what causes hydraulic pump failure supplier

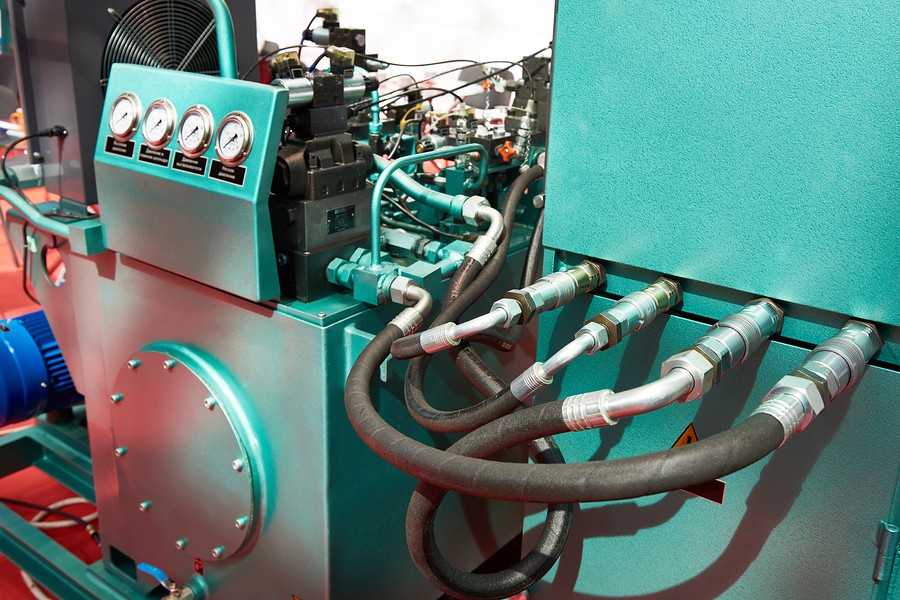

When a hydraulic system fails, finding the source of the problem can be a challenge. Though hydraulic systems primarily consist of a sump, motor, pump, valves, actuators and hydraulic fluid, any of these parts could be the source of failure. That"s not to mention the additional potential for failure through human error and faulty maintenance practices. If your system fails, you need to know why it fails, how to find the failure and how to keep it running smoothly in the future, all while keeping personnel safe.

It"s often easy to tell when a hydraulic system fails — symptoms can include high temperatures, low pressure readings and slow or erratic operation are glaring problems. But what are the most common causes of hydraulic systems failures? We can trace most hydraulic issues back to a few common causes, listed below.

Air and water contamination are the leading causes of hydraulic failure, accounting for 80 to 90% of hydraulic failures. Faulty pumps, system breaches or temperature issues often cause both types of contamination.

Air contamination is the entrance of air into a hydraulic system and consists of two types — aeration and cavitation. Both can cause severe damage to the hydraulic system over time by wearing down the pump and surrounding components, contaminating hydraulic fluids and even overheating the system. Although we are not pump manufacturers, we know it is essential to be aware of these types of contamination and how to identify their symptoms.

Cavitation:Hydraulic oil consists of about 9% dissolved air, which the pump can pull out and implode, causing pump problems and damage to the pump and to other components in a hydraulic system over time. You can identify this problem if your hydraulic pump is making a whining noise.

Aeration:Aeration occurs when air enters the pump cavity from an outside source. Usually, loose connections or leaks in the system cause this issue. Aeration also creates a sound when the pump is running, which sounds like knocking.

Water contamination is also a common problem in hydraulic systems, often caused by system leaks or condensation due to temperature changes. Water can degrade hydraulic components over time through oxidation and freeze damage. A milky appearance in hydraulic fluid can help you identify water contamination.

Fluid oxidization: Extreme heat can cause hydraulic fluid to oxidize and thicken. This fluid thickening can cause buildups in the system that restrict flow, but can also further reduce the ability of the system to dissipate heat.

Fluid thickening:Low temperatures increase the viscosity of hydraulic oil, making it harder for the oil to reach the pump. Putting systems under load before the oil reaches 70 degrees or more can damage the system through cavitation.

Fluid levels and quality can affect hydraulic system performance. Low fluid levels and inappropriate filtration can result in air contamination, while fluid contamination can cause temperature problems. Leaks can further exacerbate both issues.

Using the correct type of fluid is also essential, as certain hydraulic oils are compatible with specific applications. There are even oil options that offer higher resistance to temperature-related problems. Some oils even offer anti-wear and anti-foam additives to help prevent against wear and air contamination, respectively.

Human error is the base cause of many hydraulic system problems. Some of the most common errors that may result in your hydraulic pump not building pressure include the following.

Faulty installations: Improper installation of any component in a hydraulic system can result in severe errors. For example, the pump shaft may be rotating in the wrong direction, negatively affecting pressure buildup, or pipes may be incorrectly fitted, resulting in leaks.

Incompatible parts: An inexperienced installer may put mismatched components together, resulting in functional failures. For example, a pump may have a motor that runs beyond its maximum drive speed.

Improper maintenance or usage:Using systems outside their operational capabilities or failing to perform regular maintenance are some of the most common causes of hydraulic system damage, but are easy to rectify through updated maintenance policies and training.

The sources of system failures can be tricky to identify, but some hydraulic troubleshooting steps can help narrow down the options. So how do you troubleshoot a hydraulic system? Here are some of the fundamentals.

Check the pump: Take the pump assembly apart and assess all parts to ensure that they are functional and installed correctly. The most common problem areas include the pump shaft, coupling and filter.

Check the fluids:Check the level, color and viscosity of the hydraulic oil to ensure it meets specifications and has not become contaminated. Low hydraulic fluid symptoms include pressure or power loss. When in doubt, drain and replace the fluids.

Check the seals: Look for evidence of any fluid leakage around your hydraulic system"s seals, especially the shaft seal. Leakage can indicate worn-out or blown seals that can cause malfunctions with pumps, motors and control valves.

Check the filters: Ensure filters are clear of plugs and blockages. Common clogged hydraulic filter symptoms include sluggish operation and noisy operation.

Run the system: When you have completed all these essential checks, turn on the system and monitor it for pressure and temperature fluctuations, as well as abnormal sounds. If all seems well, check your pressure sensor for potential failure.

Hydraulic system issues are inevitable at some point. However, simple steps can help you avoid these issues and increase the longevity of your hydraulic system. On top of effective troubleshooting, you can prevent hydraulic system failure by taking the following steps.

Follow specifications: We can trace the most common hydraulic system issues back to fundamental system problems like incompatible or improperly installed parts. For this reason, it"s essential to always double-check specifications to ensure your purchased parts can work together seamlessly.

Consult with professionals: When purchasing new equipment, consult with industry peers and professionals to discover what they recommend. While manufacturers can tell you how a product should work, industry professionals can provide concrete examples of how well the equipment works for their industry.

On top of these steps, look into hydraulic system products that are specifically designed to help prevent failures. One such product is Bear-Loc® by York Precision. This innovative locking actuator is a safe, reliable feature for hydraulic components, automatically locking when sleeve pressure is relieved, preventing movement if a hydraulic system fails. This way, your can protect your personnel from injuries related to hydraulic failures. Even better, York Precision offers in-house design, engineering expertise and machining and manufacturing capabilities to produce a hydraulic locking device that meets your exact specifications.

Regularly review hydraulic system maintenance, always following manufacturer recommendations and industry best practices. Also, consider the storage condition, external influences, working pressure and usage frequency of your system to tailor your maintenance schedule and procedures.

Daily tasks:Take care of a few simple daily checks to avoid issues. For example, personnel should check the oil levels, hoses and connections and listen to the pump for abnormal sounds.

Routine tasks:Plan and execute a weekly and monthly maintenance routine, checking for the most common failure sources given your system"s working conditions. These should include components, filters and the condition of the oil.

Be mindful of location:Do not stand at endpoints while working on hydraulic systems. This safety measure can help prevent loss of limb and life, as there is a lot of pressure built up in these areas that can release and result in life-threatening situations.

The best safety measures, however, are to perform excellent maintenance and use high-quality parts. If you"re looking for a quality hydraulic component manufacturer, York Precision Machining & Hydraulics can help.

Hydraulic pumps are at the core of many essential factory operations. Unfortunately, there are numerous pitfalls to plan for, mitigate, and overcome to keep them running. Keeping up on routine maintenance is important, but the best way factory techs can avail themselves of costly, frustrating breakdowns is to understand the various catalysts for hydraulic pump failure.

The simplest way to identify the cause of pump failure is to thoroughly inspect and dissect the aftermath of the problem. In most cases, the cause of failure will be evident by the nature of the catalyst(s). Here are eight of the most common problems, some of their defining features, and how they ultimately come to fruition.

1. Fluid contamination is one of the biggest causes of hydraulic pump damage and involves debris mixing with the liquid. This debris causes friction, leading to extenuated wear on the pump itself. The result is inefficiency, culminating in malfunction.

2. Fluid viscosity issues occur when the hydraulic fluid within a pump breaks down over time. Viscosity that’s too high leads to cavitation (another catalyst for damage). Subsequently, if a tech changes and replaces fluid with a viscosity that’s too low, heat and friction become concerns.

3. Over-pressurization occurs because of excessive load on the pump itself, resulting in red-line operation that’s both unsafe and damaging. Hydraulic pumps operating under high duress for extended periods of time will likely experience component wear and premature failure, usually in spectacular fashion.

4. Excess heat can be a product of poor fluid viscosity or environmental factors. This issue is rarely a singular catalyst for pump breakdown, but it exacerbates other factors or masks other issues, such as fluid contamination.

5. Implosion invariably results in extreme failure for hydraulic pumps and is a major safety hazard. Implosion occurs when air bubbles within a hydraulic pump collapse, causing an overload of pressure to the pump that generates an intense shock.

6. Aeration occurs when hydraulic fluid traps air bubbles. The pump subjects the bubbles to pressure, causing high heat and over-pressurization when the bubbles collapse. Aeration at extreme levels leads to implosion.

7. Pump aeration pertains to air not in the hydraulic fluid, but air introduced through unsealed joints or shafts. This air quickly causes pressure instability affecting crucial parts of the pump. This can quickly lead to breakdowns — generally marked by a whine or other high-pitched sound.

8. Cavitation is a symptom of uncontrolled pump speeds, which fail to allow hydraulic fluid to completely fill the pump. It results in destabilized pressure, heat, and excess wear. Cavitation is often marked by the same type of whine or squeal as pump aeration.

Because the factors causing each of these problems differ in nature, it’s best to fully evaluate a damaged hydraulic pump to determine if more than one issue is responsible.

Maintenance is the best approach for ensuring safe, efficient hydraulic pump function. But routine service is just the start. Identifying common issues plaguing your hydraulic pumps will lead to a better quality of targeted maintenance — for example, if you pinpoint a heat issue related to viscosity, that issue may be resolved by opting for a different fluid weight.

Every piece of information learned about your pumps can translate into better care, leading to longer uptimes, fewer issues, and fundamentally better maintenance.

Having trouble identifying the catalysts for your hydraulic pump’s issues? Let the professionals at Global Electronic Services take a look! Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!

In many factories, the hydraulic pump is the heart of the operation — and hydraulic pump failure can cause huge problems. But why do hydraulic pumps break? In order to avoid hydraulic pump failure, it’s helpful to know what some hydraulic pump failure causes are.

Before getting into the reasons hydraulic pumps break, it’s important to know the signs that your hydraulic pump is broken or in danger of breaking. Some of these signs include:

Noisy System:All mechanical systems make some noise, and hydraulic systems are no exception. But if you are hearing very loud banging or knocking, there’s a good chance that your system is experiencing aeration or cavitation, which could lead to pump failure.

High Temperature:If your hydraulic system is exceeding the recommended temperature level of 82 degrees Celsius, this could be due to a buildup of debris in the filters preventing the system from dissipating heat. This is a problem you will want to address quickly, as high heat can damage your system.

Slow System:If your system isn’t operating as quickly as it’s supposed to, you definitely have a problem. A slow hydraulic system means a loss of flow, which typically means internal leakage.

The major cause of hydraulic pump failure is called fluid contamination. This is an invasion of the hydraulic fluid by foreign materials. Hydraulic pumps and valves are only designed to carry hydraulic fluid, and anything else in them will damage the system, especially since this foreign debris may remain in the system and continue to damage the valves and pipes.

Aeration:Air in the hydraulic fluid can create problems when put under pressure by the pump. When this happens, they can implode and dislodge debris, causing contamination and raising the temperature inside the pump.

Cavitation:Cavitation is a situation where the hydraulic fluid doesn’t fully take up the space in the pump because of unusually high fluid viscosity, an intake line that is too long or an overfast pump, among other reasons. It can lead to problems similar as aeration.

Excessive Heat:An overheated hydraulic system can cause some massive problems for your hydraulic system. It can damage seals, degrade the hydraulic fluid and otherwise compromise the system.

Overpressurization:Hydraulic pump systems are very sensitive and should only operate under specific conditions, including precise pressure levels. Exceeding recommended pressure levels puts undue pressure and wear on the system and can cause it to fail more quickly.

The best way to avoid hydraulic system failure is to keep your system clean. Remember: fluid contamination is the main precursor to hydraulic system failure, so keeping those contaminants out of your system is your best chance to maintain healthy hydraulics. This means high-quality filters in your system that you inspect regularly and change when necessary.

The other major way to keep your hydraulic system up and running is by keeping the components cool. An overheated system can result in real problems, and you may not notice the effects until it is too late. You’ll also want to make sure your system is operating under the right pressure specifications.

A well-maintained hydraulic system can last a long time and be extremely efficient. Although there are many problems that can occur with a hydraulic system, most can be avoided with proper care, and the benefits of having a good hydraulic system for your business can be great — well worth taking good care of your system.

Part of that care is taking quick action when necessary. If you suspect that there is a problem with one or more components of your hydraulic system, the best thing to do is have a professional inspect it and repair any faulty parts that are failing or at risk of failing. The longer you let a hydraulic system problem go without addressing it, the worse the failure will be when it does happen.

Global Electronic Services has factory-trained, certified technicians who are well-versed in hydraulic systems and hydraulic problems. If you’re delaying repairing your hydraulics because you’re afraid of taking them offline, you should know that Global Electronic Services can complete your repair in a matter of days. For more information, call 877-249-1701 or contact Global Electronic Services online.

Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!

Water mixing in with the hydraulic fluid is bad news for the hydraulic pump. When too much water is present in the hydraulic fluid, the internal components may start to corrode.In addition to its corrosion-causing qualities, water is also problematic because it could freeze inside the pump.

The hydraulic fluid present inside the pump can also be problematic even if it doesn’t mix with water.If some small particles fall into the liquid, it’s possible that they could deal damage to the inside of the pump. You must also check if the fluid level is correct or else that could alter the performance of the pump.Lastly, the viscosity of the hydraulic fluid must be just right to keep the pump from sustaining damage. Make it a habit to routinely check the viscosity of the hydraulic pump to see that it has not degraded just yet.

Heat can act as a kind of amplifier of other hydraulic pump-related issues. The heat itself can be a byproduct of other issues affecting the hydraulic pump so be sure to take note of it.

Because hydraulic pumps need the right pressure levels to function, anything that affects it can be disruptive or even damaging. Some of the joints and shafts of hydraulic pumps may spring leaks as they age causing holes to open up. If too much air gets inside the pump via the holes, it may not work as intended.

Cavitation refers to the formation of small vapor-filled bubbles in areas within the pump where the pressure is low. Once those bubbles are exposed to high pressure, they may burst and start to damage the pump.

Your hydraulic pump is the heart of your machine, pumping fluid through your hydraulic system. Pump failures mean downtime and expensive repairs, but the sooner you recognize pump problems developing the easier it is to fix. In this Shop Talk blog post, we are going to discuss, we are going to discuss the most common signs and causes of hydraulic pump failure.

If you notice any of these symptoms, keep in mind that it doesn’t necessarily mean that the pump is going out -- but it means something in your hydraulic system is about to! Check out this video below for an example of what can happen to a Bobcat pump.

Sadly, no pump will last forever because they suffer wear and tear from regular use. Bearings and seals will eventually need to be replaced, and if those replacements are put off then your pump may suffer even worse damage. If you suspect your hydraulic pump needs a tune up, then don’t hesitate to see after it -- it will extend the life of your pump and increase your machine’s overall productivity.

is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to.

When a reliable hydraulic system suddenly starts exhibiting problems, one of the first types of components most technicians assume may need to be replaced are hydraulic pumps, yet the pump should be the last component evaluated since it is often very time-consuming to replace.

There are all sorts of “warning” symptoms a hydraulic system will exhibit long before pump failure. Some of the most common types are changes in the sounds the system makes while it is in operation. If the system suddenly starts sounding different from how it has before, this could indicate various types of problems.

Another thing to check if you notice the system is not working correctly is to verify the pump is turning. Some systems are designed so that you have to manually engage or switch the pump on. You would be surprised by how many system problems are due to the pump not being turned on!

The last thing to check before getting into troubleshooting the pump is the hydraulic fluid level. If the fluid level is too low, it will allow air into the system and cause operational problems. If you discover air in the system, you will need to remove it first to avoid pump failure.

Aeration occurs when air is introduced into the hydraulic system. This can be due to defective seals, through low tank fluid level allowing air into the pump inlet line, damaged inlet hoses and connections. It is easy to check to find out if there is air in the system as the fluid returning to tank will be foamy and the oil in the tank full of bubbles.

Operating the system when air is present may result in the pump being unable to reach the pressures required to operate the system. A by-product of this problem is the generation of excessive heat. Excessive heat is of course another reason in itself for pump failure, in this case secondary to aeration but demonstrates how the primary cause can set off a vicious circle, in this case aeration, leading to excessive heat, leading to lack of lubrication, leading to contamination issues, possible partial or full bearing seizure before complete pump failure.

The opposite of aeration is cavitation. Instead of air being added to the fluid, it is removed very rapidly. Cavitation is where air bubbles form quickly and collapse inward on each other within the fluid. This occurs due to a vacuum at the pump inlet as a result of an insufficient fluid supply. As in excess of 10% by volume of hydraulic fluid is dissolved air when there is an excessive vacuum at the pump inlet it is this air that is being drawn out of the oil.

The effects of cavitation can be seen around the internal pump inlet surfaces as the air is drawn out the oil it causes the removal of tiny amounts of material from the internal pump surfaces on the inlet side. This is always particularly evident in aluminum gear pumps as it leaves a slightly pock marked or frosty looking surfaces on the bearing blocks and inside of the gear housing on the inlet side.

Every hydraulic pump has a maximum design pressure level. If you attempt to operate the pump at a higher pressure than it was designed for, it will cause premature pump failure. The pump simply cannot handle the excessive pressure.

Contaminants are one of the biggest reasons for hydraulic pump replacement. Contaminants can enter into the hydraulic system through a variety of entry points. One of the most common ones is through the hydraulic fluid reservoir.

As contaminant levels grow, they can get stuck in between key surfaces such as between gear end faces and bearing block or pressure plate or between piston barrel and valve plate in a piston pump. This then leads to further wear and the generation of more contaminant and heat. The more contaminant induced wear there is to these surfaces the larger the gap becomes between these critical surfaces leading to loss of pressure capability, overheating and failure.

The viscosity of the hydraulic fluid moving through the system could lead to premature pump failure if it is not properly maintained. Having a fluid of a higher viscosity level than specified for the pump can result in cavitation within the hydraulic pump.

On the other hand, when fluid viscosity is too low, it can lead to excessive leakage between critical surfaces leading to an increase in heat generation. As such, the fluid can become too hot, overheating the entire system, and ultimately causing premature pump failure.

Extreme heat is often caused as a byproduct of other hydraulic system problems. If you notice your system seems to be operating at a higher temperature than it normally does, take it as a warning sign that something is wrong. Continuing to operate the system can lead to more costly repairs.

Excessive heat levels not only cause parts and components to fail but also can damage drive shafts, housings, and other metal components. Additionally, damaged parts and components may not properly seal leading to fluid leaks. Furthermore, inside pumps, misalignment of moving parts could occur, causing internal damages that introduce contaminants into the system.

Many types of hydraulic pump system failures could easily be avoided with regular pump maintenance. Regular maintenance requires checking and inspecting the entire hydraulic system prior to using it. Some of the more common things you should do include:

Another vital part of maintenance is replacing worn out hoses, valves, and related parts and components when they show signs they need to be replaced. It is better to replace hydraulic system parts and components before they fail. Doing so will result in low overall maintenance and repair costs. When replacing components always make certain they are clean of dust and dirt before fitting to avoid unwanted contamination entering the system.

Furthermore, hydraulic fluid should be changed periodically as it starts to slowly break down from extended use. Your objective is to ensure the fluid provides the right viscosity level required for your hydraulic operations. Always flush the system and replace the hydraulic fluid when replacing a pump or motor and be especially vigilant in removing contaminant from every nook and cranny of the system when component failure has been due to contamination damage and the source of contamination has been ascertained.

For further help troubleshooting hydraulic pump system failures, as well as all of your hydraulic system motors, pumps, parts, and component needs, please contact White House Products, Ltd. at +44 (0) 1475 742500 today!

The hydraulic pumps on construction equipment are critical components of the machines and even though they are often designed to work under vigorous and intense conditions, no pump will last forever. Discovering a problematic pump can be complicated as the effects might seem to originate in other connected parts, and, if failures are gradual, the cascading effects of a pump failure can spread throughout a machine.

To help in your diagnosis — and with a small dash of preventive maintenance — we’ve put together this basic, short list of common pump problems and their causes.

Not every hydraulic pump on a machine is simple to inspect, but this Volvo main hydraulic pump on a EC220B-LC excavator sits behind a quick access door so an operator can check it often.

A failing hydraulic pump can be a long and subtle process, a sudden and catastrophic calamity, and all shades in-between, but often a perceptive operator will notice the signs of a pump failure in advance. It might take a few minutes of stopping and inspecting, but knowing what to watch for and taking the time to inspect your hydraulic pumps can often pay off in the long run and lead to fast and simple fixes, instead of prolonged and labor-intensive downtimes.

A hydraulic pump is often secured behind a door or guard or integrated deeply into the body of a machine, but taking the time to inspect the pump for the presence of oil (or oil and dirt clumping) can lead to the early discovery of problems. If the issue is simply a loose connection, a quick tightening can often stop a small issue from growing.

Since a hydraulic pump has both seals to prevent fluid from exiting the pump and also fluid from prematurely entering from one chamber to the next, failing seals can be both internal and external. Spotting an exterior leak is, of course, simpler, but being aware of where seals exist inside the pump can also help you diagnose a failing internal seal.

The most frequently noticed indication of a failing pump is often the start of a new sound coming from the hydraulic pump. An experienced operator will often immediately know and recognize a pump that is indicating issues through sounds, but for many it can be harder to pinpoint.

A problem with a pump can cause it to simply become louder in its operations, develop a whining sound, or even create a knocking sound. The sounds can indicate a number of problems, but often the cause is either cavitation or aeration in the pump.

Over long spans of work and under intense conditions, a hydraulic pump will often heat up, but excessive heating is often a sign of internal issues in the hydraulic pump. Checking a hydraulic pump for excess heat should always be done with safety in mind and with a secure machine and proper protective equipment. Periodically ensuring a hydraulic pump isn’t overheating allows an operator to discover if the pump is under undue strain and on a path to failure.

Overheating in a hydraulic pump can also cause fluid to thin, cause internal components to more rapidly degrade, and introduce dangerous working conditions to the machine. Overheating in a pump is both a sign of current trouble and a cause of other growing problems.

Unexpected and non-fluid movement of parts can be caused by issues with the hydraulic pump, but since the culprit can be a number of other parts in the system, diagnosing pump issues from these movements isn’t always simple. Still, if you do notice non-uniform movements in your machine, taking time to rule out the hydraulic pump is important.

A main hydraulic pump, like this one from a Komatsu PC400LC-6 excavator, comes with a working life and will need to be replaced or rebuilt at some time. This one is fresh from an H&R Recon and Rebuild shop and is headed to a customer.

Knowing some of the common causes of hydraulic pump failures is a proven way of proactively discovering developing issues and correcting them before they become disastrous to the pump and the machine.

The internals of a hydraulic pump are designed to work with fluid that meets exacting specifications. When hydraulic fluid is contaminated it can lead to issues developing in the pump, force the pump to work harder, and cause the pump to work erratically. One common culprit for contamination is water, and it can quickly lead to increased corrosion, changes in viscosity that lead to inefficiencies, and the inability to properly regulate heat in the pump.

Other debris, either introduced from outside or from the degradation of internal elements, can also lead to issues in the pump and signal failing seals or other parts.

A hydraulic pump is often containing a high level of pressure and as this pressure exerts force on seals in the pump, the seals can begin to leak or fail. Even minor leaks in seals can lead to loss of fluid and create issues in the system. Leaks can be both external and internal. For an internal leak, fluid will move from one part of the pump to another in unintended ways and force inefficiencies into the pump as it has to work harder to compensate.

While many hydraulic pumps are built to stand up to tough and continuous working conditions, every hydraulic pump is designed with an upper limit. Every time a hydraulic pump is subjected to overpressuring and overloading beyond what the manufacturer has specified, the pump is more prone to damage.

All hydraulic oil has a defined amount of air dissolved in it, but increases to this amount can lead to inefficiencies in the pump and force the pump to work harder or erratically. An increase in air can also happen inside the pump and create similar problems. Even though the pump and hydraulic system have mechanisms in place to regulate air in the system, if excess air is introduced the system should be returned to a balanced system before prolonged use of the pump.

The hydraulic system on a construction equipment machine is designed to work within defined parameters. Operating a machine with too little oil or too much oil for even the briefest amount of time can cause the pump to overwork, lead to increases in working temperatures, or create conditions for non-uniform movement. The exact type of oil used — matched to the machine and the working environment — can also impact how the hydraulic pump operates.

The operator’s guide of your machine will define the hydraulic oil change schedule and adhering to that schedule can extend the life of your hydraulic pump. When oil is changed, take time to examine the spent oil for signs of debris

Keeping a pump on a hard-working machine looking new every day is nearly impossible, but routinely peeling back dirt, grime, and oil can help catch issues early.

No one wants to take a machine out of work for cleaning, but keeping the machine clean and ensuring pumps are not covered in mud, dirt, or other debris can allow them to be inspected more easily and avoid contamination and overheating.

The hydraulic hoses connected to a hydraulic pump can wear out over time and ensuring they are well-maintained can help you avoid the introduction of debris and even catastrophic issues in the case of sudden failures.

If a hydraulic pump fails on your machine, taking time to ensure you properly diagnose why and how the failure occurred will help you avoid repeating the failure with your replacement pump. Even if the pump failed simply from prolonged use and age, taking time to confirm that can lead to insights about how to extend the life of the next pump.

A hydraulic pump on an excavator, wheel loader, dozer, or articulated truck can be an often ignored component of the machine — until it starts to act up and cause issues. If problems have brought a pump to the forefront of your mind, hopefully, this short guide has helped simplify your pump problem solving.

If you find yourself in need of a replacement hydraulic pump, our Parts Specialists are always here to help. As a supplier of new, used, and rebuilt hydraulic pumps and with our deep inventory of parts, our Parts Specialists can often find the perfect solution to get a customer back up and running quickly. Simplify your search and give them a call.

Don"t see what you are looking for? With access to specialized search tools and our extensive vendor network, our parts specialists are here to search for you and to connect you to your parts, fast and simple.

The look and design of a hydraulic pump is customized to fit the machine and the available space. This main hydraulic pump is freshly reconditioned from a Kobelco SK160LC-VI excavator.

Hydraulic pumps come in a wide range of shapes and sizes. This large Volvo main hydraulic pump requires assistive overhead cranes and forklifts to move around the warehouse.

The pump is the most expensive and critical component in any hydraulic system—it works by first creating a vacuum at the pump inlet, which generates atmospheric pressure. Liquid from the reservoir tank is then propelled through the inlet line to the pump, past a hydraulic filter or strainer, and into the hydraulic system. On a macro-level, the mechanical energy of the pump’s gears is transferred through fluid “flow” and used to power the attached hydraulic machinery.

Although hydraulic systems can be used in many everyday objects, they’re usually best suited for products that require high-power density or systems with changing load requirements. This simple yet elegant design offers exceptional consistency and speed compared to other driving mechanisms. Hydraulic systems are widely used across industries because they are reliable, easy to maintain, long-lasting, and safe. But despite their many advantages, hydraulic systems still require some degree of maintenance. The following guide explains what can make a hydraulic pump fail, as well as tips for extending its useful lifespan as much as possible.

Fluid contamination is the leading cause of pump failure and usually happens when particulates circulate through the system via a breather valve or cylinder rod, or as a result of repairs, welding slag, sealant, or refilling. Once contaminants enter the system, they can degrade parts, create buildup, change the fluid’s physical and chemical properties, corrode equipment, and lower the system’s overall efficiency.

Hydraulic pumps are designed to work within a specific pressure range. If pressures exceed the pump’s rating, it will likely overburden the pump, cause damage, and eventually halt operations completely. If the pressure changes are extreme, it could even cause an explosion.

Joints and shafts must be completely sealed for the hydraulic pump to work properly. If air gets trapped inside the system, bubbles can cause pressure and temperature fluctuations, which eventually will cause the pump to break down. Usually the first sign there’s air in the pump is a high-pitched whine.

Cavitation occurs when the pump speed is inconsistent, creating air bubbles that rapidly form and then collapse. When this happens, the pump won’t completely fill with fluid, which destabilizes pressure in the system and produces the same type of high-pitched squeal as pump aeration. A blocked pipe, clogged filter, or poor system design can all cause cavitation.

Hydraulic systems need high-quality cooling and lubrication oil with the right mineral content and viscosity. Purity is particularly important for high-pressure systems that operate with larger loads.

The best way to prevent hydraulic pump failure is to inspect and maintain your hydraulic system. Hydraulic filters and strainers will help you avoid fluid contamination, which in turn will stabilize the temperature and pressure inside the system. Filters remove particulates that are smaller than 50 microns, and strainers work tangentially to remove contaminants larger than 50 microns. Various options are available for both filters and strainers using different ratings, mesh sizes, and materials.

After they’re installed, filters and strainers need to be routinely checked and cleaned. Operators should familiarize themselves with their hydraulic system to identify any aberrant conditions as soon as possible, if problems should arise. If you maintain your hydraulic system, it will work more efficiently, necessitate fewer repairs, require less downtime, and last as long as possible.

With over 60 years of experience manufacturing high-quality suction filters, suction strainers, gauges, and diffusers for hydraulic systems, the experts at DOMS Incorporated have the expertise to keep your operation in peak condition. We’ve worked closely with organizations from many industries, including construction, forestry, mining, energy development, industrial manufacturing, aircraft equipment manufacturing, plant processing, and more.

Without heat dissipation, fluid temperatures can easily reach and surpass 180°F (82°C), which is detrimental to the hydraulic pump as the hot fluid will damage the seals and cause fluid degradation.

What is worse, the above signs like aeration, cavitation, and internal leaks can significantly increase the heat load within the system, reducing the practical life of the hydraulic fluid. Additionally, as the liquid continues to heat up, the oil film thins, meaning it has a low viscosity. This is detrimental to the pump because it will damage from inadequate lubrication.

Hydraulic pumps can withstand intense working pressure using their sturdy components. However, with time, its components degrade, performance turns sluggish, efficiency decreases, and flow cycle lengthens.

If you notice any of these signs in your hydraulic pump, repair or replace your pump. ContactQuad Fluid Dynamics, Inc., today for hydraulic repair services. We look forward to helping you.

Old or contaminated hydraulic fluid. Bad fluid can cause damage to various hydraulic components, including valves and pumps. Make sure you’re using high-quality hydraulic fluid and implementing filtration methods to keep those fluids in good working order.

Tilley Distribution recommends nothing but the best for your commercial fleets, which is why we’re a top supplier of Mobil™ hydraulic fluids, including:

To ensure your commercial fleet stays up and running, it’s critical to use the best hydraulic fluids and to monitor fluid conditions. Tilley Distribution’s Mobil Serv Lubricant Analysis can reduce hydraulic failures and help keep your operations humming.

When your hydraulic system fails, finding and troubleshooting the problem can be a challenge considering the complexity of hydraulic systems. The sump, motor, valves, pump, fluid, or actuators could be contributing to the failure in some way individually or all at once and an issue with one may have a domino effect on other parts of the machine.

There are four main causes of a hydraulic system failure that can be summed up as air or water contamination, fluid level or quality problems temperature issues, or simple human error. Many of the technical issues that can lead to a hydraulic system failure fall into one of these broad categories.

This is by far the most common source of failure for a hydraulic system, as much as 90% of failures can be sourced to some sort of contamination in the air or water inside the system. This is usually because air enters the system (either by way of cavitation or aeration) which causes damage to the system and eventual breakdown.

This form of failure usually leads to either an air or water contamination, as mentioned above. Low fluid levels can result in poor filtration. The wrong quality of fluid can cause temperature issues. On top of this you have to be on the lookout for leaks. One way to avoid this is to make sure you’re using the right type of fluid for your machine.

Hydraulic systems can overheat or freeze. When the system is too cold fluid can thicken, forcing the pump to work harder to move it through. If the temperature is to warm then the opposite can happen, the fluids thin and lack lubrication and can lead to leaks. Extreme heat can cause the fluid to oxidize and build up in the system as it thickens.

The best way to troubleshoot is to go through all the parts of the machine—motor, pump, valves and lines, and fluid—while the system is running to see if you can pinpoint the source of error, Keep in mind multiple symptoms can lead to different sources of error.

Check the fluid levels and connections daily and always be on the lookout for strange sounds. About once a month, do a deeper check of the system. If you find an issue, contact a hydraulic repair service so they can run systems check.

If your industrial hydraulic equipment has failed or is posing issues, it needs a reliability centered maintenance check. The team of hydraulics experts at Servo Kinetics in Ann Arbor offers the highest quality hydraulic repairs at the lowest possible cost, in the shortest turn around time possible. For more than 45 years our satisfied customers have trusted our process with their critical hydraulic repair needs.

Our services include hydraulic pump and motor repair, field piping, flight simulator repair, reverse engineering services and more. Take advantage of our rapid response hydraulic repair services and Save Big over the cost of new OEM equipment. Questions? Call and speak to a Specialist today!

Whether it"s your construction vehicle or another piece of heavy machinery, the failure of a hydraulic pump can mean the failure of a project. However, before a hydraulic pump fails, it will often give a lot of warning signs first. Don"t ignore these signs of a failing hydraulic pump.

Hydraulic pumps make noise as they operate. You will grow accustomed to whatever noise you hear, which can help when the noises start to change. If you hear unusual noises, you may have a problem. At no time should your hydraulic system create banging or rattling noises.

A major cause of noise is aeration, which is what happens air becomes trapped within the system. Noises can also occur because the pump isn"t getting enough fluid. When there"s a lack of fluid, corrosion can take place which will contaminate the little fluid still in the system.

As that fluid circulates it can cause damage to every part of a hydraulic system. If you"re hearing odd noises from your hydraulic pump, then cease operating your heavy equipment or vehicle. You need to have the pump looked at to determine if you should repair or replace it.

Any leaking of hydraulic fluids should give you some concern. In larger hydraulic equipment, leaking is sometimes considered inevitable. However, when heavy equipment and vehicles show signs of leaking, you should immediately do what you can to mitigate the issue.

A leak that occurs inside or around the pump should prompt you to seek a repair. Equally, if you see signs of leaking outside the vehicle, then you can assume an interior leak has taken a turn for the worse. With a leak, the hydraulic system cannot maintain pressure, which can lead to issues with performance or outright system failure.

Sometimes, the leak doesn"t begin with the pump itself, but rather with a loose seal or a break in a line. Even when this is the case, the leak can lead to poor pump performance. Starting the investigation from the pump can often help to spot an issue with some other hydraulic component.

If your hydraulic system overheats, there"s a good chance a buildup of dirt and debris is causing the issue. Your hydraulic pump will have a hard time dissipating heat if the filters become clogged. The inability to release heat will cause temperatures to rise even higher.

As the heat increases, so does the temperature of the fluid. Hot fluid can weaken seals and degrade a lot faster than it should. Both those outcomes can mean further trouble for your hydraulic pump.

A bad hydraulic pump will lead to poor or sluggish performance. All the aforementioned issues can lead to a hydraulic pump that isn"t performing as it should. Nevertheless, even if you don"t experience any other issues, the drop in performance is a key sign you need to have your hydraulic pump repaired or replaced.

If your equipment depends on a functioning hydraulic system, you must stay diligent about keeping that system healthy. Monitor your hydraulic system and pay attention to any signs that something isn"t working as it should. Routine maintenance of your hydraulic system will help to keep its performance intact while also helping you find potential issues before they become problems.

Often, protecting the viability of your hydraulic pump only requires that you keep up with changing the fluid and replacing smaller components when necessary. You can often save a hydraulic pump with an issue by having it repaired or rebuilt by a professional service.

AtCarolina Hose & Hydraulics, we specialize in high-quality hydraulic components for heavy equipment and vehicles. Contact us for any of your hydraulic pump concerns immediately.

Hydraulic pumps are used in almost every type of production system, from plastic mold injection machines to the common conveyor belt. With proper maintenance, most hydraulic pumps will operate smoothly for years, but even with proper maintenance, the pressure inside these devices will eventually cause failures that need to be addressed as soon as possible. The way to avoid total system failure is by monitoring your pumps and looking for the following warning signs.

Liquids should remain in the tubes that were designed for them. If you notice any liquids anywhere else inside the pump, you have a problem. A line may have a break, or a seal may be loose. No matter what the case, an interior leak means your pump has gone bad.

Have you discovered liquid on the outside of your pump? This means either an interior leak has worsened or there could be a leak on the HPU that the pump is mounted to. This leakage results in reduced pressure in the system and immediate action is required to repair and salvage the pump. Leaking reduces the pressure, which increases the temperature of the system. This affects the viscosity of the oil, reducing the pressure in the system.

Increased fluid temperatures can be the result of the system’s inability to dissipate heat. In most systems, heat within the fluid dissipates through the fluid in the reservoir and a heat exchanger. Heat can cause the fluid to thin, which prevents proper lubrication and may cause pump leaks, reducing pump efficiency and system performance.

Hydraulic fluid that has a milky appearance is a clear indication of water contamination. One source is condensation buildup on the walls of the fluid reservoir as a result of temperature changes from warm days to cool nights. Water contamination can also corrode the pump and other critical components, which can shorten component life. Periodic fluid changes and draining of the water from the reservoir ensure water removal from the system.

If your seals continuously leak and fail, your pump may be operating with a bent or misaligned rod. Depending on the extent of the damage, a skilled machine shop may be able to repair your existing equipment, allowing you to get the most out of your equipment and minimizing costs.

System moving slow? If performance decreases, this could be a sign that your hydraulic pump is starting to go bad or your system is designed incorrectly. This lack of efficiency indicates a lack of flow.

You never want to let your system run if your pump is suffering from any of these problems listed above because it means your system is on the verge of experiencing pump failure. These symptoms are an indicator that something could be seriously wrong and could result in some expensive damage to your hydraulic system. The hydraulic experts at Pneumatic And Hydraulic Company can help in identifying the warning signs and replacing your pump before the damage becomes too costly.

The pump is probably the component most subject to wear in a hydraulic system, and the one most likely to cause a sudden or gradual failure in the system.

Pump trouble is usually characterized by increased noise, increased heat, erratic operation of cylinders, difficulty or inability to develop full output, decreased speed of cylinders or hydraulic motors, or failure of the system to work at all.

Cavitation is the inability of a pump to draw in a full charge of oil. When a pump starts to cavitate its noise level increases, and it may become extremely hot around the shaft and front bearing. Other symptoms of pump cavitation are erratic movement of cylinders, difficulty in building up full pressure, and a milky appearance of the oil. If cavitation is suspected, check these points:

a. Check condition of pump suction strainer. Clean it even if it does not look dirty. Use a solvent then blow dry with an air hose. Varnish deposited in the wire mesh may be restricting the oil flow but may be almost invisible. If you find varnish deposits on internal surfaces of pumps or valves, the system is operating at too high a temperature. A heat exchanger should be added.

b. Check for restricted or clogged pump inlet plumbing. If hoses are used, be sure they are not collapsed. Only those hoses designed for vacuum should be used in the pump inlet. They have an internal wire spiral to prevent collapse.

c. Be sure the air breather on top of the reservoir is not clogged with lint or dirt. On systems where the air volume above the oil is relatively small, the pump could cavitate during its extension stroke if the breather became clogged.

d. Oil viscosity could "be too high for the particular pump. Some pumps cannot pick up the prime on heavy oil or will run in a partially cavitated condition.

Cold weather start-up is particularly damaging to a pump. Running a pump for several hours in a cavitated condition until the oil warms up can greatly shorten its life. On equipment operating outdoors use an oil not only of the recommended viscosity but also with as high as possible viscosity index. This minimizes the viscosity change from cold to hot oil operation and reduces cavitation on a cold start-up.

g. Determine recommended speed of pump. Check pulley and gear ratios. Be sure the original electric motor has not been replaced with one which runs at a higher speed.

h. Be sure pump has not been replaced with one which delivers a higher flow which might overload the suction strainer. Increase suction strainer size if necessary.

a. Be sure the oil reserve is filled to Its normal level, and that the pump intake is well below the minimum oil level. The NFPA reservoir specifications call for the highest point on the suction strainer to be at least 3 inches below minimum oil level.

b. Air may be entering around the pump shaft seal. Gear and vane pumps which are pulling suction oil from a reservoir located below them, will have a slight vacuum behind the shaft seal. When this seal becomes badly worn, air may enter through the worn seal. Piston pumps usually have a small positive pressure, up to 15 PSI, behind the shaft seal. Air is unlikely to enter these pumps through the seal.

c. Check all plumbing and joints in the pump inlet line, especially unions. Check for leaks in hoses used in· the inlet line. One easy way to check for plumbing leaks is to pour oil over a suspected leak. If the pump noise diminishes, you have found your leak.

e. Be sure the main tank return line discharges well below the minimum oil level and not on top of the oil. On new designs it is helpful to increase the diameter of the tank return line for a few feet before it discharges. This causes oil velocity to decrease, reducing turbulence inside the reservoir.

a. Leakage Around the Shaft. On some pumps (piston pumps or those pumps operating with an overhead reservoir), there may be a slight pressure behind the shaft seal. As the seal becomes well worn, external leakage may appear. This will usually be more pronounced while the pump is running, and may disappear while the pump is stopped.

b. Leakage Around a Pump Port. Sometimes leakage at these ports is caused from screwing a taper pipe thread fitting into a straight thread port. Once the threads have been damaged there is no easy way to repair the pump.

Check tightness of fittings in the ports. If dryseal pipe threads are used, there should be no need to use a pipe thread sealant. Beware of screwing taper pipe threads too tightly into a pump body casting. This may cause the casting to crack.

c. If leakage is from a small crack in the body casting, this most likely has been caused either by screwing a pipe fitting in too tightly, or from operating the pump in a system where either the relief valve is set too high, or where high transient pressure spikes are generated as a result of shocks. It is possible that the casting may originally have been defective but this has rarely turned out to be the problem.

a. Shaft turning in wrong direction. Shut down immediately. Reversed leads on a 3-phase motor are the commonest cause for wrong rotation. Pumps must be run in the direction marked on their nameplate or case.

g. Pump running too slow. Most pumps deliver a flow at all speeds, proportional to RPM. But some vane pumps which depend on centrifugal force to extend the vanes, will deliver little or no flow at slow speeds such as engine idle RPM.

f. Misalignment of pump shaft with driving motor or engine. Note: When replacing a foot mounted pump, leave the bracket and replace only the pump and the new pump will not have to be re-aligned with the driving source.

8613371530291

8613371530291