features include parts interchangeability, heavy-duty, temperature & moisture sensors, semi-open & adjustable impellers & self lubricating bronze sleeve bearings. Capabilities include up to 6,000 gpm delivery, 800 ft. head, 3450 rpm speed & 720 psi pressure. Applications include municipal, commercial, steel mills, metal finishing, chemical, paper, petroleum, agriculture & general industrial.

Distributor of vertical centrifugal pumps. High and low viscosity, gear, general purpose water, boiler feed, condensate, sump, submersible, air operated, drum, machine tool coolant, multi-stage booster, vacuum, magnetic drive, seamless, metering, piston, progressing cavity, self-priming, solid handling, and turbine pumps are also available. Repair, testing, and inspection services are available. Value-added pump services include design and application consulting, engineering, research and recommendations, project and individual pump quotations, pick-up and delivery, and rebuilding. Industries served include industrial, HVAC, commercial, biomedical, and chemical sectors. 24-hour shipping available.

The new generation of FLUX progressive cavity pump VISCOPOWER F 570 for Industry & Hygienic with planetary gear is suitable to pump thin to medium viscous media. The positive displacement pump ...

... new generation FLUX eccentric worm-drive pump VISCOPOWER F 580 for Industry & Hygienic with bearing flange is suitable to pump thin to highly viscous, pasty and still flowing media. The positive displacement ...

The small drum pump JUNIORFLUX F 310 with fixed motor FEM 3070 and mechanical seal is especially suitable for pumping comparatively small quantities out of containers such as canisters ...

The ECP is designed to lubricate bearings and linear guides with oil or fluid grease. The pump works reliably in single-line systems of up to 20 lubrication points and a main line length of approximately 15 meters. It ...

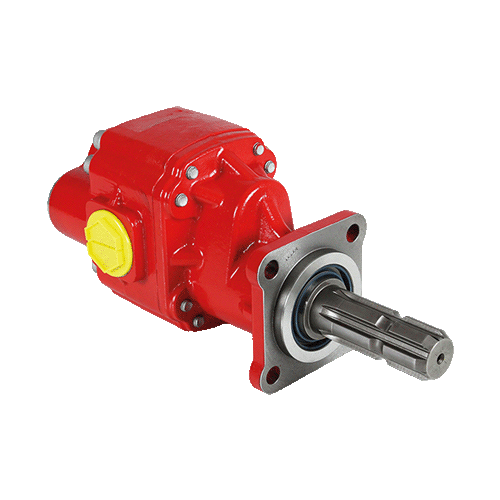

... positive-displacement pumps with fixed displacement and high efficiency. They are suitable for a variety of applications, such as hydraulic, hydrostatic, cooling as well as oil circulation and total-loss lubrication systems. ...

The B70V SanitaryPlus food pump is a powerful positive displacement pump for heavy-sensitive, viscous and viscous media up to the limits of flowability. It pumps liquid foodstuffs, ...

The B70V SanitaryPlus food pump is a powerful positive displacement pump for heavy-sensitive, viscous media with and without fiber or solids content up to the limits of flowability. It pumps ...

... reliability, safety and last but not least functionality are important. The submersible centrifugal pump was specially developed as a vertical, wet-installed pump for the rapid emptying ...

When the application calls for high-volume and/or high head vertical pumps, the practical solution is the use of the Hazleton® vertical, double-suction, Twin-Volute VDM. Designed for ...

When the application calls for high-volume vertical pumps, the practical solution is the use of the Hazleton® vertical, double-suction, Twin-Volute VDS and VND. Designed for slurry handling ...

The VN Family of pumps is designed for the ultimate flexibility in slurry handling applications. The vertical cantilever design eliminates submerged beargings, top suction design eliminates air binding, ...

Vertical single-stage submersible motor pump for wet installation, with cutter (S), stationary or transportable version. Amarex N pumps are floodable, single-stage, single-entry close-coupled ...

Chemical pump with electrical temperature control. The CHEM series is designed to be easy to maintain. Separate pump covers allow a quick inspection of the inner workings from both sides of the pump. ...

Horizontal or vertical seal-less volute casing pump in back pull-out design with fully enclosed canned motor, low noise emission, with radial impeller, single-stage, single-entry, casing connecting dimensions ...

... LSC pump is a submersible single-phase portable residue drainage pump. The specially designed bottom plate enables the pump to drain down to 1mm water level. It has a swing check valve ...

... surface from scratching. Though the pump is a single-phase unit, it has the durability equivalent to three-phase drainage pumps as the wear parts are made of abrasion-resistant materials. The pump ...

The TVM-series is a vertical multistage centrifugal pump designed for handling freshwater. Since it is an in-line type, the pump occupies less installation space. The major wetted parts ...

... Product Line Series 493 and 4193 steel external pumps are available in capacities up to 75 GPM. These pumps can be furnished directly connected to a 50HZ or 60 HZ motor. Series 493 is designed for vertical ...

... plants. The inline housing design allows you to install it in pipeline systems to protect the following equipment, such as your pumps. Despite the pipeline installation, the macerator offers you the proven FSIP® concept ...

ViscoTec dispenser 3VMP18, as a volumetric dispensing pump for larger volumes, ensures smooth and reliable product supplying of abrasive, high-filled or shear sensitive material - with a repeatability of +/- 1 %!

ViscoTec dosing and filling pump type RD-hygienic for food and cosmetics is a volumetric conveying pump based on the endless piston principle. Suitable for discontinuous or continuous pulsation-free metering ...

The DSL pumps are single-stage, double-suction, vertical, centrifugal pumps. The design of the suction side provides for a perfect flow, and the inlet is placed in line with the outlet.

The durable Waukesha Clean-out-of-Place (COP) Positive Displacement "Can-Do Pump". Versatile in application, its reliability has made it the industry ...

The heavy-duty type TPC-M vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents ...

The heavy-duty type TPC vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents ...

The ST42 - 22 out of tank vertical pump range benefits from proven design features gained through over 60 years of experience and developments, and has been specially designed to handle the transfer of ...

As an extension to the standard Epsilon range, a vertical pump is available in various materials, including stainless steel or super duplex steels. This competitively priced high pressure pump ...

Vertical pumps are constructed from stainless steel, aluminum or cast iron and must be strong enough to withstand internal and external pressures. These pumps are most often used for lifting and transporting water, an application that finds many uses in residential, general purpose, industrial and commercial situations.

Centrifugal pumps are used in wastewater and sewage treatment plants to handle trash and refuse; certain heavy duty models can pump mixtures of solids that are suspended in liquid. As water pumps, vertical pumps are used for deep well pumping and move water from its underground source to buildings for human use or to prevent flooding or drainage issues.

If vertical pumps are made of strong corrosion resistant materials, they are able pump chemicals and acids which is a useful way of transporting hazardous liquids throughout a processing plant.

Vertical centrifugal pumps are simply designed machines. A casing called a volute contains a horizontal impeller mounted perpendicularly on an upright rotating shaft. The electric motor uses its mechanical energy to turn the impeller whose blades impart kinetic energy to the liquid as it begins to rotate up the casing.

Momentum and pressure carry the liquid (most commonly water) through the expanding volute until it exits through a discharge opening, sometimes at high velocities. Vertical pumps are located underground near the source of liquid which they move up to the surface. They are usually electric because a gas tank would be impractical to store and fill. The power cords are kept in a durable protective casing to prevent any leaks or damage.

One example of a vertical pump is an axial flow pump whose impeller is actually a kind of propeller that lifts the liquid in a direction parallel to the pump shaft instead of pushing it in a perpendicular direction like horizontal centrifugal pumps would. Vertical pumps are generally designed in a close-coupled arrangement where the motor and the pump are held in the same slim enclosure that can be lowered into a deep well hole. Another technique is to have the motor at ground level and install the pump underground.

Guidelines on when to use a SUBMERSIBLE PUMP versus a Vertical Turbine Pump:When shaft elongation problems occur on a deep Vertical Turbine pump setting.

Yes, as of September 20, 2019, National Pump has NSF/ANSI/CAN 61 & NSF/ANSI 372 certification for Vertical and Submersible Turbine Pump assemblies. The deep-set Vertical Turbine Pumps are available in configurations that include either oil-lubricated or fresh water flushed enclosed lineshaft or pre-lubricated open line shaft. The short-set Vertical Turbine Pumps are available in either product lubricated or enclosed linshaft configurations. NPC has certified many optional materials to allow our customers the ability to choose the best materials for their specific application. Whether its standard materials, stainless steel or aluminum bronze, we can meet your needs. Bearings options also include bronze, neoprene, marine or vesconite. Wear rings are available in stainless steel or aluminum bronze. Seal options include mechanical seals in split or single cartridge configurations or expanded PTFE yarn packing. Standard coating is Tnemec N-140 Pota-Pox Plus to provide long-lasting protection of the steel components. The complete pump, from the suction to the discharge, is certified to pump drinking water without imparting chemical contaminants or impurities that can affect our health.

Yes, all pumps that are required to be built to the ISO9001 certification must be manufactured at National Pump’s ISO 9001 certified plant in Glendale, AZ.

National Pump manufactures pumps in a variety of materials to meet our customer’s preference or needs. Bowls and Impellers are available in Cast or Ductile Iron, Cast Steel, Stainless Steel, a variety of Bronzes or Duplex Stainless Steels. Bearing materials are available in Bronze, Marine rubber, and engineered composites.

Every piece of rotating machinery (motor, pump, etc.) has a natural frequency or vibration of operation. As the discharge head of the pump supports the motor, it is the responsibility of the pump manufacturer to design the discharge head to withstand the natural frequencies of the motor through its operating speed range (say 45 – 60 HZ, or 1350 – 1800 rpm). Reed Critical analysis is a calculation that is done that looks at the motor frequency and its effect on the stability of the fabricated head and motor structure. Design adjustments are made to the fabricated head to insure vibration free service. (See story on Tacoma Narrows Bridge failure in 1940)

When using a cast iron discharge head, National Pump Company can only guarantee vibration free operation at full load speed. A cast iron discharge head may be acceptable for operating at reduced speeds if precautions are made by locking-out the operating speed(s) on the VFD IF vibration is experienced from the natural resonant frequency of the motor and discharge head structure. In some cases, modifications can be made to the discharge head to change the resonate frequency of the structure.

Normally catalog performance and efficiencies are ‘best obtainable’ performance derived from testing using standard materials of construction (i.e. Cast Iron Enameled lined bowls & Bronze impellers) with backfilled and highly polished impellers. Any material change or use of a ‘standard’ polish, may reduce pump performance. The Hydraulic Institute sets performance standards and test tolerances for what a manufacturer can or cannot provide. These standards range from – 9% to +16% deviation on Flow, – 7% to +10% on Head, -7% to 0% on efficiency. When specifying a pump, it is important to define early on what your expectations are so that the manufacturer can meet those expectations. Call a National Pump Representative to learn more about the Hydraulic Institute Test Tolerances.

NPSHR is the minimum pressure required at the first impeller of the pump to keep the pump from cavitating (i.e. turning water to water vapor in the pump). This differs from NPSHA (available) which is the absolute pressure at the pump suction. Both values are represented in ‘feet’ of pressure. NPSHA must be a minimum of 3 feet more than NPSHR.

... oil - High temperature of water - Level of cooling liquid - Control of working pressure - Stop the engine with timer - Water pump exclusion - Settings for high and low working pressure - Main functions > Engine number ...

CHIOR VPH Long-Shaft Cutting Pumps with suction from above and double chopping tool excel through their high pumping capacity and cutting efficiency. The design of the pump housing, either made of cast ...

The LP pump is characterised by the absence of the mixing system and the possibility of using lower power as compared to the LE series. The LP pump is also supplied with the "impeller system", it is used ...

... developing a slurry pump with greater output than any pump already available. Since the introduction of the Super 350 in early 1995, this has proven to be the case for the many farmers and contractors ...

Vertical lineshaft pumps available with flanged drive head for electric motors, with horizontal right angle gear, with overgear driven by tractor p.t.o and with vertical pulley.

Vertical lineshaft pumps with submerged pump bowl, lineshaft and drive unit on the surface, for installation in deep wells or tanks. Featuring an extremely solid and reliable construction ...

... FAST, Load FastHigh-volume delivery with fast agitation, transfer, and loadingAdjustable flow rate without damaging the pumpAbrasion-resisting steel used in high wear areas. All stainless steel hardware used below ...

... alternative for submersible pumps and mixers, EYS vertical shaft series pumps and mixers are the right choice for you. Thanks to it’s modular design, vertical shaft units ...

... submersible electric 3,5 inch pump to prevent water backflow and reduce water hammer on the pump, protecting the impeller and diffuser.BG series pumps can be coupled with a 35OS motor.BG ...

... slurry pump has gained a reputation for being strong, Reliable and virtually maintenance free across the range. To improve mixing performance the off- set nozzle allows the slurry to be mixed in almost all directions. ...

ELECTRIC SUBMERSIBLE PUMPS CASED VERSION 4” (SERIES 95 PR N/) >The submersible pumps series 95 PR N/ are the smallest in the wide range of submersible pumps produced by PANELLI and sumarize ...

... lubrication system at the top of the pump, control over the level of oil in the oil bath seals and filling the sealants with grease, the pump will not require the withdrawal from service.

8613371530291

8613371530291