vickers hydraulic pump repair manual made in china

vickers vane pump repair manual pdf comes to you after months of searching and searching for the best possible place to get this book. In this website, many questions about this author and their products are answered so that you can be sure to find what you are looking for. Let’s share this page in social networks such as Facebook, Twitter and Reddit.

After removing the pump from the system and before disassembly, cap or plug all ports and disconnected hydraulic lines. Clean the outside of the unit thoroughly to prevent entry of dirt into the system.

Absolute cleanliness is essential when working on a hydraulic system. Always work in a clean area. The presence of dirt and foreign materials in the system can result in serious damage or inadequate operation. Periodic maintenance of the pump will generally not require disassembly to the extent described here.

Troubleshooting is one of the best virtues to acquire if you are an industrial pump repair technician. All in all, troubleshooting is a process. Firstly, you have to define the problem, gather information, and analyze data that will help you solve the problem, implement the solution and check if it worked for you or not. This form collects vickers vane pump problems, symptoms, and solutions!

4.Install gasket (2) in place in the face of compensator body (11). Cover the compensator body with clean Kraft pa- per and set aside for final assembly of the pump.

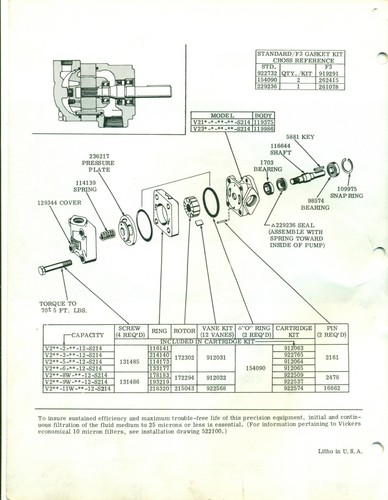

19.Remove retaining ring (44) then press shaft seal (45) from pump housing (27).If yoke (56) and front shaft bearing (61) were not defective, perform the following step.

a. Install a nine inch piece of 1 1/2” heavy wall tubing over drive shaft (48) within the housing. The end of the tub- ing will rest against the inner race of tapered roller bearing (61) and extend out beyond the end of the pump housing. Place the complete unit with tubing into an arbor press with drive spline up. Press the drive shaft through the bearing and out of the unit. A 0.001 press exists between the shaft and bearing so considerable force is required to remove the bearing. See Figure 17 (PVE19/21).

c. Press drive shaft (48) into shaft bearing (61) as follows: Use a short piece of 1 1/2” inch heavy wall tubing (approximately 6” long) over the drive spline of the shaft. The tubing must be long enough to go through the shaft seal end of the pump and make contact with the inner race of the front bearing. Press the shaft through the bearing with an arbor press until the bearing bottoms against the shoulder of the shaft (snap ring on the PVE12). See Figure 18.

d. Place spherical washer (41) on top of the three pins, then install shoe plate (42) with nine piston and shoe subassemblies (43) over spherical washer (41) and into cylin- der block. Wobble shoe plate (42) to make sure that each piston is free within its bore in the cylinder block.e. Set housing (27) on its side and hold pump shaft (48) horizontal. Slide rotating group into the housing. Rotate the shaft to match the shaft splines to the cylinder block and spherical washer.

5.Inspect valve block (26) for burrs, nicks, plugged body passages, flatness of the pump wafer plate area and porosity. Inspect check valve seat (64). Make sure the seat is tight with- in the valve block and does not protrude above the valve block face. Repair or replace the valve block if defective.

Lubricate all moving parts of the piston pump with system fluid to facilitate assembly and provide initial lubrication. Pour system fluid liberally over the rotat- ing group and wafer plate as these parts are without lubrication until the pump primes.

This article will provide you with tips and tricks when it comes to finding gaskets, seals and other quality components for your vickers vane pump repair manual.

tags: {vickers hydraulic pump repair manual,vickers hydraulic pump repair,vickers piston pump repair,3 stage vickers hydraulic pump repair georgia,vickers hydraulic pump repair parts,vickers hydraulic pump repair manual v201p6p1c11,vickers hydraulic pvb 10 pump repair manual,vickers hydraulic pvm pump repair manual,simplicity vickers pump repair parts,vickers pump repair santa ana,repair parts gpc vickers pump,how-to repair vickers hydraulic pump repair manual,vickers vane pump repair,3 stage vickers hydraulic pump repair

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Vickers Hydraulic Pump Repair Manual, Hydraulic Ram Pump Youtube, Hydraulic Pump Parker, Discount Hydraulic Pump for Die-casting machinery,Vickers Hydraulic Vane Pump Catalogue. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you! The product will supply to all over the world, such as Europe, America, Australia,Pakistan, Cyprus,South Africa, Romania.Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Hydraulic pumps are vital to the role of heavy equipment such as excavators, tractors, forklifts and cranes. The hydraulic pump converts mechanical energy into hydraulic energy through the movement of the fluid in the conveying pipeline, thereby driving the equipment to work. It can determine the effectiveness of these devices on the job site. If the hydraulic pump fails or runs below an acceptable level, it needs to be repaired immediately to avoid sudden equipment shutdowns and greater losses.

Elephant Fluid Power provides repair parts for tractor hydraulic pump overhaul, excavator hydraulic pump repair, forklift hydraulic pump repair, etc. It also provides hydraulic pump repair kits for many heavy equipment manufacturers, hydraulic brands and hydraulic product distributors, such as John Deere hydraulic pump repair, rv hydraulic pump repair, enerpac hydraulic pump repair, HITACHI hydraulic pump repair, KAWASAKI hydraulic pump repair, UCHIDA hydraulic pump repair, MITSUBISHI hydraulic pump repair, CAT hydraulic pump repair, Komatsu hydraulic pump repair, NACHI hydraulic pump repair, NABTESCO hydraulic pump repair, KAYABA hydraulic pump repair, LIEBHERR hydraulic pump repair, DOOSAN hydraulic pump repair, DAIKIN hydraulic pump repair, SAUER hydraulic pump repair, SUNDUSTRAND hydraulic pump repair, SHIBAURA hydraulic pump repair, TEIJIN SEIKI hydraulic pump repair, VOLVO hydraulic pump repair, JCB hydraulic pump repair, LINDE hydraulic pump repair, HYDROMATIC hydraulic pump repair, EATON hydraulic pump repair, REXROTH hydraulic pump repair and other major brand repairs

The cost of downtime is high. The delivery of new equipment may take weeks or months. The lead time for repair parts provided by Elephant Fluid Power is 3-7 days.

The wide-range fixed and variable displacements of Eaton PVX & PFX Series piston pumps make them ideal for use with primary metal power units, test stands, mixer drives and more. They come in a robust housing enclosure and are available with displacements from 66 cc to 250 cc (4.03 to 15.26 cu in) at operating pressures up to 350 bar (5,075 psi) for broader application.

HEASH TECHNICAL B.V. specialised in the sale of Eaton pumps and motors across their entire range. We supply Eaton Vickers PVXS and PFXS all sizes, as PVXS066, PVXS090, PVXS130, PVXS180, PVXS250, PFXS066, PFXS090, PFXS130, PFXS180, PFXS250. for other Eaton Vicksers pumps as PVH, PVM, PVQ and valves as KBHDG, KDG4V, KFDG, KBDG, KSDG..., please don’t hesitate to contract with us if u have any interested in our sale.

We support many major brands, such as: Bosch/Rexroth, Parker, Vickers (Eaton), Atos & Hydac. Our massive inventory of new product supports a rapid response to customer needs. Most orders ship the same day and we have the capability to convert & test product prior to shipping. Our support staff has the most qualified personnel in the marketplace with over 300 combined years of experience.

8613371530291

8613371530291