kelly bushing elevation quotation

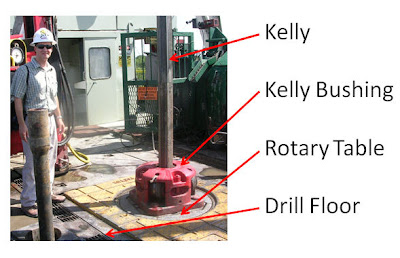

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly. The kelly is a 4 or 6 sided steel pipe.

The purpose of the rotary table is to generate the rotary action (torque) and power necessary to rotate the drillstring and drill a well. The torque generated by the rotary table is useless if it is not transferred to the kelly (the drillstring is connected to the kelly).

Hence, through the kelly bushing the torque generated at the rotary table is transferred to the kelly. To achieve this connection, the inside profile of the kelly bushing matches the outer profile of the kelly so that the kelly fits or “sits” comfortably in the kelly bushing.

There are various designs for the kelly bushing including the split type, the pin-drive type and the square-drive type. Each of these designs has different ways in which they are connected and disconnected from the rotary table.

The internal diameter of the kelly bushing can be cut into the shape of a square (4-sided) or a hexagon (6-sided) depending on the outer shape of the kelly that will be used. The internals of a Kelly bushing is designed to resemble the outer shape of a Kelly just like the insides of a key lock is cut to exactly match the outer shape of the key.

The kelly bushing is not designed to hold tightly onto the Kelly; the kelly is still permitted to move up and down through the kelly bushing. This requirement is a must since drilling cannot progress if the kelly remains on a fixed spot. As the well is drilled deeper, the kelly also moves downward through the Kelly bushing.

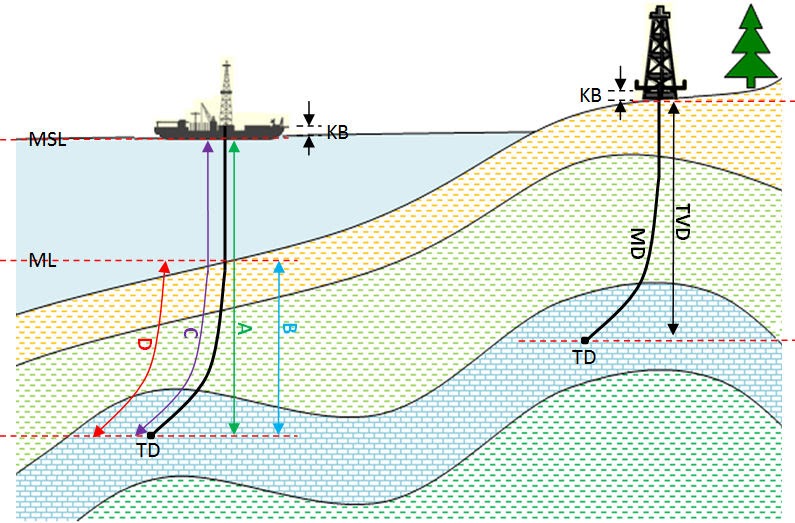

The kelly bushing is sometimes used as a reference point from which depth measurements can be taken. All depths must be recorded with respect to a reference point; the kelly bushing (KB) is one of the depth references used in the oil and gas industry.

The top of the kelly bushing is normally used as the depth reference.For example, 7500ft KB means 7500ft below the kelly bushing or 7500ft measured from the top of the kelly bushing down to that point in the well.

In some other cases, depths could be recorded as 7500ft MDBKB meaning 7500ft measured depth below the kelly bushing. This is mostly used when the measured depth is different from the true vertical depth of the well, common with deviated and horizontal wells.

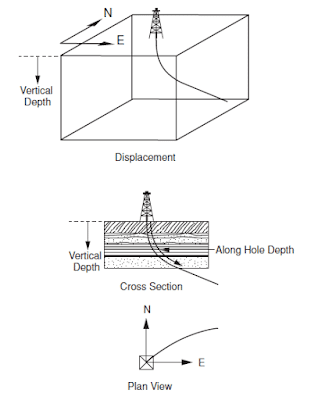

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, “depth” also refers to the location itself.

Because wells are not always drilled vertically, there may be two “depths” for every given point in a wellbore: the measured depth (MD) measured along the path of the borehole, and the true vertical depth (TVD), the absolute vertical distance between the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), rotary table (RT), kelly bushing (KB) and mean sea level (MSL). [1]

Kelly Bushing Height (KB):The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, “depth” also refers to the location itself.

Because wells are not always drilled vertically, there may be two “depths” for every given point in a wellbore: the measured depth (MD) measured along the path of the borehole, and the true vertical depth (TVD), the absolute vertical distance between the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), rotary table (RT), kelly bushing (KB) and mean sea level (MSL). [1]

Kelly Bushing Height (KB):The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

In most drilling operations the rotary table elevation is used as the working depth reference. The abbreviation BRT (below rotary table) and RKB (rotary kelly bushing) are used to indicate depths measured from the rotary table. This can also be referred to as derrick floor elevation. For floating drilling rigs the rotary table elevation is not fixed and hence a mean rotary table elevation has to be used.

In order to compare individual wells within the same field, a common depth reference must be defined and referred to (e.g. When drilling a relief well into a blow-out well, the difference in elevation between the wellheads has to be accurately known). Offshore, mean sea level (MSL) is sometimes used. Variations in actual sea level from MSL can be read from tide tables or can be measured.

In the oil and gas industry, depth in a well is the measurement, for any point in that well, of the distance between a reference point or elevation, and that point. It is the most common method of reference for locations in the well, and therefore, in oil industry speech, "depth" also refers to the location itself.

By extension, depth can refer to locations below, or distances from, a reference point or elevation, even when there is no well. In that sense, depth is a concept related to elevation, albeit in the opposite direction. Depth in a well is not necessarily measured vertically or along a straight line.

Because wells are not always drilled vertically, there may be two "depths" for every given point in a wellbore: the borehole, and the datum and the point in the wellbore. In perfectly vertical wells, the TVD equals the MD; otherwise, the TVD is less than the MD measured from the same datum. Common datums used are ground level (GL), drilling rig floor (DF), Rotary table (RT), kelly bushing (KB or RKB) and mean sea level (MSL).

Sign Convention - Depth increases positive in the downward direction. This may seem intuitive but confusion can arise when using certain references while integrating data from different sources. Workers mapping surfaces typically use elevation which, by convention, increases positive in the upward direction. Be mindful when integrating depth and elevation. For example, shallow wells drilled onshore often encounter reservoir at negative depths when referenced to sea level, mappers would define these same reservoirs at positive elevations when referenced to sea level.

The acronym TVDSS is commonly used in the oil industry to represent TVD minus the elevation above mean sea level of the depth reference point of the well. The depth reference point is the kelly bushing in the United States and a few other nations, but is the drill floor in most places.

Common references used in operations include: Rotary Table (RT), Drill Floor (DF), Kelly Bushing (KB), Sea Bottom (SB), Ground Level (GL), Casing Bowl Flange (CBF).

In April and May 1977, a drilling program financed by the Solution Mining Research Institute (SMRI) investigated the geometry of the roof failure in the rock strata beneath and surrounding the sinkhole developed in October 1974 on the property of Cargill, Inc., Hutchinson, Kansas. Four vertical and two inclined (30" from vertical) exploratory boreholes were drilled in the vicinity of the sinkhole by Nebraska Testing Laboratories, using a tractor-mounted Mobile-50 drilling rig. Casing with 4-inch inside diameter was set in shale bedrock near elevation 70 feet to prevent cave-ins from the shallow water sand. A tricone bit attached to 2 5/8-inch drilling rods was used in all holes except V-3, in which continuous 1 7/8-inch diameter NX core was taken. The investigation was conducted by Alfred J. Hendron, Jr., Ronald E. Heuer, and Gabriel Fernandez-Delgado, who submitted a preliminary report entitled "Field Investigations at Cargill Sinkhole, Kansas" to SMRI June 13, 1977. Information from their report, abstracted by the author, is here included with the permission of SMRI. Dr. Fernandez was resident engineer at the site during drilling and coring operations.

In the vertical borehole V-1, on the southwest bank of the sinkhole, normal rock sequence was drilled to a depth of 388 feet. At elevations 208 and 210 feet excessive rig vibration indicated the presence of thin (4" to, 6") fractured layers in the shale. Between depths 240 and 250 feet the presence of a very fractured zone was also indicated by excessive vibration of the drilling rig. At 388 feet water circulation was completely lost, indicating the presence of a heavily fractured zone. The material below 388 feet started to squeeze against the drilling rods and the walls started to cave. Further continuous penetration below a depth of 400 feet was not possible without the use of casing. Immediately after drilling in V-1 was stopped, a split-spoon sample was taken from 400 to 405 feet total depth. The material in the sample consisted of contorted gray shale mixed with fine sand, the amount of sand decreasing downward.

The JOTKB MODEL 27 PDHD OR 20 PDHD are developed for pin drive master bushing for rotary table sizes from 27-1/2" to 49-1/2" having 25-3/4" and 23" dia pin center. This unit is used for heavy duty drilling operations and high torque conditions on off shore as well as on shore drilling operations, and handle Kelly sizes from 3" to 6" Square or Hexagonal.

8613371530291

8613371530291