vickers hydraulic pump pressure adjustment quotation

As a worldwide leader, Vickers Hydraulics designs and manufactures a comprehensive line of reliable, high-efficiency hydraulic systems and components. They globally market as a complete line of reliable, high-efficiency hydraulic components through the most extensive distributor network in the fluid power industry.

Customized performance on every application assures most complete line pf standard fluid power pumps ever offered to industry so there is no need to compromise on performance. Your choice of pump is backed by Vickers know how, assuring that you get the exact pump needed for the job.

Extensive use of powdered metallurgy and other advanced manufacturing techniques permits them to offer in-line series piston pumps at substantial weight and cost reductions to you so whether fixed or variable displacement, these pumps feature high volumetric efficiency and pressure range of 1000 to 5000 psi. Various types of pressure control devices that they manufacture, tailored to you specific demand.

Exclusive hydrocushion design reduces pressure shocks from the system. Operate these valves remotely for unloading and sequencing, or directly for pressure relieving and reducing. Precise volumetric control is possible with temperature and pressure compensated flow control valves.

Vickers Hydraulic Valves are available with or without integral relief valve section and are suitable for pressures up to 3000 psi. Models are available to meet any requirement. Their directional valves offer the ultimate in compactness and versatility of application for many directional control requirements f hydraulic machinery. Ruggedness of design, controlled manufacturing quality and world-wide parts interchangeability are important parts of the overall story. Even on the most exacting industrial applications, you’ll find our directional controls keep your maintenance simple and downtime at a minimum. When your application needs rotary power, they have a hydraulic motor to do the job.

Both fixed and variable displacement models make up this range of axial piston pumps. Their high performance ratings and efficiency are achieved with a variety of hydraulic fluids. Fixed displacement models are noted for their volumetric and mechanical efficiency. Variable displacement models can closely match pressure and/or flow demand with a variety of control options as follows:

Replace your old Vickers PVB with the Continental HPV range of piston pumps. Output flow sizes are equal to the Vickers pumps including the 6, 10, 15, 20 and 29 gallons per minute @ 1750 RPM units. Contact us with your Vickers PVB part number for a direct Continental hydraulics replacement pump.

We repair and supply re-manufactured and new Eaton hydraulics, which included Eaton hydraulic pumps and Eaton hydraulic motors. Search our online catalog or contact us and let us know how we can help you.

We can supply what you need or repair what you have, so before purchasing, there is a good chance that your current hydraulic pump, motor, valve or cylinder can be repaired. Eaton hydraulic pump repairs, including motors, valves & cylinders come with our two-year warranty.

When purchasing, consider Eaton hydraulics remanufactured or after-market hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or remanufactured Eaton unit, getting you back in business without breaking the bank.

In 1900, Viggo Torbensen invents and patents the first gear-driven rear truck axle. Then in 1911, he teamed up with Joseph Eaton to form the Torbensen Gear and Axle Company in Bloomfield, New Jersey. In 1914 they moved the business to Cleveland, Ohio. When the Torbensen Axle Company was bought out, Eaton and Tobensen developed Eaton Axle Company in 1919. After several successful acquisitions, the company was changed to Eaton Manufacturing Company in 1932. Throughout the upcoming decades, Eaton Manufacturing continued to expand, acquiring more small companies and expanding their market. This led them to be the industry leader they are today. Eaton Hydraulics is now a manufacturer of well-known hydraulic brands including Charlynn, Dynapower, and Cessna.

When it comes to Low-Speed, High-Torque hydraulic motor technology, Eaton is an industry leader with their Charlynn product line. Each of Charlynn’s motor product lines includes a wide range of displacements that can be customized to fit specific application needs.

Small but mighty, find these low-pressure motors in a variety of pressures and displacements with a combination of features is perfect for a variety of demanding applications. You’ll often find them used in harvesters, augers, conveyors, and food processing equipment.

Medium-pressure motors offer higher flows and pressures than the spool valve motors which deliver the lowest pressure drop in the industry and the widest range of options to fit any application. Find them used in brush cutters, mowers, trenchers, forestry equipment, and turf equipment.

Heavy-duty, pressure-balanced motors featuring low speeds and high torque. Find these high-pressure motors in closed-loop applications because of the durable, compact design which are perfect for grinders, sprayers, augers, and equipment requiring higher pressure capability.

HP30 Hydraulic Motorsfeature a two-speed capability and outstanding starting torque efficiency that offers significant advantages over radial piston and cam lobe designs.

HP50 Hydraulic Track Motorsfeatures high power density, high starting torque efficiency, and high capacity bearings to help get any job done. The HP50 track motor’s direct drive provides higher top speed and horsepower transfer while maintaining a high mechanical and volumetric efficiency.

Eaton is continuously producing reliable motors known for their economic design, modularity and high-power density. This is what makes Eaton an industry leader. Eaton Hydraulics uses torque density, making smarter, more economical designs.

Axial piston motors have the largest shaft bearings to promote a long life span and full through-drive capability and features a range of pressures, displacements, and control options that help fit the motor to any application. They are commonly used in crushers, centrifugal pumps, primary metals, and pulp and paper applications.

Deliver success in tight mobile applications and high-pressure applications. Find them in a number of speeds, displacements, and pressures and the Series 1 features a cast-iron housing and fixed clearance design that reduces noise and allows for efficient operation.

Piston Pumps offer solutions for a variety of mobile and industrial applications and they feature a range of displacements, pressures, speeds, and drive options and you can find them in numerous mounting options. Their lightweight, durable housing allows for easy service and accessibility.

Axial piston motors feature an efficient, swashplate design that produces a low sound level while the Hydrokraft Series can handle a wide range of fluids and is available in a range of control options. They are commonly used in chemical pump drives, pulp and paper, marine winches and primary metals.

Known for their quality, longevity, and efficiency. Its fixed clearance slipper design and cast-iron housing reduces noise and allows for exceptional operation. Find the Series 1 variable motors in a range of speeds, pressures, and displacements with applications covering the most demanding applications such as combines and transit mixers.

Eaton has been manufacturing balances, cost-efficient external gear pumps for over 50 years. Eaton’s external gear pumps are the first choice for applications in agriculture, forestry, mining, automotive manufacturing, entertainment, and more. Find them in a range of configurations, designs and multi-pump combinations. Eaton external gear pumps offer longer life, quieter operation, high pressure and a full range of features to choose from.

Available in varying displacements and pressures. Its compact packaging and die-cast aluminum housing make it the perfect fit for many industrial and agricultural equipment and applications.

Offer impeccable productivity and reliability in one lightweight, compact package and this makes them perfect for a range of medium-pressure mobile applications. Some commonly used applications include sprayers, combines, fire trucks, salt spreaders, backhoe loaders, snow removal trucks, and cranes, just to name a few.

Long lasting axial piston pumps available in a variety of displacements, pressures, and control options. HPV pump designs offer flexibility, precision, and efficiency in mind, making them a great fit for a wide range of hydraulic systems. Find them used in applications such as agriculture, forestry, construction, mining, and more.

Great middle solution for a range of hydraulic applications. The self-lubricating system is responsive, cost-effective and easy to operate. Eaton medium duty pumps can transfer power to remote locations without the need for a mechanical power train which makes them a perfect fit for mid-range hydraulic systems.

Optimized for the most demanding applications, Eaton heavy-duty pumps offer the most efficient and reliable performance on the market. The fluid-linked system allows for hydrostatic braking which helps optimize engine power and performance with the easy, responsive operation and you can find them used in combines, farm tractors, timber harvesters, and construction equipment.

Variable closed-circuit piston pumps that offer a variety of displacements, precision controls, and operating pressures. They feature extra-large bearings to help extend the pump life and reliability. Find them used in applications such as crusher feeder drives, dewatering presses, and cranes.

These feature a through-drive design available in a variety of displacements, controls and operating pressures which helps maximize flexibility. The range of mounting options available to ensure easy installation. Find them used in thrusters, marine cranes and turbine starters.

Eaton fixed displacement vane pumps fit a wide range of applications that features a modular design that is available with flexible displacement and mounting options. Find Eaton vane pumps commonly used in molding material handling, manufacturing, construction, and automotive applications.

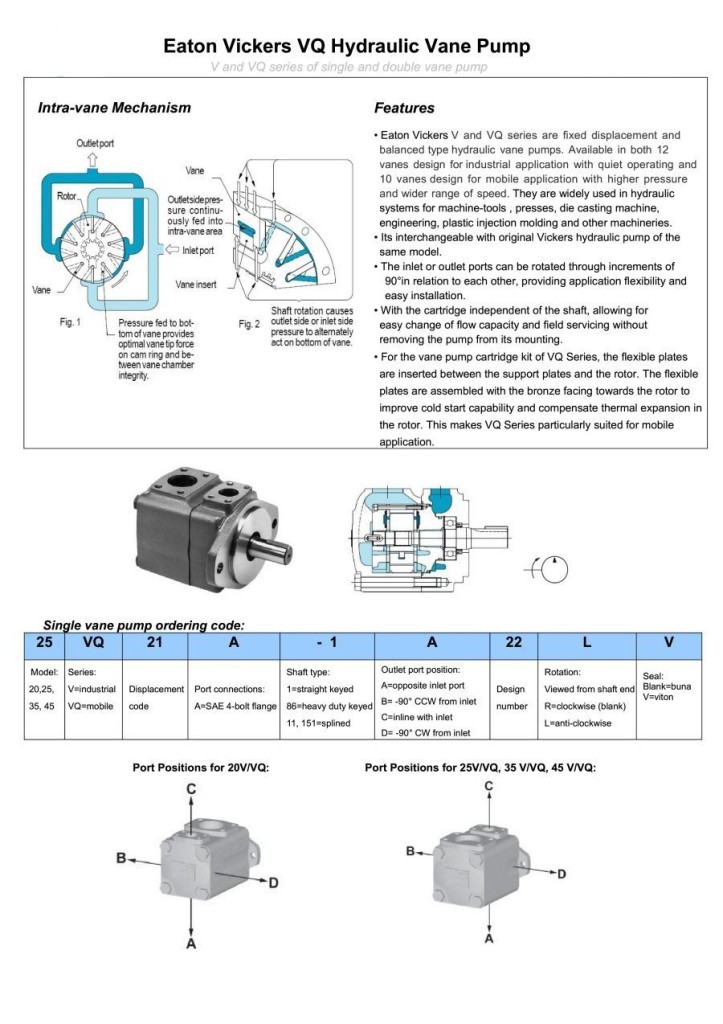

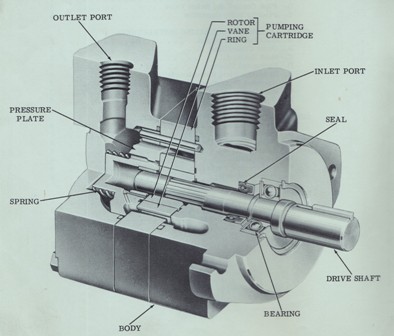

These feature intra-vane cartridge design technology so that they provide excellent efficiency, serviceability, and operating life. Eaton V Series pumps are extremely quiet, making them the first choice for indoor applications. Find them commonly used in plastic injection molding, presses, industrial power units, and more.

Feature a unique bi-metallic wafer plate design that can handle the highest pressures and the lowest noise levels. This makes them great for equipment such as combines, oil fields, balers, compactors, die casting, and mobile cranes.

The first choice for medium and low-pressure applications since the pressure-balanced, modular design helps reduce noise, improve serviceability and extend pump life. Find the V10/V20 Series commonly used for mobile and industrial applications including lift trucks, balers, power units, and power steering.

Stand-alone relief valves are relatively simple to set properly. After installing a relief valve in a circuit, with the pressure port connected to the pressure line and the tank port connected directly to the reservoir, adjust the relief valve to its lowest possible pressure setting. This will avoid an unexpected condition when the hydraulic power is applied to the circuit with this newly-installed relief valve.

Once the relief is properly installed and set at its minimum setting, turn on the fluid power. There may be noise coming from the relief valve, as flow may be racing through the relief when it is at its lowest pressure setting. Next, begin to increase the relief valve setting and monitor the pressure gauge associated with the circuit of this new relief valve. This method for setting a system relief valve is common to a circuit with a fixed displacement pump.

As described above, install the relief valve in the circuit with the pressure port connected to the pressure line and the tank port connected directly to the reservoir. Ensure that the relief valve is adjusted to its lowest possible pressure setting. Again, this avoids an unexpected condition when the hydraulic power is applied to the circuit with this newly-installed relief. Once properly installed, set both the pump compensator and the newly-installed relief valve to their minimum settings. Start the hydraulic pump and begin to turn the system relief valve to nearly the maximum adjustment position. Now begin to adjust the pump pressure compensator to a setting about 200 PSI above the final desired system pressure setting. Next, begin to reduce the setting on the system relief valve until the pressure on the pressure gauge begins to drop below the pressure setting of the pump compensator. Now, lock the system relief valve at the position that remains the 200 PSI above required pressure. Last, set the pump pressure compensator setting to the actual system pressure that is required.

Remember, the system pressure relief valve must be set about 200 PSI above the pump pressure compensator setting, or the two pressure settings will fight each other. This would result in the system acting as if it were a fixed displacement system. Loud noises can be generated by the pump and this condition will also begin to develop high heat generation in the hydraulic fluid!

Quality Hydraulics & Pneumatics, Inc. offers design, products, and systems for the improvement of machine performance, in both mobile or industrial circuits, and their hydraulic systems. The Certified Fluid Power Specialists at Quality Hydraulics will assist in selecting the most appropriate components and systems to provide the most efficient and cost effective solutions.

Ex-stock availability and Reasonable rates make HYDRANK H-4535 V/VQ pump and spare the first choice when replacing your existing VICKERS pumps and Spares.

We support many major brands, such as: Bosch/Rexroth, Parker, Vickers (Eaton), Atos & Hydac. Our massive inventory of new product supports a rapid response to customer needs. Most orders ship the same day and we have the capability to convert & test product prior to shipping. Our support staff has the most qualified personnel in the marketplace with over 300 combined years of experience.

eaton aerospace hydraulic pump eaton axial piston pump pdf eaton hydraulic motor breakdown eaton hydraulic motor catalogue pdf eaton hydraulic motor char-lynn eaton hydraulic motor for brush cutter eaton hydraulic motor for sale eaton hydraulic motor manual eaton hydraulic motor near me eaton hydraulic motor numbers eaton hydraulic motor pdf eaton hydraulic motor price eaton hydraulic motor rebuild eaton hydraulic motor rebuild kit eaton hydraulic motor repair eaton hydraulic motor repair manual eaton hydraulic motor seal kit eaton hydraulic motor seal replacement eaton hydraulic motor service manual eaton hydraulic motor shaft seal replacement eaton hydraulic motor specifications eaton hydraulic motor specs eaton hydraulic motor speed sensor eaton hydraulic motor with brake eaton hydraulic orbit motor eaton hydraulic parts catalog eaton hydraulic piston pump eaton hydraulic pump eaton hydraulic pump 26001-rzg eaton hydraulic pump 26004-rzc eaton hydraulic pump 26007-rzc eaton hydraulic pump 70423-rbt eaton hydraulic pump 72400-rmp-04 eaton hydraulic pump dealers eaton hydraulic pump dealers near me eaton hydraulic pump distributors in india eaton hydraulic pump manua eaton hydraulic pump motor eaton hydraulic pump parts eaton hydraulic pump pdf eaton hydraulic pump pressure adjustment eaton hydraulic pump pvq32-b2r eaton hydraulic pump qatar eaton hydraulic pump rebuild kit eaton hydraulic pump repair eaton hydraulic pump repair near me eaton hydraulic pump seal kit eaton hydraulic pump uae eaton hydraulic pump uk eaton hydraulic pump yuken eaton hydraulic pump zf eaton hydraulic pumps and motors eaton hydraulic pumps canada eaton hydraulic pumps edmonton eaton hydraulic pumps for sale eaton hydraulic steering pump eaton hydraulic vane pump eaton hydraulic winch motor eaton hydraulics pump singapore eaton hydrostatic hydraulic pump eaton load sensing hydraulic pump eaton make hydraulic pump eaton piston pump distributors eaton piston pump pdf eaton pto hydraulic pump eaton tandem hydraulic pump eaton variable displacement hydraulic pump eaton vickers hydraulic pump

The wide-range fixed and variable displacements of Eaton PVX & PFX Series piston pumps make them ideal for use with primary metal power units, test stands, mixer drives and more. They come in a robust housing enclosure and are available with displacements from 66 cc to 250 cc (4.03 to 15.26 cu in) at operating pressures up to 350 bar (5,075 psi) for broader application.

HEASH TECHNICAL B.V. specialised in the sale of Eaton pumps and motors across their entire range. We supply Eaton Vickers PVXS and PFXS all sizes, as PVXS066, PVXS090, PVXS130, PVXS180, PVXS250, PFXS066, PFXS090, PFXS130, PFXS180, PFXS250. for other Eaton Vicksers pumps as PVH, PVM, PVQ and valves as KBHDG, KDG4V, KFDG, KBDG, KSDG..., please don’t hesitate to contract with us if u have any interested in our sale.

Founded nearly 25 years ago, Panagon Systems has remained a trusted company producing hydraulic parts on demand for a number of shops, manufacturers and industries. The company, located in Macomb, Michigan, is the largest aftermarket hydraulic piston pump and parts manufacturer in North America, providing a vast variety of current and obsolete components. Panagon has the ability to produce a product from raw materials to a finished pump, assembled, tested, painted and shipped from our facility. Due to the phasing out of old products, customers usually find that the parts they need are no longer available, or that the delivery time is too long or the cost is too high. Panagon Systems attempts to fill the void OEM’s create by manufacturing the phased out, expensive, unavailable pumps, motors and transmissions, from companies like Vickers, Denison and Rexroth.

We manufacture hydraulic pumps, motors and parts for a variety of industrial and mobile applications. Our replacements are equivalent to the Eaton/Vickers line of PVH, PVQ, PVB, PVM, PVE, PFB, MFB, MFE, TA19, TA1919, TDV10 and TDV20 series units and Rexroth A10V series units.

WE CAN GIVE YOU ONE TO ONE PUMPS AGAINST VICKERS VANE PUMPS IN HYDRANK BRAND. THIS WILL BE ONE TO ONE FOR YOUR VICKERS VANE PUMPS REQUIREMENTSpecifications:

ApplicationIndustrialHydrank pumps are 100% interchangeable with eaton vickers design vane pumps. Our spares are also interchangable with eaton vickers spares.

Max. Speed1800 RPMHydrank pumps are 100% interchangeable with eaton vickers design vane pumps. Our spares are also interchangable with eaton vickers spares.

Max. Speed1800 RPMHYDRANK PUMPS ARE 100% INTERCHANGEABLE WITH EATON VICKERS DESIGN VANE PUMPS. OUR SPARES ARE ALSO INTERCHANGABLE WITH EATON VICKERS SPARES.

Max. Speed1800 RPMHydrank pumps are 100% interchangeable with eaton vickers design vane pumps. Our spares are also interchangable with eaton vickers spares.

Maximum Displacement(P1= 42 to 75 GPM) (P2= 21 to 38 GPM)Hydrank pumps are 100% interchangeable with eaton vickers design vane pumps. Our spares are also interchangable with eaton vickers spares.

Maximum displacement(P1= 42 to 75 GPM)Hydrank pumps are 100% interchangeable with eaton vickers design vane pumps. Our spares are also interchangable with eaton vickers spares.

8613371530291

8613371530291