what causes hydraulic pump whine brands

Pump cavitation is first and foremost caused by insufficient flow. This happens when the volume of fluid being supplied doesn’t meet the demands of the hydraulic circuit, and the pressure at the suction end of the pump isn’t sufficient. This leads to the absolute pressure falling below the vapor pressure of the liquid, which leads to air bubbles being formed. These tiny bubbles implode as they pass through the system, creating shockwaves and causing pump vibrations.

The process of these bubbles forming and collapsing is done with a great deal of force, and leads to eventual metal erosion inside the pump. The mechanical damage caused by cavitation can have irreversible impacts on system components and may possibly lead to complete failure. Cavitation happens only on the suction side of the pump, and may be caused by a series of different malfunctions, including:

Cavitation is typically characterised as a high-pitched whining or screeching sound, and in some extreme cases, can present itself as a loud rattling sound. Whilst these hydraulic pump whine noises are generally the most obvious telltale signs of cavitation, other symptoms to look out for also include:

By design, hydraulic pumps contain a miniscule amount of air which allows space for the hydraulic fluid to heat up and expand. However, too much air in the pump can cause serious issues – this is known as aeration.

Aeration in a hydraulic pump occurs when there is an air leak in the suction line. When outside air enters the pump through a damaged connector, loose pump seal, pipe fitting, or any other damage, it gets drawn into the pump’s hydraulic fluid supply. This unwanted air quickly gets dissolved into the hydraulic fluid and leads to contamination.

Contaminated hydraulic fluid can have serious implications for the system, as the excess air means that it cannot conduct heat as efficiently and can cause the fluid to foam. This can lead to overheating and in some cases, a substantial decrease in power. Aeration may happen on both sides of the pump, and has several causes including:

Similar to cavitation, aeration is usually indicated by a sudden change in noise, which can sometimes make it difficult to differentiate between the two causes However, aeration tends to produce a more erratic low-pitched ‘rumbling’ or ‘rattling sound, as opposed to the more consistent whining noise of cavitation.

Excessive or erratic hydraulic pump noise is a symptom of malfunction that could cause damage or accelerated wear if not addressed quickly and correctly. While it’s never nice to hear strange noises emitted from your pump, different forms of noise, which are related to different faults can provide valuable clues that can help you to diagnose your problem and get it fixed before it turns into something major.

So it pays to know what different pump noises mean and with practice you can quickly distinguish between the normal operating sounds and signs that something is wrong. In this article, we’ll talk about what causes some of these sounds, so you can identify them.

A constant hissing sound is indicative of a relief valve that is set too low or is stuck open and is continually releasing pressure. An erratic whistling sound is a symptom that a relief valve is set incorrectly or is damaged. It is common for pump settings to be changed carelessly or inadvertently - sometimes to overcome other issues with the hydraulic system - sometimes due to a lack of understanding of the correct operating conditions, so include this in your regular checks. In addition to noise problems, relief valve damage can be accompanied by slamming of actuators, stalls and excessive heat generation.

Noise issues are just one symptom that gives you a clue when things go wrong with your hydraulic pump. There are several other issues to know and understand, which could help you to identify pump problems quicker. Which means you can sort them out sooner - potentially saving big money down the road. These include heat problems, pressure problems and flow problems.

Every hydraulic pump makes some noise. If all is well with a pump, then this noise stays more or less the same. However, if something goes wrong with the pump or its connected system parts, then you may start to hear sounds that you haven"t heard before.

The fluid that flows through your system needs to move at a smooth and even rate. The pump has to deliver the fluid at a specific flow for things to work.

If something prevents the fluid from achieving and maintaining its optimum flow, then your pump may start to make unusual noises. For example, you may hear a high-pitched whine coming from the pump. This can be a constant or intermittent sound.

If your pump whines constantly, then you may have a cavitation problem. Here, the pump can"t deliver its fluid at the right volume or rate. There isn"t enough fluid coming through the pump"s suction line.

In some cases, this is a sign that your pump"s motor is on the wrong setting. So, the pump itself is working at the wrong speed to create the right flow.

A hydraulic pump might get noisy if one of its parts or connections has a problem. A faulty or failing pressure control, bearing, valve, seal, or coupling can make a noise you haven"t heard before.

In some cases, you may hear vibrating clunks as your pump works if you have a problem with a connecting pipe. A loose seal or connector might allow the pipe to move. It then passes vibrations along to the pump itself.

While some noise problems are easy to fix, some are a sign that your pump is close to the end of its working life. Sometimes, this is due to natural wear, usage, and age. However, in some cases, minor problems cause more widespread damage if you don"t fix them quickly.

For example, if you"ve had cavitation problems for a while, then your system may not have been getting the lubrication it needs; it may have overheated regularly. Even if you fix the cavitation issue, you may be left with a damaged pump that needs a more significant repair, rebuild, or replacement.

So, while new sounds or an increase in operating noise don"t necessarily mean that you have a serious pump problem, you should investigate any unusual noise. Typically, this is a sign that something isn"t working right.

A minor problem in your system could go on to cause significant damage. For an expert diagnosis, contact Quad Fluid Dynamics, Inc. Ourhydraulic pump repair and rebuild servicewill get your pump running smoothly and efficiently again.

Longer cycle times are often the first indication that there is something wrong with a hydraulic system. Decreased speed of hydraulic actuators (such as cylinders) points to decreased flow through the system.

Decreased flow can be caused by either external or internal leaks. External leakage can often be spotted very easily. Look for leaking/busted hydraulic hose, hydraulic fluid around connectors or under components.

See the related blogs on preventive maintenance of hydraulic hoses and knowing when to replace a hydraulic hose. Another related blog, “What is Causing Your Hydraulic System to Leak” has a free download of our Port End Assembly Guide, which can educate your maintenance personnel on preventing connector leaks in the first place.

Internal leaks (such as high-pressure fluid passing around the cylinder piston, or incorrectly set relief valve pressure) are more challenging to identify. One way to identify an internal leak is by detecting elevated temperature of a failing component. A leak generates heat. Higher temperature results in decreased viscosity of the hydraulic fluid. Decreased viscosity of the fluid further increases leakage, leading to additional increases in temperature… You get the picture of how the situation escalates.

In some cases, temperature measurement is not conclusive. If an internal leak cannot be detected by locating a component generating abnormal heat, use a hydraulic flow meter.

Knocking, loud whining, or screeching often indicates aeration or cavitation. Aeration means air inclusion in the hydraulic fluid, cavitation is the presence of vaporized hydraulic fluid in the system.

Banging or knocking noises can indicate that air is included in the hydraulic fluid. Other symptoms of air inclusion are foaming of the fluid, and erratic actuator movements.

Air in the system accelerates breakdown of the hydraulic fluid and decreases hydraulic fluid’s lubricating properties. Both conditions lead to increased wear of the system’s components, through increased friction, overheating, and burning of seals.

Air usually enters the system through the pump intake. Check the fluid level and a condition of the suction hose. If the hose is old or shows any warning signs, replace it. See related blogs on knowing when to replace a hydraulic hose, scheduled hydraulic hose replacement, and preventive maintenance of hydraulic hoses for more information on the subject.

Cavitation results from demand for hydraulic fluid not being met. Typically (but not exclusively), this happens at the pump. The insufficient flow causes the absolute pressure in the affected part of the circuit to fall below the vapor pressure of the hydraulic fluid, which in turns causes formation of vapor cavities within the fluid. When the vapor cavities are compressed, they implode and produce a knocking noise.

Excessive temperature of hydraulic fluid (generally above 180°F), reduces its working life and damages seals in the system. In addition, viscosity of hydraulic fluid decreases with increasing temperature, which in turn results in inadequate lubrication and increased wear of the system"s components.

There are two general causes for increased hydraulic fluid temperature: either a component produces more heat than it should, or the heat dissipation capacity of the system is reduced/inadequate.

Regularly check the hydraulic oil level and viscosity. Check the heat exchanger for any obstructions in both coolant lines and hydraulic fluid lines. Make sure that the heat exchanger has adequate space around it.

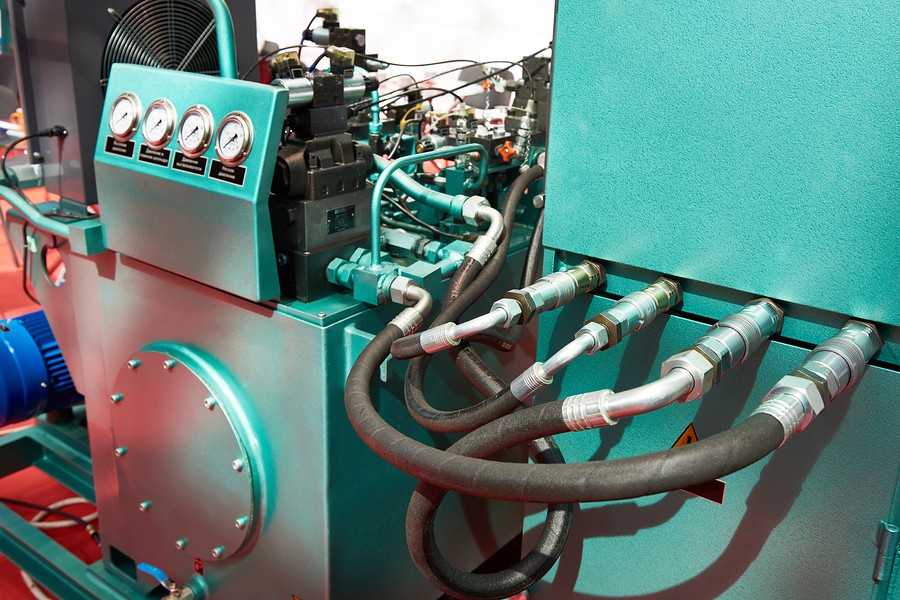

To properly analyze and/or troubleshoot your hydraulic system, you will need some tools. At minimum, you need to be able to measure pressure, temperature, and flow at different parts of your circuit. The more complex your hydraulic system, the more sophisticated meters you will need to get the job done.

Parker SensoControl family of diagnostic meters offers four different diagnostic solutions to address the needs of maintenance personnel, based on the complexity of their hydraulic circuits.

Check that the pump shaft is rotating. Even though coupling guards and C-face mounts can make this difficult to confirm, it is important to establish if your pump shaft is rotating. If it isn’t, this could be an indication of a more severe issue, and this should be investigated immediately.

Check the oil level. This one tends to be the more obvious check, as it is often one of the only factors inspected before the pump is changed. The oil level should be three inches above the pump suction. Otherwise, a vortex can form in the reservoir, allowing air into the pump.

What does the pump sound like when it is operating normally? Vane pumps generally are quieter than piston and gear pumps. If the pump has a high-pitched whining sound, it most likely is cavitating. If it has a knocking sound, like marbles rattling around, then aeration is the likely cause.

Cavitation is the formation and collapse of air cavities in the liquid. When the pump cannot get the total volume of oil it needs, cavitation occurs. Hydraulic oil contains approximately nine percent dissolved air. When the pump does not receive adequate oil volume at its suction port, high vacuum pressure occurs.

This dissolved air is pulled out of the oil on the suction side and then collapses or implodes on the pressure side. The implosions produce a very steady, high-pitched sound. As the air bubbles collapse, the inside of the pump is damaged.

While cavitation is a devastating development, with proper preventative maintenance practices and a quality monitoring system, early detection and deterrence remain attainable goals. UE System’s UltraTrak 850S CD pump cavitation sensor is a Smart Analog Sensor designed and optimized to detect cavitation on pumps earlier by measuring the ultrasound produced as cavitation starts to develop early-onset bubbles in the pump. By continuously monitoring the impact caused by cavitation, the system provides a simple, single value to trend and alert when cavitation is occurring.

The oil viscosity is too high. Low oil temperature increases the oil viscosity, making it harder for the oil to reach the pump. Most hydraulic systems should not be started with the oil any colder than 40°F and should not be put under load until the oil is at least 70°F.

Many reservoirs do not have heaters, particularly in the South. Even when heaters are available, they are often disconnected. While the damage may not be immediate, if a pump is continually started up when the oil is too cold, the pump will fail prematurely.

The suction filter or strainer is contaminated. A strainer is typically 74 or 149 microns in size and is used to keep “large” particles out of the pump. The strainer may be located inside or outside the reservoir. Strainers located inside the reservoir are out of sight and out of mind. Many times, maintenance personnel are not even aware that there is a strainer in the reservoir.

The suction strainer should be removed from the line or reservoir and cleaned a minimum of once a year. Years ago, a plant sought out help to troubleshoot a system that had already had five pumps changed within a single week. Upon closer inspection, it was discovered that the breather cap was missing, allowing dirty air to flow directly into the reservoir.

A check of the hydraulic schematic showed a strainer in the suction line inside the tank. When the strainer was removed, a shop rag was found wrapped around the screen mesh. Apparently, someone had used the rag to plug the breather cap opening, and it had then fallen into the tank. Contamination can come from a variety of different sources, so it pays to be vigilant and responsible with our practices and reliability measures.

The electric motor is driving the hydraulic pump at a speed that is higher than the pump’s rating. All pumps have a recommended maximum drive speed. If the speed is too high, a higher volume of oil will be needed at the suction port.

Due to the size of the suction port, adequate oil cannot fill the suction cavity in the pump, resulting in cavitation. Although this rarely happens, some pumps are rated at a maximum drive speed of 1,200 revolutions per minute (RPM), while others have a maximum speed of 3,600 RPM. The drive speed should be checked any time a pump is replaced with a different brand or model.

Every one of these devastating causes of cavitation threatens to cause major, irreversible damage to your equipment. Therefore, it’s not only critical to have proper, proactive practices in place, but also a monitoring system that can continuously protect your valuable assets, such as UE System’s UltraTrak 850S CD pump cavitation senor. These sensors regularly monitor the health of your pumps and alert you immediately if cavitation symptoms are present, allowing you to take corrective action before it’s too late.

Aeration is sometimes known as pseudo cavitation because air is entering the pump suction cavity. However, the causes of aeration are entirely different than that of cavitation. While cavitation pulls air out of the oil, aeration is the result of outside air entering the pump’s suction line.

Several factors can cause aeration, including an air leak in the suction line. This could be in the form of a loose connection, a cracked line, or an improper fitting seal. One method of finding the leak is to squirt oil around the suction line fittings. The fluid will be momentarily drawn into the suction line, and the knocking sound inside the pump will stop for a short period of time once the airflow path is found.

A bad shaft seal can also cause aeration if the system is supplied by one or more fixed displacement pumps. Oil that bypasses inside a fixed displacement pump is ported back to the suction port. If the shaft seal is worn or damaged, air can flow through the seal and into the pump’s suction cavity.

As mentioned previously, if the oil level is too low, oil can enter the suction line and flow into the pump. Therefore, always check the oil level with all cylinders in the retracted position.

If a new pump is installed and pressure will not build, the shaft may be rotating in the wrong direction. Some gear pumps can be rotated in either direction, but most have an arrow on the housing indicating the direction of rotation, as depicted in Figure 2.

Pump rotation should always be viewed from the shaft end. If the pump is rotated in the wrong direction, adequate fluid will not fill the suction port due to the pump’s internal design.

A fixed displacement pump delivers a constant volume of oil for a given shaft speed. A relief valve must be included downstream of the pump to limit the maximum pressure in the system.

After the visual and sound checks are made, the next step is to determine whether you have a volume or pressure problem. If the pressure will not build to the desired level, isolate the pump and relief valve from the system. This can be done by closing a valve, plugging the line downstream, or blocking the relief valve. If the pressure builds when this is done, there is a component downstream of the isolation point that is bypassing. If the pressure does not build up, the pump or relief valve is bad.

If the system is operating at a slower speed, a volume problem exists. Pumps wear over time, which results in less oil being delivered. While a flow meter can be installed in the pump’s outlet line, this is not always practical, as the proper fittings and adapters may not be available. To determine if the pump is badly worn and bypassing, first check the current to the electric motor. If possible, this test should be made when the pump is new to establish a reference. Electric motor horsepower is relative to the hydraulic horsepower required by the system.

For example, if a 50-GPM pump is used and the maximum pressure is 1,500 psi, a 50-hp motor will be required. If the pump is delivering less oil than when it was new, the current to drive the pump will drop. A 230-volt, 50-hp motor has an average full load rating of 130 amps. If the amperage is considerably lower, the pump is most likely bypassing and should be changed.

Figure 4.To isolate a fixed displacement pump and relief valve from the system, close a valve or plug the line downstream (left). If pressure builds, a component downstream of the isolation point is bypassing (right).

The most common type of variable displacement pump is the pressure-compensating design. The compensator setting limits the maximum pressure at the pump’s outlet port. The pump should be isolated as described for the fixed displacement pump.

If pressure does not build up, the relief valve or pump compensator may be bad. Prior to checking either component, perform the necessary lockout procedures and verify that the pressure at the outlet port is zero psi. The relief valve and compensator can then be taken apart and checked for contamination, wear, and broken springs.

Install a flow meter in the case drain line and check the flow rate. Most variable displacement pumps bypass one to three percent of the maximum pump volume through the case drain line. If the flow rate reaches 10 percent, the pump should be changed. Permanently installing a flow meter in the case drain line is an excellent reliability and troubleshooting tool.

Ensure the compensator is 200 psi above the maximum load pressure. If set too low, the compensator spool will shift and start reducing the pump volume when the system is calling for maximum volume.

Performing these recommended tests should help you make good decisions about the condition of your pumps or the cause of pump failures. If you change a pump, have a reason for changing it. Don’t just do it because you have a spare one in stock.

Conduct a reliability assessment on each of your hydraulic systems so when an issue occurs, you will have current pressure and temperature readings to consult.

Al Smiley is the president of GPM Hydraulic Consulting Inc., located in Monroe, Georgia. Since 1994, GPM has provided hydraulic training, consulting and reliability assessments to companies in t...

Hydraulic pumps are at the core of many essential factory operations. Unfortunately, there are numerous pitfalls to plan for, mitigate, and overcome to keep them running. Keeping up on routine maintenance is important, but the best way factory techs can avail themselves of costly, frustrating breakdowns is to understand the various catalysts for hydraulic pump failure.

The simplest way to identify the cause of pump failure is to thoroughly inspect and dissect the aftermath of the problem. In most cases, the cause of failure will be evident by the nature of the catalyst(s). Here are eight of the most common problems, some of their defining features, and how they ultimately come to fruition.

1. Fluid contamination is one of the biggest causes of hydraulic pump damage and involves debris mixing with the liquid. This debris causes friction, leading to extenuated wear on the pump itself. The result is inefficiency, culminating in malfunction.

2. Fluid viscosity issues occur when the hydraulic fluid within a pump breaks down over time. Viscosity that’s too high leads to cavitation (another catalyst for damage). Subsequently, if a tech changes and replaces fluid with a viscosity that’s too low, heat and friction become concerns.

3. Over-pressurization occurs because of excessive load on the pump itself, resulting in red-line operation that’s both unsafe and damaging. Hydraulic pumps operating under high duress for extended periods of time will likely experience component wear and premature failure, usually in spectacular fashion.

4. Excess heat can be a product of poor fluid viscosity or environmental factors. This issue is rarely a singular catalyst for pump breakdown, but it exacerbates other factors or masks other issues, such as fluid contamination.

5. Implosion invariably results in extreme failure for hydraulic pumps and is a major safety hazard. Implosion occurs when air bubbles within a hydraulic pump collapse, causing an overload of pressure to the pump that generates an intense shock.

6. Aeration occurs when hydraulic fluid traps air bubbles. The pump subjects the bubbles to pressure, causing high heat and over-pressurization when the bubbles collapse. Aeration at extreme levels leads to implosion.

7. Pump aeration pertains to air not in the hydraulic fluid, but air introduced through unsealed joints or shafts. This air quickly causes pressure instability affecting crucial parts of the pump. This can quickly lead to breakdowns — generally marked by a whine or other high-pitched sound.

8. Cavitation is a symptom of uncontrolled pump speeds, which fail to allow hydraulic fluid to completely fill the pump. It results in destabilized pressure, heat, and excess wear. Cavitation is often marked by the same type of whine or squeal as pump aeration.

Because the factors causing each of these problems differ in nature, it’s best to fully evaluate a damaged hydraulic pump to determine if more than one issue is responsible.

Maintenance is the best approach for ensuring safe, efficient hydraulic pump function. But routine service is just the start. Identifying common issues plaguing your hydraulic pumps will lead to a better quality of targeted maintenance — for example, if you pinpoint a heat issue related to viscosity, that issue may be resolved by opting for a different fluid weight.

Every piece of information learned about your pumps can translate into better care, leading to longer uptimes, fewer issues, and fundamentally better maintenance.

Having trouble identifying the catalysts for your hydraulic pump’s issues? Let the professionals at Global Electronic Services take a look! Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!

Hydraulic pumps are essential components in countless different types of applications. In many cases, they’re expected to run around the clock, and any downtime can grind operations to a halt.

Hydraulic pump failure has a number of different internal and external causes, and understanding what those are can help prevent issues in the future. Poor maintenance, extreme operating conditions, and problems with other components can all contribute to failure and can all be carefully planned for and monitored to prevent any issues.

Ideally, you’ll discover that there’s an issue with the pump before a complete failure. Identifying any problems earlier will give you more time to plan a response instead of scrambling when operations shut down unexpectedly. Minor fixes can even be incorporated into your

Loud noises are going to be one of the most serious indicators of hydraulic pump failure. While your pumps will be making noise during regular operation, various faults can cause a loud knocking or banging. If you start to hear these noises from your pump, failure is likely right around the corner. Consider it your pump crying out for help.

Temperature is another key factor to watch for hydraulic pumps. Most hydraulic systems recommend operating at no more than 180 degrees Fahrenheit or 82 degrees Celsius, and temperatures climbing higher than that are a clear indication that something is wrong.

Continuing to use the system with a partially damaged pump will only speed up the complete failure of the hydraulic pump, so it’s best to address these issues as soon as you notice any signs.

Many different factors can lead to hydraulic pump failure. No matter what the specific cause, it’s important to remember that pump components likely haven’t broken for no reason at all. Pump failure is a sign that something must be wrong somewhere in the system, with the effects ultimately leading to the failure of the pump.

Cavitation is a likely cause of loud banging noises coming from the pump. Dissolved gasses within the oil can react to pressure differences by coming out of the oil and then being collapsed by the high pressure.

Aeration can have similar effects. This issue occurs when external air enters the system through leaks, loose connections, or other problem areas. It generally creates a much more mild knocking but is still causing damage that eventually leads to hydraulic pump failure.

The look of the hydraulic oil itself can give an indication of water contamination by appearing hazier and less clear than usual. Water contamination will wear down hydraulic components and can cause oxidation over time as well.

Significant overheating can lead to oxidation of the hydraulic fluid, which causes the fluid to become thicker. This thickening can limit flow through the system, further reducing heat dissipation and potentially causing even more severe overheating.

Low temperatures can also cause problems. The hydraulic fluid can only effectively flow once it approaches operating temperatures. Pump failure can be caused by increasing the load before the operating temperature is met, which is more common with lower ambient temperatures.

Many different mistakes can lead to premature or even immediate hydraulic pump failure. A faulty installation could result in instantaneous and catastrophic damage to the system or gradual wear that isn’t discovered for years. Poorly fitted pipes and other pump components could contribute to leaks.

An incorrect combination of different parts can cause hydraulic pump failure as well. A motor might have excessive drive speed for a pump, or various types of control equipment can be incompatible. In any case, these issues can lead to increased wear or even immediate failure.

Failing to implement effective maintenance will also lead to premature failure. If the proper maintenance schedule isn’t followed, excessive wear can develop. This risk is true for both the pump and other system components that can affect the pump if not properly maintained.

Even if a hydraulic pump is replaced or repaired, the issue is likely to occur again if the root cause isn’t identified and resolved. This diagnostic could mean evaluating the entire system to find out just what went wrong. There could be other components that allow for fluid leaks or air and water to enter the system.

To prevent future hydraulic pump failure, you should ensure that the system follows all relevant specifications. Operating outside of these specifications could cause damage to the pump and other components that eventually lead to hydraulic pump failure.

After a pump failure, a professional inspection of the entire system may be in order. Avoiding this precaution could lead to another failure shortly or even more excessive damage to your hydraulic systems.

Many hydraulic components are relatively quick and inexpensive replacements, and avoiding necessary repairs can only lead to serious issues down the line.

The team at MAC Hydraulics can provide all of the services you need for your hydraulic system, including professional troubleshooting. We offer replacement hydraulic pumps, repair pumps, and cover maintenance to prevent unexpected hydraulic pump failure.

For fast and effective troubleshooting, you can reach out to us as soon as you notice issues like increased noise, oil leaks, loss of power, limited flow, or overheating. Our team will determine the root cause of the problems you’re experiencing with your pump to ensure that they won’t happen again.

That also includes effective resealing to help you get the most out of your existing components, instead of having to replace them before their time. Our experienced team can go over your options and find the best solution for your hydraulic systems today.

You rely on your hydraulic systems every day and can’t afford to let hydraulic pump failure grind operations to a halt. Whether the issue is air or water contamination, overheating, over-pressurization, human error, or anything else, the end result will be the same when your pump quits.

Every component within a hydraulic setup will affect the overall system. Hydraulic pump failures can indicate further issues with other parts of the system. Looking into exactly what the real cause is can help prevent additional failures in the future.

Whenever your system suffers from pump failure, it’s best to go with trusted professionals for the replacement or repair you need to get running again. An experienced team can ensure that you have the right pump for your system and that the installation is carried out safely and reliably.

Noise is undesirable because it can cause additional load on hydraulic components leading to premature failure, additional system cost, operator fatigue and potential hearing loss. The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) states that exposure to 85 dB(A) of noise for more than eight hours per day can result in permanent noise-induced hearing loss (NIHL)1.

Noise is known to cause many issues with components in hydraulic systems but in particular steel tube assemblies are known to be very susceptible to vibration failure.

Vibration can travel through the system via the fluid and/or metal components transmitting to all parts of the equipment. Noise travels easily through the metal components such as pumps, valves, cylinders, steel tubes and elbow fittings but can also travel through the steel wire reinforcement in the hose.

A quick and easy solution that some designers have discovered to eliminate noise in power steering systems, hydrostatic pumps, pump outlets, motor inlet/outlet and PTOs is to utilize thermoplastic fiber reinforced hose. This hose is constructed using a variety of smooth bore polymer inner cores for a high degree of chemical compatibility, high strength fibers, and a polymer jacket. Fiber braided thermoplastic hose is available in pressure ratings from 500 psi to 7500 psi.

Parker"s Parflex Division is contacted at least once a month by companies looking to bring the noise down below audible noise level (vibration). Through years of studying noise and its effects on hydraulic systems, as well as, working closely with our customers to reduce application-specific noise, Parflex has developed an extensive line of thermoplastic hoses with a high degree of dampening effects.

Parflex 510D, 518D, 520Nand 53DM are most suited for reducing noise and have a working pressure range of 1500 to 5000 psi at a 4:1 design factor. Hose selection tools and application engineering expertise are available through Parflex for your equipment hydraulic design needs.

Traveller Premium Transmission Fluid is compatible with the 134D. I"ve used it quite a bit. When you change fluid, look carefully at the big pipe going from the main hydraulic filter to the pump. Look for any connection that might be loose and drawing air. Air leaking into the hydraulics will cause the pump to cavitate and make noise. Also, keep an eye on your engine oil level. If the hydraulic pump bearing and seal go out, it could dump hydraulic fluid into the engine crankcase. So if the engine level goes above full, it"s probably from the hydraulic pump. Just be sure it"s your hydraulic pump making noise. You can loosen your fan belt enough that the alternator and water pump don"t turn. Start the engine for a few seconds to ensure the noise is from the hydraulic pump instead of the water pump or alternator. You won"t hurt anything by running the engine for a minute or two that way, but don"t run it long or the engine will overheat.

When hydraulic systems do not receive the routine maintenance they need, they become vulnerable to a number of major performance problems. Few of these issues are more annoying than excessive noise.

A noisy system not only creates unnecessary disruptions in the workplace, it’s also the symptom of a potentially severe mechanical issue. Therefore, a hydraulic system that keeps emitting loud vibrations, knocking sounds, or other hard-to-ignore noises should be inspected at the earliest opportunity so the problem can be located and properly corrected.

A hydraulic system that won’t stop emitting strange noises is an irritation that no one should have to endure, as it tends to disrupt the concentration and peace of mind of personnel who work in the area.

An excessively noisy hydraulic system may even violate the law. In the U.K., employers are required to ensure that workplaces do not have pieces of equipment that generate excessive noise levels. The relevant legislation is the Control of Noise at Work Regulations 2005.

Although noise can emit from many areas along the system, the most common cause is a defect with the pump(s). Noise may be generated by the mechanical motion of the unit (e.g., the bearings) and/or the movement of the hydraulic fluid through the pump. If you’re searching for the source of system noise, it’s a good practice to start with these components.

Another frequent culprit is the electric motor connected to the pump. Fluid conductors such as hoses and tubes can also generate excessive noise if these components are worn out or improperly connected to the system. Later on, we’ll explore some specific tips for pinpointing issues with these kinds of parts.

Aeration – The presence of air in the hydraulic fluid is known as aeration, and it can trigger serious problems. Aeration can lead to a reduction inf fluid quality, compromising its ability to lubricate moving parts and prevent overheating. Pockets of air in the system tend to make a loud knocking or banging noise as they travel through the hydraulic system.

Cavitation – When a hydraulic system fails to provide a sufficient amount of fluid to a particular area, vapor bubbles (or cavities) can form. This is known as cavitation. An increase of system pressure makes the cavities implode, generating a shock wave. Cavitation in a hydraulic system makes a distinctive knocking sound—but the problem is more serious than mere annoying noises. The imploding cavities can harm system components, possibly causing them to fail altogether.

Check the Hoses – Improperly configured hoses are a frequent cause of excessive noise in hydraulic systems. The problem develops when the hose is bent at a sharp angle in order to connect it properly. Bent hose, however, tends to generate noise, significantly more than straight hose does. You may be able to reduce noise levels dramatically simply by replacing these bent hoses with metal tubing, which will not generate as much racket. If it is the inlet hose that is bent, oil supply may become restricted by the end leading to noise as a result of pump cavitation.

Check the Electric Motor – The cooling fan in the motor may be contributing to the noise emanating from your hydraulic system. Bi-directional fans produce more racket than ones designed to move in one direction. If you have a fan of the former type, it may be worth the expense of replacing it with a uni-directional fan. It may also be that the fan cowling is blocked or the motor bearings are needing to be replaced.

Pumps—even brand-new modern pumps—produce a certain amount of vibration that generates noise. Reducing these vibrations can substantially contribute to your efforts to solve your noise problem. How can you go about achieving this? An accumulator teed into the pressure line is an excellent shock absorber that has the effect of dampening noise. If your system already has an accumulator, check it to ensure that nothing is amiss—keep in mind that these units require periodic maintenance. You may also wish to change the type of accumulator in your system, as each kind has its own particular advantages. Accumulators are available in three basic types: piston, bladder, and diaphragm. Bladder accumulators are known for their fast response time, while piston accumulators are capable of managing a higher gas compression ratio.

Check the Pump Intake Lines – As we mentioned earlier, aeration is a potentially serious issue. When air gets into the system, it often does so via the pump intake lines, so you should examine these to ensure that they are properly connected and still in acceptable condition.

Check the Pump Speed – Reducing the pump speed, when possible, helps to reduce the amount of noise produced by this device. Adding more pumps to the system may allow you to run them at a lower speed without interfering with performance. Figuring out how many pumps to use at which speed can be problematic, so make sure that you have considered all variables before proceeding.

To a large extent, the task of reducing hydraulic system noise requires using high-quality components and performing routine maintenance checks to ensure that everything is in good working condition. White House Products Ltd. is a reliable resource for many organizations across the U.K. that need state-of-the-art hydraulic parts and components. Please explore our online catalog for first-class products from the leading manufacturers active today. Please contact uswith any questions you have about our range—we will respond as soon as possible.

Although cavitation can occur anywhere in a hydraulic system, it commonly occurs within the suction line of a pump. This will cause excessive noise in the pump – generally a high pitched “whining” sound. However, this excessive noise is only the tip of the iceberg! The real result of this phenomenon is severe pump damage and a decrease in pump life. I have personally seen many instances where a customer was replacing pumps frequently, thinking they were receiving defective pumps from their vendor. In reality, the pump failures were not due to poor pump quality – the failures were occurring because of cavitation.

Simply put, cavitation is the formation of vapor cavities in the hydraulic oil. In hydraulic pumps, cavitation will occur any time the pump is attempting to deliver more oil than it receives into the suction (inlet) line. This is commonly referred to as “starvation” and results from a partial vacuum in the suction line. To fully illustrate what is happening when this occurs, we need to discuss vapor pressure. Vapor pressure is the pressure below which a liquid at a given temperature will become a gas, and this pressure varies significantly depending on the liquid. Generally, as the temperature of a liquid rises, the vapor pressure will proportionally increase. Likewise, as the temperature decreases, the vapor pressure will decrease. Most of us know that water will boil (turn to vapor) at 212°F (100°C) at 14.7 PSI (atmospheric pressure at sea level). In other words, the vapor pressure of water at 212°F is 14.7 PSI. If the pressure is reduced, the temperature at which the water boils will be reduced. If the temperature is lowered, the vapor pressure will decrease. In fact, water will boil at room temperature if the pressure is sufficiently reduced! The same principle applies to hydraulic oil, although the vapor pressure will be somewhat different than that of water. The vapor pressure of hydraulic oil is somewhere between 2 and 3 PSI at normal temperatures. In ideal conditions, the pressure in the suction line of the pump will be around 14.7 PSI at sea level. Of course, this pressure decreases with altitude, but sufficient pressure will normally be maintained in the suction line to prevent cavitation of the oil. However, if the pressure in the suction line of the pump is sufficiently reduced to the vapor pressure of the oil, vapor cavities will form. As the oil passes from the suction line to the outlet of the pump, the pressure will increase and the vapor cavities will implode violently. These extremely powerful implosions will cause erosion and premature failure of the pump components. In fact, a brand-new pump can be destroyed in a matter of minutes if the cavitation is severe enough. The picture below shows a rotor and cam ring from a vane pump that had failed due to severe cavitation.

In my 35-plus years of troubleshooting hydraulic components, this is the worst case of cavitation damage I have ever seen. In addition to the usual erosion of the parts, the vanes were actually fused to the rotor slots! Although this is an extreme example, it shows the potential damage to a pump due to cavitation. The good news is that cavitation is preventable and we will look at several conditions that can trigger this phenomenon.

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves supplier and manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer"s demands are met.

CML, Camel Hydraulic, Camel Precision welcomes you to view our high quality products Vane Pump, Gear Pump, Solenoid Valve, Modular Valve, Hydraulic Pump and feel free to Contact Us.

8613371530291

8613371530291