webster k series hydraulic pump quotation

Quality, Long-life, Performance are words often used to describe the Webster Hydraulic Pump brand. The brand has changed hands over the years and limited products are still be produced by other OEMs and manufacturers. Hydraulic.net is your source for Webster KB series pumps.

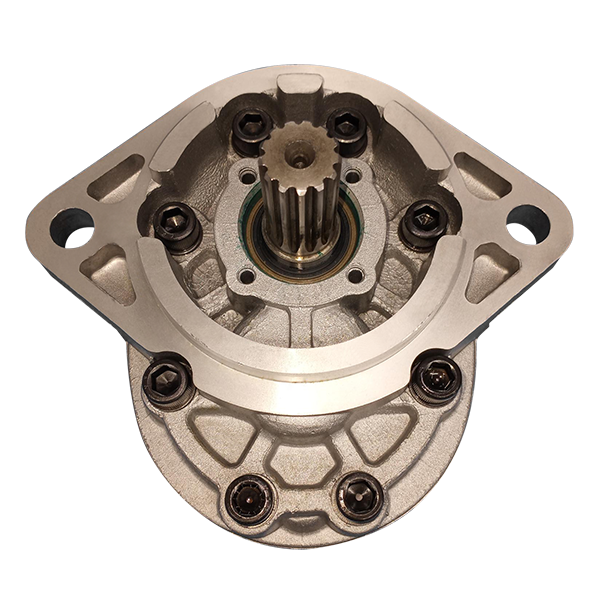

KB series gear pumps were designed to be versatile and adaptable to a broad range of applications. There are seven basic displacements ranging from .032 to 4.74, featuring heat-treated alloy steel shafts and gears, high-density gray iron gear plates, double lip seals, and heavy-duty needle bearings for long life and top mechanical efficiency. Straight-keyed shafts are standard on all models with splined shafts optional.

The above table includes some of the KB series product numbers. If you don’t see your product number listed or perhaps you have the serial number, no problem! Our hydraulic experts can help. Give us a call at (800) 765-5670 between 8:30 AM to 5:00 PM EST or submit a quote request. We will cross-reference your numbers in our system and confirm. Our goal is to get you an answer as quickly as possible. Our inventory is everchanging as we try to keep stock on the pumps and parts our clients need. In many cases, we are able to ship your pump in 24 to 48 hours.

Hydraulic.net prides itself in delivering accurate, reliable, quality pumps to our customers. For over 30 years we have served OEMs, distributors, repair shops, and end-users. When you have a hydraulic gear pump that needs to be replaced we can help. Our expertise with the Webster is strong, we have been supplying the market with Webster pumps from the beginning and although many models are no longer in production we have the knowledge and ability to build to order to the original specifications. Hydraulic.net is your source for hard to find pumps. Our facility is in North East Florida. We build the pumps here in-house and test prior to shipping.

The page you are looking for is no longer here, or never existed in the first place (bummer). You can try searching for what you are looking for using the form below. If that still doesn"t provide the results you are looking for, you can always start over from the home page.

The page you are looking for is no longer here, or never existed in the first place (bummer). You can try searching for what you are looking for using the form below. If that still doesn"t provide the results you are looking for, you can always start over from the home page.

You must — there are over 200,000 words in our free online dictionary, but you are looking for one that’s only in the Merriam-Webster Unabridged Dictionary.

Webster K-Series Gear Pump. 15/16" (24 mm). HI up for sale is this Webster K-Series Gear Pump. Despite being used, This Hydraulic Motor Does not appear to have sustained any significant damage and is still in great condition to be used once again. If you have any questions please feel free to email me. Thanks for looking! OPENINGS: 1-1/4" (34 mm) 15/16" (24 mm)

Condition: Used, Condition: VISIBLE, BUT SLIGHT, WEAR FROM PRIOR USE, HOWEVER THE MOTOR HAS NOT SUSTAINED ANY SIGNIFICANT DAMAGE *SEE PICS*, Hydraulic Pump Type: Hydraulic Gear Pump, Bundle Listing: No, Equipment Type: Pump, Brand: Webster, Type: Hydraulic

I found this on the Surplus Center website, https://www.surpluscenter.com/. I thought you might be interested in seeing it for yourself. Please click on the following link to view the page:

The Pump/Motor is warranted for a period of one year from the date of installation. If during the warranty period the Pump/Motor fails to operate to Muncie’s specifications due to a defect in any part in material or workmanship that existed at the time of sale by Muncie, the defective part will be repaired or replaced, at Muncie’s election, at no charge, if the defective part is returned to Muncie with transportation prepaid.

WARNING. The above warranty shall terminate if any alterations or repairs are made to the Pump/Motor other than at a Service Center owned by Muncie, or if the Pump/Motor is used on any equipment other than the equipment upon which it is first installed.

Webster/Webtec manufactures hydraulic flow controls, pressure control valves and directional control valves for mobile machinery. We offer choices of threading and port size for standard or custom specifications. We offer replacements for Webster gear pumps, Milwaukee cylinders, and Teledyne valves.

The ILFC is a pressure compensated flow control valve (fixed, in-line) with 2 ports. Can be used to maintain the flow rate of hydraulic fluid for operating cylinders and motors at a constant speed.

Fixed priority flow dividers allow you to split a single input flow into a regulated flow and an excess flow. The regulated (Priority) flow can be used to perform the required task while the excess flow which can be routed directly back to the oil reservoir or redirected to drive another system, which can eliminate the need for an additional pump to drive an ancillary system. This is a 3-port flow divider which is pressure compensated and contains an on-board relief valve.

Priority Type Flow Dividers split a single input flow into a Priority flow which is a regulated flow, and a bypass flow, which is excess flow. The excess bypass flow can can be rerouted to the hydraulic fluid reservoir or used to power a second system, which can eliminate the need for a second pump to drive another hydraulic circuit. Easy adjustments to the priority flow can be made visually using a hand dial. Pressure compensation allows both flows (priority and bypass) to be controlled concurrently at their own pressures without changing the flow rate of the priority flow.

A hand dial on this manually-controlled flow divider allows visual adjustments to pre-determined regulated flow to meet pressure requirements. Pressure compensation in the model 2FV2V allows both the regulated flow and bypass (excess) flow to be controlled with a check valve, including an anti-cavitation check valve, which can be routed between the priority and bypass flows. This flow divider is available in a version that can be controlled remotely.

Driven by a 12 VDC (12 - 16 VDC) allows adjustment to the valve from a distant position such as in a heavy machine cab or a remote control panel. Pressure compensation allows both flows to be used at the same time at different pressures without affecting the priority (regulated) rate of flow. Blocking the bypass port while using a relief valve on the inlet line allows you to use the model 2FV2V as a unidirectional two port in line flow control.

A great choice for agricultural and industrial uses, as this remote control flow divider is vibration and contamination resistant and can be powered from a vehicle supply using the on-board 9 - 28 V D.C. supply. Current draw is automatically limited to avoid overheating or motor overload. Model FDM offers a low-cost method of controlling the speed of a hydraulic motor. The regulated (priority) flow port gives an output free of affect by load pressure while the bypass port can be directed to power a secondary hydraulic circuit. Remote control use from up to 130 feet is possible using a potentiometer.

These cast iron and steel Flow Divider-Combiners divide a primary flow into two separate flows which are pressure compensated to maintain the same ratio irregardless of pressure differences between the lines. Return line flows are also held in the same ratio. Lack of aluminum in the construction makes them a good choice for mining and other high-endurance applications.

As an alternative to using a directional control valve, a diverter valve is adequate when there is no need for a neutral position. Flows can be quickly switched between two lines, allowing fast switches from one system to another, or from a system to the reservoir, creating an idling circuit. Flow may be directed two ways: mechanically pushing the spool with spring offset or mechanical push pull operation with an adjustment knob.

Allows the flow to be diverted mechanically by an offset spring pushing the spool. The spool and spring are contained in a sealed housing to prevent environmental corrosion. Available in one spool or two spool versions. The 2-spool version allows you to divert flow from one circuit to another or to a hydraulic fluid reservoir. A wide variety of spool ends and port threading are available.

A rotary spool type directional control valve which contains a rotor that rotates relative to body of the valve. Inlet and outlet ports can be connected in many different flow patterns to control pressurized fluid for start, stop or directional changes. Webster’s flat rotors compensate for valve wear, creating near zero-leak through the life of the valve. Available with 7 different flow patterns, 3 flow ratings and several porting options. These valves may be mounted on a manifold, on a panel or used inline on the hydraulic circuit. Manual control is achieved using ball handles, spring centring and detents.

Durable hydraulic directional control valve used for mobile and industrial systems. Minimal leakage in the spool even under the 3625 psi pressure tank port rating. Methods of operation include lever, cam and pilot (air or oil).

Pressure relief valves protect hydraulic circuits from overload by limiting maximum pressure to a pre-set capacity. The relief pressure setting is set by Webster to the customers specifications within pressures from 290 psi to 3000psi. The fast response of this valve protects the hydraulic circuit from shock and overload or the expansion of thermal fluids. Due to straight-through porting, the valve can be connected inline using a “T” connector. Model RV020 direct acting in-line relief valve is minimally affected by particle contamination

Casappa Kappa K series gear pumps and motors are made of cast iron in two pieces, and are available as: Kappa, Kappa Compact or Kappa 40 Plus for heavy duty applications

8613371530291

8613371530291