voith hydraulic pump distributors factory

For hydraulic systems that place high demands on control engineering, servo pumps are the perfect solution. The basic version of these pump systems also consists of three main components:Servo inverter

Servo pumps control the pressure or the volume flow. They precisely convert electrical energy into the hydraulic energy that is currently needed in the system. The classic use of valves for control can be either completely or partially omitted. This considerably simplifies every hydraulic system.

Voith traces its North American manufacturing lineage back to 1877, when Stephen Morgan Smith began designing and producing hydraulic turbines. Today, Voith has manufacturing locations throughout North America and the US, offering a range of state-of-the-art services and products for a variety of businesses and industries.

Backed by a global network of engineering expertise, Voith’s product and service portfolio serves US customers in five key markets: Energy, Oil & Gas, Paper, Raw Materials, and Transport & Automotive.

Voith pumps offer high volumetric efficiency and provide the ideal solution for variable speed drives while offering overall efficiency improvements through reducing machine or system power consumption.

The range of internal gear pumps comprises: IPS, IPVA, IPVAP, IPCA, IPCAP, IPC, IPVS, IPH and IPV series. They are well-suited for any application in the low, medium, and high-pressure range. The pumps are available as: single pumps, pump combinations (multi-flow pumps, multi-circuit pumps), motor pump units, variable speed pumps and servo pumps.

Please contact us for further technical details and configuration options or if you cannot see the Voith hydraulic pumps that you need listed – we’ll be delighted to help!

Voith Turbo H + L Hydraulic (VTHL) is a world-class manufacturer of innovative components and systems of fluid-technical drive and control engineering. Voith systems are characterized by:

Energy-saving – through internal gear pumps with high efficiencies, low and high-pressure systems with automatic change-over and accumulator charging technology

Voith Turbo hydraulicThe use of liquids to transmit force and energy. pumps / internal gear pumps - IPH, IPV, IPC and IPN - also as double pumps, multiple pumps or add-on pumps:

Are you looking for a dual flow or multiple flow pump, or a single internal gear pump by Voith? No problem, contact us and our team will help you as quickly as possible!

Zuosen Hydraulic is one of the world"s leading manufacturers and suppliers of professional hydraulic piston pumps, hydraulic vane pumps, gear pumps, hydraulic valves, and accessories. The Factories are located in the Chinese leading manufacturing center- Foshan and Dongguan city.ZUOSEN owned advanced and precision machines and equipment, like Emag gear hobbing machine, Mitsubishi gear hobbing machine, Liebherr gear shaping machine, Horizontal machining center DMG MORI, CNC grinding machine, NC honing machine, CNC lathe, etc. Zuosen also owned the precision measuring equipment, like the three coordinates measuring instrument, Gear measuring center, Rockwell hardness tester, the noise test room, Pressure &Flow & Temperature test platform, Surface Roughness & Dynamic Balance Tester leakage detecting tools, etc. Now Zuosen has a hundred long-term distributors and partners worldwide.

Voith Turbo H + L Hydraulic is a subsidiary of Voith Turbo. Voith Turbo, a Group Division of Voith GmbH, is a specialist for intelligent drive solutions and systems. Customers from highly diverse industries such as oil and gas, energy, mining and metal processing, mechanical engineering, ship technology, rail and commercial vehicles rely on advanced technologies from Voith Turbo.

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transportation & automotive. Founded in 1867, Voith employs almost 39 000 people, generates EUR 5.3 billion in sales, operates in about 50 countries around the world and is today one of the largest family-owned companies in Europe.

Voith Turbo H+L Hydraulic (VTHL) is a manufacturer of innovative components and systems of fluid-technical drive and control engineering, taking a leading position world-wide.

Energy-saving - through internal gear pumps with high efficiencies, low and high-pressure systems with automatic change-over and accumulator charging technology.

FLSPL using Nachi hydraulic components since years, now has a technical partnership for the use of Nachi hydraulic components in the application design. FLSPL committed to the performance guarantee and extending service.

NACHI Hydraulic is a division of NACHI-FUJIKOSHI CORP, JAPAN, is a comprehensive manufacturer of a full range of hydraulic equipment, Nachi-Fujikoshi manufactures, markets, and provides a wide range of other services for a full lineup of outstanding hydraulic products.

Nachi-Fujikoshi reputation for compact equipment that delivers energy efficiency, safety, and high performance. The equipment is also constantly refined by the quest for ultimate hydraulics that combine great power with flexible motion control.

Sophisticated manufacturing processes and the competence of developing high performance conventional hydraulic valves along with the economical feasibility, puts them apart from the competitors in the segment

SUN Hydraulics, designs and manufactures high-performance, screw-in hydraulic cartridge valves and manifolds which control force, speed and motion as integral components.

FLSPL bring you Sun Hydraulics" products providing superior value due to their high-quality, high-performance characteristics. Sun Hydraulics" cartridge valves are differentiated by their two-piece, floating style construction, which allows them to operate reliably at higher pressures and flow rates than competitive products of equal size. These products provide our designers the opportunity to develop unique, reliable solutions for hydraulic control applications.

FLSPL brings in another technically strong company that manufacturing high quality external gear pumps and flow dividers. It is been since years now, FLSPL extending the support and service for these high quality products.

Vivoil Oleodinamica Vivolo, have been producing high quality, high performance hydraulic gear pumps, hydraulic gear motors and geared flow dividers since 1985. The company applies innovative solutions to hydraulic system requirements.

Flow dividers allowing a single pump flow to be "split" into a varying number of separate flows is a significant proportion of Vivoils" production. Their accrued expertise in this field means that they have the technical ability to offer solutions to many circuit applications.

Using their precision gear pump technology, allows Vivoil to produce an extensive range of flow dividers, with or without “phase correction “ integral valves”. Equal or un-equal displacements, up to 16 sections, can be combined to offer many solutions for applications requiring flow to be divided to operate different parts of the hydraulic circuit.

Alibaba.com offers 104 voith hydraulic pump products. such as construction works , energy & mining, and manufacturing plant. You can also choose from 1 year. As well as from provided. And whether voith hydraulic pump is united states, south korea, or mexico.

Alibaba.com offers 192 voith products. such as euro 3. You can also choose from machinery repair shops, construction works , and energy & mining. As well as from 1 year, 6 months, and 3 months. And whether voith is provided.

We"re well-known as one of the leading voith manufacturers in China. If you"re going to wholesale voith in stock, welcome to get quotation from our factory. All customized products are with high quality and low price. A2FE160 pump, Piston Pump For Mixer, danfoss piston pump

Voith internal gear pumps are especially well-suited for any application in the low, medium, and high-pressure range. The pumps are available assingle pumps,

Voith internal gear pumps feature very low pressure pulsation – usually up to 50% less than other comparable internal gear pumps. This considerably improves the controllability of the pump. It also reduces noise emissions by up to 6 dB(A).

Decades of design improvement have resulted in high volumetric efficiency. At rated speed, the volumetric efficiency of our pumps is often 5 to 10% better than other pumps on the market. This makes Voith internal gear pumps the ideal solution for variable speed drives. And that improves your overall efficiency while reducing machine or system power consumption.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.I UNDERSTAND ADVANCEHYDRAULICWORKS Products

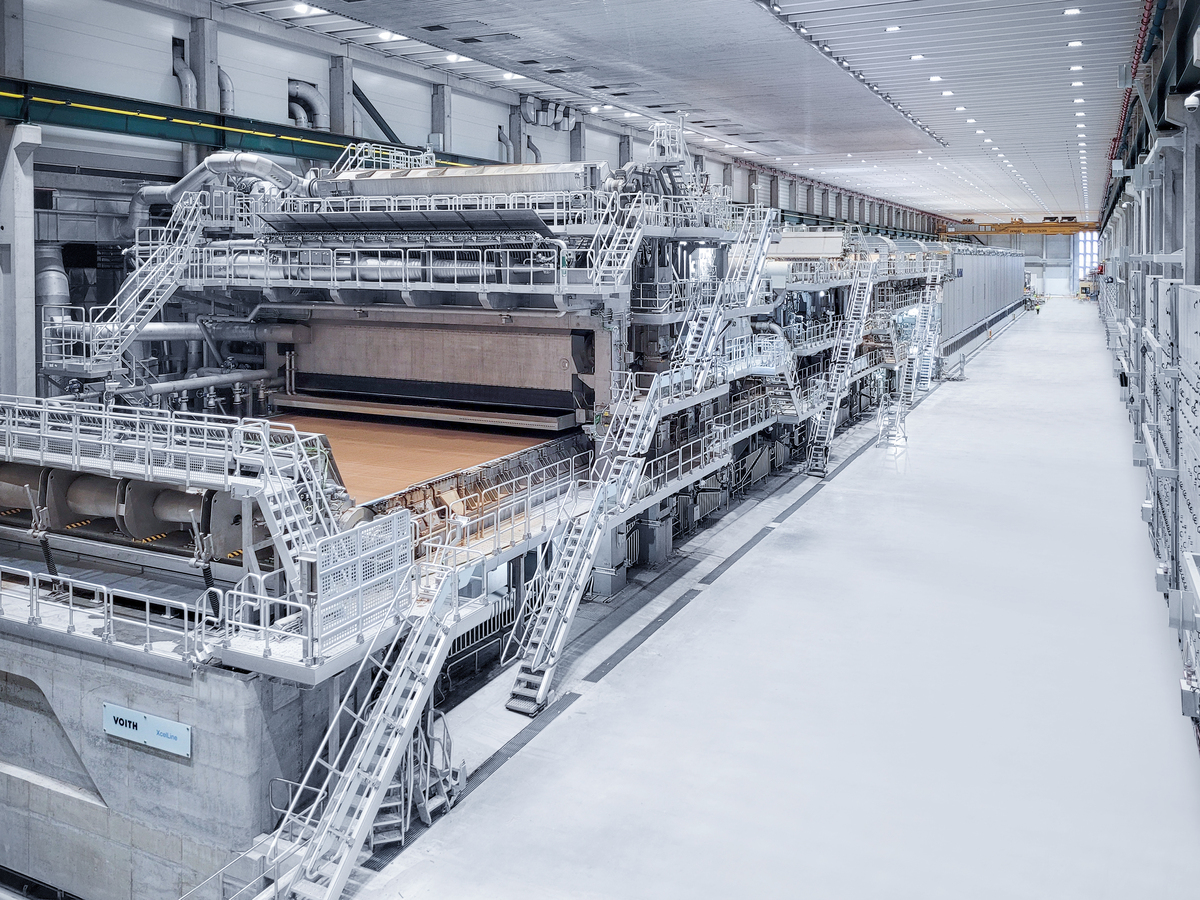

Products: gearboxes and related equipment; variable drives (fluid couplings, torque converters, planetary gears); starting turbo couplings, vane propellers, propellers; gear pumps; SafeSet torque limiting clutches; cardan shafts; paper machines; hydraulic turbines; generators. Applications of products: automotive industry; chemical and petrochemical industry; food processing, beverage and cigarette manufacturing; marine technology; mechanical engineering; mining; Oil and gas industry; steel industry; paper production; railway vehicles; wind power plants.

The Voith Group pulp and paper industry, technical equipment for hydropower plants and drive and braking systems. The family-owned company, which operates worldwide and has its headquarters in Heidenheim an der Brenz, was founded in 1867.

In 1825, Johann Matthäus Voith took over his father"s locksmith"s workshop in Heidenheim with five employees, mainly carrying out repairs to water wheels and paper mills.

Around 1830 in Heidenheim, there were about 600 people working in 15 factories, mostly textile factories that had been established by wealthy merchants and publishers. The necessary maintenance and repair of the expensive machinery offered a source of income to several workshops, particularly the locksmiths and metalworkers in what was still a small town at the time. In 1830, Johann Matthäus Voith and his workshop were involved in the construction of a paper machine developed by Johann Jakob Widmann from Heilbronn.

Voith developed the first wood grinders based on the patented design of Friedrich Gottlob Keller. In doing so, he laid the cornerstone for the industrial enterprise Voith. As the company got bigger and bigger, so too did the private wealth of its owners. According to town council records dated September 28, 1849, the assets of Johann Matthäus Voith in 1849 amounted to more than 7,000 fl., and eight years later grew to an estimated 15,000 fl. In 1850 , Johann Matthäus Voith was summoned to serve on the town council, and in 1855, along with nine other Heidenheim entrepreneurs, he received a grant to attend the international exhibition in Paris.

After 1850, the company, which had specialized in repairs like other Heidenheim-based metal workshops, began to replicate various machines imported from England. The workshop produced whatever the customers ordered. The transition from a small metalworking shop to a machine factory was completed when contracts were signed for the fabrication of machines for paper manufacturer Heinrich Voelter. Since 1856, these machines had consisted of mechanical wood grinders (based on a patent originally sold in 1846 by Friedrich Gottlob Keller to Voelter"s father that Friedrich Voith improved upon and re-registered himself in 1868). From 1861, the machines were wood pulp refiners for crushing coarse wood chips. The result of this development was that the company started to specialize in machines for paper and pulp production. In 1863, a new metalworking shop was added and fitted with one of the few steam engines in Heidenheim. Until the development of cast steel, the machines were built from cast iron. It was difficult to transport cast iron, so the company built its own foundry. No figures have been preserved on the company"s sales and profits at the time, but the physical expansion of the company is taken as proof of its good economic performance.bark mill, where he set up the first research center for the production of wood pulp.

After Voelter"s paper mill was destroyed by a fire in 1864, Voith received its first major order for the fabrication of eight hollander beaters, which required building another machine hall. The company"s name was changed from Mechanicus Voith to Mechanische Werkstätte und Eisengießerei (Mechanical Workshops and Foundry).

The official founding date of the company J. M. Voith is January 1, 1867. At this point, the company employed around 35 people. On January 1, 1867, the only son of 63-year-old Johann Matthäus Voith, the 26-year-old Friedrich Voith, took over the business as the sole owner. Under his leadership, his father"s workshop became a larger company and specialized in paper machines and the construction of water wheels and turbines. In 1869, Voith was granted the first patent for a wood grinder with a toothed loading rack. On November 18, 1869, the company applied for official registration in the Commercial Register and changed its name to Maschinenfabrik und Eisengießerei von J. M. Voith in Heidenheim.

Voith added another business segment to its existing product lines of paper machines and stock preparation technology – with the construction of a 100-HP Henschel-Jonval turbine. The sources available provide differing information on the relevant figures.

At the 1873 World Exhibition in Vienna, Friedrich Voith and Heinrich Voelter exhibited the Voith wood grinder and received the "Progress Medal" for their development.

In 1881, Voith fabricated the first complete Voith paper machine PM1, with a wire width of 2.35 m, for Raithelhuber, Bezner & Cie. in Gemmrigheim. The first administration building was built in 1886. This was followed by a staff canteen in 1887 and another large assembly hall in 1889 that enlarged the factory grounds from 5,090 m2 to 9,590 m2. In 1896, a new machine hall was established for turbine construction. This was the first building to be located on the right bank of the River Brenz.

In 1890, Voith began to supply high-pressure Pelton turbines (also known as impulse-type turbines). In the same year, Friedrich Voith was appointed by Karl I., the King of Württemberg, to his Council of Commercial Advisor.Wilhem II., the last King of Württemberg, visited the private home of Friedrich Voith. At the time, Voith"s mechanical engineering factory was the second largest company in Heidenheim. The king visited a total of four companies in Heidenheim.Kingdom of Württemberg.

Starting in 1893, J. M. Voith began building Pelton turbines. For Friedrich Voith, the fabrication of the impulse-type turbines was further progress from both an economic and technical perspective. He regarded contact with the research and development community as essential. In 1903, Voith received an order to build the largest turbines in the world: 12 Francis turbines each with 12,000 HP for power plants at Niagara Falls in the US and Canada.

Friedrich"s eldest son had been managing the factory in Austria since 1904, and the second-eldest, Hermann, joined the management in 1906. The practical knowledge that had been applied so far was now increasingly being displaced by theoretical knowledge acquired through scientific education. For example, in 1907, Voith built a research and testing center for turbines in Hermaringen and another in Brunnenmühle in 1908. In the same year, the first hydraulic R&D center, Brunnenmühle in Heidenheim, started operating. Alongside the R&D center, Voith built Germany"s first pumped storage hydropower plant.3. The turbine tests were carried out just 100 m below in the Brunnenmühle (water mill) in the Brenz valley.

The increase in the number of Voith employees is a major reason why by 1908 there were already 800 trade union members in Heidenheim. Formerly there was said to be a good relationship between workers and factory owners in Heidenheim. This changed following the establishment of the German Metal Workers Union. That the conflicts at Voith began to accumulate before World War I is held to have been due to the management practices of the company rather than – as often claimed – because of the metalworkers" union official Sebastian Geiger.

In 1910, a building was constructed to accommodate a modelmaking hall and a fettling shop, and in 1911, a new foundry was built. That same year, Voith built at its plant in St. Pölten in Austria what was at the time the fastest and widest paper machine for newsprint paper. In 1912, Friedrich converted the company to a general partnership and transferred most of his shares to his two sons. Walther managed the St. Pölten plant, Hermann took charge of the commercial side of the Heidenheim headquarters, and Hanns was responsible for the technical department.

The papers from the estate of Friedrich Voith include the financial statement at the end of the fiscal year 1912/1913. On July 1, 1913, the total assets of J. M. Voith in Heidenheim were around 15.9 million marks, and those of J. M. Voith in St.. Pölten around 4.4. million kronen or 3.8. million marks. The liabilities from loans were around 7.2. million marks in Heidenheim and around 2.4. million marks in St. Pölten. The deposits of the general and silent partners in Heidenheim combined totaled 7.3. million marks. As the company got bigger and bigger, so too did the private wealth of its owners. According to municipal council records dated September 28, 1849, the assets of Johann Matthäus Voith in 1849 amounted to more than 7,000 florins, and eight years later this was already estimated to be 15,000 florins. In 1909, in his capacity as a natural person, Friedrich Voith declared a private income of 913,405 marks and paid 5% of this in taxes, namely 45,670 marks.

After World War I the brothers decided on a strategic expansion of the company and got the drive technology segment operating. In 1922 , Voith started building gear transmissions where its long-standing expertise in fluid dynamics acquired in previous turbine projects provided an advantage. The breakthrough came with the help of Hermann Föttinger and his research into hydrodynamic energy transfers. In the same year, the first Kaplan turbine, named after its inventor Viktor Kaplan, left the Voith factory.

In 1927, the Viennese engineer Ernst Schneider and the Voith company in Sankt Pölten applied jointly for a patent for the Voith Schneider propeller, which had been developed the year before based on the former"s plans. This marine propulsion system, which also acts as a steering device, allows maneuverability previously impossible. Schneider"s design was further developed and improved at Voith.

In 1929, Voith developed the first hydrodynamic couplings based on the Föttinger principle. These were used Koepchenwerk, a pumped storage hydropower plant in Herdecke. This was followed by new drive systems for rolling stock and road vehicles. The company also made a name for itself with hydrodynamic transmissions and couplings for industrial applications.

Following the successful sea trials of the experimental vessel "Torqueo," which was equipped with a Voith Schneider Propeller for the first time, Voith Schneider Propellers were first used in Italy in 1937 for passenger transport in the narrow canals of Venice. At the World Fair in Paris in 1937, Voith won the "Grand Prix" three times for its exhibits of Voith Schneider Propellers and Voith turbo gear units. A year later in Paris, two fireboats fitted with VSPs went into operation on the Seine.

World War II, began in 1939 and deprived Voith of the basis for its business. The export business halted. Total output was drastically reduced. The construction of paper machines in particular was decimated. 600 of the company"s 4,000 employee died or went missing during the war.

Following the death of Hermann Voith, Hanns Voith assumed the overall management of the Voith factory in Heidenheim in 1942. On April 24, 1945, the U.S. army occupied Heidenheim and issued an ultimatum that the town needed to be surrendered within an hour. As the deputy mayor could not be found, Hanns Voith personally arranged the peaceful handover of the town to American troops.

Its triple-converter transmissions for long-distance railcars and DIWA bus transmissions put Voith at the forefront of technical development in 1952.newsprint for Feldmühle AG. With a speed of 600 m/min, it achieved a production capacity of 200 tons per day.

In the 1960s, Voith became an internationally operating group and became a pioneer in paper recycling. The company worked with the Palm and Haindl paper mills to develop a new flotation deinking process to produce paper stock from recovered paper.

In 1962, the company supplied two spiral turbines, four storage pumps and two pump turbines for what was then the largest European pumped storage power plant in Vianden. To expand the drive technology segment, an increase in production capacities was necessary. In 1963, the company"s plant in Garching near Munich began producing automatic transmissions for buses.São Paulo in Brazil.

In the 1970s, Voith developed the Zentrimatic clutch and the Voith retarder for buses and trucks. In 1974, Voith established a company in Appleton, Wisconsin and in the same year acquired a majority stake in Morden Machines in Portland, Oregon. Two years later, Voith founded its first subsidiary in Japan. After the death of Hanns Voith, Hugo Rupf became chairman of the management board in 1971, and from 1973, he led the company as Chairman of the Supervisory.

Voith entered the paper machine clothing market with its acquisition of Appleton Mills in 1983. In addition, in 1986 Voith took over the hydro operations of U.S. market leader Allis-Chalmers in York, Pennsylvania.Hyderabad, India.

In the early 1990s, different views among the family led to the splitting of the company"s assets. The Hermann Voith side of the family withdrew, receiving a large proportion of the financial investments and the machine tool part of the business,

At Voith, the focus shifted to expansion in the Far East, especially in China. In 1994, Voith supplied turbines for the world"s largest pumped storage hydropower plant Guangzhou II. Two years later, Voith supplied the largest fine paper machine in the world to Gold East Paper in Dagang District. New production facilities were opened in Kunshan and Liaoyang in 1996. Under the leadership of Michael Rogowski, who became spokesman for the management board in 1986, the principle of control from corporate headquarters was replaced by a management holding structure with independent corporate divisions.

Other milestones were the introduction of the R 115 integration retarder in 1988 and the commissioning of Europe"s largest Deinking facility in Schongau, Germany in 1989. In 1994, Voith and Swiss company Sulzer merged their technical papermaking operations to create Voith-Sulzer Papertec. This also included the paper activities of the Krefeld-based company Kleinewefers Group, which Sulzer had only acquired in 1992. In 1998, Voith acquired a majority stake in this enterprise. In 1999, Voith acquired the technical papermaking operations of British company Scapa, making it one of the leading companies for paper machine clothing technology. The year 2000 saw the creation of Voith Siemens Hydro Power Generation, a joint venture of the two leading manufacturers of turbine and generator technology. At the helm of the company, Michael Rogowski transferred operational responsibility to Hermut Kormann in 2000. Under his leadership, the group grew to become a global player with orders totaling €4 billion and a workforce of 34,000 people.

At the end of 2001, via the Voith Paper Holding, Voith took over Jagenberg"s Jagenberg Papiertechnik in Neuss with its product lines including winders, cross-cutters and paper coating machines, as well as its manufacturing subsidiary Jagenberg Maschinenbau and overseas subsidiaries Jagenberg Inc. in Enfield, CT, USA, and Basagoitia in Tolosa, Spain.Voith Austria Holding AG. As German Property it had been integrated into the USIA (Administration for Soviet Property in Austria) by Soviet troops in 1945. Following the Austrian State Treaty in 1955 the company was an Austrian state-owned enterprise before Voith was able to recover its shares again over the years.

Voith went from strength to strength in the field of technical industrial services. With a controlling stake in the Stuttgart-based DIW Deutsche Industriewartung, the foundations were laid for the Voith Industrial Services division. This division grew over the following years and further acquisitions were made, e.g., the Imo-Hüther Group and Hörmann Industrietechnik. At the end of May 2005, Voith Industrial Services strengthened its leading position in the market for technical services and acquired the U.S. Premier Group.Kössler, which was based in St. Georgen.

In May 2006, the Voith Paper Technology Technology Center opened in Heidenheim. In Scotland the Voith subsidiary Wavegen operated the world"s first wave power plant, to feed electricity to a grid. The research activities in Inverness, Scotland, were discontinued in 2013.

In 2008, Voith gathered with 200 customers and partners from all over the world to celebrate the 100-year anniversary of the "Brunnenmühle" in Heidenheim, which had previously been upgraded at an investment cost of €20 million.

At the Shipbuilding, Machinery & Marine Technology trade fair in 2010, Voith Turbo and one of its rivals each presented for the first time a rim-driven thruster for ships. Over an 18-month construction period, the world"s most powerful single-engine diesel-hydraulic locomotive – the Voith Maxima – was developed. Since 2010, a large number of Voith Gravita shunting locomotives have been in operation at Deutsche Bahn (German Railways). In the same year, Voith celebrated the official opening of its new production and service center for the paper industry in Asia at Voith Paper CityKunshan, China.

Also in 2010, the world"s first wave power plant went into commercial operation in Mutriku on the Basque coast. For this plant, Voith supplied Spanish energy utility Ente Vasco de la Energia (EVE) with the equipment for the 16 Wells turbine units, which have a total output of 300 kilowatts and produce enough power for 250 households. The "oscillating water column" technology used in Mutriku means that the turbines do not come into contact with water. Instead, a column of air is set in motion that drives the machines.

Following the successful completion and in-depth analysis of the one-year test run in a model power plant near the South Korean island of Jindo Voith systematically continued its tidal current program with the construction of a one-megawatt machine on a 1:1 scale and developed the innovative low-maintenance tidal current turbine technology at the European Marine Energy Centre (EMEC) in Scotland to a commercial scale. Voith built a test turbine at its Heidenheim facility that was installed off the Scottish Orkney island of Eday from 2013 to 2015.

In 2013, the most powerful generator-turbine unit in Voith"s history went into operation at the Chinese hydropower plant Xiluodu on the River Jinsha. After a 72-hour test run, Voith handed over the first of three of these machines to the China Three Gorges Corporation. At 784 megawatts, the generator-turbine unit generates more power than the largest hydropower plants in the world. Upon completion, the total output of the three Voith units for Xiluodu will be roughly equivalent to the most powerful nuclear power plant in Germany Gundremmingen.

April 2014 saw the official opening of the Voith China Training Center. The vocational training and further education center in Kunshan (around 80 km northwest of Shanghai) is the company"s largest training center outside of Germany. In the same year, Voith also celebrated the official opening of a new training center in Heidenheim, which every year provides training in 10 skilled commercial and technical occupations.

In February 2015, it was announced that Voith in Germany and Austria would cut 800 jobs in the paper machine segment and close the Voith Paper plants in Krefeld, Neuwied and St. Pölten.Leadec, while the process and power plant industry segment became known as Veltec.

On August 1, 2017, Voith GmbH changed its name and legal status to Voith GmbH & Co. KGaA. With more than 260 workforce and family parties taking place at over 160 locations, the year 2017 was all about celebrating the company"s 150th anniversary.

Voith is represented in around 60 countries and maintains a worldwide network of sales, service, production, R&D and administrative locations. Even in its early years, the company was focused on developing global business relationships. As early as 1903, Voith had supplied turbines for a hydropower plant on the American side of Niagara Falls and for the first Chinese hydropower plant Shi Long Ba.

Voith is engaged in projects in the education, social welfare, sporting and cultural spheres. Its corporate responsibility commitments range from financial support for relief projects and sponsorships to corporate-volunteering activities. These are realized through Voith GmbH & Co. KGaA – in some cases in collaboration with charitable organizations and also through the foundation Hanns Voith Stiftung Fundação Voith set up in Brazil in 2004.

With its portfolio of production plants, products and industrial services, Voith serves five key markets: energy, oil & gas, paper, raw materials, and transport & automotive.

Voith GmbH & Co. KGaA, which is headquartered in Heidenheim an der Brenz, is the operational management holding company for the Group. The Board of Management of Voith GmbH & Co. KGaA is responsible for the strategic management and operations of the Group. The Shareholders" Committee and Supervisory Board act as advisory and supervisory bodies, respectively. The latter is also the monitoring authority with respect to the Management Board.

Voith"s operations are organized into three corporate divisions: Voith Hydro, Voith Paper and Voith Turbo. The business operations of the subsidiaries of the corporate divisions are each managed by legally independent management companies. In addition, Voith had a 9.14% stake in SGL Carbon in Wiesbaden, and between December 2014 and July 2016, had a 25.1% share in KUKA beteiligt. Voith"s stake in SGL Carbon was reduced to just under 3% by December 2016.

Voith Hydro is a full-line supplier of equipment for hydropower plants of all sizes. Its range of products and services includes generators, turbines and pumps; measuring and control equipment and instrumentation; automation; hydropower plant upgrades; and services like maintenance and spare parts.

Around a quarter of the energy generated by hydropower comes from plants operating with Voith technology.Niagara (1903), Macagua (1959 - 1963) in Venezuelam, here install 6 Francis Turbine, Itaipú (1976) and the Three Gorges Dam (2003). The construction of the Belo Monte Dam in the Brazilian part of the Amazon Basin, in which Voith Hydro is also involved, began in January 2012.2 of (mostly forested) land and displace 20,000 people.

Voith Paper is a system supplier for the international paper industry that covers the entire paper manufacturing process. Most paper production worldwide is done on Voith Paper machines.

Voith Turbo is a supplier of mechanical, hydrodynamic, electrical, hydraulic and electronic drive and braking systems. Voith Turbo is the market leader worldwidehydrodynamic transmissions.

For industries including steel, mining and metalworking: Fluid couplings, hydraulic systems and components, Hirth serrations, high-performance cardan shafts, safety couplings and highly flexible couplings

In fiscal 2021/2022, Voith invested a total €213 million in boosting productivity and the strategic alignment of the Voith Group. In the reporting period (2021/2022), the investment ratio as a proportion of revenue was 4,4% of the consolidated revenue (4,5% in previous year). Of the total R&D expenditure, €5 million was capitalized. At the same time, amortization of €9 million was recognized on capitalized development costs.

Voith"s research and development activities have an international focus. The main R&D center is in Germany, but centers in America, Asia and the rest of Europe conduct specialized R&D projects in the respective Group Divisions. For example, the Tissue Innovation Center, which was established in São Paulo in 1994, was reopened in November 2011 following a major rebuild.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. (= Schriftenreihe zur Zeitschrift für Unternehmensgeschichte 9), Beck, München 2003, ISBN 3-406-49630-X.

Hermann Schweickert: Der Wasserturbinenbau bei Voith zwischen 1913 und 1939 und die Geschichte der Eingliederung neuer Strömungsmaschinen. Dissertation der Universität Stuttgart, Siedentop, Heidenheim 2002, ISBN 978-3-925887-19-2.

Voith GmbH: Mit guten Ideen voran – seit 1867: Die Voith Geschichte. Unternehmensbroschüre, Heidenheim, Januar 2013 / 2016 als PDF-Datei; 76 S., 1,7 MB oder auf docplayer.org.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 26, Anm. 11., Ausschnitte in Google Bücher.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 25–27.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 25.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 26 Anm. 11.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 30. Eine andere Quelle spricht fürs Jahr 1867 von 25 Arbeitern. Siehe dazu S. 56 Anm. 11.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 32–33.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 26–30.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 29–30.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 33.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 28, Anm. 20

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 32, Anm. 41.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 32, Anm. 40.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 57.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 34.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 35.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 30–32.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 32.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 33–34.

Zu Walther Voith siehe Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 62.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co. C. H. Beck, München 2003, S. 28, Anm. 20.

Friedrich Voith: Die Turbinen Versuchsstationen und die Wasserkraft Zentralen mit hydraulischer Akkumulierungsanlage der Firma J.M.Voith in Heidenheim a.d.Brenz., Springer, 1909, Ausschnitte in Google Bücher.

Anne Nieberding: Unternehmenskultur im Kaiserreich. Die Gießerei J. M. Voith und die Farbenfabriken vorm. Friedr. Bayer & Co., Beck, München 2003, S. 29–30, Ausschnitte in Google Bücher.

8613371530291

8613371530291