kelly bushing depth factory

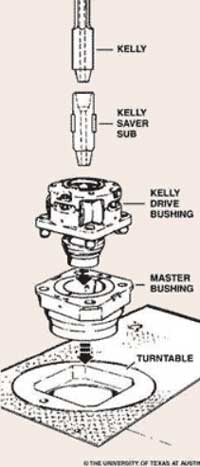

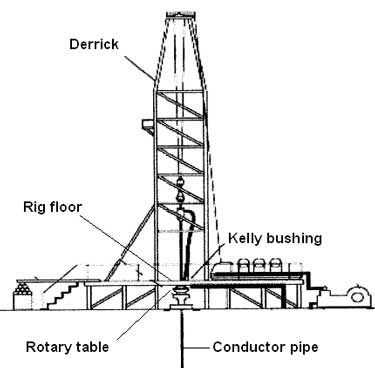

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly. The kelly is a 4 or 6 sided steel pipe.

The purpose of the rotary table is to generate the rotary action (torque) and power necessary to rotate the drillstring and drill a well. The torque generated by the rotary table is useless if it is not transferred to the kelly (the drillstring is connected to the kelly).

Hence, through the kelly bushing the torque generated at the rotary table is transferred to the kelly. To achieve this connection, the inside profile of the kelly bushing matches the outer profile of the kelly so that the kelly fits or “sits” comfortably in the kelly bushing.

There are various designs for the kelly bushing including the split type, the pin-drive type and the square-drive type. Each of these designs has different ways in which they are connected and disconnected from the rotary table.

The internal diameter of the kelly bushing can be cut into the shape of a square (4-sided) or a hexagon (6-sided) depending on the outer shape of the kelly that will be used. The internals of a Kelly bushing is designed to resemble the outer shape of a Kelly just like the insides of a key lock is cut to exactly match the outer shape of the key.

The kelly bushing is not designed to hold tightly onto the Kelly; the kelly is still permitted to move up and down through the kelly bushing. This requirement is a must since drilling cannot progress if the kelly remains on a fixed spot. As the well is drilled deeper, the kelly also moves downward through the Kelly bushing.

The kelly bushing is sometimes used as a reference point from which depth measurements can be taken. All depths must be recorded with respect to a reference point; the kelly bushing (KB) is one of the depth references used in the oil and gas industry.

The top of the kelly bushing is normally used as the depth reference.For example, 7500ft KB means 7500ft below the kelly bushing or 7500ft measured from the top of the kelly bushing down to that point in the well.

In some other cases, depths could be recorded as 7500ft MDBKB meaning 7500ft measured depth below the kelly bushing. This is mostly used when the measured depth is different from the true vertical depth of the well, common with deviated and horizontal wells.

An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table. The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the kelly itself through the square or hexagonal flat surfaces between the kelly and the kelly bushing. The kelly then turns the entire drillstring because it is screwed into the top of the drillstring itself. Depth measurements are commonly referenced to the KB, such as 8327 ft KB, meaning 8327 feet below the kelly bushing.

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, “depth” also refers to the location itself.

Because wells are not always drilled vertically, there may be two “depths” for every given point in a wellbore: the measured depth (MD) measured along the path of the borehole, and the true vertical depth (TVD), the absolute vertical distance between the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), rotary table (RT), kelly bushing (KB) and mean sea level (MSL). [1]

Kelly Bushing Height (KB):The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

Driller’s Depth below rotary table (DDbrt): The depth of a well or features within the wellbore as measured while drilling. The measured length of each joint of drillpipe or tubing is added to provide a total depth or measurement to the point of interest. Drillers depth is the first depth measurement of a wellbore and is taken from the rotary table level on the rig floor. In most cases, subsequent depth measurements, such as those made during the well completion phase, are corrected to the wellhead datum that is based on drillers depth (reference: Schlumberger Oilfield Glossary).

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, “depth” also refers to the location itself.

Because wells are not always drilled vertically, there may be two “depths” for every given point in a wellbore: the measured depth (MD) measured along the path of the borehole, and the true vertical depth (TVD), the absolute vertical distance between the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), rotary table (RT), kelly bushing (KB) and mean sea level (MSL). [1]

Kelly Bushing Height (KB):The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

Driller’s Depth below rotary table (DDbrt): The depth of a well or features within the wellbore as measured while drilling. The measured length of each joint of drillpipe or tubing is added to provide a total depth or measurement to the point of interest. Drillers depth is the first depth measurement of a wellbore and is taken from the rotary table level on the rig floor. In most cases, subsequent depth measurements, such as those made during the well completion phase, are corrected to the wellhead datum that is based on drillers depth (reference: Schlumberger Oilfield Glossary).

Although depth calculation is an intuitive concept, it is the source of much confusion because it is frequently not specified correctly. Absolute depth should always be specified with three components:

True vertical depth is obtained from a record of the deviation survey report. These surveys are generally run on deviated wellbores. It records measured depth (MD), inclination (deviation angle), azimuth angle, true vertical depth, and dogleg severity at various increments. To obtain a TVD, simply obtain a measured depth, go to the survey, and read off the TVD. If the desired measured depth is not in the survey, then extrapolate between the two closest points.

This invention pertains to kelly drives used in the rotary method of drilling. More particularly the invention pertains to roller kelly drive bushings adapted to fit in the master bushing of a rotary table such as used in drilling for oil by the rotary method.

Briefly the invention includes a body having a circular base beneath which extends a square pin adapted to be received in the square socket of a rotary table master bushing and above which extend four pairs of posts providing four sets of shaft support holes. The posts of each pair are asymmetrically placed relative to the base diameters. Between each pair of posts is pivotally mounted an H shaped cage with a shaft extending through the cross bar of the H shaped cage into the pair of support holes provided by the posts, the cage cross bar having a bushing where it pivots about the shaft. Each cage carries a pair of rollers rotatably mounted on shafts carried by the opposite ends of the cage, the rollers being provided with bushings to rotate on the shafts. Releasable means is provided to fix each cage and roller shaft against rotation and prevent axial motion thereof. Each cage and roller shaft has an axial grease passage therethrough joining radial passages communicating with the exterior of the shaft within the corresponding bushing. Each bushing is recessed adjacent the ends of the radial passages in the shaft to communicate the grease with the whole periphery of the shaft. Spring pressed ball check valves in the ends of the axial passages through the shafts provide means for introducing grease. Different sizes and shapes of rollers can be used. A lower cylindrical housing is secured to the body on top of the base; an upper housing is releasably connected to the tops of the posts. Ports in the housings permit access to the grease valves for lubricating the shafts and bushings.

The centrally pivoted cage mounted rollers cause the kelly to be driven smoothly without wobbling, whip, vibration, or binding during axial feed, despite misalignment of the rotary table and crown block and despite crookedness of the kelly, while assuring positive drive and adequate dispersal of driving pressure on the kelly. This arises by virtue of the kinematic geometry of the pivot cage mounted rollers whereby the normal tolerances needed to fit any bushing around a kelly allow the caged rollers to align themselves with the kelly despite such misalignment and crookedness. The resulting absence of bending moments in the kelly reduces wear and vibration and prevents binding. The kinematics of the caged rollers makes it impossible for but one of the rollers of each cage to take all of the driving torque, thereby insuring adequate dispersal of driving pressure and avoiding Brinnelling of the kelly.

The ready removal and replacement of the roller cage shafts makes it a simple matter to remove two adjacent cages so that the apparatus can be threaded over the enlarged end of a kelly and the cages replaced prior to use.

The adaptability of the apparatus to use with standard A.P.I. master bushings and the easy removal and replacement of the roller shafts whereby change of rollers to fit difierent sizes and shapes of kellys is facilitated makes the apparatus of wide applicability.

FIGURE 1 is a front elevation of a kelly bushing embodying the invention having rollers therein adapted to engage a square kelly of medium size, the housings being cut away in vertical section to show the interior of the apparatus, and portions of the front cage and lower roller being sectioned to show the lubrication systems therefor;

FIGURE 2 is a plan View of the FIGURE 1 apparatus with both of the housings broken away and one cage broken away partially to show the lower roller, different rollers having been substituted suitable for use with a large size hexagonal kelly;

FIGURE 3 is a perspective of the apparatus of FIG- URE 2 showing the exterior thereof, the apparatus being shown disposed in a rotary table and around a hexagonal kelly, and illustrating the manner of servicing the bearings.

Referring now to FIGURES l and 2, the twoapparatuses being identical except for the rollers, there is shown a body 10 having a circular base portion 11. Beneath the base extends a square pin 12 adapted to fit in the master bushing of a conventional rotary table. The upper portion 13 of the base 11 is of reduced diameter providing a shoulder 14 on which rests a cylindrical lower husing :15. The lower housing is welded to the base at 16.

There is a circular cross section passage 20 through the body adapted to receive a kelly such as hexagonal kelly 21, shown only in FIGURE 2 (and FIGURE 3). There is a counterbore 22 in the lower end of pin 12 adapted to rest on the pin of a support in the rat hole (not shown) when the kelly and kelly bushing are not in use: Preferably passage 20 is slightly flaring downwardly, as shown in FIGURE 1, to facilitate placement thereof over the upper end of a kelly.

Each plate is provided with a hole 50 beneath which is disposed a threaded nut 51 welded to the plate concentrio with the hole. The peripheries of plates 39-42 are of less radial extent than the outer edges of the posts leaving shoulders such as 56., 57 to facilitate placement of an per housing 58. Housing 58 is dome shaped and has an opening 59 through the top thereof through which a kelly may pass. There are four indented portions such as 60, 61 around the upper housing, the lower portions of which are fiat and adapted to rest on top of the plates. There is a hole through each indented portion of the upper housing adapted to receive a screw such as 62, 63 which engages the nuts beneath the plates to hold the housing in position.

Each shaft 72 has a cage 80 pivotally mounted thereon. Each cage is of H shape with a hole 81 through the cross bar receiving the corresponding shaft 72. The holes 81 are provided with bronze bushing sleeves 82. Within each sleeve 82 is an annular grease reservoir groove 83. Communicating with groove 83 are radial passages 84, 85 in the shaft 72 which connect to axial passage 86 extending from one end of shaft 72 to the other. The ends of passage 86 are counterbored and threaded as shown at 87, 88 to receive check valve fittings 89 adapted to be connected to a conventional grease gun. Referring momentarily to FIGURE 3, four openings 90 spaced around the lower housing 15 provide access to the grease check valve fittings without the necessity of removing the housings.

Returning to FIGURES 1 and 2, when grease is pumped through a check valve 89 it goes through an axial passage 86 and out through radial passages 84, 85 into annular reservoir 83 and thence out between the bushing sleeve 82 and shaft 72, flushing out the old grease ahead of it. The grease escaping at the ends of shaft "72 goes into the space between bosses 90, 91 on the cage and bosses 92, 93 on the posts forming a seal against entrance of dirt, water and other foreign matter to the bearing area between sleeve82 and shaft 72.

Between the pairs of legs 101-102, 101"-102 at the"upper and lower ends of each H-shaped cage 80 are rotatably mounted rollers such as rollers 103, 104, 105", 106" shown in FIGURE 1. The rollers are mounted on shafts such as 107 on which rollers 104 is mounted. Each roller has a bushing sleeve such as 108 in roller 104. Shaft 107 is prevented from turning and moving axially by washers such as 109, 110, similar to the mounting of shaft 72. Shafts 107 and bushing sleeves 108 are provided with axial, radial, and annular grease passages 111, 112, 113 similar to those of shaft 72 and sleeve 82, to which grease is pumped through check valves 114, 115, screwed into counterbores 116, 117 in the ends of the shaft 107. When it is desired to lubricate the rollers, a conventional grease gun is used the same as for the cage.

When the grease in the roller lubrication passages is flushed out, the excess grease exuding between the ends of bushing sleeves 108 and shafts 107 escapes into the space between bosses 140, 141 on the inside of the cage and the adjacent sides of the rollers to form seals against dirt, water and other foreign matter.

Referring particularly to FIGURE 2, there are shown the rollers used to drive a hexagonal kelly. In the cages 80, on the front and back sides of the apparatus there are cylindrical rollers such as 151, 152 in the tops of the cages and like rollers in the bottoms of the cages. In the cages 153, 154 at the sides of the apparatus are disposed pairs of rollers such as upper roller 155 and lower roller 156. Top roller 155 in cage 153 is conical and adapted to engage a side of the kelly adjacent the side engaged by roller 151. The roller in the bottom of cage 153 is similar to roller 156 and is adapted to engage the side of the kelly adjacent to the side engaged by roller 152. Similarly the upper and lower rollers of cage 154 are adapted to engage different sides of the kelly.

It will be noted that the pairs of posts supporting each roller are asymmetrically located with respect to the diameters through the center of the kelly perpendicular to the roller axes, being displaced clockwise, so that when larger diameter rollers are used to drive smaller size kellys, the rollers do not interfere, while at the same time each roller bears at or near the leading corner of the adjacent side of the kelly where it has the maximum torque radius. The posts provide means holding each cage against all rotation about a vertical axis relative to the body 10.

It is because of the asymmetric positioning of the pairs of posts that the two rollers for the side cages are of different shape to engage the two different sides of the kelly. The roller 156, engaging the side of the kelly, has its largest cone diameter at the end of the roller nearest the perpendicular diameter (the diameter through the kelly center and perpendicular to the roller axis). Therefore the largest cone diameter of roller 156 is smaller than that of roller 155 whose largest cone diameter is at the end of the roller farthest from the perpendicular diameter. Because the largest diameter of roller 156 is smaller, it is necessary to discontinue the cone taper after it leaves the kelly and finish off with a cylindrical portion 181. The juncture between the conical and cylindrical portions is provided with a stress relief groove 182.

When larger diameter rollers are substituted to engage a smaller kelly, the cylindrical rollers are bevelled on their ends that are farthest from the perpendicular diameter. This is shown at 191, 192, 193 in FIGURE 1. This provides additional clearance without reducing the area of contact with the kelly which in such case has smaller sides available for contact by the rollers.

In operation of the kelly bushing above described, it is to be noted that if a cage tilts so that one of its rollers is out of contact with the kelly or has less contact pressure than the other, there is created a torque automatically turning the cage about its axis to equalize the pressures of the upper and lower rollers. The same torque also automatically places each cage parallel to the kelly axis instead of placing a bending moment on the kelly to align it with the cage. These are marked advantages over roller kelly bushings having the rollers mounted on fixed axes.

In connection with the alignment of the cages with the kelly, it is to be noted that when the cages turn out of their vertical positions in order to follow a crooked or non-vertical kelly, the distance between the cages is reduced slightly. However with the usual tolerances required to manufacture and assemble the apparatus and to place it over a kelly, the distance between the cages and their rollers is not reduced to a point sufficient to bind on the kelly until the cage has moved far more than the maximum amount needed to accommodate any deviation of the kelly from vertical that is to be expected in practice. The elasticity of the materials increases the amount of angular displacement of the cages possible without binding on the kelly.

1. A roller kelly bushing comprising a body having a vertical hole therethrough to receive a kelly, a plurality of pairs of cages, the cages of each pair being disposed on diametrically opposite sides of said hole, means independently pivotally mounting each cage directly on the body for rotation about a horizontal axis perpendicular to a radius from said hole extending through the cage and simultaneously holding the cage against all rotation about a vertical axis relative to said body, each cage having a roller rotatably mounted thereon above the cage pivot axis and another roller rotatably mounted thereon below the cage pivot axis, the position of each of said pairs of cages being unaffected by the rotation of the other of said pairs of cages.

3. A roller kelly bushing comprising a body including a base having a vertical hole therethrough to receive a kelly and four pairs of vertical posts on the upper side of of the base, four shafts disposed with one between each pair of posts with its axis horizontal, said pairs of posts being placed so as to locate said four shafts with the axis of each lying along a different one of the four sides of a rectangle extending around said hole, fou-r cages each independently pivotally mounted on one of said shafts for rotation about the axis thereof, the location of said shafts disposing said cages in two pairs with the cages in each pair on opposite sides of said hole, each cage having a roller rotatably mounted thereon above the cage pivot axis and another roller rotatably mounted thereon below the cage pivot axis, the rollers of one cage of one pair of cages being adapted to engage one side of a kelly and the rollers of the other cage of said one pair being adapted to engage the opposite side of the kelly and said cages of said one pair rotating equal amounts about their shafts in case of misalignment of the kelly, the position of the other of said pairs of cages being unaffected by the rotation about its shafts of said one of said pairs of cages, said posts holding said cages against all rotation about a vertical axis relative to said body and against all rotation about a horizontal axis other than the axis of said shaft.

4. A roller kelly bushing comprising a body including a base having a vertical hole therethrough to receive a kelly and a plurality of pairs of vertical posts on the upper side of the base, a shaft disposed between each pair of posts with its axis horizontal and perpendicular to a radius from the hole, a plurality of cages each pivotally mounted on one of said shafts for rotation about the axis thereof, each cage being of H shape with the bar of the H forming the pivot axis of the cage, eagh cage having a roller rotatably mounted thereon between the upper legs of the H and another roller rotatably mounted thereon between the lower legs of the H.

5. A roller kelly bushing comprising a base having a hole vertically therethrough to receive a kelly and a plurality of cages each pivotally mounted thereon for rotation about a horizontal axis, each cage having a roller rotatably mounted thereon above the cage pivot axis and another roller rotatably mounted thereon below the cage pivot axis, characterized by the fact that there are four pairs of posts, four cages, one cage being mounted between each of the four pairs of posts, the pairs of posts are equally spaced around the top of the base, the rollers on two opposite cages all have cylindrical portions for contacting a kelly, and the other two cages have conical rollers for contacting a kelly, the upper and lower conical rollers in each of the last two said cages tapering in opposite directions.

Mitchell Rotary Rig #21 is the newest and most advanced rig in the Illinois Basin. It has depth capabilities of up to 12,500 feet (3.81 km) total vertical depth (TVD) and full horizontal and directional capabilities.

Rig #21 has a 17 foot (5.2 m) Kelly Bushing Height (KB) and is outfitted with an 800 Bbl steel pit system that is equipped with dual shaker technology as well as 1,000 GPM mud cleaning capabilities. This rig can be outfitted with up to two 1,005 hp triplex pumps with 5,000# fluid ends. Rig #21 has handling equipment for slim hole and regular hole drill strings. It is outfitted with a full stack blowout preventer (BOP) and can also utilize a rotating head if requested.

Mitchell Rotary Rig #21 has the capability to drill the depths required Carbon Capture Sequestration and Enhanced Oil Recovery (CCS-EOR) technologies.

The global kelly drive market was valued at $1.6 billion in 2021, and is projected to reach $2.3 billion by 2031, growing at a CAGR of 3.7% from 2022 to 2031.

Report Key HighlightersThe kelly drive market is consolidated in nature with few players such as NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH. that hold significant share of the market.

The study covers in-depth analysis of 16 countries from different regions including North America, Europe, Asia-Pacific, and LAMEA. In addition, country-wise data of every country has been provided for better understanding of kelly drive market dynamics in every country.

A kelly drive is a particular kind of well drilling tool which uses a section of pipe with a polygonal or splined outer surface and feeds it through a rotary table and matching kelly (mating) bushing which have the same shape or splines. The Kelly is a long, four- or six-sided steel bar having a hole bored through the center to allow drilling fluid to pass through. The kelly bushing allows the drill string to be lifted or lowered while it rotates by transferring rotating motion from the rotary table or kelly bushing to the drill string. Crewmembers make up several attachments to the kelly. The attachments include the upper kelly cock, the lower kelly cock (drill pipe safety valve), and the kelly saver sub.

Kelly drilling is one of the most used dry rotary drilling techniques. The kelly drive is used to create large-diameter bored piles (from a size of approx. 500 mm). With the increasing drilling activities is booting the kelly drive market share in coming year. The kelly drive works with almost any kind of rock and soil. According to kelly drive market forecast, the demand for short rotary drilling instruments, such as augers, core barrels, buckets, and specialized drilling tools which are used to move the dirt will be more in the market. The drill rod which is also known as a kelly bar, is a typical component of this drilling technique. The strong kelly bars enables deep drilling and help in boosting the kelly drive market trend in forecast period.

Globally, there has been a surge in oil exploration activity, which is driving the demand for kelly drive in rig and drilling industry. Apart from the pandemic time, a boom in exploration has tripled over the last five years. Kelly drive market analysis showcase the owing to a global boom in exploration of oil reserves, several oil companies are getting into the rig sector. With the ongoing expansion in petroleum products, large oil extraction companies are contracting with drilling equipment manufacturers for the rent and sale of drilling equipment. Oil exploration companies and equipment companies collaborate to provide offshore support services that can increase production. Factor such as oil exploration activities is likely to boost the market for kelly drive in near future.

Advances in technology and equipment have enabled more oil and natural gas to be recovered from the length of each well, improving production and reducing the environmental footprint of energy production. Kelly drive is cheaper however, technology is slow, inefficient, and unsafe as compared to the other technology which are present or coming in the market. These factors may restrain customers from using kelly drive; thus, hampering the market growth.

With combination of seismic surveys and drilling wells, companies are doing the search of oil reserve and deposits beneath the surface of the earth. Exploration projects can be expensive, time-consuming, and risky, drilling a well may cost tens of millions of dollars. Several factors are considered the number of wells to be drilled, recovery method, type of installation to be used, separation systems for the gas & fluids, and how the oil and gas will be transported to a processing facility. High demand for the petroleum products in the market resulting into several new excavations projects in different regions. This factor is anticipated to increase the sales of kelly drive; thus, creating lucrative kelly drive market opportunities.

The kelly drive market is segmented into product type, and region. On the basis of product type, the market is bifurcated into cleaners, braking oil, grease and lubes, degreaser, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

In 2021, the square kelly segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.6% during the forecast period. With the increasing horizontal drilling operations result in increasing demand for square kelly in the market. To increase the output from a single well, drilling square kelly equipment are being used frequently in the market. Square Kelly is advantageous for end-users, however equipment can be used for both onshore and offshore drilling operations. Drilling activities are becoming more challenging which are demanding the high quality of kelly equipment. Several oil firms engage in new types of drilling on land, such as horizontal well drilling which covers a significantly larger area under the earth. With the increasing horizontal well drilling creates the opportunity for square kelly segment in global kelly drive market.

In 2021, the kelly bar segment was the largest revenue generator, and is anticipated to grow at a CAGR of 4.0% during the forecast period. With the increasing number of excavation projects and finding of deep oil reserves will increase the demand for kelly bars in the market. Companies are entering into the agreement for the drilling operations which is driving the kelly bars market. Today, reserves are found very deep under the land of sea which require the high strength bars for handling the pressure. Vertical and horizontal drilling activities are increasing which is increasing the demand for different shapes of kelly bars.

The North America kelly drive market size is projected to grow at the highest CAGR during the forecast period. The region is experiencing more drilling activities of oil and gas extraction as the demand for oil-related goods rises worldwide. Kelly drive equipment is particularly helpful for drilling through hard rock and getting to the oil deposits. The Kelly Drive can be used to reduce operational expenses in drilling operations. For field operators and engineers, it ensures long-term project success and a high rate of return.

LAMEA was the second-largest contributor in terms of revenue in the global kelly drive market in 2021, and is anticipated to grow at a CAGR of 3.8% during the forecast period. Accelerated investment across the upstream sector along with crude oil price recovery will foster the drilling activities in the region. Robust growth in petrochemical products demand along with increase in industrial and commercial activities across the developing economies will boost the kelly drive market growth in LAMEA region.

The leading players operating in the global kelly drive market include, NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH, Bridges Equipment LTD, Lake Petro., TEXAS INTERNATIONAL OILFIELD TOOLS, LTD, Goldman, Tianhe Oil Group Co. Ltd., XI"AN KINGWELL OILFIELD MACHINERY CO.,LTD, El Didi Group.

It outlines the current Kelly drive market trends and future estimations from 2021 to 2031 to understand the prevailing opportunities and potential investment pockets.

The invasion of Russia has further worsened an already precarious scenario for the energy and drilling markets, notably in Europe. To minimize the possibility of an interruption in Russian oil and gas supply, oil and gas corporations must collaborate with governments. In longer term, the sector needs to increase its adaptability and relevance in a rapidly evolving energy environment. The scenario brought about by the conflict between Russia and Ukraine influences the Kelly Drive market as well. Many projects that were previously underway in the nations are now on hold, and new projects are being delayed, which has slowed the market"s expansion in recent years.

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, "depth" also refers to the location itself.

By extension, depth can refer to locations below, or distances from, a reference point or elevation, even when there is no well. In that sense, depth is a concept related to elevation, albeit in the opposite direction. Depth in a well is not necessarily measured vertically or along a straight line.

Because wells are not always drilled vertically, there may be two "depths" for every given point in a wellbore: the borehole, and the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), Rotary table (RT), kelly bushing (KB or RKB) and mean sea level (MSL).

Although it is an intuitive concept, depth in a well is the source of much confusion because it is frequently not specified correctly. Absolute depth should always be specified with three components:

Example: the top of a reservoir may be found at 1,500 mMDRT in a particular well (1,500 m measured depth below the rotary table), which may be equal to 1,492 mTVDMSL (1,492 m true-vertical-depth below mean sea level) after correction for deviations from vertical.

Well depth values taken during the drilling operation are referred to as "driller"s depth". The "total depth" for the well, core depths and all analysis of core / mud and other materials from the drilling hole are measured in "drillers depth".

Well depth values from the wireline loggers operation are referred to as "logger"s depth". The loggers depth are typically considered more reliable than the drillers depth.

The differences between loggers and drillers depths are due to different stretch in the drilling string when drilling, and the wire line entered into the bore hole during wireline logging operations. This difference is estimated and referred to as "core shift". A core from a certain drillers depth is lined up with a wireline log (loggers depth) and structures in the core are compared with the log and matched.

Sign Convention - Depth increases positive in the downward direction. This may seem intuitive but confusion can arise when using certain references while integrating data from different sources. Workers mapping surfaces typically use elevation which, by convention, increases positive in the upward direction. Be mindful when integrating depth and elevation. For example, shallow wells drilled onshore often encounter reservoir at negative depths when referenced to sea level, mappers would define these same reservoirs at positive elevations when referenced to sea level.

The acronym TVDSS is commonly used in the oil industry to represent TVD minus the elevation above mean sea level of the depth reference point of the well. The depth reference point is the kelly bushing in the United States and a few other nations, but is the drill floor in most places.

Differential (or relative) depths or thicknesses should generally be specified with at least two components: a unit and a path, plus any eventual specifiers to remove any possible ambiguity. No specifier should ever be left "implicit" or "understood". There are cases where a path is not needed and in fact should not be specified, because it is defined by the specifier, e.g. isochore (true stratigraphic thickness, independent of well path or inclination).

The distinction between "loggers" depth" and "drillers" depth" is becoming blurred due to the increasing use of logs acquired while drilling (LWD). At the time of writing, the common practice remains that the petrophysicists or geologists define the "official depths" in a well, and these depths are frequently different from the "drillers" depth", after various corrections, tie-ins, etc., have been applied.

Petrophysicists and drilling operations tend to express depths with reference to the rotary table or the original drill floor; geologists tend to use a common datum such as the mean sea level; geophysicists use the mean sea level. This can introduce much confusion when a unit is not specified with all 3 components: unit, path, and reference.

Special consideration must be given to depth measurement in toe-up laterals (J-profile). In these cases the measured depth will continue to increase while true vertical depth will decrease toward the toe of the wellbore.

Path: common expressions of path are measured depth (MD) – elsewhere often known as along hole depth (AHD) – and true vertical depth (TVD). Note that using TV for true vertical depth is not consistent with the use of MD for measured depth, hence the recommended TVD.

the legal datum offshore Australia is Lowest Astronomical Tide (LAT) – (Ref. 1 & 2). Note that this requirement in itself can cause difficulties as it is difficult to measure offshore and can vary greatly between locations and even with time. There is, however, an advantage to this convention: tidal corrections should always be of the same sign (negative depth), i.e. the sea level is always higher than or equal to LAT.

Common references used in operations include: Rotary Table (RT), Drill Floor (DF), Kelly Bushing (KB), Sea Bottom (SB), Ground Level (GL), Casing Bowl Flange (CBF).

Any combination of unit, path, and reference can be used, as long as they result in fully specified, unambiguous depths. A well may reach to many kilometers.

Specification of an absolute depth: in Figure 1 above, point P1 might be at 3207 mMDRT and 2370 mTVDMSL, while point P2 might be at 2530 mMDRT and 2502 mTVDLAT.

Specification of a differential depth or a thickness: in Figure 2 above, the thickness of the reservoir penetrated by the well might be 57 mMD or 42 mTVD, even though the reservoir true stratigraphic thickness in that area (or isopach) might be only 10 m, and its true vertical thickness (isochore), 14 m.

CONTENTS Introduction How does Kelly Bushing work? Fixing (Engagement) of the kelly drive bushing Types of Kelly bushing Kelly bushing design Maintenance

Introduction Kelly drive bushing is advise that is fitted to the rotary table and which the Kelly passes The Kelly bushing has inside diameter profile that matches that of the Kelly , usually square or hexagonal Depth measurements are commonly referenced to the KB,

How does kelly bushing work? The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the Kelly itself through the square or hexagonal flat surfaces between the Kelly and the Kelly bushing. The Kelly then turns the entire drill string because it is screwed into the top of the drill string itself.

B) By a square on the bottom of the Kelly drive bushing fitting into the corresponding square recess of the master bushing The result of this engagement is that when the rotary turns the Kelly and the Kelly bushing turns the entire drill string

Types of Kelly bushing Three types of Kelly bushing are available: Heavy, Medium, light-duty Heavy duty Kelly Bushing This unit is used for heavy duty drilling operations and high torque conditions on off shore as well as on shore drilling operations. Medium duty Kelly Bushing Designed for shallow to medium depth applications. Light duty Kelly bushing designed for shallow, slim hole drilling and workover rig applications

ROLLER KELLY BUSHING Model 27 HDS 27 HDP 20 HDP RTM4 Medium Type Heavy Drive style Square Pin Pin Square 20 1/2 MSPC and MDSP 17 1/2 MSPC and MDSP 17 - 27 1/2 inch Master Bushing 23 - 49 1/2 Inch 23 - 491/2 Inch 20 - 22 1/2 inch Square Kelly size 3 - 6 3 - 6 3 - 6 2 - 5 1/4 Hex Kelly size 3 - 6 3 - 6 3 - 6 3 - 4 1/4

Kelly bushing design The Kelly drive bushing is equipped with rollers that permit the Kelly to move freely upward or down word either when the rotary is turning or when it is stationary

The Kelly bushing may be designed to fit either shape of Kellys (square hexagonal triangular ) or it may be designed to accommodate either shape by changing rollers to fit The Kelly bushing may have an optional lock assembly that locks it into the master bushing , that is especially useful for use with motion compensators offshore

Maintenance1. Lubrication to reduce wear is the most important aspect of maintenance , it is done with a grease gun , it can be done each tour or each day but must not be neglected 2. Keep top nut tight to keep roller pins from working in the body journal area 3. The bushing regardless of its design type , must be inspected regularly for wear 4. Parts can be removed and replaced right on the rig floor by the floor crew under the supervision of the driller

8613371530291

8613371530291