what is a case drain on a hydraulic pump brands

Often in hydraulic systems, hydraulic motors and pumps run case drain hoses. The reason for this is to drain excess internal oil leakage from the motor. This is certainly critical in a piston motor and pump as the pistons have some internal leakage as they are actually just metal on metal. If no case drain hose is installed then the result will be, at the least, a blown shaft seal, and at worst, a split or damaged housing.

With gear pumps the leakage drains back into the suction hose internally, so no case drain is required. With gear motors and geroller/geroter motors, the oil can drain into the outlet port, however, that means that the oil pressure in the outlet port must not exceed the pressure rating of the seal. If it does, then a case drain needs to be installed. This will then usually mean you can run motors in series without damaging the motor.

If you require assistance with your hydraulic system, motors, pumps, hoses, seals, case drain, oil, lubricants or anything else for that matter, please give us a call on (03) 5382 0574 or call in and see us at Horsham Hydraulics, 84 GolfCourse

This article is based on a basic circuit with single hydraulic internal gear motor. More complex circuits with multiple motors can have different solutions. Collaborate with your motor supplier for the best results for your particular design.

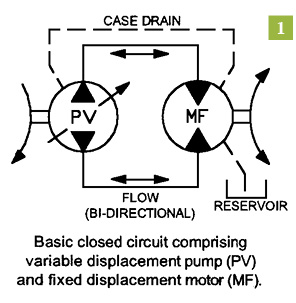

Background: Hydraulic motors have a volumetric efficiency of 90-98%. That means 2 - 10% of the flow entering the motor leaks internally into the case. This is intentional and vital for internal lubrication and clearance between mating pieces.If not allowed to escape, that leakage can build pressure inside the pump case, causing seal leaks or worse, cracks in the cast iron case. The main purpose of a case drain is to allow the internal leakage to escape, but there are other benefits too.

Alternatives: The motor below has a clever solution making the case drain "optional". Two smaller plugs on the rear of this internal gear motor are for check valves.

In the absence of a case drain line, these check valves allow fluid in the case to enter the low-pressure fluid stream. This allows leaked fluid and contamination to exit the motor via the drain line. That might explain why you have seen some hydraulic motors without case drains. However, in a reversing application, that heat and contamination returns to the motor when the direction is reversed.

With a case drain vented to tank, heat and contamination are sent to the reservoir, extending motor life. Even if the case drain port is located on the bottom of the motor, the case will remain filled if the reservoir is above the motor.

The system has three separate circuits, each with an axial-piston pump and a common reservoir. Case drain filtration was included to reduce the possibility of cross-contamination if a failure occured. The pump manufacturer led me to believe that although it isn’t the norm, if the pressure drop across the filter is kept to less than 30 PSI it will be all right. This forces filter maintenance.

Filters in a hydraulic system maintain fluid cleanliness at a level that maximizes component life. The appropriate cleanliness level is based on factors such as operating pressure and the internal clearances of components within a system.

Given that the objective of this process is to extend the service life of components in a system, it is imperative to understand that some filter locations can have the opposite effect.

The rationale for installing filters in piston pump and motor case drain lines is similar to the rationale for locating filtering media in the return line, meaning; if the reservoir and the fluid it contains start out clean and all air entering the reservoir and returning fluid is adequately filtered, fluid cleanliness will be maintained.

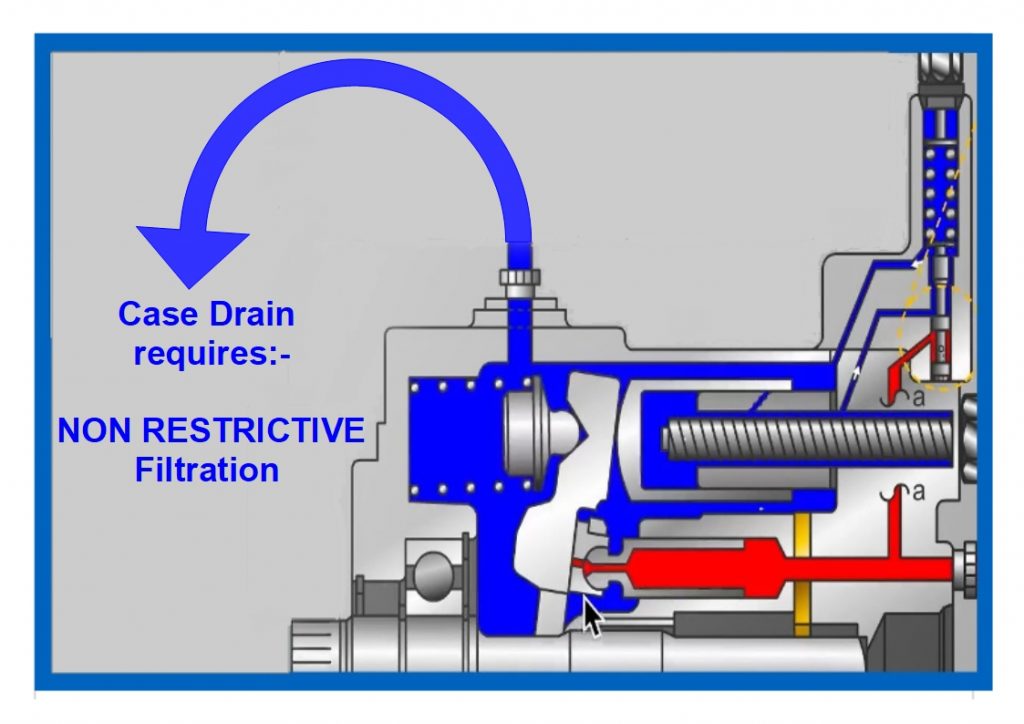

The main disadvantage of installing filters on piston pump or motor case drain lines is that the back pressure created by the element can cause failures. Drain line filters can cause excessive case pressure, resulting in seal failure and mechanical damage.

High case pressure results in excessive load on the lip of the shaft seal. This causes the seal lip to wear a groove in the shaft, eventually resulting in leakage past the seal. If case pressure exceeds the shaft seal’s design limits, instantaneous failure can occur. The subsequent loss of oil from the case may result in damage through inadequate lubrication.

The effect of high case pressure on axial piston pumps is similar to excessive vacuum at the pump inlet. Both conditions put the piston-ball and slipper-pad socket in tension during inlet (Figure 1). This causes buckling of the piston retaining plate and/or separation of the slipper from the piston, resulting in catastrophic failure.

High case pressure can cause the pistons of radial piston motors to be lifted off the cam. This occurs in operation during the outlet cycle. The pistons are then hammered back onto the cam during inlet, destroying the motor.

If residual case pressure remains high when the motor is stopped, loss of contact between the pistons and cam allows the motor to freewheel, resulting in uncontrolled machine movement.

I recently witnessed a situation where these problems occurred. I was asked to locate a replacement for a radial piston motor no longer in production. The motor in question was powering a winch on a barge working in an offshore oilfield. The situation was urgent because the downtime was costing the company $40,000 per day. When I inquired about the nature of the failure of the original motor, he reported the following symptoms:

On-site personnel had torn down the motor and sent photos back to the company’s onshore office. The photos of the motor internals showed no obvious failure, confirming my suspicions. I explained that the symptoms described were consistent with high case pressure, most likely as a result of a blocked or restricted case drain line. I later learned that a technician, who had recently completed a contamination control course, connected the motor case drain line back to the tank through the system’s return filter.

To avoid these problems, piston pump and motor case drain lines should be returned to the reservoir through dedicated penetrations. These penetrations must be higher than the unit’s case port and be connected to a drop-pipe inside the reservoir that extends below minimum fluid level.

Due to the reasons above, filters are not recommended on case drain lines. While this does allow a small percentage of fluid to return to the reservoir unfiltered, in most applications the contamination risk is low and can be effectively managed using oil analysis and other condition-based maintenance techniques.

The primary objective of contamination control is extending the service life of hydraulic components. Unfortunately, case drain filters can reduce the service life of piston pumps and motors, making their installation in pursuit of this objective a paradox.

Effective contamination control is achievable using alternative filter locations that do not compromise component reliability. However, if case drain filters are included in a system, precautions must be taken to ensure that damage is not caused to the components they were installed to protect.

If a filter is fitted to a piston pump or motor drain line, I recommend a 125-micron screen, grossly oversized for the maximum expected flow rate to ensure that pressure drop is minimized, even under the most adverse conditions.

The filter housing must incorporate a bypass valve with an opening pressure lower than the maximum allowable case pressure for the particular component (typically 5 to 15 PSIG). Installing a gauge or transducer upstream of the filter for monitoring case pressure is also advisable.

Brendan Casey has more than 20 years experience in the maintenance, repair and overhaul of mobile and industrial equipment. For more information on reducing the operating cost and increasing the...

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/07/2023 08:41 AM UTC

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/07/2023 08:41 AM UTC

A case drain is a specific component of a hydraulic system, its objective is to extend the life of a system and reduce time spent on repairs and maintenance.An unrestricted case-drain line is essential on a piston-type hydraulic motor, whether it has axial, radial or bent-axis design. Most skid steers rely on hydraulic systems to power their front loading arms.

Sometimes referred to as a ‘third line’,a case drain drains back the oil which has leaked past the primary seal, and in doing so, prevents pressure from building up against the outer seal.This oil is then returned to the tank or reservoir.

A case drain will have an in-line case drain filter to prevent contaminants from travelling from the hydraulic motor to the tank. Operating a skid steer without a case drain line could result in a full system failure as the shaft seal will be irreparably blown out, if not installed properly your hydraulic line will not work and in worst cases become damaged beyond repair.

A good case drain makes your hydraulic system more energy efficient and lowers the pressure on the tank, good general maintenance of your hydraulic system results in longer durability for your skid steer and attachments.

A case drain is made up of multiple elements whose materials vary, it’s important to know how to remove and disassemble the case drain in order to understand its function and materials. A case drain filter is contained within an aluminum canister.

To remove the filter make sure to plug the drain lines to avoid losing hydraulic fluid or introducing contamination into the system. Simply unscrew the hex nut to access the filter element.

You may be surprised to find that case drain filters are made from a metal, sintered bronze to be specific. To the naked eye, the sintered bronze looks like one solid piece of metal but is actually thousands of bronze spheres that have been sintered together. Sintering is a heat treatment, like welding or soldering, that imparts strength and integrity to a ‘powdered’ material.

Sintering can determine a filter’s porosity which affects what goes through the filter and what doesn’t. Once sintered, the filter is now porous enough to allow hydraulic fluid to flow through it, yet remains dense enough to capture contaminants like metal and rubber debris which will eventually lead to a total system failure if left unmaintained.

Filters in a hydraulic system maintain fluid cleanliness at a level that maximizes component life. The appropriate cleanliness level is based on factors such as operating pressure and the internal clearances of components within a system.

If your case drain filter is blocked, then the hydraulic pressure of the motor will increase severely which will eventually lead to a myriad of mechanical and hydraulic issues and even a total system failure. Seals can be blown allowing hydraulic fluid and lubricant to leak out and also allowing contaminants to make their way into the skid steer and damage it irreparably.

If the filter in your case drain is no longer bronze in colour and looks mucky or dirty we suggest that you replace it. If your case drain is blocked then its worth dissembling the other filters and drain on the hydraulic system to ensure they have remained clean. It’s highly discouraged to attempt to clean your case drain or its filter.

Even if you had power tools or a heavy duty wire brush you will only move more trapped solids into the filter, clogging it even further. Case drain replacements are cheap when compared to replacing your whole final drive. Case drain maintenance is a key part of maintaining the life of your skid steer, and is often overlooked.

The main disadvantage of installing a filter on your hydraulics system is that back pressure created by the filter can cause total system failure caused by excessive pressure on the case drain if installed improperly

In some cases, case drains are considered optional. The case drain line is for low volume flow to the tank. In theory, by installing a high-pressure shaft seal and two check valves then internal leakage is technically drained into the return line, which is the usual function of a case line.

It has generally been found that systems without case drains often result in failure due to shaft seal leaks. Case drain line installation can be tedious but will eradicate any problem relating to shaft seal leakage.

Oftentimes, if a vehicle doesn’t already have a case drain line fitted, the manufacturer will not necessarily outline the need for hydraulic fluid to be returned to the tank. If you want optimum reliability from your tank and hydraulics then fitting a case drain line is the way to go.

Case drain lines are a very specific component, its use is debated among hydraulics experts - some say you need a case drain and others suggest you don’t. Ultimately, understanding how a case drain works is fundamental to upholding your machines maintenance and making sure that your tools last for a long time.

Many system failures in hydraulics are caused by leaks from the tank. It’s important not to neglect your hydraulics system as it could put you, or your workers, at risk.

Once you know how case drain filters work and what their function is within the hydraulic system of a skid steer, then you can visit your mechanical professional and ask for their opinion on whether you need to install a case filter on your skid steer or not.

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain,

that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

Sizing case drain lines.Typically, hydraulic motors and pumps have hoses that run to a case drain in order to drain excess internal oil from the motor. Having a case drain usually requires running motors in series to avoid damage. If the case drain line is undersized on a hydraulic pump (piston),it can cause the pressure in the case to be too high. As the pump’s life depreciates, its volumetric efficiency will decrease, which in turn will increase leakage from the case drain line. If there is extreme case pressure, it can cause the piston shoe to lift off of the swash plate. This will cause damage that will force the pump to stop working. Go by the case drain port size or up-size it. It is important to make sure the case pressure is below the max rating, which, if necessary, can be adjusted at the case drain port size, or increase the size of the port. Case pressure can also become too high at:

Alleviate pump failure by mitigating caveated or aerated components.If air is allowed to enter the system, the aeration will produce erosive damage when passing through the pump. In addition, cavitation can cause insufficient pump inlet, which can damage the pump. Either of these conditions can be very destructive.

Aeration is caused by air entering the pump inlet and mixing with the fluid. Low pump pressure at the inlet will cause air bubbles to expand and, as the aerated fluid reaches the pressure side of the pump, the bubbles will disintegrate and implode which causes internal erosion of the system.

Similar to aeration, extreme vacuum in a component will cause cavitation, which allows vapor bubbles to form in the fluid, ultimately damaging the pump.

Either of these conditions will cause pump noise to go up. If the system is allowed to continue to operate the pump will eventually fail. To safeguard against this problem in the design phase any source of air must be contained and the potential of vacuum at the inlet must be alleviated.

If the proper size of the lines is not selected to handle a higher flow rate, unwanted heat will occur causing damage to motors or other hydraulic system components. When designing a hydraulic system valvesmust be selected and sized correctly, or flow will be restricted which can cause it to unseat. In addition, the filter must be sized correctly, or the bypass valve may open causing some of the fluid to be unfiltered or cause a flow surge that could collapse the element.

The control of pressure in a system is paramount in the design. Within hydraulic system components and their functions, pressure control valves are essential in preventing leaks or bursting of pipes, hoses or tubing. This is largely dependent on the proper selection of pressure control valves, which may include:

White House Products Ltd., one of the leading hydraulic gear pump suppliers, is familiar with the importance of monitoring case drain flow and offers some valuable tips for monitoring your hydraulic pump, lines, and overall system performance.

Monitoring the case drain flow in hydraulic piston pumps and motors is beneficial to determine the current state of the hydraulic pump and the status of fluid flow rates. This type of monitoring is considered to be preventative/predictive pump maintenance because you can see the conditions slowly start to degrade over time from continuous pump use. Without maintenance, the pump’s performance and pressure load capability will degrade; excessive wear due to particulate contamination is responsible for the vast majority of all hydraulic component failures.

In the past, it was common to just continue to run piston pumps & motors without any monitoring. Once the fluid degraded and the conditions become too poor to continue to operate the system, the pump was either replaced or rebuilt. Plus, the system was flushed. This often led to long downtimes while the work was being done.

Not to mention, the costs to replace/rebuild a pump and flush the hydraulic system are more expensive than case drain monitoring. Case drain monitoring allows the operator and maintenance technicians to determine the current flow rates and evaluate the pump without having to stop operations.

Once the flow rates start to drop below a percentage of the total expected pump output on the case drain monitor, maintenance technicians will know the pump needs to be serviced, by either rebuilding it or replacing it. Monitoring can also help prevent having to flush the system each time the pump is serviced.

If your case drain flow meter is properly sized, it should be easy to take readings and there should be minimal back pressure on the case of the pump or motor. When selecting a device, determine your application’s flow rate (one method is to calculate 10% of the pump’s total output and picking the closest flow range). When results don’t correspond to a specified range, rounding to the nearest one is helpful.

A case drain monitor can reveal abrupt changes in drain flow and can provide years of service. During installation, check manufacturers’ guidelines for the pump or motor to be certain that the maximum allowable case drain pressure, exceeds the back pressure exerted by the flow monitor. While monitoring pump performance, you can log the baseline flow from the pump case to reservoir and any changes at set time intervals. You’ll instantly know when maintenance or hydraulic pump replacement is required.

Order a hydraulic motor or complete hydraulic pump system from one of the most trusted hydraulic piston pump suppliers. We offer a full range of high-quality hydraulic components so you can have the most reliable hydraulic system possible. Also, find hydraulic diagnostic equipment including flowmeters and pressure gauges to help maximize the reliability of your hydraulic pump installation. For assistance in choosing the right case drain monitors for your hydraulic systems, do not hesitate to call White House Products, Ltd. at +44 (0) 1475 742500 today!

By installing a high-pressure shaft seal and two check valves as shown in the schematic diagram inset above, internal leakage is drained via the return line–something that’s not acceptable for a piston motor or pump!

So the presence of a high pressure shaft seal and check valves renders a dedicated external drain line optional. But not if reliability is the primary concern. Here’s one application example from the ‘coal face’:

“Part of a design modification we carried out to our fleet of drilling rigs required two, low speed, high torque (gerotor) motors being installed on the front of the drilling rig to turn a shaft that housed wire rope brushes to clean the spoil from the drill string. The early design was without case drains because the motors did not require it according to the specification. However after several failed motors due to leaking shaft seals, we installed external case drain lines. It meant quite a bit of extra work and materials (hoses, brackets, fittings etc.) to return the drain back to tank but since then the problem has been eliminated.”

This issue is one of many apparent conflicts in hydraulics between what is OK to do-according to the component manufacturer, and what is best for optimum reliability. Of course, there will always be exceptions to the rule. You may have a gerotor motor without an external drain line that has never leaked and doesn’t look likely to (and this is most probably because the hydraulic system it’s installed on has a low and stable return line pressure).

In other words, not installing a case drain line, even when it’s optional, can turn out to be a costly mistake. And to discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get “Six Costly Mistakes Most Hydraulics Users Make… And How You Can Avoid Them!” available for FREE download here.

?I get e-mails like this all the time. I never find time to read them. I decided to read Issue #30 and I couldn"t put it down. I"ll make time from now on.?

?I just love this newsletter. As a Hydraulics Instructor for Eaton, I make copies and distribute them to my students as I address various topics. Please keep "em coming.?

In this Shop Talk Blog post, we are going to discuss the answers to five very common questions about hydraulic motors: what is a case drain, how do hydraulic motors fail, what exactly is displacement, how are hydraulic motors rated, and how does a hydraulic motor differ from a final drive?

Some people may use the terms hydraulic motor and final drive interchangeably, but they aren"t exactly the same. A final drive usually refers to a hydraulic motor that has a speed-reducing

We"ve only covered five of the most common questions about hydraulic motors. If you have any hydraulic motor questions, why not mention them in the comments? We"d love to hear what kind of topics you"d like to have addressed in future blog posts.

is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to.

One way to troubleshoot a final drive that seems weak is to take a look at the rate of flow from the case drain line. In this Shop Talk Blog post, we are going to review the purpose of a case drain line, look at what case drain flow can tell us about a final drive, and then discuss how to estimate the case drain flow. We"ll finish up by looking at how to evaluate the case drain flow to determine if the problem is your final drive.

When a final drive is damaged or badly worn, however, there will be more internal leakage. This excessive leakage will negatively impact the performance of the final drive and can be the cause of a lack of power. If there is too much leakage, it can be detected by monitoring the flow from the case drain line.

If the rate of case drain flow is greater than it should be, then there is a good probability that you have a problem with that final drive. Examples of too much case drain flow would be flow that is greater on the “bad” side than the “good” side, more than what the manufacturer specifies, or more than a very slow rate of flow). If your final drive"s case drain flow is too much, it should be serviced before things get any worse. On the other hand, if the case drain flow is within normal parameters, then the problem is probably not going to be your final drive and you need to keep investigating.

Investing the case drain flow from a final drive or travel motor can help when troubleshooting what seems to be a weak final drive or travel motor. Just keep in mind that it"s important to investigate all the possibilities before deciding the cause is your final drive motor.

is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to.

Maintaining a proper oil temperature in a hydraulic system is essential for successful operation. High fluid temperatures can damage components and significantly alter the way the system performs, resulting in costly repairs and downtime.

Hot oil increases internal leakage in pumps and motors, causing the machine to operate more slowly. O-rings also harden at higher temperatures, leading to more leaks in the system.

Further, hydraulic fluid temperatures above 180°F (82°C) may damage seal compounds and accelerate oil degradation. Operators should avoid running a hydraulic system at temperatures above 180°F (82°C). Every 18-degree increase in temperature above 140°F cuts the oil life in half. Systems that operate at high temperatures can produce sludge and varnish, which result in damage to the hydraulic system and reduce efficiencies.

Pressure-compensating piston pumps are commonly used in industrial hydraulic systems. Tolerances allow for a small amount of oil to bypass, generating heat that is piped back to the reservoir through the case-drain line. There are many other reasons for heat generation in hydraulic components and systems; the inefficiency of the pump, friction in the pipes, joints, line fittings, and so on, are the major contributors to heat generation. The tolerances inside pumps and valves are generally in the ten-thousandths of an inch. These tolerances permit a small amount of oil to continuously bypass the internal components, causing the fluid temperature to rise.

Flow controls, proportional valves, and servo valves control the oil’s flow rate by causing a pressure loss as oil flows through the valves. This means that higher pressure exists at the valve’s inlet port than at its outlet port. Anytime oil flows from higher pressure to a lower pressure, it generates heat that is absorbed in the oil.

Gear pumps and motors generally do not have a case drain, but they do have internal leakage, which, by design, usually accumulates in a small cavity just before the shaft seal. Air-cooled compact heat exchangers can be used to address the heat in this area.

When a pump or motor is worn or damaged, internal leakage increases, and therefore the flow available to do useful work decreases. This means the hydraulic efficiency decreases and results in additional heat generation. Implementing a case-drain cooler can assist with maintaining a viscosity range at which your machinery operates most efficiently. System checks should be performed regularly to determine the amount of bypassing oil. The pump should be changed when the oil flow reaches 10% of the pump volume.

By introducing cooling into the system, efficiencies increase, resulting in less power consumption. In some cases, high oil temperatures that are reflected back to the drive motor lead to wasted electricity by forcing the drive motor to pull more current to operate the system.

Case-drain coolers are ideal for applications requiring minimal cooling. These coolers offer minimal mounting to reduce installation time, typically with horizontal and vertical options. The cooler mounts behind an existing TEFC motor, using the electric-motor fan airflow. Cooling flow is obtained from the case drain of the hydraulic machine and is then guided to the integrated electrical machine. Pressure losses in the electrical machine can be seen as negligible. The outgoing flow moves by gravity as long as the outlet and inlet ports are of adequate dimensions.

To select the best air oil cooler, provide as much information about the application as possible, including oil heat load in Btu/h or hp, oil flow rate in gpm, maximum inlet oil, and maximum ambient air temperatures during operation.

If the required heat dissipation is unknown, it can be estimated that 20% to 30% of the installed horsepower will be converted into heat load. Heat exchangers can be used to remove the excess heat in a hydraulic system. The implementation of a heat exchanger has many variables that need to be taken into account.

The heat exchanger and reservoir should be sized when a system is initially designed to remove the generated heat. The reservoir allows some of the heat to dissipate through the walls to the atmosphere. The heat exchangers should be sized to remove the balance of the heat. The heat exchanger needs to be maintained to ensure excess heat is removed. If an air-type heat exchanger is used, the cooler fins should be cleaned regularly. A degreaser may be necessary to clean the fins.

To ensure profitable and efficient success in a manufacturing operation, maintaining a proper oil temperature in all hydraulic systems is essential. High hydraulic-fluid temperatures can damage system components and significantly alter the way a hydraulic system performs, resulting in costly repairs and downtime.

The AKG Thermal Systems CD Series is designed to fit in tight spaces and conveniently mounts onto a power unit with limited envelope space. The narrow profile conditions and cools for a wide array of applications.

The AKG tube fin design offers more significant cooling and does not require a protective guard. This cooling setup is compact, low cost, and low flow with minimal heat removal.

You"ll often find case drain filters on skid steer loaders, compact track loaders, and mini-excavators -- especially with brands like Case and Bobcat. How important are those filters? And what happens if they get clogged?

In the context of final drive motors, a case drain line returns any internally leaked hydraulic fluid to the tank on your machine. And before we go any further, keep in mind that

seals on your drive motor start to leak, then grit, sand, and dirt can make their way into your final drive. And if your final drive experiences a catastrophic failure, there is going to be a significant amount of generated contamination that is released. And without a case drain filter, that contamination in your final drive can reach other parts of your hydraulic system. With no filter, a simple drive motor failure can become a very expensive hydraulic system failure.

If your machine has a case drain filter and you don"t replace it often enough, then the hydraulic fluid can"t pass through and pressure builds. And even though the case drain line is designed to be low-pressure, that pressure will get high. And high pressure is always going to look for the weakest point to make its escape.

In most instances, the weakest point in your drive motor will be the seals. The seals will start leaking fluid, and that affects performance and will lead to accelerated wear on key components. Leaking fluid will reduce the amount of lubrication available, which means components will start generating even more contamination.

Failed seals will only relieves the pressure so much. In the worst cases we"ve seen, the cover plate of your motor can split and even fly off at high speed. Obviously, none of this is good.

insideyour drive motor. The pressure can go so high that components get displaced. If you"ve got an axial piston final drive motor, the piston ball and shoes are going to be in tension because of the pressure. As that tension continues to build, the shoes can be pulled off. This will wreak havoc in your drive motor, and results in damage that cannot be repaired.

In a radial piston motor, the high pressure can cause the pistons to lift off the cam and then be hammered back into the cam. And if the pressure builds high enough, the pistons and cams can completely lose contact. The final drive motor then freewheels and you won"t be able to control the movement of your machine.

So how often should you replace case drain filters? Here at Final Drive Parts, we recommend that you replace them whenever you are replacing the other hydraulic filters. Adding this to your maintenance routine can save you thousands of dollars in totaled final drive motors.

8613371530291

8613371530291