what is a case drain on a hydraulic pump for sale

On most skidsteer and excavator Hydraulic systems, Hydraulic motors and pumps require a case drain line. Sometimes referred to as a third line, the case drain line will relieve any excess pressure and drain it back to your return line, then into the reservoir. Without a properly installed case drain,

that extra pressure could blow a seal or damage your hydraulic line. For higher flow motors or on piston and gear motors, a case drain line is always required. Although, no matter the size of your motor, a case drain is always a good idea as it will relieve the amount of pressure on your shaft seal, helping to prolong its life. A case drain line

Since most machines have a unique style of coupler, BaumaLight does not include a coupler on our case drain line, although they are available. If your skidsteer is not equipped with a case drain, then it can be field installed.

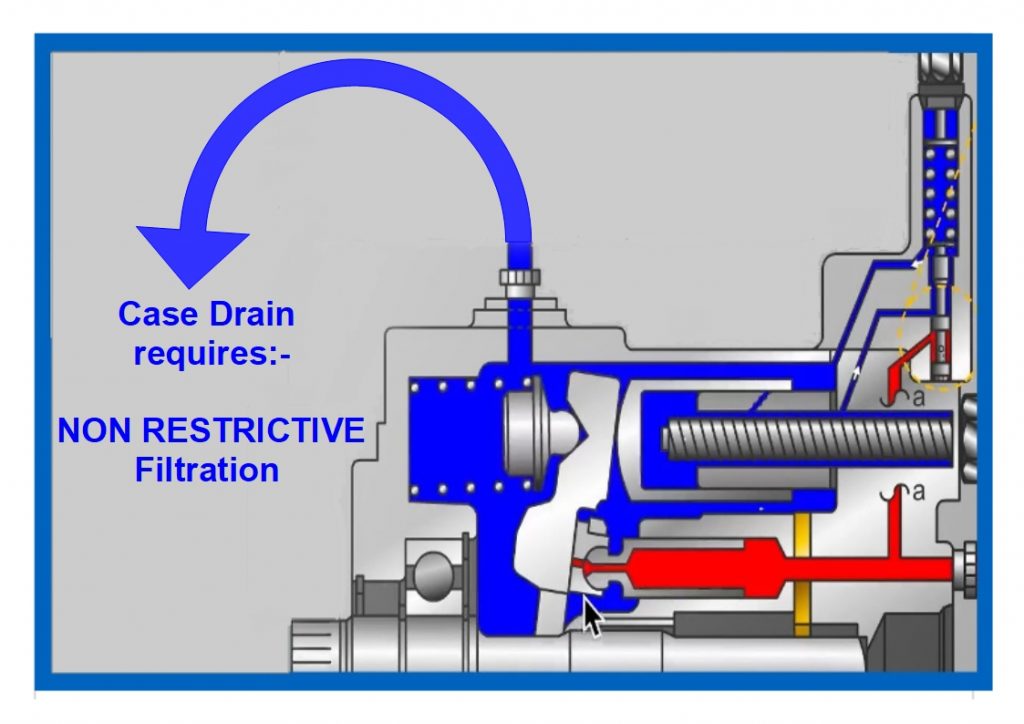

A case drain is a specific component of a hydraulic system, its objective is to extend the life of a system and reduce time spent on repairs and maintenance.An unrestricted case-drain line is essential on a piston-type hydraulic motor, whether it has axial, radial or bent-axis design. Most skid steers rely on hydraulic systems to power their front loading arms.

Sometimes referred to as a ‘third line’,a case drain drains back the oil which has leaked past the primary seal, and in doing so, prevents pressure from building up against the outer seal.This oil is then returned to the tank or reservoir.

A case drain will have an in-line case drain filter to prevent contaminants from travelling from the hydraulic motor to the tank. Operating a skid steer without a case drain line could result in a full system failure as the shaft seal will be irreparably blown out, if not installed properly your hydraulic line will not work and in worst cases become damaged beyond repair.

A good case drain makes your hydraulic system more energy efficient and lowers the pressure on the tank, good general maintenance of your hydraulic system results in longer durability for your skid steer and attachments.

A case drain is made up of multiple elements whose materials vary, it’s important to know how to remove and disassemble the case drain in order to understand its function and materials. A case drain filter is contained within an aluminum canister.

To remove the filter make sure to plug the drain lines to avoid losing hydraulic fluid or introducing contamination into the system. Simply unscrew the hex nut to access the filter element.

You may be surprised to find that case drain filters are made from a metal, sintered bronze to be specific. To the naked eye, the sintered bronze looks like one solid piece of metal but is actually thousands of bronze spheres that have been sintered together. Sintering is a heat treatment, like welding or soldering, that imparts strength and integrity to a ‘powdered’ material.

Sintering can determine a filter’s porosity which affects what goes through the filter and what doesn’t. Once sintered, the filter is now porous enough to allow hydraulic fluid to flow through it, yet remains dense enough to capture contaminants like metal and rubber debris which will eventually lead to a total system failure if left unmaintained.

Filters in a hydraulic system maintain fluid cleanliness at a level that maximizes component life. The appropriate cleanliness level is based on factors such as operating pressure and the internal clearances of components within a system.

If your case drain filter is blocked, then the hydraulic pressure of the motor will increase severely which will eventually lead to a myriad of mechanical and hydraulic issues and even a total system failure. Seals can be blown allowing hydraulic fluid and lubricant to leak out and also allowing contaminants to make their way into the skid steer and damage it irreparably.

If the filter in your case drain is no longer bronze in colour and looks mucky or dirty we suggest that you replace it. If your case drain is blocked then its worth dissembling the other filters and drain on the hydraulic system to ensure they have remained clean. It’s highly discouraged to attempt to clean your case drain or its filter.

Even if you had power tools or a heavy duty wire brush you will only move more trapped solids into the filter, clogging it even further. Case drain replacements are cheap when compared to replacing your whole final drive. Case drain maintenance is a key part of maintaining the life of your skid steer, and is often overlooked.

The main disadvantage of installing a filter on your hydraulics system is that back pressure created by the filter can cause total system failure caused by excessive pressure on the case drain if installed improperly

In some cases, case drains are considered optional. The case drain line is for low volume flow to the tank. In theory, by installing a high-pressure shaft seal and two check valves then internal leakage is technically drained into the return line, which is the usual function of a case line.

It has generally been found that systems without case drains often result in failure due to shaft seal leaks. Case drain line installation can be tedious but will eradicate any problem relating to shaft seal leakage.

Oftentimes, if a vehicle doesn’t already have a case drain line fitted, the manufacturer will not necessarily outline the need for hydraulic fluid to be returned to the tank. If you want optimum reliability from your tank and hydraulics then fitting a case drain line is the way to go.

Case drain lines are a very specific component, its use is debated among hydraulics experts - some say you need a case drain and others suggest you don’t. Ultimately, understanding how a case drain works is fundamental to upholding your machines maintenance and making sure that your tools last for a long time.

Many system failures in hydraulics are caused by leaks from the tank. It’s important not to neglect your hydraulics system as it could put you, or your workers, at risk.

Once you know how case drain filters work and what their function is within the hydraulic system of a skid steer, then you can visit your mechanical professional and ask for their opinion on whether you need to install a case filter on your skid steer or not.

Often in hydraulic systems, hydraulic motors and pumps run case drain hoses. The reason for this is to drain excess internal oil leakage from the motor. This is certainly critical in a piston motor and pump as the pistons have some internal leakage as they are actually just metal on metal. If no case drain hose is installed then the result will be, at the least, a blown shaft seal, and at worst, a split or damaged housing.

With gear pumps the leakage drains back into the suction hose internally, so no case drain is required. With gear motors and geroller/geroter motors, the oil can drain into the outlet port, however, that means that the oil pressure in the outlet port must not exceed the pressure rating of the seal. If it does, then a case drain needs to be installed. This will then usually mean you can run motors in series without damaging the motor.

If you require assistance with your hydraulic system, motors, pumps, hoses, seals, case drain, oil, lubricants or anything else for that matter, please give us a call on (03) 5382 0574 or call in and see us at Horsham Hydraulics, 84 GolfCourse

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/07/2023 05:40 AM UTC

www.powermotiontech.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 8bf2006c85a66667641f5dd58dcb3d35 63.210.148.230 03/07/2023 05:40 AM UTC

Sizing case drain lines.Typically, hydraulic motors and pumps have hoses that run to a case drain in order to drain excess internal oil from the motor. Having a case drain usually requires running motors in series to avoid damage. If the case drain line is undersized on a hydraulic pump (piston),it can cause the pressure in the case to be too high. As the pump’s life depreciates, its volumetric efficiency will decrease, which in turn will increase leakage from the case drain line. If there is extreme case pressure, it can cause the piston shoe to lift off of the swash plate. This will cause damage that will force the pump to stop working. Go by the case drain port size or up-size it. It is important to make sure the case pressure is below the max rating, which, if necessary, can be adjusted at the case drain port size, or increase the size of the port. Case pressure can also become too high at:

Alleviate pump failure by mitigating caveated or aerated components.If air is allowed to enter the system, the aeration will produce erosive damage when passing through the pump. In addition, cavitation can cause insufficient pump inlet, which can damage the pump. Either of these conditions can be very destructive.

Aeration is caused by air entering the pump inlet and mixing with the fluid. Low pump pressure at the inlet will cause air bubbles to expand and, as the aerated fluid reaches the pressure side of the pump, the bubbles will disintegrate and implode which causes internal erosion of the system.

Similar to aeration, extreme vacuum in a component will cause cavitation, which allows vapor bubbles to form in the fluid, ultimately damaging the pump.

Either of these conditions will cause pump noise to go up. If the system is allowed to continue to operate the pump will eventually fail. To safeguard against this problem in the design phase any source of air must be contained and the potential of vacuum at the inlet must be alleviated.

If the proper size of the lines is not selected to handle a higher flow rate, unwanted heat will occur causing damage to motors or other hydraulic system components. When designing a hydraulic system valvesmust be selected and sized correctly, or flow will be restricted which can cause it to unseat. In addition, the filter must be sized correctly, or the bypass valve may open causing some of the fluid to be unfiltered or cause a flow surge that could collapse the element.

The control of pressure in a system is paramount in the design. Within hydraulic system components and their functions, pressure control valves are essential in preventing leaks or bursting of pipes, hoses or tubing. This is largely dependent on the proper selection of pressure control valves, which may include:

White House Products Ltd., one of the leading hydraulic gear pump suppliers, is familiar with the importance of monitoring case drain flow and offers some valuable tips for monitoring your hydraulic pump, lines, and overall system performance.

Monitoring the case drain flow in hydraulic piston pumps and motors is beneficial to determine the current state of the hydraulic pump and the status of fluid flow rates. This type of monitoring is considered to be preventative/predictive pump maintenance because you can see the conditions slowly start to degrade over time from continuous pump use. Without maintenance, the pump’s performance and pressure load capability will degrade; excessive wear due to particulate contamination is responsible for the vast majority of all hydraulic component failures.

In the past, it was common to just continue to run piston pumps & motors without any monitoring. Once the fluid degraded and the conditions become too poor to continue to operate the system, the pump was either replaced or rebuilt. Plus, the system was flushed. This often led to long downtimes while the work was being done.

Not to mention, the costs to replace/rebuild a pump and flush the hydraulic system are more expensive than case drain monitoring. Case drain monitoring allows the operator and maintenance technicians to determine the current flow rates and evaluate the pump without having to stop operations.

Once the flow rates start to drop below a percentage of the total expected pump output on the case drain monitor, maintenance technicians will know the pump needs to be serviced, by either rebuilding it or replacing it. Monitoring can also help prevent having to flush the system each time the pump is serviced.

If your case drain flow meter is properly sized, it should be easy to take readings and there should be minimal back pressure on the case of the pump or motor. When selecting a device, determine your application’s flow rate (one method is to calculate 10% of the pump’s total output and picking the closest flow range). When results don’t correspond to a specified range, rounding to the nearest one is helpful.

A case drain monitor can reveal abrupt changes in drain flow and can provide years of service. During installation, check manufacturers’ guidelines for the pump or motor to be certain that the maximum allowable case drain pressure, exceeds the back pressure exerted by the flow monitor. While monitoring pump performance, you can log the baseline flow from the pump case to reservoir and any changes at set time intervals. You’ll instantly know when maintenance or hydraulic pump replacement is required.

Order a hydraulic motor or complete hydraulic pump system from one of the most trusted hydraulic piston pump suppliers. We offer a full range of high-quality hydraulic components so you can have the most reliable hydraulic system possible. Also, find hydraulic diagnostic equipment including flowmeters and pressure gauges to help maximize the reliability of your hydraulic pump installation. For assistance in choosing the right case drain monitors for your hydraulic systems, do not hesitate to call White House Products, Ltd. at +44 (0) 1475 742500 today!

This article is based on a basic circuit with single hydraulic internal gear motor. More complex circuits with multiple motors can have different solutions. Collaborate with your motor supplier for the best results for your particular design.

Background: Hydraulic motors have a volumetric efficiency of 90-98%. That means 2 - 10% of the flow entering the motor leaks internally into the case. This is intentional and vital for internal lubrication and clearance between mating pieces.If not allowed to escape, that leakage can build pressure inside the pump case, causing seal leaks or worse, cracks in the cast iron case. The main purpose of a case drain is to allow the internal leakage to escape, but there are other benefits too.

Alternatives: The motor below has a clever solution making the case drain "optional". Two smaller plugs on the rear of this internal gear motor are for check valves.

In the absence of a case drain line, these check valves allow fluid in the case to enter the low-pressure fluid stream. This allows leaked fluid and contamination to exit the motor via the drain line. That might explain why you have seen some hydraulic motors without case drains. However, in a reversing application, that heat and contamination returns to the motor when the direction is reversed.

With a case drain vented to tank, heat and contamination are sent to the reservoir, extending motor life. Even if the case drain port is located on the bottom of the motor, the case will remain filled if the reservoir is above the motor.

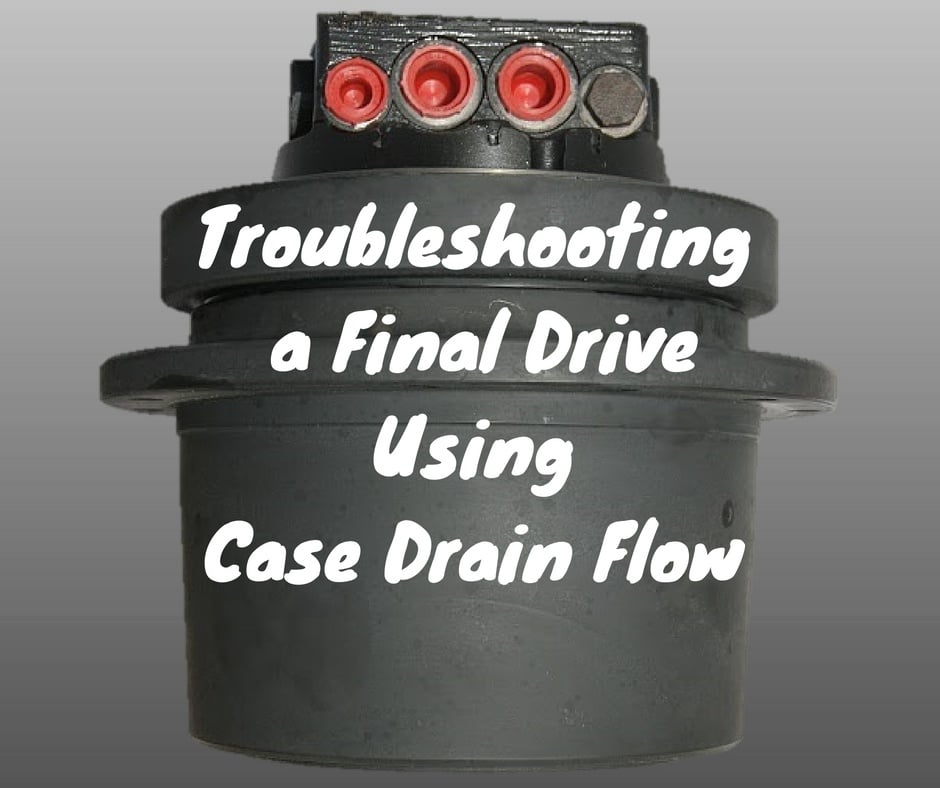

One way to troubleshoot a final drive that seems weak is to take a look at the rate of flow from the case drain line. In this Shop Talk Blog post, we are going to review the purpose of a case drain line, look at what case drain flow can tell us about a final drive, and then discuss how to estimate the case drain flow. We"ll finish up by looking at how to evaluate the case drain flow to determine if the problem is your final drive.

When a final drive is damaged or badly worn, however, there will be more internal leakage. This excessive leakage will negatively impact the performance of the final drive and can be the cause of a lack of power. If there is too much leakage, it can be detected by monitoring the flow from the case drain line.

If the rate of case drain flow is greater than it should be, then there is a good probability that you have a problem with that final drive. Examples of too much case drain flow would be flow that is greater on the “bad” side than the “good” side, more than what the manufacturer specifies, or more than a very slow rate of flow). If your final drive"s case drain flow is too much, it should be serviced before things get any worse. On the other hand, if the case drain flow is within normal parameters, then the problem is probably not going to be your final drive and you need to keep investigating.

Investing the case drain flow from a final drive or travel motor can help when troubleshooting what seems to be a weak final drive or travel motor. Just keep in mind that it"s important to investigate all the possibilities before deciding the cause is your final drive motor.

is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to.

You"ll often find case drain filters on skid steer loaders, compact track loaders, and mini-excavators -- especially with brands like Case and Bobcat. How important are those filters? And what happens if they get clogged?

In the context of final drive motors, a case drain line returns any internally leaked hydraulic fluid to the tank on your machine. And before we go any further, keep in mind that

seals on your drive motor start to leak, then grit, sand, and dirt can make their way into your final drive. And if your final drive experiences a catastrophic failure, there is going to be a significant amount of generated contamination that is released. And without a case drain filter, that contamination in your final drive can reach other parts of your hydraulic system. With no filter, a simple drive motor failure can become a very expensive hydraulic system failure.

If your machine has a case drain filter and you don"t replace it often enough, then the hydraulic fluid can"t pass through and pressure builds. And even though the case drain line is designed to be low-pressure, that pressure will get high. And high pressure is always going to look for the weakest point to make its escape.

In most instances, the weakest point in your drive motor will be the seals. The seals will start leaking fluid, and that affects performance and will lead to accelerated wear on key components. Leaking fluid will reduce the amount of lubrication available, which means components will start generating even more contamination.

Failed seals will only relieves the pressure so much. In the worst cases we"ve seen, the cover plate of your motor can split and even fly off at high speed. Obviously, none of this is good.

insideyour drive motor. The pressure can go so high that components get displaced. If you"ve got an axial piston final drive motor, the piston ball and shoes are going to be in tension because of the pressure. As that tension continues to build, the shoes can be pulled off. This will wreak havoc in your drive motor, and results in damage that cannot be repaired.

In a radial piston motor, the high pressure can cause the pistons to lift off the cam and then be hammered back into the cam. And if the pressure builds high enough, the pistons and cams can completely lose contact. The final drive motor then freewheels and you won"t be able to control the movement of your machine.

So how often should you replace case drain filters? Here at Final Drive Parts, we recommend that you replace them whenever you are replacing the other hydraulic filters. Adding this to your maintenance routine can save you thousands of dollars in totaled final drive motors.

About 90% of all final drives have a return line to the tank, and the case drain filter (aka the in-line filter) is located on that return line. Many drives have only one case drain filter for both motors, but some will have a separate case drain filter for each. The case drain filter is typically a silver canister-style filter with a golden-colored element on the inside. Its purpose is to filter out contaminants in the

hydraulic fluid pressure begins to build up higher and higher. Next, that highly pressurized hydraulic fluid blows the lower shaft seal (aka, oil seal), allowing the fluid to now flow into the gear section – still under tremendous pressure. With nowhere else to go, that high pressure fluid will force its way through the weakest link: the cover plate. The cover plate will either crack, blow off, or even skyrocket off. The figure below shows just such a damaged cover plate, which looks like it was torn apart.

You can imagine the kind of pressure it took to tear that cover plate apart — and you can also probably imagine the damage that occurred to the expensive seals and bearings inside that hub.

To prevent this type of failure, you need to make sure your case drain filter is clean. To locate the case drain filter, first look for the case drain line – it"s the small line next to your two in and out lines. As you follow the line, you"ll encounter the filter itself. The filter looks like an aluminum canister that is about 1 ¼" in diameter and between 3" and 3 ½" long. Remove the filter from the drain lines and be sure to plug the drain lines to avoid losing hydraulic fluid. A fully assembled case drain filter is shown below for reference.

sintered-bronze filter element and two springs holding the filter element in place. If the filter is no longer a bronze color, it needs to be replaced. Otherwise, you should be able to clean it and put it back in. The two figures below show a dirty filter that needs to be replaced, and a clean filter for comparison.

Just taking the time to check the case drain filter on a regular basis can save you thousands of dollars in repairs and alert you when something serious is going wrong inside your final drive.

In this Shop Talk Blog post, we are going to discuss the answers to five very common questions about hydraulic motors: what is a case drain, how do hydraulic motors fail, what exactly is displacement, how are hydraulic motors rated, and how does a hydraulic motor differ from a final drive?

Some people may use the terms hydraulic motor and final drive interchangeably, but they aren"t exactly the same. A final drive usually refers to a hydraulic motor that has a speed-reducing

We"ve only covered five of the most common questions about hydraulic motors. If you have any hydraulic motor questions, why not mention them in the comments? We"d love to hear what kind of topics you"d like to have addressed in future blog posts.

is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to.

Hydraulic pump and motor users have been faced with an ongoing dilemma… do I install filters on my case drains and risk causing major component damage? …. Or…

PumpMD™ (manufactured by IoT Diagnostics, serviced & distributed by Airline Hydraulics Corp.) provides critical first alerts for your workhorse axial piston pumps. This cost-effective sensor pack allows you to scale across your fleet of pumps and manage schedules around real-time performance data.

Whether you are in the shop, the office, or on the road, never miss a critical alert. Receive instant notifications on pump health (via text, email, and other notifications).

We can configure your PumpMD™ specifications, help place yourorder, or just answer your questions! Connect with an expert by submitting the form below.

string(741) "We understand the importance of quality brakes and supply a range with exceptional holding power for both wet and dry conditions, for a variety of applications and industries. Designed and built for the harshest conditions, our range of brakes are utilised on a arrange of equipment including loaders, cotton harvesters, oil rig equipment, cranes, serial work platforms and boom lifts. We supply multi-disc brakes and torque lock brake systems from leading manufacturers including Ausco and Fairfield. Our hydraulic brake range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic brake range please fill out a form, call or email us using the links below."

string(741) "We understand the importance of quality brakes and supply a range with exceptional holding power for both wet and dry conditions, for a variety of applications and industries. Designed and built for the harshest conditions, our range of brakes are utilised on a arrange of equipment including loaders, cotton harvesters, oil rig equipment, cranes, serial work platforms and boom lifts. We supply multi-disc brakes and torque lock brake systems from leading manufacturers including Ausco and Fairfield. Our hydraulic brake range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic brake range please fill out a form, call or email us using the links below."

string(673) "Coolers and heaters work to maintain an ideal working temperature of hydraulic fluid to prevent fluid damage or system failures. We source a range of hydraulic coolers and heaters from well-known suppliers including Olaer. Our range of Olaer coolers and heaters includes: Air/oil heat exchangers including LAC Series, LDC Series, LHC Series Water/oil heat exchangers including PWO Series Air/water coolers Our hydraulic coolers and heaters range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic coolers and heaters range please fill out a form, call or email us using the links below."

string(673) "Coolers and heaters work to maintain an ideal working temperature of hydraulic fluid to prevent fluid damage or system failures. We source a range of hydraulic coolers and heaters from well-known suppliers including Olaer. Our range of Olaer coolers and heaters includes: Air/oil heat exchangers including LAC Series, LDC Series, LHC Series Water/oil heat exchangers including PWO Series Air/water coolers Our hydraulic coolers and heaters range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic coolers and heaters range please fill out a form, call or email us using the links below."

string(884) "Hydraulic gearboxes are a reliable and effective solution for power transmission and motion control, suitable for many types of off-road, mobile vehicles and equipment. We source a complete range for light duty industrial automation applications from well-known brands such as Fairfield and Bonfigioli. Our range of Fairfield gearboxes includes: Torque-hub wheel drives Torque-hub shaft output drives Excel Series including 7000, 11000, 18000 Series Torque-hub planetary final drives including CT and CW Series Our range of Bonfiglioli gearboxes includes: Industrial gearboxes including 300 Series Multipurpose Gearbox Planetary gearboxes Our hydraulic gearbox range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic gearbox range please fill out a form, call or email us using the links below."

string(884) "Hydraulic gearboxes are a reliable and effective solution for power transmission and motion control, suitable for many types of off-road, mobile vehicles and equipment. We source a complete range for light duty industrial automation applications from well-known brands such as Fairfield and Bonfigioli. Our range of Fairfield gearboxes includes: Torque-hub wheel drives Torque-hub shaft output drives Excel Series including 7000, 11000, 18000 Series Torque-hub planetary final drives including CT and CW Series Our range of Bonfiglioli gearboxes includes: Industrial gearboxes including 300 Series Multipurpose Gearbox Planetary gearboxes Our hydraulic gearbox range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic gearbox range please fill out a form, call or email us using the links below."

string(722) "Berendsen sources a large selection of hydraulic hoses and fitting sizes such as braided, spiral and multi-purpose hydraulic hoses. These ultimate fluid conveyance solutions are equipped with wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities. We supply hydraulic hose, fittings, adapters, couplings and fluid connectors from well-known suppliers including Eaton Aeroquip. Our hydraulic hose and fitting range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic hose and fitting range please fill out a form, call or email us using the links below."

string(722) "Berendsen sources a large selection of hydraulic hoses and fitting sizes such as braided, spiral and multi-purpose hydraulic hoses. These ultimate fluid conveyance solutions are equipped with wide operating pressure ranges, optimal levels of abrasion resistance, long-lasting durability and high-performance transfer capabilities. We supply hydraulic hose, fittings, adapters, couplings and fluid connectors from well-known suppliers including Eaton Aeroquip. Our hydraulic hose and fitting range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic hose and fitting range please fill out a form, call or email us using the links below."

string(750) "Instrumentation and gauges are essential elements of hydraulic systems and include pressure gauges, pressure switches, flow meters, pressure sensors, temperature sensors, turbine flow meters, gear flow meters, speed sensor infrareds and mini test fittings and hoses. We source a large range of instrumentations and gauges from MP Filtri, Hystar and The Hydraulic Warehouse. Our range of MP Filtri instrumentation and gauges includes: ICM particle counter LPA2 particle counter Our instrumentation and gauges range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic instrumentation and gauges range please fill out a form, call or email us using the links below."

string(750) "Instrumentation and gauges are essential elements of hydraulic systems and include pressure gauges, pressure switches, flow meters, pressure sensors, temperature sensors, turbine flow meters, gear flow meters, speed sensor infrareds and mini test fittings and hoses. We source a large range of instrumentations and gauges from MP Filtri, Hystar and The Hydraulic Warehouse. Our range of MP Filtri instrumentation and gauges includes: ICM particle counter LPA2 particle counter Our instrumentation and gauges range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic instrumentation and gauges range please fill out a form, call or email us using the links below."

string(1167) "Manifolds regulate the fluid flow between pumps, actuators and other components in a hydraulic system, allowing the operator to control how much fluid flows between the different components. Berendsen is proud to have developed our own range of standard manifolds and custom designed and manufactured manifolds to meet the needs of a range of industrial applications. Our standard range of manifolds includes station manifolds, CETOP 3 manifolds, CETOP 5 manifolds and sub-plates. Custom Designed and Manufactured Manifolds Manufactured to the highest quality at our ISO certified manufacturing hub in Newcastle, our range includes steel, aluminium and stainless steel manifolds. Our world class CAD manifold design software and the latest technologies applied in our manufacturing process make us the first choice supplier of custom and standard manifolds. Click here for more information on our custom manifold manufacturing capabilities. Our manifold range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our manifold range please fill out a form, call or email us using the links below."

string(1167) "Manifolds regulate the fluid flow between pumps, actuators and other components in a hydraulic system, allowing the operator to control how much fluid flows between the different components. Berendsen is proud to have developed our own range of standard manifolds and custom designed and manufactured manifolds to meet the needs of a range of industrial applications. Our standard range of manifolds includes station manifolds, CETOP 3 manifolds, CETOP 5 manifolds and sub-plates. Custom Designed and Manufactured Manifolds Manufactured to the highest quality at our ISO certified manufacturing hub in Newcastle, our range includes steel, aluminium and stainless steel manifolds. Our world class CAD manifold design software and the latest technologies applied in our manufacturing process make us the first choice supplier of custom and standard manifolds. Click here for more information on our custom manifold manufacturing capabilities. Our manifold range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our manifold range please fill out a form, call or email us using the links below."

string(580) "Berendsen source pneumatic filters, valves and cylinders to assist in compressed air applications. These products are available to suit a variety of applications and are guaranteed to fit your system requirements. Our range of pneumatic filters, valves and cylinders are sourced from well-known brands including Norgren, SMC and Parker. Our pneumatic product range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our pneumatic product range please fill out a form, call or email us using the links below."

string(580) "Berendsen source pneumatic filters, valves and cylinders to assist in compressed air applications. These products are available to suit a variety of applications and are guaranteed to fit your system requirements. Our range of pneumatic filters, valves and cylinders are sourced from well-known brands including Norgren, SMC and Parker. Our pneumatic product range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our pneumatic product range please fill out a form, call or email us using the links below."

string(674) "Power steering products, such as control units, steering wheels, pumps and steering columns, assist with controlling and directing fluid pressure. Berendsen source innovative power steering pumps from Eaton Char-Lynn. Our range of Eaton Char-Lynn power steering products includes: Power steering pumps including the VTM Series Steering control units including Series 3, 6, 10, 12 and 20 Steering accessories including wheels and columns Our power steering range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our power steering range please fill out a form, call or email us using the links below."

string(674) "Power steering products, such as control units, steering wheels, pumps and steering columns, assist with controlling and directing fluid pressure. Berendsen source innovative power steering pumps from Eaton Char-Lynn. Our range of Eaton Char-Lynn power steering products includes: Power steering pumps including the VTM Series Steering control units including Series 3, 6, 10, 12 and 20 Steering accessories including wheels and columns Our power steering range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our power steering range please fill out a form, call or email us using the links below."

string(1324) "Hydraulic Power Units and Power Packs Hydraulic power units, also referred to as hydraulic power packs, are used to provide hydraulic power through liquid flow and pressure. Our hydraulic power units are suitable for applications such as mining, lubrication systems, industrial, defense, automotive, manufacturing, cardboard waste compactors, marine hook lock systems, agricultural, rotary dairies, grain stackers, produce sorting systems, emergency brake systems for cranes and personal lift systems. Berendsen is proud to supply both a standard range of power units and a custom designed and manufactured power units. Standard Power Units Our standard range of power units are supplied by The Hydraulic Warehouse (THW) and Eaton. Our standard range of THW power units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. The THW range of Power Units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. Each power unit can be built and tested within three working days. Custom Designed and Manufactured…"

string(1324) "Hydraulic Power Units and Power Packs Hydraulic power units, also referred to as hydraulic power packs, are used to provide hydraulic power through liquid flow and pressure. Our hydraulic power units are suitable for applications such as mining, lubrication systems, industrial, defense, automotive, manufacturing, cardboard waste compactors, marine hook lock systems, agricultural, rotary dairies, grain stackers, produce sorting systems, emergency brake systems for cranes and personal lift systems. Berendsen is proud to supply both a standard range of power units and a custom designed and manufactured power units. Standard Power Units Our standard range of power units are supplied by The Hydraulic Warehouse (THW) and Eaton. Our standard range of THW power units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. The THW range of Power Units are designed to power hydraulic actuators, including cylinders and motors. Available with a 50L, 100L or 200L tank, the range is ideal for hydraulic systems commonly found in a range of industrial applications. Each power unit can be built and tested within three working days. Custom Designed and Manufactured…"

string(857) "Tools and equipment are an essential part of hydraulic activity and include products such as general purpose cylinders, centre hole cylinders, double acting cylinders, high tonnage cylinders, hydraulic hand pumps, air hydraulic pumps, electric hydraulic pumps, high pressure hoses and quick couplers, sourced from SPX Power Team. Our tools and equipment range includes products such as: Electric operated pumps Pneumatic operated pumps Mechanical operated pumps Hoses Gauges Nut splitters Hydraulic punches Spreaders Jaw type pullers Push pullers Tire removers Hydraulic testers Torque wrenches Our hydraulic tools and equipment range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic tools and equipment, please fill out a form, call or email us using the links below."

string(857) "Tools and equipment are an essential part of hydraulic activity and include products such as general purpose cylinders, centre hole cylinders, double acting cylinders, high tonnage cylinders, hydraulic hand pumps, air hydraulic pumps, electric hydraulic pumps, high pressure hoses and quick couplers, sourced from SPX Power Team. Our tools and equipment range includes products such as: Electric operated pumps Pneumatic operated pumps Mechanical operated pumps Hoses Gauges Nut splitters Hydraulic punches Spreaders Jaw type pullers Push pullers Tire removers Hydraulic testers Torque wrenches Our hydraulic tools and equipment range is currently not available to purchase through our online shop. For product information, pricing and availability regarding our hydraulic tools and equipment, please fill out a form, call or email us using the links below."

8613371530291

8613371530291