what is pto hydraulic pump pricelist

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

There are hydraulic piston pump tractors, in which the soil is filled with piston pump tractors are divided into two types. Firstly, the piston hydraulic pump tractors are divided into two types, one of them is the piston hydraulic piston tractors.

There is a piston hydraulic tractor, which is powered by a piston hydraulic tractor and is also called the piston hydraulic tractor. A pto hydraulic tractor is divided in three types, one of them is the piston hydraulic tractor, and the other is the piston hydraulic tractor. It has a series of piston hydraulic tractor and can be divided into two types.

A hydraulic pump tractor is used to work on a soil or is a multi-purpose tractor that is used to work on construction sites. There are many types of tractor for sale online at affordable prices on Alibaba.com. Choose from a hydraulic pump tractor for sale at affordable prices!

A hydraulic pump tractor, also known as a pto pump tractor, is a tractor that uses hydraulic pressure to force concrete or pipes. It is a called hydraulic pump tractor, and a tractor that uses hydraulic pressure to force pipes on a tractor, is a type of tractor, and a tractor that uses hydraulic pressure in order to run concrete. It works like hydraulic piston pump, a hydraulic pump tractor, or a tractor that uses hydraulic pressure system to control water pressure. However, it is also called a pto pump tractor, and a tractor, is a tractor that uses hydraulic pressure in order to run concrete.

This brand new Italian-made P.T.O (Power Take Of) comprises a 3:1 speed increase Gearbox and Hydraulic Gear Pump. It is ideal for adding Hydraulic power to tractors and landscape equipment that are not already equipped with hydraulic circuits.

Used to power hydraulic Auger, front-end loaders, mowers, rotary sweepers, Post Hole Borers, and Post Drivers. These gearboxes are used mainly for connecting to the power output shaft at the rear of the tractor to drive hydraulic pumps to generate fluid power.

The standardized tractor PTO output of either 540 (turns into 1620 Rpm) or 1,000 rpm, is, in this way, increased to optimum operating speeds for the hydraulic pumps.

This gearbox and pump offer either direct or remote mounting options to the tractor P.T.O to provide independent hydraulic service. This gearbox is rated to provide up to 20 KW or 27 HP to the hydraulic gear pump. This figure is nothing to do with your engine horsepower

This comes with standard Female 1-3/8" 6 splined shafts generic to most PTO output shafts. (photos) If your shaft has " grooves", there is an Optional Shaft "Quick release" coupler available for an extra $40.

Please see the last photo which shows the "groove" in the PTO shaft which fits the "Quick" release. Also available at no extra cost is a Male shaft. There is the option of a few other couplers so feel free to ask or send photos for confirmation

This step-up gearbox has a ratio of 3:1 which means, if your PTO is spinning at 540 RPM, it will step up the speed to 1620 RPM. There are a variety of pump sizes to choose from, please see the options next to the photos. All are the same price.|The main considerations in choosing the correct size pump for your application, is the amount of flow required & the pressure required. As the need for higher pressure (PSI) is increased, the power required to produce this pressure rises.

It is easy to pump fluid at a high flow rate if low psi pressure is required, but it takes a lot of HP to pump high flow rates at a high PSI. Please refer to our chart below, & feel free to message or call with any queries.

Please take careful note of the flow & pressures in the chart below. This unit is rated for up to 10Kw hydraulic power only. If you require more flow & higher PSI, please see our other size gearboxes/pumps in the agricultural category of our store.

Brand new cast iron made P.T.O gearbox is ideal for adding hydraulic power to tractors and landscape equipment not already equipped with hydraulic circuits, or in need of auxiliary hydraulics. Used to power hydraulic Auger, front-end loaders, mowers, rotary sweepers, etc. These gearboxes are used mainly for connecting hydraulic pumps to the power take-offs of agricultural tractors. It is powerful enough to transfer the load of 100 LPM @ 2850 psi. Please note the last photo is of the gearbox fitted with a Vivoil Group 3 pump. This pump is not included in this sale, it is purely to show how this looks once you mount a pump.

These PTO speed increases can be used with either a Group 2 DIN mount pump, or a Group 3 DIN mount pump. See other listings for a PTO Speed increaser complete with a pump. This listing is just the speed increase box with a pump shaft spline adapter. If you supply your own pump, it needs to be CW, clockwise rotation.

If running your PTO at ; 540 RPM x 3 = 1620 RPM . Then multiply the pump CCs. ie. 39cc x 1620 = 63180ccm / 1000 = 63LPM Please allow for approx 20% pump inefficiency, so if after 60LPM, go up to 43cc pump, 1620 x 43 =69LPM less 20% = 56 PM

The standardized PTO output of 540 Rpm is, in this way, increased x 3:1 to optimum operating speeds for the hydraulic pumps. This gearbox and pump offer either direct or remote mounting options to the tractor P.T.O to provide independent hydraulic service. This gearbox itself is rated to provide up to 37 KW or 50 HP to the hydraulic gear pump. This figure is nothing to do with your engine horsepower, only the power the gearbox is able to transfer to the hydraulic pump(see chart below) Female or Male shafts are the same prices.

This comes with standard Female 1-3/8" 6 splined shafts generic to most PTO output shafts. This step-up gearbox has a ratio of 3:1 which means, if your PTO is spinning at 540 RPM, it will step up the speed to 1620 RPM.

The main considerations in choosing the correct size pump for your application; are the amount of Flow required & the pressure required. As the need for higher pressure (PSI) is increased, the power required to produce this pressure rises. It is easy to pump fluid at a high flow rate if low psi is required, but it takes a lot of HP to pump high flow rates at a high PSI.

PTO driven pumps for use with tractors equipped with power take off (PTO) hookups. PTO pumps are made for 540 RPM or 1000 RPM use depending on the model. PTO driven sprayer pumps come in roller pump, hydraulic roller pump and centrifugal pump models. PTO hookup pumps are commonly used with boom sprayers and boomless nozzle systems. They are approved for use with performance and maintenance chemicals for fields, pastures, crops and livestock. Use them with fertilizers, pesticides, fungicides and herbicides. Common applications include crop care, treating livestock for pests, weed killers, treating rights-of-way, and landscaping.

PTO driven roller pumps are built by Pentair Hypro® and manufactured from cast iron, Ni-Resist or Silvercast. Cast iron roller pumps are a cost effective option great for many applications. Ni-Resist versus cast iron roller pumps are more resistant with a longer service life. Silvercast roller pumps provide the greatest corrosion resistance, versatility and work life. Roller pumps come in 4 roller, 5 roller, 6 roller, 7 roller and 8 roller designs with greater number of rollers providing greater output in pump pressure and flow capacity. Gallons per minute (GPM) flow rate maximums range from 7.2 GPM up to 62 GPM. Output pressure maximums range from 150 PSI to 300 PSI. Available pump inlet, outlet sizes include 3/4", 1", 1 1/4", and 1 1/2" NPT.

PTO drive centrifugal pumps are manufactured by ACE Pumps. They are built with a cast iron pump housing, Valox® impeller, stainless steel shaft and wear ring, and Viton® carbon/ceramic seal. 540 RPM and 1000 RPM models are available that feature a spring loaded idler to absorb the shock from PTO engagement. 540 RPM centrifugal pumps come with a standard 6 spline by 1-3/8” (34.9mm) shaft. 1000 RPM pumps come with a 20 spline 1-3/4” (44.5mm) split bore shaft with locking collar. PTO pumps are also available with 1” (25.4mm) stub shaft for installation on trailer sprayers driven by PTO tumblerod. Gallons per minute (GPM) flow rate maximums range from 65 GPM up to 100 GPM. Output pressure maximums range from 80 PSI to 110 PSI. Available pump inlet, outlet sizes for ACE Pumps® brand include 1 1/2" x 1 1/4", 1" 1/4 x 1", 1" x 1 1/2" NPT for suction and discharge. Flange type 220 x 200 suction discharge models also available.

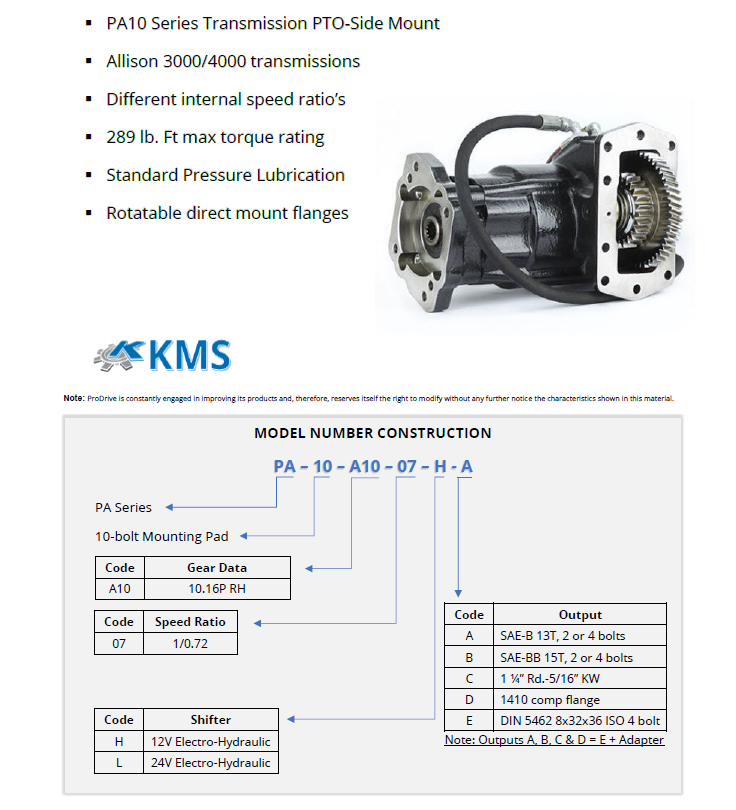

This range of hot shift AISIN PTO Pumps offers the best and most cost efficient solution for the 6-bolt and 10-bolt PTO openning of Allison automatic 1000, 2000, 3000, 4000 and AISIN A465 transmissions on ISUZU, HINO and DODGE trucks. With its rotatable direct mount flanges and different speed ratio’s, it is the most durable AISIN PTO Pump for automatic transmissions.

APPLICATIONS: Combined with any of our wide range of hydraulic pumps, dump pumps, gear pumps or bent axis piston pumps, it can power your hydraulic wetline or equipment on dump trucks, dump trailer, end dumps, live bottoms, shuttle floor, float, walking floors and combo systems.

Aisin automatic transmissions are manufactured by Aisin Seiki and Aisin AW, formerly known as Aisin-Warner, and which was established in 1969 as a joint venture between Aisin Seiki and BorgWarner. The joint venture terminated in 1987. While Aisin Seiki manufactures a variety of automotive components including automatic transmissions for heavy duty vehicle applications, Aisin AW manufactures automatic transmissions for light vehicle applications, including hybrid electric vehicle powertrains, as well as NAV Radio.

As of 2005, Aisin AW surpassed General Motors Powertrain Division as the largest producer of automatic transmissions in the world, producing 4.9 million units, with a market share of 16.4% of the global market for automatics.Toyota Motor Corporation and Aisin Seiki are the two major shareholders of Aisin AW, with 51.9% and 42% respectively.Toyota A transmission for a complete list of Toyota/Aisin models. Aisin AW supplies automatic transmissions to 55 automotive manufacturers around the world,

PTO driven pumps for use with tractors equipped with power take off (PTO) hookups. PTO pumps are made for 540 RPM or 1000 RPM use depending on the model. PTO driven sprayer pumps come in roller pump, hydraulic roller pump and centrifugal pump models. PTO hookup pumps are commonly used with boom sprayers and boomless nozzle systems. They are approved for use with performance and maintenance chemicals for fields, pastures, crops and livestock. Use them with fertilizers, pesticides, fungicides and herbicides. Common applications include crop care, treating livestock for pests, weed killers, treating rights-of-way, and landscaping.

PTO driven roller pumps are built by Pentair Hypro® and manufactured from cast iron, Ni-Resist or Silvercast. Cast iron roller pumps are a cost effective option great for many applications. Ni-Resist versus cast iron roller pumps are more resistant with a longer service life. Silvercast roller pumps provide the greatest corrosion resistance, versatility and work life. Roller pumps come in 4 roller, 5 roller, 6 roller, 7 roller and 8 roller designs with greater number of rollers providing greater output in pump pressure and flow capacity. Gallons per minute (GPM) flow rate maximums range from 7.2 GPM up to 62 GPM. Output pressure maximums range from 150 PSI to 300 PSI. Available pump inlet, outlet sizes include 3/4", 1", 1 1/4", and 1 1/2" NPT.

PTO drive centrifugal pumps are manufactured by ACE Pumps. They are built with a cast iron pump housing, Valox® impeller, stainless steel shaft and wear ring, and Viton® carbon/ceramic seal. 540 RPM and 1000 RPM models are available that feature a spring loaded idler to absorb the shock from PTO engagement. 540 RPM centrifugal pumps come with a standard 6 spline by 1-3/8” (34.9mm) shaft. 1000 RPM pumps come with a 20 spline 1-3/4” (44.5mm) split bore shaft with locking collar. PTO pumps are also available with 1” (25.4mm) stub shaft for installation on trailer sprayers driven by PTO tumblerod. Gallons per minute (GPM) flow rate maximums range from 65 GPM up to 100 GPM. Output pressure maximums range from 80 PSI to 110 PSI. Available pump inlet, outlet sizes for ACE Pumps® brand include 1 1/2" x 1 1/4", 1" 1/4 x 1", 1" x 1 1/2" NPT for suction and discharge. Flange type 220 x 200 suction discharge models also available.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

I own a Kubota 7500 with a Woods 6500 backhoe using the tractors auxiliary hydraulics which produces 4.4 gals/min. I was reading the Woods owners manual (after 3yrs) and Woods recommended using a Aux. pump which produces 6gals/min. I believe my set up works fine, not having any lack of power but a 25% increase nice. My question is what could I expect to pay for the pump, is the cost worth it?

I have been away for a while (with a new camper) and see the site has changed it format, and is still a great place for information. BTY if you guys/gals need trailer advice RV.net Open Road Form is another great place for information. Like this site my wife thinks I"m married to the computer.

The web site now stores cookies on your computer. You may restrict this to using only some of them or none, however you may not be able to use certain features of the web site including but not limited to: log in, buy products, see personalized content, switch between site cultures.

PRINCE PTO HYDRAULIC PUMPS Up to 40 gallons per minute and up to 2250 psi UNIQUE FEATURES: PLUS STANDARD FEATURES: • Self-adjusting wear plates on both sides of the gears. • Proper size hose adapters are provided for inlet ports. • Two outlet ports are provided with a NPT adapter for one port and a plug to seal unused port. • Center section available in high strength aluminum alloy for std. duty cycle or in high strength cast iron for high duty cycle use. • Tractor front end loaders • Pull-type cotton pickers • Cotton balers (module builders) • Reliable • Efficient • Roller Bearings • Run fitted body • Internally splined drive shaft. • High-tensile cast iron end plates. • Slips onto tractor PTO shaft (no gear box required). • Two-bolt installation on farm tractors of all sizes. • Tractors imported without integral hydraulics • Landscape equipment • Rotary mowers • Street Sweepers • Back hoes MODEL FEATURES ALUMINUM CENTER HOUSING • Standard duty cycle • Reduced weight • Smaller housing CAST IRON CENTER HOUSING • High duty cycle • Use in circuits with motors • Better at higher temperatures • Increased wear resistance REAR PORTED • Higher flows • Simplified hose connections • Higher flows at reduced engine rpm as compared to other PTO pumps Prince PTO pumps are specifically designed for PTO drive operation on all sizes of farm tractors. No additional gear box is required. Pumps are mounted by sliding the internally splined pump onto the PTO splined shaft and restraining rotation with a torque arm. See page P6 for the PTO pump torque arm kit. • FILTRATION The pump must be used in a clean system with clean oil. The fluid cleanliness should meet the ISO 4406 17/14 level. As a minimum, 10 micron filtration is recommended. • HYDRAULIC FLUID A good quality mineral base hydraulic fluid with a viscosity in the 70-250 SUS range at operating temperature is recommended. • OPERATING TEMPERATURE Oil operating temperature should not exceed 180°F. If it does, the reservoir may be too small or a heat exchanger may be needed. • SHAFT SPEEDS Prince PTO pumps are designed to operate at up to 110% of standard PTO shaft speeds. Standard speeds are 540 rpm for the 6 tooth shaft and 1000 rpm for the 21 tooth shaft. CATP 3-01-20-01 • CLOSE RUNNING CLEARANCE FOR HIGH FLOW RATE Another feature that contributes to the excellent and long-lived efficiency of the PTO-Series pump is the minimum clearance between the gears and the center housing. Each pump is assembled with zero clearance between the housing and the tips of the gear teeth, then test run until the teeth establish a proper wear path in the housing. The result is a much tighter clearance than found in traditional pumps. • PRESSURE RATING Pumps are designed for 2250 PSI max. relief valve setting. A relief valve, external to the pump, must be provided in the system. • PORTS All pumps are provided with an inlet port adapter (SAE O-ring boss to hose barb) and outlet port adapter (SAE O-ring boss to female pipe thread) sized appropriately for the ports and required line sizes. A steel plug is provided for the second outlet port. • RESERVOIR As a guideline, a reservoir size in gallons should equal the pump output in gallons per minute. A larger reservoir and/or an oil cooler may be needed for high duty cycle applications. PRINCE MANUFACTURING CORPORATION/WORLD HEADQUARTERS • NORTH SIOUX CITY, SOUTH DAKOTA 57049 URL: www.princehyd.com • E-MAIL: prince@princehyd.com O.E.M. CUSTOMER SERVICE: (605) 235-1220 • FAX (712) 233-2181 DISTRIBUTOR CUSTOMER SERVICE: PHONE (605) 235-1220 • FAX (712) 233-2181 • SELF ADJUSTING WEAR PLATES Prince PTO pumps have self-adjusting wear plates that seal around the two unequal size gears. T

PTO is one of the most critical components in the truck hydraulic system. It is accountable for transferring mechanical energy from the hydraulic pump to auxiliary parts for executing given applications. However, a slight issue with the truck PTO hydraulic pump can cause system failure resulting in loss of revenue.

If you"re noticing whining or high-pitched sound – it could be because PTO"s gears are not appropriately merged or being too tight, issues with bearings or hydraulics. However, the clattering sound indicates that gears are too loose or have torsional vibrations.

In general, PTO hydraulic pump"s engagement issues could cause due to blocked hoses or bad fittings, connections, or the solenoid. In addition, mechanical engagement could generate from low air pressure, backlash too tight or improper cable deployment.

Once identifying the symptoms, it needs to operate rightly to enhance the vehicle"s life. Routine and scheduled maintenance is essential to ensure the PTO tool functions trouble-free. In this blog, we"ve outlined the maintenance steps for helping the end-users.

Before starting maintenance tasks, you should stop the vehicle, and the engine must be off, the wheels chalked, and a vehicle parked in a safe place. That"s because working under rotating elements is very dangerous. Opting for safe practices and adhering to all safety warnings eventually help avoid mishaps.

The PTO maintenance is divided primarily into three stages. The initial stage, short-term and system stages. The maintenance process needs adequate planning, operational expertise and thorough system knowledge. So, keep that in mind before the initiation of the process of vehicle maintenance.

The first step should be carried out within 24 to 48 hours of use or after experiencing symptoms of PTO hydraulic system damage. It would be best to analyse drive train sound if it seems louder than usual – it means further investigation may be required.

Further in the process, after cooling down the engine, look for potential damage such as leaks. These leaks could impact the transmission fluid level and affect the system performance over time. The PTOs must be checked within a week of installation for making sure that its mounting bolts have been torqued appropriately.

After the initial check-up, the truck operator needs to think about the next maintenance schedule based on the duty cycle. Usually, the duty cycles are divided into normal or severe duties. When the PTO operates five minutes extra out of every 15 minutes, it is defined as a severe duty. Lower than that compared as a normal duty. You can choose which duty cycle is ideal for long-term maintenance based on PTO performance.

The more complex a truck PTO hydraulic pump works, the more it needs to be inspected. Based on previous maintenance, the normal duty cycle inspects which items need replacement, checks the fluid level, or verifies that the equipment is tight and secure.

Long-term PTO maintenance is essential, suggested by vehicle manufacturers. It can help improve the performance of the hydraulic pump. Check fasteners are torqued rightly, and no fluid is leaking around the seal. If you find any leak source, seals need replacement.

Keeping the vehicle in optimal condition and PTO functioning requires periodic maintenance. When regular maintenance is carried out on the vehicle chassis (frame), it will be good to inspect the PTO of the hydraulic system.

During a weekly or monthly maintenance schedule, along with other components, PTO is checked for cleaned shaft proper lubrication. The application of lube simplifies parts engagement and disengagement issues. Applying an anti-seize grease helps smoothen parts movement in high-temperature cases. Also, make sure to clean off the grease fitting once the lube is applied.

In regular maintenance, timely inspections are also essential to determine whether the parts are running as expected. Here is what you can do with the help of experts.

Visual Inspection – To make the equipment run smoothly, the PTO inspection needs to be performed weekly or monthly. The inspections include checking for leaks, wear or tear, making sure the hose and wire are not rubbing against the transmission. Through visual inspections, you can prevent many issues immediately.

Physical Inspection –When it comes to checking the condition of PTO – physical inspection is equally important. It is suggested to perform after 100 hours of use. If you have removed the PTO from the hydraulic system for inspection, check the wear patterns and bearings. The periodic physical inspection could reduce the amount of downtime and expenses.

Surya Truck Parts – Your Trusted Online Supplier for Heavy Truck PartsWe are one of the best market leaders in Power Take-Off (PTO) products for the truck and mobile vocational markets. We are an establishedsupplier,having years of experience serving customers with the best and most affordable products.

We offer a complete range of PTO hydraulic system parts to match your needs. At Surya Trucks, you can enjoy cost benefits and get crucial components like PTO wet kit for sale.

Road planers, dredges, and other equipment require power from some type of engine to perform their designed function. Without a power take-off, it would be necessary to add a second engine to provide the power required to run hydraulic pumps and other driveline attached equipment.

Adding an additional engine is simply not practical, which makes power take-off (PTO) a valuable element in providing power to secondary functions. To recognize their value requires a better understanding of these systems, their various types, and their diverse applications.

Power take-offs allow mobile crushing plants, road milling machines, and other vehicles to perform auxiliary functions without needing an additional engine to power them. A PTO is a device (a mechanism) usually seated on the flywheel housing, which transfers power from the driveline (engine) to a secondary application. In most cases, this power transfer applies to a secondary shaft that drives a hydraulic pump, generator, air compressor, pneumatic blower, or vacuum pump.

PTO choice is critical to provide sufficient power to the auxiliary equipment without severely limiting the main function of the prime mover. Selection of a power take-off requires specific information relating to the application and the power needs of the secondary or driven component.

Speed and rotation requirements of a PTO are among the most critical specifications in the list above, with speed being necessary for calculating torque. The torque and horsepower requirements of the driven component are essential for optimal performance.

In most cases, the owner’s manual of the driven component will provide this information, but the calculation of these requirements, if necessary, is relatively straightforward using two basic formulas.

Keep in mind that these calculations only apply to PTOs that drives a hydraulic pump. In cases where power take-off is providing power to a different type of drive component, it will require the manufacturer’s specifications of the driven element.

Though they perform the same general function—transferring power from the primary drive shaft to a secondary drive shaft for a driven component—there are various PTO types available that serve specific industrial applications. These diversifications are why WPT Power supplies OEM’s units in agricultural, energy, forestry, and road building sectors, among others.

The distinguishing characteristic of this type of PTO is the intentional removal of the pilot bearing. Benefits of this design feature come with an increased side load capacity, reduced inventory, increased uptime and engine life, and a quicker and easier installation. Industrial applications of the Pilotless Mechanical PTO include:

This type of flywheel PTO applies to either inline or sideload uses. It includes a sealed-for-life pilot bearing, utilizing a lever-actuated manual clutch. The benefit of this type of PTO is a straightforward installation which minimizes downtime and maintenance requirements. This type most commonly applies to:

This is a rugged, high-capacity power take off used in a broad range of industrial functions. Characteristic of this type of PTO are the sheaves between heavy-duty spherical roller bearings designed to utilize their full load potential. This bearing arrangement reduces the damage produced by crankshaft loading. Among the most common applications for the Type 1 PTO are:

The design of the Type 2 PTO features a heavy-duty side loading capacity using sizeable spherical roller bearings. Actuation of this PTO can be either hydraulic or pneumatic. It is self-adjusting and removes the need for the pilot bearing inside the engine flywheel. Features include reduced maintenance, less chance of premature failures, and improved engine and bearing life since there is no direct loading to the crankshaft. Common applications for Type 2 PTOs include:

This PTO design eliminates the need for the pilot bearing while providing increased side loading or inline potential. Its engineering accommodates the most demanding requirements of high-loading diesel engines. Features include simple installation, reduced downtime, and improved engine service life. This style of PTO is used on inline applications with its hydraulic and air fittings. They are mounted near the bell housing instead of at the rear of the shaft like type 1 and type 2.

The GM Style PTO reduces maintenance time and cost by using sealed main bearings and eliminating the need for the pilot bearing. Designed to mount directly to GM® style engines, these operate without the need for any particular PTO or engine adaptations. Notable features include clutch adjustments using an external ball stud and jam nut adjustment points.

Also known as “flat-faced” style PTOs, they incorporate similar design characteristics, features, and benefits of the GM style PTO. It is a spring-loaded clutch making it easier to engage and disengage than over the center power take-offs. Typical uses include irrigation units, brush chippers, or other gas or diesel engine applications.

PTOs are relatively simple mechanical units with minimal operational problems, but a few common issues are associated with them, and each has a straightforward solution. Here are some of the most frequently encountered issues:

The Clutch will not disengage. Slipping and overheating are common causes of these issues and are fixable by disassembling, inspecting, and replacing if necessary.

PTO is hot. A newly installed PTO will run hot for the first 10-20 hours of operation after installation. Several issues contribute to overheating (220º F measured by infrared thermometer at the bearing carrier), including too much or too little grease, excessive sideload, or a new installation. Follow proper lubrication specifications and reduce the sideload to remedy the first two problems.

Getting the appropriate PTO to meet your operational needs is a priority at WPT Power. Manufacturing our PTOs takes place in our ISO 9001:2015 facilities, where all our products are engineered to meet the highest standards of quality demanded by our customers. ABS type approvals and ATEX certifications minimize risks, time, and costs. Type approval certification available: DNV & ABS (Others available on request)

Our broad range of products is developed to meet most requirements on standard industrial applications. Custom or modified PTOs are available for original equipment manufacturers (OEM) requiring specialized design and where volume is needed.

Power take-offs play an essential role in allowing for the transfer of power from a primary mover to a secondary or driven component without needing an additional separate engine. Various PTO types serve many applications, from smaller-scale operations to major industrial and construction projects. Choosing the correct PTO for a specific application is critical to the proper performance of the driven component.

Contact us for more information about the range of solutions offered by WPT Power Corporation, for assistance in selecting the right PTO to fit your specific application, or request a quote from one of our experts.

8613371530291

8613371530291