vickers hydraulic pump repair factory

One of the most experienced and respected names in hydraulics, Vickers hydraulic pumps and other hydraulic products can be found in critical installations all over the globe. Pioneer of the hydraulic industry’s first fluid analysis service, Vickers continues to be one of the most reliable brands in service for defense, aerospace, industrial, marine, and mobile applications worldwide.

At Servo Kinetics Inc, we engineer and manufacture all Classic 2000 Series pumps and motors, in our Ann Arbor, Michigan facility, to meet or exceed Vickers OEM aircraft/aerospace quality specifications, using all original metals. When we return your 2000 Series unit, it will be equal to or better than new.

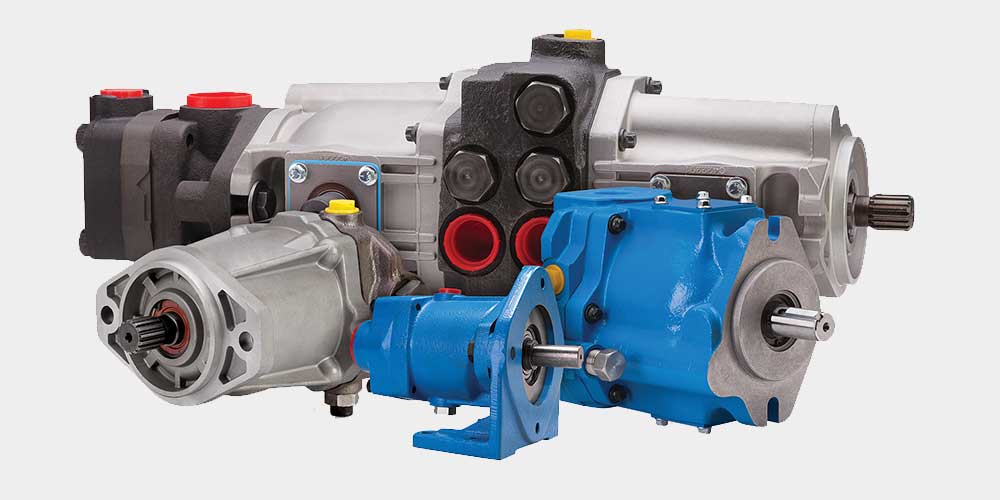

As a worldwide leader, Vickers Hydraulics designs and manufactures a comprehensive line of reliable, high-efficiency hydraulic systems and components. They globally market as a complete line of reliable, high-efficiency hydraulic components through the most extensive distributor network in the fluid power industry.

Customized performance on every application assures most complete line pf standard fluid power pumps ever offered to industry so there is no need to compromise on performance. Your choice of pump is backed by Vickers know how, assuring that you get the exact pump needed for the job.

Extensive use of powdered metallurgy and other advanced manufacturing techniques permits them to offer in-line series piston pumps at substantial weight and cost reductions to you so whether fixed or variable displacement, these pumps feature high volumetric efficiency and pressure range of 1000 to 5000 psi. Various types of pressure control devices that they manufacture, tailored to you specific demand.

Vickers Hydraulic Valves are available with or without integral relief valve section and are suitable for pressures up to 3000 psi. Models are available to meet any requirement. Their directional valves offer the ultimate in compactness and versatility of application for many directional control requirements f hydraulic machinery. Ruggedness of design, controlled manufacturing quality and world-wide parts interchangeability are important parts of the overall story. Even on the most exacting industrial applications, you’ll find our directional controls keep your maintenance simple and downtime at a minimum. When your application needs rotary power, they have a hydraulic motor to do the job.

Tri-State Hydraulics has over 45 years of expertise with Vickers pumps and motors. They know the repair and replacement of Vickers hydraulic equipment. Vickers leads the hydraulic business for good reason. They’re the gold standard for vane pumps, piston pumps, valves and cylinders. The power management company and industry titan Eaton recently acquired Vickers.

All Vickers parts are long lasting, reliable, and efficient components. These models are known for their 12 vane system and quiet operation, with sounds levels as low as 62 dB(A). Vickers products are found in plastic injection molding, aluminum die casting, material handling, power units and various industrial machining or applications.

Our company, Tri-State Hydraulics, carries a massive inventory of Vickers pumps and motors onsite and are ready for immediate shipping. Tri-State fully tests and sets to OEM specifications using our proven check system before shipping the product. Additionally, we offer a wide range of maintenance services including comprehensive reconditioning service, full part replacement, expert support and test facilities. Contact us today to learn more at (847.439.8987) and our experts will quickly diagnose and repair your Vickers pumps and motors.

We will contact you to inform you of what we found, give you a quote for repair and a timeframe for completion, or let you know if we cannot repair it.

Do you need Eaton hydraulic pump repair, rebuild, or replacement? We specialize in Eaton pump repair and rebuilds. If you need a free estimate for any Eaton pump, get in touch with us today to find out how much it will cost for repairs.

We provide fast, reliable hydraulic pump repair service on all Eaton models. We are guarantee all repair work will be done with genuine OEM parts, so you know that you aren’t getting gray market or counterfeit parts.

Our team of skilled technicians will give your pump the attention it needs, and put it through our detailed inspection and repair process. Once the pump has been reassembled, we’ll test it thoroughly with our state-of-the-art-test equipment.

When you get your pump back, it will meet or exceed factory specs. Once you work with us, we think that you will keep coming back to us for all of your Eaton hydraulic repair needs, including Eaton hydraulic motors and Eaton hydraulic cylinders.

If you don’t see your model listed below, don’t hesitate to call or contact us. We service just about every model of pump that is available from Eaton and other manufacturers, including gear pumps, piston pumps, and vane pumps.

Eaton started making gear pumps for the aerospace industry in the 1960s. Today, their pumps are used in various mobile and industrial applications. Eaton works to create a compact, affordable pump by incorporating valves and controls into the pump itself. External Gear Pumps from Eaton that we provide service for include:

Eaton manufactures these pumps for medium-duty industrial applications. These products are marketed under the Vickers brand and can be used in machine tools, automotive plans, power generation plants, civil engineering, and many other industries. Eaton Vickers Open Circuit Piston Pumps that we provide service for include:

These Eaton pumps provide the flexibility to drive a broad range of fluid power systems. Based on designs from Vickers, these pumps can be customized to a wide variety of uses, including backhoes, skid steers, and boom lifts. We offer repair and service on the following Open Circuit Piston Pumps from Eaton.

Eaton’s Hydrokraft closed-circuit piston pumps are axial pumps with a cradle-type swash plat design. They are designed for closed circuit applications with integrated valves and filters. This provides an entire closed-circuit system in one unit. We offer repair and service on the following:

Vickers brand vane pumps from Eaton are fixed displacement pumps used in both mobile and industrial markets. They feature a cartridge kit that allows for easy repair and interchangeable parts between pumps. These pumps are used in combines, balers, mobile cranes, skid steers, presses, booms, lift trucks, and other types of machinery. We offer repair and service on these Eaton Vickers vane pumps:

When you are on the job and under a deadline and equipment fails, you need fast, reliable repair. We can send in our field technicians to get your Eaton pump back up and running as soon as possible. Our reliable, experienced team can perform diagnostic services and minor repairs for equipment and machinery used in many industries. Our team can travel throughout the United States and many international locations, including North America and South America.

If repairs cannot be made on-site to your Eaton pump, you can ship it to our facility. If you’re close enough, you can drop it off. We know how important it is to get your operations back up and running. So you can trust us to get your pump repaired and back to you as fast as possible, and working properly.

Eaton hydraulic pumps offer proven technology and design no matter what line of work you are in. From agriculture and aviation to energy and manufacturing, Eaton makes a hydraulic pump to fit your needs. And just in case your Eaton pump fails or isn’t performing up to expectation, we can fix it and make it just like new again.

Don’t see your Eaton hydraulic pump model number? Not a problem. Call 800-800-6971 or send us an email. Chances are we’ve worked on it before and have parts for it, even if it’s not listed on our website.

We are the only manufacturer in North America who produces OEM-grade replacement pumps, motors and parts with complete proficiency. As the largest aftermarket hydraulic piston pump manufacturer, we ensure the utmost quality every step of the way. With our recent expansion, we’re more able than ever to work with shops, manufacturers and distributors in a variety of industries. When you need it most, demand nothing less than Panagon Systems.

Repairing and supplying remanufactured and new Vickers hydraulics – Vickers hydraulics pumps, Vickers hydraulics valves, and Vickers hydraulics motors. Looking for new Vickers hydraulic units? Search our online catalog or contact us and let us know how we can help you.

We can supply Vickers Hydraulics that you need or repair the Vickers hydraulic pumps that you have. Before purchasing, there may be a good chance that your current Vickers hydraulic pump, motor, valve or cylinder can be repaired. Vickers hydraulic pump repairs, including motors, valves & cylinders comes with our two year warranty. Use our repair form to get a quick quote onVickershydraulic repairs.

When purchasing new Vickers hydraulic parts, consider remanufactured Vickers hydraulics or after market Vickers hydraulic pump units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or remanufactured Vickers hydraulic unit.

As a founder in the industry, Vickers hydraulics pioneered the first fluid analysis system. They have become a worldwide leader in vane hydraulic pumps, piston pumps, valves, electro-hydraulic controls, cylinders. Vickers hydraulic pumps are found in all industries including mobile, aerospace, agriculture, automotive, marine, defense, construction, mining, forestry, utility, material handling, machine tools, moulding, and entertainment. Vickers hydraulics was purchased by Eaton in 1999 thus joining the Eaton Brand Family.

They build cylinders for harsh and heavy duty industrial usage. Vickers hydraulic cylinders come in bore sizes ranging from 20 mm (0.75 in) to 1500 mm (60 in) and strokes up to 22 m (900 in). Includes L Series light duty pneumatics, T Series threaded cylinders, R Series medium duty NFPA tie rod, I Series Isometric, N Series NFPA tie rod, W Series industrial welded, G Series large tie rod, and M Series mill duty.

Vickers valves offer continuous, reliable performance in demanding operating conditions. They are engineered for a long service life and to help deliver increased productivity. Includes servo performance proportional valves, check valves, directional valves, flange valves, flow controls, pressure controls, proportional flow valves and proportional pressure valves.

Vickers piston motors are built for large and small applications from demanding industrial environments to the smallest mobile machinery. Offers a complete line of bent axis and in-line piston motors with displacements from 11cc to 4100 cc (0.067 in3 to 250.2 in3)/rev and speeds to 5500 rpm at pressures to 413 bar (6000 psi). Includes bent axis motors, HMV Series, HMR Series, HMA Series, HMF Series, heavy duty piston motors, Hydrokraft MV(F)X and MF(F)W, ME Series and medium duty piston motors.

Vickers vane motors are built for industrial and mobile applications. They are easily serviceable, engineered for improved uptime. Provide an efficient means for applying variable speed and rotary hydraulic power. Their relieve valve allows them to be stalled under load without damage. Includes M vane motors series.

Vickers Hydraulic pumps are quiet! The low-noise displacement hydraulic pumps are perfect for a broad range of mobile and industrial applications. Vickers hydraulic pumps are easily interchangeable and easy to repair. Vickers Hydraulic pumps include V Series, V10 & V20 Series, VMQ Series and VQ(H) Series.

Vickers servo valves are primarily for metal, wood and paper processing as well as plastics, manufacturing and more. Servo valves are a perfect solution for closed-loop control applications. They are excellent for exact positional accuracy, repeatable velocity and predictable force. Technical information: Rated pressure up to – 350 bar/5000 psi, Rated flow up to – 151 LPM/40 GPM, Function – positioning, speed, and pressure, Size – SM4/10 – 40; SX4/20.

Years of wear and tear can render your Vickers pneumatic and hydraulic cylinders, pumps, or motors useless. This not only hampers your normal course of operations, but also results in costly downtime. When you need performance stability even in the most demanding applications, Motor & Gear Engineering, Inc. is your partner of choice.

Our hydraulic cylinder specialists have more than 40 years of combined experience in repairing and remanufacturing Vickers cylinders. The management team and crew are dedicated to giving our customers the best service available. We can repair your obsolete cylinders or design and build you a custom cylinder.

We repair and service the following brands of hydraulics and support current as well as obsolete products dating back to 1940. All repairs are bench tested and include a free failure analysis, startup procedure and matching factory new warranty.

Extensive cost savings, minimal downtime, model code identification, failure analysis, component upgrades, custom modifications performed during the hydraulic repair service, OEM matching paint colors, person to person hydraulic technical support and extensive repair and service workmanship warranty are all very important reasons to have your existing hydraulics repaired and serviced. But most importantly, when using our hydraulic repair services, you are maintaining the original hydraulic unit that was engineered and selected specifically for your hydraulic equipment and application.

When ordering factory new, it is typical to experience product design changes, unreasonably long lead times, quantity requirements, advance payments and no return policies. In addition, suggested lead times are frequently extended. Our hydraulic repair services not only provide a substantial cost savings, but also will have your equipment up and running in a fraction of the time.

Every year the factories release new products and obsolete others. If downtime is acceptable, a new pump, motor, valve or transmission replacement may require a change of oil type, reservoirs, filters, fittings, hoses, electric motors, couplings, mounting brackets and valves. Location and size constraints can also become a huge burden, as well as hourly technician fees required during the design and installation of the newly specified products. Utilizing our hydraulic repair services will allow you to maintain and keep your existing system as it was originally intended and engineered to be.

We have over two decades of experience specializing in the same hydraulic brands. This dedication has allowed us to establish an extensive knowledge base of the specific products we support. Since we have repaired the same products thousands of times, we know exactly what to look for and how to repair it correctly the very first time. Companies around the world have used our hydraulic repair services to maintain current as well as obsolete systems dating back to the 1940’s. Our real world experience will keep you up and running well into the future.

We start by taking pictures and verifying model codes. Individual components are dimensionally compared to factory new tolerances. During this process, the cause of failure is identified and a detailed report is drafted. All hydraulic repairs include these services.

A detailed failure analysis is performed when hydraulic assemblies are inspected during our repair services. This information can then be utilized to prevent the newly repaired products from premature failure. When sending your products in for repair or service, please specify any additional information or recent changes in operation. We will consider these details when finalizing our report.

Our technical support department provides a service that can identify and recreate model codes when products were altered or have misplaced labels. When evaluating units sent in for our repair services, we frequently receive products with tags that do not match the actual unit. In most cases, they have been modified in the field but not on the label. This service is completed during the repair evaluation.

Hydraulic repairs are thoroughly tested to existing, customer supplied or factory original settings. We provide this service to guarantee that each repaired assembly meets or exceeds factory original specifications. Utilizing numerous test stations with data acquisition, all repaired and serviced products are guaranteed to perform like new.

Please review the solutions section of this website. It provides necessary information to assist with troubleshooting previous failures, oil recommendations, start-up procedures and other additional information required when installing your newly repaired hydraulics back into service.

Our authorized hydraulic pump repair centers can perform pump, cylinder, valve and system repairs for all top brands including Haskel, Butech and Sheffer. We also repair units from Hawe, HIP, Vickers, Parker, Oilgear and Nachi.

All pumps are repaired and tested to factory specifications. Our experienced technicians have the ability to repair any size equipment, including but not limited to pumps, valves, cylinders, and systems.

Pneumatic and Hydraulic conducts most types of hydraulic pump repair from double diaphragm to hydraulic gear, vane, piston pumps to gas boosters and air amplifiers. Our repairs range from basic seal and soft good replacements to complete overhauls.

Advanced Fluid Systems is proud to offer hydraulic repair services for hydraulic pumps and motors, from gear pumps to vane pumps to the largest radial piston pumps, regardless of brand. Our inventory includes seals, parts and re-manufactured pumps available for immediate shipment.

100HP programmable variable frequency drive (VFD) test system for mineral oil and water glycol fluids that allows us to test pumps with electronic controls.

NN Hydraulic India offers new and remanufactured hydraulic pumps mounted on Vickers machinery. We repair, rebuild, and remanufacture all Vickers hydrostatic pumps, and Vickers hydraulic pumps. If your Vickers equipment hydraulic pump is not functioning as designed, contact us for a quote.

We are an eminent manufacturer, supplier and service provide of V10 and V20 pumps, which are available with integrated flow control valves to simplify system design and installation.

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Vickers Hydraulic Pump Repair Manual, Hydraulic Ram Pump Youtube, Hydraulic Pump Parker, Discount Hydraulic Pump for Die-casting machinery,Vickers Hydraulic Vane Pump Catalogue. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you! The product will supply to all over the world, such as Europe, America, Australia,Pakistan, Cyprus,South Africa, Romania.Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Just a quick email to thank you for the hydraulic pump repair. My neighbour is really grateful; he said that without the repair the machine would have just been “ferraille” (scrap). Guess I owe you a bottle of red!

When new customers ask what services we can offer, we keep it simple and say: “If it’s hydraulic we can design it, supply it, solve it or repair it…” That means that if you’re looking for a

As with other hydraulic equipment, many of our well-repaired and refurbished hydraulic pumps are virtually indistinguishable to a brand new unit. Our service includes a free evaluation – having examined your existing pump to diagnose the extent of work needed, and ability to recover and re-use existing components.

When evaluating your hydraulic pump our team could offer recommendations to improve its design and productivity, so that you could reduce running costs and minimise the likelihood of any future downtime and hydraulic pump repair work. Our assessment may determine that a hydraulic pump repair is not feasible, not good value for money or simply not recommended. If this is the case then we will quote for a new, replacement new unit in addition to quoting for your hydraulic pump repair if appropriate.

To give you a quick example: our technical team received a phone call from a well-known, global oil company asking whether we could fix one of the pumps (a Parker, Commercial Intertech P15H 6 Section pump) in their system. We asked to see a quick photograph of the defective pump first, before confirming that, yes, we could undertake the repair. The pictures below show the pump, “before” and “after”… Not a bad looking makeover is it?

At Hydraulics Online we can offer direct equivalents to a vast range of hydraulic manufacturers. We’re always up for a challenge, and even if components are discontinued or seemingly obsolete, we can more often than not source an equivalent suitable to your application.

Some of the popular hydraulic pump manufacturers and brands that we can supply include: Adan, Atos, Bosch Rexroth, Breuninghaus, Bucher, Casappa hydraulic pumps, Commercial, Continental, Dowty hydraulic pump, Dynapower, Eaton, Eaton Vickers, Hamworthy, Hydromatik, Kawasaki, Linde, Parker, Permco, Poclain hydraulic pumps, Racine, RHL, Sauer Danfoss hydraulic pumps, Sauer Sundstrand, Salami hydraulic pumps, Tyrone, Uchida, Vickers and White hydraulic pumps.

We supply a variety of hydraulic pump types including: gear pumps, rotary vane pumps, fixed displacement pumps / screw pumps, bent axis piston pumps, axial piston pumps, and radial piston pumps. We can help identify the pump that will be appropriate for your application, even if you’re not certain on what type of hydraulic pump you need.

So back to that hydraulic pump repair you were looking for. If you’ve read this far then you’re hopefully tempted to give us a try. So what are you waiting for? We promise you, your brand is in safe hands. Contact us now and let us know ho we can help.

Our engineers can rebuild/remanufacture your hydraulic pump to bring its operation back to OEM specifications. Our technicians have been factory trained by multiple OEM’s in the rebuild process of hydraulic pumps. After the remanufacturing process is complete, each pump is fully tested to max PSI to ensure proper operation under load.

It’s always exciting to see new equipment run for the first time. It’s also a bit saddening to realize that it may never run that well again. Naturally, with continued use, equipment becomes a little less efficient and productive. That is where K+S Services comes in. Our hydraulic pump repair services restore hydraulic pumps to peak efficiency. We also do expert hydraulic cylinder repair and standard hydraulic repairs.

Hydraulic pump repair companies and manufacturers machine the internal parts to tight tolerances. Lubrication by hydraulic fluid keeps the parts moving and cuts down on wear. Seals keep contaminants out as best they can to keep those lubrications operating as they should. Still, there is no type or amount of lubrication that will keep pumps running forever and contaminants will always work their way in. Eventually, pumps become less efficient, start leaking fluid leaks or seize completely.

Hydraulic pumps and accessories have long service lives. They may have been standard catalog items in the beginning but, today, they are obsolete. Retrofitting your system with different units would be costly and time-consuming. The best option is to breathe new life into your existing equipment. That means having a hydraulic pump repair service rebuilding or remanufacturing it to the original equipment manufacturer (OEM) specifications.

Final hydraulic pump testing at K+S Services occurs in a simulated real-world application. At the end of the extended test, a supervisor reviews the unit. If it is operating properly and conforms to OEM specifications, the repair is complete.

You knew that your hydraulic pump wasn’t going to last forever. Maybe it let you know the end is near. Perhaps it just stopped working altogether and a hydraulic pump repair is necessary. Do you have a spare? If not, one may be available.

Where do these parts come from? They come from customers like you. Replacing and repairing obsolete and discontinued equipment is always a challenge. Having a huge volume of reconditioned spare parts and equipment is good for everyone. Contact us to discuss how we can help you recycle your surplus or unneeded equipment.

Are you in the middle of a hydraulic equipment crisis? Do you have hydraulics that are ready to fail? Is there a spare hydraulic vacuum pump or blower that you are ready to recycle? Contact one of our hydraulic pump repair representatives at K+S Services and let us help you address your hydraulic pump needs.

In order to maximize equipment performance and efficiency and improve reliability in your operation, you need a trustworthy partner. How do you do it? With an authorized warranty repair center partner, engineering expertise, innovative technology and experienced field support. The product specialists and engineers at Scott Industrial can work with you to customize and design solutions for your fluid power systems and mobile electronic controls.

When equipment and systems don’t perform as expected, you need to respond and resolve issues immediately to prevent downtime. Whether for emergency service or routine maintenance, access to quality replacement parts can mean the difference between your operations running smoothly and unexpected downtime. With a wide array of replacements parts for hydraulic and pneumatic systems, we can respond quickly to your needs. Offering high-quality standard and custom parts, allows you to decrease downtime.

Scott is an Authorized Repair Center for Moog servo valves. Along with conducting a full factory failure analysis and inspection, we provide a two year factory warranty on all servo valve repairs. Find out more.

For your most complex problems, it’s critical that equipment, systems and processes are efficient as possible. Our repair team and experienced engineers can trouble-shoot and provide solutions to improve uptime and safety at your site or ours. You will receive a comprehensive oil analysis, on-site troubleshooting and diagnostics with advanced electronic test equipment to properly service your equipment. Working with your team, Scott’ technicians and engineering experts will then provide recommendations. To ensure your operation keeps moving, we test all repairs of your power unit equipment on our VFD test stands (200HP). For your peace of mind, a one-year warranty is guaranteed on all repairs and in some cases, extended time when factory authorized warranties are included. To decrease downtime in the future, customized preventative maintenance programs are available.

Hymon Hydraulics provide Hydraulic Pump Repair Kits 100% interchangeable with oem parts. We can make varies of hydraulic pumps parts with factory direct prices and have state of the art machining testing facilities to assist clients with their projects.

8613371530291

8613371530291