kelly bushing drilling supplier

As ARK Drilling our machine are avaible for both Mud and Air Drilling operations. Mud operations with Mud Pumps and Air Drilling operations with high pressure compressors. Our rigs hose lines desinged for high pressure of water&mud and air.

These 2 important is very important for drilling rig owner. After years when your machine needs maintenance you wont need our factory send you parts for maintenance. If you will have any trouble while drilling you will able to solve your problem easly finding spare parts at your local market and changing parts will be not complicated as Hydraulic system top drive drilling rigs.

Distributor and manufacturer of new and rebuilt oilfield drilling equipment & supplies including mud pumps and parts. Drilling equipment includes swivels, mud pumps, rotary table & draw works. Drilling supplies include tongs, roller chains, valves, drive bushings & rotary heads. Mud pump supplies include duplex & triplex liners & piston & pony rods. Pump parts include crossheads, slides & cranks. Catheads, washpipes, bearings, union pipes, pump heads, pipe nipples, crankshafts, roller chain sprockets & chain & pump drives are available. Capabilities include contractors" equipment repairing services. Drilling equipment & supplies are used in oilrigs.

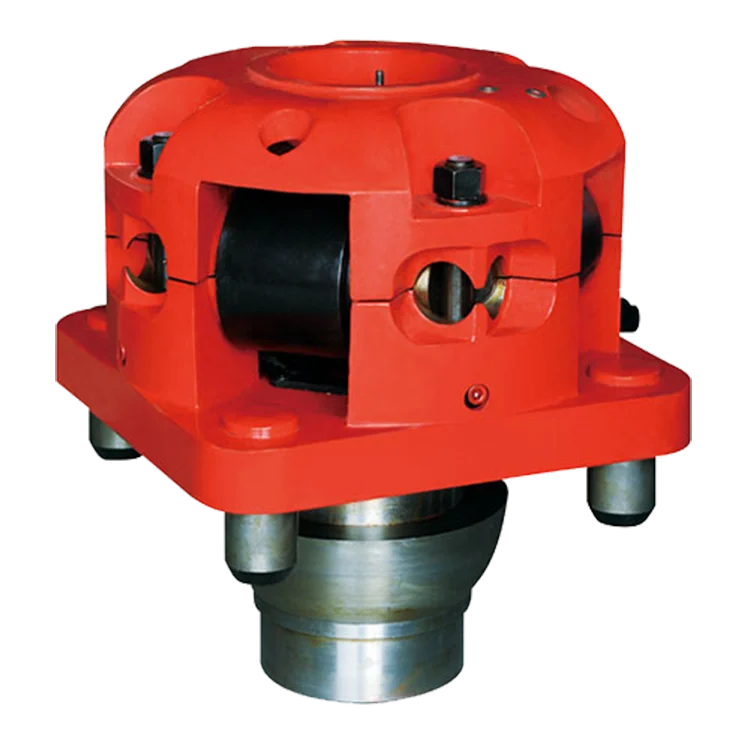

The Kelly Drive Bushing acts as an adapter that serves to connect the rotary table to the Kelly. The Kelly bushing has an inside diameter profile that matches that of the Kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table. The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the kelly itself through the square or hexagonal flat surfaces between the Kelly and the Kelly drive bushing. The Kelly then turns the entire drillstring because it is screwed into the top of the drillstring itself.

Start shopping at Alibaba.com to discover wholesale rotary kelly bushing at incredible prices.Browse through rotary kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of rotary kelly bushing now. For those of you who are looking for quality wholesale rotary kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

Roller Kelly Bushings are designed and manufactured as per API Spec 7K "Drilling and Well Servicing Equipment" for driving Kelly in the drilling operation.

Roller kelly bushings are constructed in upper body half, low body half, rollers, rollers pin and etc., can be available in square drive or pin drive. Square drive roller kelly bushing designed with taper contact surface in low body half, while pin drive roller kelly bushing designed with pin to be installed in low body half.

According to torque of drilling, roller kelly bushing can be available in heavy duty, medium duty and light duty, heavy duty bushings are for high torque and high speed drilling operations while medium duty and light duty are for medium or shadow depth drilling operations.

Roller kelly bushings can accommodate square Kelly or hex Kelly, for square Kelly, the bushing is designed with four flat rollers, and for hex Kelly, the bushing is designed with two V-shaped rollers and two flat rollers. By changing roller size, roller kelly bushing can accommodate square Kelly from 2½" to 5¼" or hex Kelly from 3" to 6", and can be installed in rotary table range from 17½" to 37½".

The JOTKB MODEL 27 PDHD OR 20 PDHD are developed for pin drive master bushing for rotary table sizes from 27-1/2" to 49-1/2" having 25-3/4" and 23" dia pin center. This unit is used for heavy duty drilling operations and high torque conditions on off shore as well as on shore drilling operations, and handle Kelly sizes from 3" to 6" Square or Hexagonal.

The JOTKB MODEL 27 PDHD OR 20 PDHD are developed for pin drive master bushing for rotary table sizes from 27-1/2" to 49-1/2" having 25-3/4" and 23" dia pin center. This unit is used for heavy duty drilling operations and high torque conditions on off shore as well as on shore drilling operations, and handle Kelly sizes from 3" to 6" Square or Hexagonal.

The NOV CUL & CB Casing Bushings are inserted directly into the rotary table and insure that the casing being run is perfectly aligned with the center of the hole. Model CU is a solid bushing and model CB is a split bushing. All of the bushings accept bowls of different sizes to accommodate a wide range of casing. Using CMS-XL or CP-S slips, since these bushings fit into the rotary table, the casing string can be easily rotated during cementing operations.

All CategoriesAdapters (20)B.O.P. (4)Bit Breakers (4)Casing (52)Drill Collars (51)Drill Pipe (77)Downhole/Tubulars (1)Elevators (10)Flanges (13)Heavy Weight Drill Pipe (49)Hooks (5)Insert Bowl (1)Kelly Bushing (5)Kellys (3)Pony Collars (4)Pumps (1)Pup Joints (5)Rams (10)Rotary Tables (1)Spools (6)Stabilizers (1)Stabilizers, Non-Mag (2)Subs, Bits (24)Subs, Cross-Over (43)Subs, Double Pin (22)Subs, Double Pin Kick (2)Subs, Lift (23)Subs, Pump-In Outlet (3)Subs, Saver (4)Tubing (8)Valves (2)Wash Pipe (1)

This is the brief explanation of a Kelly rotating system on the rig. Kelly rig is on an old style rigs and nowadays it is mostly used on land operations. For offshore operation, a top drive system is used instead.

The upper end of the drill pipe is screwed onto the saver sub. The saver sub is used to protect and minimize wearr and tear on the threads at the bottom of the Kelly. The Kelly is about 40 ft in length with a square or hexagonal shape and it is hollow throughout in order to transport the drilling mud. Kelly moves freely through a Kelly bushing even though the drill stem is rotated.

A Kelly cock valve is located at the top of a Kelly and it is a safety valve which can be closed to stop back pressure from coming back to damage other surface equipment.

A swivel attached to the hook does not rotate, but at the bottom part it supports the Kelly which is being rotated while drilling. Drilling mud is pumped from a mud pump to a stand pipe manifold, Kelly hose and then to a gooseneck connection at a swivel.

A rotary table rotates a Kelly bushing and it simultaneously rotates a Kelly and a drill string and a drill bit. A rotary table has two main functions. The first one is to provide rotation to a drill stem and a bit and the second function is to hold slip in order to support the weight of a drill stem when it is not connected to a Kelly.

A master bushing severs its function as a rotary motion transmission from a rotary table to a Kelly. Additionally, it is a link between a slip and a rotary table.

A Kelly bushing (some people call “rotary Kelly bushing”) engages a master bushing via four pins and rollers inside a Kelly bushing to allow a Kelly to move up or down freely while it is rotated or in a static mode.

Supplying drill rig replacement parts has been the specialty of Drilling Supply and Manufacturing (DSM) since it first opened its doors in 1977. Today, it is not only known as a supplier of essential replacement parts, it is also known as a drill rig manufacturer and rebuilder.

In 1977, Young came to Austin to join forces with Palmer and Stanley Martin (father and son) to form DSM. Ken had been a partner and manager of the Midway Supply & Manufacturing in Odessa, Texas, (the manufacturer of Midway Drill Rigs) until he sold out in 1974. As a condition of the sale, he remained with Midway for three years after the change in ownership. At this point in his life, Ken considered a number of options in the drilling business before moving to Austin and forming a partnership with the Martin’s.

Palmer Martin began his career in the drilling business in 1945 and opened his own machine shop, Martin Machine Corp., in 1963. From 1963 to 1977, Palmer manufactured parts for Midway Supply & Manufacturing, where he dealt with Ken Young. Palmer’s son, Stanley Martin, began helping out at the family machine shop at the age of 13 and is today the general shop manager and consulting engineer for the company. “Designing drill rig parts and components is not an easy task, “Stanley notes.

“We do a lot of drill collar and cross-over sub work, too,” Ken says. “We make most of the parts right here in our own shop using special lathes and equipment. We make all of our own kelly bushing and slips. We have our own sand-casting molds, but have the casting done outside.”

Roller Kelly Bushings can be classed as two types based on different ways of drive, square drive and pin drive. Also they can be classed as three types based on different style, heavy, medium and light-duty. They are used for 17.1/2 to 49.1/2inch rotary tables. They are designed and manufactured according to API Spec 7K.

8613371530291

8613371530291