vickers hydraulic pump repair manual supplier

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Vickers Hydraulic Pump Repair Manual, Hydraulic Ram Pump Youtube, Hydraulic Pump Parker, Discount Hydraulic Pump for Die-casting machinery,Vickers Hydraulic Vane Pump Catalogue. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you! The product will supply to all over the world, such as Europe, America, Australia,Pakistan, Cyprus,South Africa, Romania.Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

As a worldwide leader, Vickers Hydraulics designs and manufactures a comprehensive line of reliable, high-efficiency hydraulic systems and components. They globally market as a complete line of reliable, high-efficiency hydraulic components through the most extensive distributor network in the fluid power industry.

Customized performance on every application assures most complete line pf standard fluid power pumps ever offered to industry so there is no need to compromise on performance. Your choice of pump is backed by Vickers know how, assuring that you get the exact pump needed for the job.

Extensive use of powdered metallurgy and other advanced manufacturing techniques permits them to offer in-line series piston pumps at substantial weight and cost reductions to you so whether fixed or variable displacement, these pumps feature high volumetric efficiency and pressure range of 1000 to 5000 psi. Various types of pressure control devices that they manufacture, tailored to you specific demand.

Vickers Hydraulic Valves are available with or without integral relief valve section and are suitable for pressures up to 3000 psi. Models are available to meet any requirement. Their directional valves offer the ultimate in compactness and versatility of application for many directional control requirements f hydraulic machinery. Ruggedness of design, controlled manufacturing quality and world-wide parts interchangeability are important parts of the overall story. Even on the most exacting industrial applications, you’ll find our directional controls keep your maintenance simple and downtime at a minimum. When your application needs rotary power, they have a hydraulic motor to do the job.

bobcat hydraulic pump repair, bosch hydraulic pump repair, bosch rexroth hydraulic pump repair, can hydraulic pump be repaired, car hydraulic pump repair, casappa hydraulic pump repair, case hydraulic pump repair, cat hydraulic pump repair, caterpillar hydraulic pump repair, daikin hydraulic pump repair, danfoss hydraulic pump repair, dowty hydraulic pump repair kit, eaton hydraulic pump repair, eaton hydraulic pump repair near me, excavator hydraulic pump repair, gear pump repair kit, hyd pump repair near me, hydraulic gear pump repair, hydraulic gear pump repair kit, hydraulic gear pump repair manual, hydraulic gear pump repair near me, hydraulic motor repair kits, hydraulic motor repair near me, hydraulic piston pump repair near me, hydraulic pump rebuild kit, hydraulic pump rebuild near me, hydraulic pump repair, hydraulic pump repair excavator, hydraulic pump repair in ahmedabad, hydraulic pump repair in delhi, hydraulic pump repair in faridabad, hydraulic pump repair in hyderabad, hydraulic pump repair in india, hydraulic pump repair in jaipur, hydraulic pump repair in kolkata, hydraulic pump repair in pune, hydraulic pump repair in qatar, hydraulic pump repair indianapolis, hydraulic pump repair ireland, hydraulic pump repair parts, hydraulic pump repair pdf, hydraulic pump repair service, hydraulic pump repair service near me, hydraulic pump repair shop, hydraulic pump repair shop near me, hydraulic pump replacement cost, industrial hydraulic pump repair, jcb 3cx hydraulic pump repair, jcb hydraulic pump repair, john deere 2010 hydraulic pump repair, john deere 4020 hydraulic pump repair, john deere hydraulic pump repair, john deere hydraulic pump repair kit, kawasaki hydraulic pump repair, kawasaki hydraulic pump repair manual, kawasaki k3v112dt hydraulic pump repair manual, komatsu excavator hydraulic pump repair, komatsu hydraulic pump repair, liebherr hydraulic pump repair, linde hydraulic pump repair, linde hydraulic pump repair manual, linde hydraulic pump repair manual pdf, local hydraulic pump repair, marine hydraulic pump repair, nachi hydraulic pump repair, nachi hydraulic pump repair kit, parker hydraulic pump repair, parker hydraulic pump repair parts, piston hydraulic pump repair, poclain hydraulic pump repair manual, rexroth hydraulic pump repair, sundstrand hydraulic pump repair, sundstrand hydraulic pump repair near me, vickers hydraulic pump repair manual, vickers hydraulic pump repair near me, voith hydraulic pump repair, yuken hydraulic pump repair,

We repair and service the following brands of hydraulics and support current as well as obsolete products dating back to 1940. All repairs are bench tested and include a free failure analysis, startup procedure and matching factory new warranty.

Extensive cost savings, minimal downtime, model code identification, failure analysis, component upgrades, custom modifications performed during the hydraulic repair service, OEM matching paint colors, person to person hydraulic technical support and extensive repair and service workmanship warranty are all very important reasons to have your existing hydraulics repaired and serviced. But most importantly, when using our hydraulic repair services, you are maintaining the original hydraulic unit that was engineered and selected specifically for your hydraulic equipment and application.

When ordering factory new, it is typical to experience product design changes, unreasonably long lead times, quantity requirements, advance payments and no return policies. In addition, suggested lead times are frequently extended. Our hydraulic repair services not only provide a substantial cost savings, but also will have your equipment up and running in a fraction of the time.

Every year the factories release new products and obsolete others. If downtime is acceptable, a new pump, motor, valve or transmission replacement may require a change of oil type, reservoirs, filters, fittings, hoses, electric motors, couplings, mounting brackets and valves. Location and size constraints can also become a huge burden, as well as hourly technician fees required during the design and installation of the newly specified products. Utilizing our hydraulic repair services will allow you to maintain and keep your existing system as it was originally intended and engineered to be.

We have over two decades of experience specializing in the same hydraulic brands. This dedication has allowed us to establish an extensive knowledge base of the specific products we support. Since we have repaired the same products thousands of times, we know exactly what to look for and how to repair it correctly the very first time. Companies around the world have used our hydraulic repair services to maintain current as well as obsolete systems dating back to the 1940’s. Our real world experience will keep you up and running well into the future.

We start by taking pictures and verifying model codes. Individual components are dimensionally compared to factory new tolerances. During this process, the cause of failure is identified and a detailed report is drafted. All hydraulic repairs include these services.

A detailed failure analysis is performed when hydraulic assemblies are inspected during our repair services. This information can then be utilized to prevent the newly repaired products from premature failure. When sending your products in for repair or service, please specify any additional information or recent changes in operation. We will consider these details when finalizing our report.

Our technical support department provides a service that can identify and recreate model codes when products were altered or have misplaced labels. When evaluating units sent in for our repair services, we frequently receive products with tags that do not match the actual unit. In most cases, they have been modified in the field but not on the label. This service is completed during the repair evaluation.

Hydraulic repairs are thoroughly tested to existing, customer supplied or factory original settings. We provide this service to guarantee that each repaired assembly meets or exceeds factory original specifications. Utilizing numerous test stations with data acquisition, all repaired and serviced products are guaranteed to perform like new.

Please review the solutions section of this website. It provides necessary information to assist with troubleshooting previous failures, oil recommendations, start-up procedures and other additional information required when installing your newly repaired hydraulics back into service.

vickers vane pump repair manual pdf comes to you after months of searching and searching for the best possible place to get this book. In this website, many questions about this author and their products are answered so that you can be sure to find what you are looking for. Let’s share this page in social networks such as Facebook, Twitter and Reddit.

After removing the pump from the system and before disassembly, cap or plug all ports and disconnected hydraulic lines. Clean the outside of the unit thoroughly to prevent entry of dirt into the system.

Absolute cleanliness is essential when working on a hydraulic system. Always work in a clean area. The presence of dirt and foreign materials in the system can result in serious damage or inadequate operation. Periodic maintenance of the pump will generally not require disassembly to the extent described here.

Troubleshooting is one of the best virtues to acquire if you are an industrial pump repair technician. All in all, troubleshooting is a process. Firstly, you have to define the problem, gather information, and analyze data that will help you solve the problem, implement the solution and check if it worked for you or not. This form collects vickers vane pump problems, symptoms, and solutions!

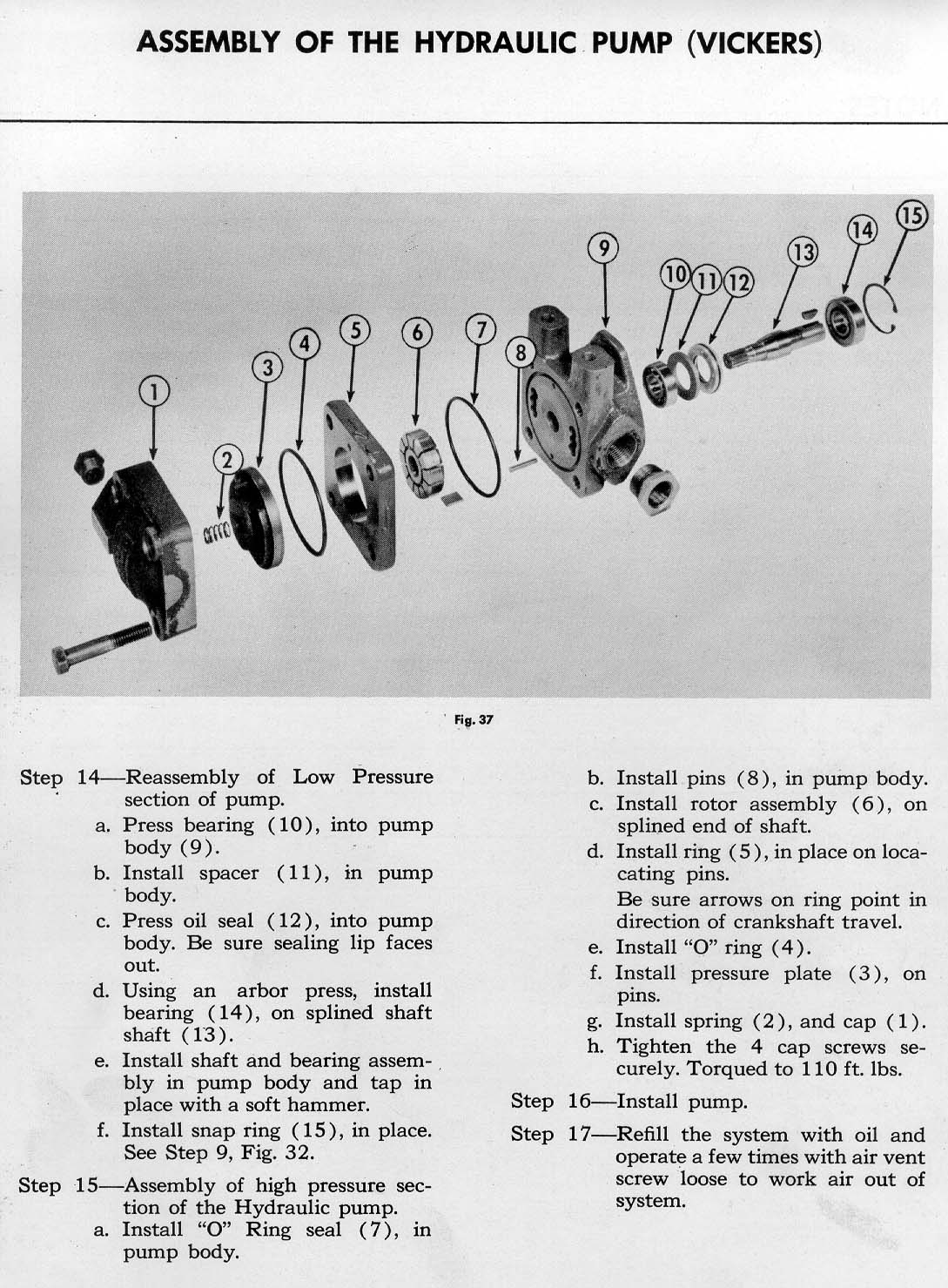

4.Install gasket (2) in place in the face of compensator body (11). Cover the compensator body with clean Kraft pa- per and set aside for final assembly of the pump.

19.Remove retaining ring (44) then press shaft seal (45) from pump housing (27).If yoke (56) and front shaft bearing (61) were not defective, perform the following step.

a. Install a nine inch piece of 1 1/2” heavy wall tubing over drive shaft (48) within the housing. The end of the tub- ing will rest against the inner race of tapered roller bearing (61) and extend out beyond the end of the pump housing. Place the complete unit with tubing into an arbor press with drive spline up. Press the drive shaft through the bearing and out of the unit. A 0.001 press exists between the shaft and bearing so considerable force is required to remove the bearing. See Figure 17 (PVE19/21).

c. Press drive shaft (48) into shaft bearing (61) as follows: Use a short piece of 1 1/2” inch heavy wall tubing (approximately 6” long) over the drive spline of the shaft. The tubing must be long enough to go through the shaft seal end of the pump and make contact with the inner race of the front bearing. Press the shaft through the bearing with an arbor press until the bearing bottoms against the shoulder of the shaft (snap ring on the PVE12). See Figure 18.

d. Place spherical washer (41) on top of the three pins, then install shoe plate (42) with nine piston and shoe subassemblies (43) over spherical washer (41) and into cylin- der block. Wobble shoe plate (42) to make sure that each piston is free within its bore in the cylinder block.e. Set housing (27) on its side and hold pump shaft (48) horizontal. Slide rotating group into the housing. Rotate the shaft to match the shaft splines to the cylinder block and spherical washer.

5.Inspect valve block (26) for burrs, nicks, plugged body passages, flatness of the pump wafer plate area and porosity. Inspect check valve seat (64). Make sure the seat is tight with- in the valve block and does not protrude above the valve block face. Repair or replace the valve block if defective.

Lubricate all moving parts of the piston pump with system fluid to facilitate assembly and provide initial lubrication. Pour system fluid liberally over the rotat- ing group and wafer plate as these parts are without lubrication until the pump primes.

This article will provide you with tips and tricks when it comes to finding gaskets, seals and other quality components for your vickers vane pump repair manual.

tags: {vickers hydraulic pump repair manual,vickers hydraulic pump repair,vickers piston pump repair,3 stage vickers hydraulic pump repair georgia,vickers hydraulic pump repair parts,vickers hydraulic pump repair manual v201p6p1c11,vickers hydraulic pvb 10 pump repair manual,vickers hydraulic pvm pump repair manual,simplicity vickers pump repair parts,vickers pump repair santa ana,repair parts gpc vickers pump,how-to repair vickers hydraulic pump repair manual,vickers vane pump repair,3 stage vickers hydraulic pump repair

We offer a full line of piston pump replacement parts including Ball Guides, Bearings, Block Springs & Disc Springs, Cylinder Blocks & Valve Plates, Housings & Casings, Pilot Pumps, Piston Sets, Seal Kits, Set Plates, Shoe Plates, Shafts and Swash Plate Assemblies.

We stock an extensive inventory of replacement vane pump parts including shafts, rotors, vanes, seals & bearings. This includes pumps from manufacturers such as: Vickers® and Denison®.

We stock OEM spec new aftermarket replacement hydraulic parts for Hitachi HPV102, HPV116 and HPV145 hydraulic pumps. These pumps are typically found on many of today"s mobile construction equipment machines.

We stock an extensive inventory of aftermarket replacement pump parts for Komatsu® HPV Series units. These units include PC200-3/220-3, PC200-5/220-5, PC200-6/220-6, PC200-7/220-7, PC300-3/400-3, PC300-5/400-5, PC300-6/400-6 and PC300-7.

We regularly stock parts for the HPR, HPV, BPR, and BPV Series. Including parts like: Ball Guides, Bearings, Block Springs & Disc Springs, Cylinder Blocks & Valve Plates, Housings & Casings, Pilot Pumps, Piston Sets, Seal Kits, Set Plates, Shoe Plates, Shafts and Swash Plate Assemblies.

Our Rexroth inventory consists of parts like Ball Guides, Bearings, Block Springs & Disc Springs, Cylinder Blocks & Valve Plates, Housings & Casings, Pilot Pumps, Piston Sets, Seal Kits, Set Plates, Shoe Plates, Shafts and Swash Plate Assemblies.

eaton aerospace hydraulic pump eaton axial piston pump pdf eaton hydraulic motor breakdown eaton hydraulic motor catalogue pdf eaton hydraulic motor char-lynn eaton hydraulic motor for brush cutter eaton hydraulic motor for sale eaton hydraulic motor manual eaton hydraulic motor near me eaton hydraulic motor numbers eaton hydraulic motor pdf eaton hydraulic motor price eaton hydraulic motor rebuild eaton hydraulic motor rebuild kit eaton hydraulic motor repair eaton hydraulic motor repair manual eaton hydraulic motor seal kit eaton hydraulic motor seal replacement eaton hydraulic motor service manual eaton hydraulic motor shaft seal replacement eaton hydraulic motor specifications eaton hydraulic motor specs eaton hydraulic motor speed sensor eaton hydraulic motor with brake eaton hydraulic orbit motor eaton hydraulic parts catalog eaton hydraulic piston pump eaton hydraulic pump eaton hydraulic pump 26001-rzg eaton hydraulic pump 26004-rzc eaton hydraulic pump 26007-rzc eaton hydraulic pump 70423-rbt eaton hydraulic pump 72400-rmp-04 eaton hydraulic pump dealers eaton hydraulic pump dealers near me eaton hydraulic pump distributors in india eaton hydraulic pump manua eaton hydraulic pump motor eaton hydraulic pump parts eaton hydraulic pump pdf eaton hydraulic pump pressure adjustment eaton hydraulic pump pvq32-b2r eaton hydraulic pump qatar eaton hydraulic pump rebuild kit eaton hydraulic pump repair eaton hydraulic pump repair near me eaton hydraulic pump seal kit eaton hydraulic pump uae eaton hydraulic pump uk eaton hydraulic pump yuken eaton hydraulic pump zf eaton hydraulic pumps and motors eaton hydraulic pumps canada eaton hydraulic pumps edmonton eaton hydraulic pumps for sale eaton hydraulic steering pump eaton hydraulic vane pump eaton hydraulic winch motor eaton hydraulics pump singapore eaton hydrostatic hydraulic pump eaton load sensing hydraulic pump eaton make hydraulic pump eaton piston pump distributors eaton piston pump pdf eaton pto hydraulic pump eaton tandem hydraulic pump eaton variable displacement hydraulic pump eaton vickers hydraulic pump

Of the three primary hydraulic pump types — gear, vane, and piston — vane pumps offer flexibility in application, long life, quiet performance, and lower maintenance costs. Whether it’s time for repair or replacement, understanding old Vickers vane pump identification can save time and expense.

Originally developed nearly a century ago, the vane pump is a positive displacement device that uses centrifugal force on rotating vanes combined with under-vane pressure from the outlet port to cause the vanes to follow the elliptical inner surface of the cam ring.

Vane pumps also benefit from the ease of service. At Panagon Systems, we have found that most can be restored to a like-new performance by replacing just the vane cartridge kit without having to remove the unit from the application.

Once we finish the old Vickers vane pump identification, we can determine how best to service the equipment. For V10 and V20 models, the rotation of the pump can easily be reversed by opening the cover, removing the pressure plate and spring and flipping the cam ring. We can also assess other performance issues that may be present.

As tribute to their durability, we have found that many early model pumps are still in service. Although sometimes we must examine a unit closely to find the model code, once Vickers vane pump identification is completed, we can learn everything needed for pump repair or replacement and evaluate if that model is still the right choice for the job.

In general, with old Vickers vane pump identification, the V10 and V20 series are indicated at the second and third positions of the model code. Look for F3 code in the first position because it indicates the use of special O-rings or seals. However, an F3 code in the first position may be omitted if not required on that pump. In that case, the pump model should appear in the first position.

The second and third positions of the model code also designate the double pumps in the V2010 and V2020 series, with the same caveat for an F3 code in the first position. After that, the fourth position indicates the cover type, the fifth is the mounting type, and the sixth the mounting position of the foot bracket.

Further old Vickers vane pump identification reveals that with the V10 and V20 series, the seventh position indicates the rated ring capacity while on the V2010 and V2020, the seventh position designates a four-bolt flange at the inlet port. Also note that the eighth position on the V10 designates the size and thread type for outlet port connections, while the eighth position on the V20 model code indicates shaft type.

For mobile applications, look for a VTM and model number in the first and second positions. High-speed, high-pressure pumps are indicated by VQ after the model number.

Similar to earlier V10 and V20 models, the V series pumps are designated with the model number before the letter. On single pump models, higher numbers generally indicate greater displacement.

The Vickers V series double pumps, from 2520V through 4535V, and the thru-drive pump series, 25VT through 45VT, are selected for use in tight spaces or when a reduction in the number of motors and drive extensions is required.

Vickers vane pump identification also reveals the latest line-up from Eaton Vickers. The VMQ-series single and thru-drive pumps are designated VMQ1, double pumps are VMQ2 and triple pumps are VMQ3.

8613371530291

8613371530291