kelly bushing oil and gas pricelist

Start shopping at Alibaba.com to discover wholesale kelly bushing at incredible prices.Browse through kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

This particular type of rolling component has had a lengthy lifespan, originally made popular in bicycles then, automobiles. It decreases spinning rubbing while withstanding axial and radial loads and has the potential to be used across a broad spectrum of different industries, of which aerospace, agricultural and machinery, wagons and other automobiles, skateboards, and of course fidget spinners!

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of kelly bushing now. For those of you who are looking for quality wholesale kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

Start shopping at Alibaba.com to discover wholesale rotary kelly bushing at incredible prices.Browse through rotary kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

This particular type of rolling component has had a lengthy lifespan, originally made popular in bicycles then, automobiles. It decreases spinning rubbing while withstanding axial and radial loads and has the potential to be used across a broad spectrum of different industries, of which aerospace, agricultural and machinery, wagons and other automobiles, skateboards, and of course fidget spinners!

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of rotary kelly bushing now. For those of you who are looking for quality wholesale rotary kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

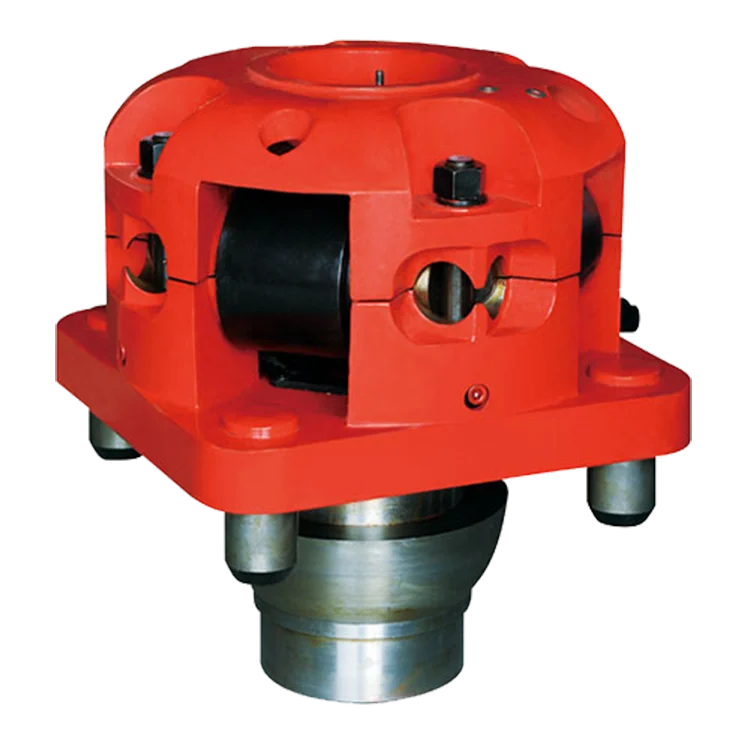

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly. The kelly is a 4 or 6 sided steel pipe.

The purpose of the rotary table is to generate the rotary action (torque) and power necessary to rotate the drillstring and drill a well. The torque generated by the rotary table is useless if it is not transferred to the kelly (the drillstring is connected to the kelly).

Hence, through the kelly bushing the torque generated at the rotary table is transferred to the kelly. To achieve this connection, the inside profile of the kelly bushing matches the outer profile of the kelly so that the kelly fits or “sits” comfortably in the kelly bushing.

There are various designs for the kelly bushing including the split type, the pin-drive type and the square-drive type. Each of these designs has different ways in which they are connected and disconnected from the rotary table.

The internal diameter of the kelly bushing can be cut into the shape of a square (4-sided) or a hexagon (6-sided) depending on the outer shape of the kelly that will be used. The internals of a Kelly bushing is designed to resemble the outer shape of a Kelly just like the insides of a key lock is cut to exactly match the outer shape of the key.

The kelly bushing is not designed to hold tightly onto the Kelly; the kelly is still permitted to move up and down through the kelly bushing. This requirement is a must since drilling cannot progress if the kelly remains on a fixed spot. As the well is drilled deeper, the kelly also moves downward through the Kelly bushing.

The kelly bushing is sometimes used as a reference point from which depth measurements can be taken. All depths must be recorded with respect to a reference point; the kelly bushing (KB) is one of the depth references used in the oil and gas industry.

The top of the kelly bushing is normally used as the depth reference.For example, 7500ft KB means 7500ft below the kelly bushing or 7500ft measured from the top of the kelly bushing down to that point in the well.

In some other cases, depths could be recorded as 7500ft MDBKB meaning 7500ft measured depth below the kelly bushing. This is mostly used when the measured depth is different from the true vertical depth of the well, common with deviated and horizontal wells.

The complexities of the oil and gas industry can make keeping up with all the terms and definitions related to drilling difficult. To simplify things, we’ve compiled a glossary of the most important terms related to drilling and to the oil and gas industry.

To pause or stop drilling operations or production from a well. Reasons for abandoning are if a well is a dry hole or if it’s not producing enough to be kept active.

This process allows a bidder to participate in an auction without being present. An absentee bidder will usually submit their offer before the auction and they need to follow the guidelines set in place by the auctioneer.

When a person or institution is considered capable of understanding and affording the financial risks of unregistered securities, they are known as an accredited investor. The federal securities laws have more specific guidelines for who qualifies as an accredited investor in Rule 501 of Regulation D:

8. A trust with over $5 million in assets managed by a person capable of understanding the risks of unregistered securities is qualified. The trust’s original intent must not have been to purchase the securities offered.

To increase the flow of oil or gas in drilling, hydrochloric acid can be pumped into the well. The acid works to break down limestone, reducing the restrictions the oil or gas was previously facing to increase flow.

Also known as caustic flooding, the alkaline flooding process involves injecting alkaline chemicals during polymer flooding or waterflooding. Sodium hydroxide, sodium carbonate, or other alkaline chemicals react with specific types of oils, and this reaction results in surfactants. These surfactants then increase oil production by reducing interfacial tension between oil and water. Alkaline flooding shouldn’t be used in carbonate reservoirs.

A salt mixture of aluminum hydroxide and stearic acid typically mixed with oil. The resulting solution is sprayed on foamy water mud to release gas bubbles from the mud.

A test of oil mud to determine if the aniline point temperature (aninline point) of the oil will damage elastomers (rubber compounds). The aniline point corresponds to the amount and type of hydrocarbons found in an oil sample, so a low aniline point indicates higher aromatics, and vice versa.

An area between two concentric objects where fluid can flow. An example is the space between the wellbore and casing or the space between casing and tubing.

Anticlines are folds in the earth’s surface where at least 80% of the world’s oil and gas has be found. An anticline has strata that slope downward on both sides and usually has surface formations like hills, knobs, and ridges.

The logo of the American Petroleum Institute (API) is added to equipment that meets their minimum standards. API also provides industry-related publications about recommended practices and standards.

Solid or high-viscosity hydrocarbons found in natural deposits or in petroleum refining residue that are used as additives of oil- and water-based muds (drilling fluids).

Also known as “As Is, Where Is” and “In Its Present Condition”, “As Is” states there are no guarantees about the condition or usage of the property. The buyer is responsible for determining its condition and use cases.

Abbreviated as an AFE, this is a proposal given to each stakeholder that estimates the cost of drilling and completing a proposed well. The proposal will contain dry hole costs, completion costs, and the total cost. Dry hole costs are the spend needed to drill to the casing point, while completion costs are the funds needed to complete the well.

Simply put, base oil is the continuous phase in oil-based drilling fluids (water-in-oil emulsions where water is in the dispersed phase and oil is in the continuous phase).

An extremely viscous form of crude oil that contains sulfer and other metals; to be produced, bitumen must be heated or combined with lighter hydrocarbons.

There are two instances where burner valves are used. The first is in a dehy unit or line heater where it maintains a constant temperature in the process bath by controlling the flow of gas to the fire tube. The second is on a heater treater where constant temperatures are maintained in the vessel by the burner valve.

A steel pipe that’s placed in an oil or gas well after drilling is completed to prevent the well hole from caving in. Casing also prevents fluids from moving from one formation (like groundwater) to another and helps in well control.

Drill Rig: The machinery that’s used to drill oil and gas wells. There are two types of drill rigs: rotary and cable tools, with rotary drill rigs being more efficient.

Describes the continous pumping of mud from surface-level mud tanks, down the drill pipe, out the drill bit nozzles, and through the gap between the drill pipe and the borehole to the surface. This movement carries rock cuttings via the shale shaker to the mud system.

The stub attached to a check that includes relevant information like the well name, production month, total volume produced, price received, and the net decimal interest of the payee.

Used to describe all activities between drilling to casing point and putting the well to production. Includes cleaning out the well bore, setting the casing and tubing, adding surface equipment, and perforating the casing.

A government grant awarded to oil and gas companies to explore and produce oil and gas – usually on government-owned property. Typically, the government receives a bonus or license fee and a portion of the production.

As the name suggests, a counterbalance weight is used to balance an existing weight. Often used in oil production pumping units to balance the weight of the upstroke (fluids and the column of the sucker rod) and downstroke (rods) of the pump.

Paid to the lessor by the lessee, this consideration extends the oil and gas lease terms when there is no operations or production. The payment typically gives the lessee another year, however, if no payment is made and operations cease, the lease is considered abandoned.

This radioactivity contact log responds to variations in the specific gravity of formations by emitting neurtrons and measuring the secondary gamma radiation from the detector to the instrument. This is particularly helpful when measuring porosity in shaley sands.

A removable, steel, serrated piece that fits into the jaws of tongs. Die inserts grip drill pipes, drill collars and casing while the tongs are making up or breaking out pipe.

An internal-combustion engine frequently used for powering drilling rigs. A diesel engine is a high-compression engine that draws air into its cylinders and compresses the air to very high pressures; ignition then occurs as fuel is injected into the compressed, hot air. Combustion takes place in the cylinder above the piston; the combustion then powers the piston.

Also called a dip meter or dip log, this surveying method determines the direction and angle of a formation dip in relation to the borehole to provide geological structure of the formation.

The industry that includes: oil refineries, petrochemical plants, petroleum products distributors, retail outlets and natural gas distribution companies. The Downstream operates anywhere oil, plastics and natural gases are used.

The cutting or boring element used to access oil or gas in the drilling process. Not only are most bits roller-cone bits, but the drill bit also typically includes both the cutting element and the circulating element.

A heavy steel tube that’s placed between the drill pipe and the bit in the drill stem. Drill collars are used to add weight to the bit to make drilling easier.

A piece of seamless tubing used to rotate the bit and circulate the drilling fluid. The pipe joints are usually about 30 feet long and are joined together by tool joints.

The machinery that’s used to drill oil and gas wells. There are two types of drill rigs: rotary and cable tools, with rotary drill rigs being more efficient.

Transmits fluid and rotational power from the kelly bushing to the drilling collar. As the name suggests, the drill string is a column, or string, with attached tool joints.

Describes a well that does not produce oil or gas at commercial volume; typically is a producing well, but does not have enough resources to justify production.

Monitors the amount of oil and gas flowing from a wellhead; measurements are expressed in real time, actual flow, cumulative flow, and historical data.

Used by geologists to determine the nature of rocks, a special tool is used in an uncased hole that outputs electrical current into the rock and records the rock’s resistance.

Hinged steel devices with manual operating handles that are attached to rotary and top drive rigs. Crew members latch elevators onto tool joints to operate them.

This oil recovery process that restores formation pressure and improves oil displacement can be used at any point of the productive life of an oil reservoir. There are three major types of enhanced oil recovery: chemical flooding, miscible displacement, and thermal recovery. Each recovery type alters the original properties of oil, but the specific type used is dependent on the temperature, depth, and other traits of the reservoir.

Also known as heavy oil, this substance contains dispersed gas bubbles that were created at the wellhead of a heavy oil reservoir. The bubbles in foamy oil stay small, keeping the oil viscosity low, while still creating the energy needed to drive the oil to the producing well.

A liquid, typically water, oil, or an acid, that’s used in hydraulic fracturing. Fracturing fluid assists in the hydraulic fracturing process by carrying propping agents that hold open formation cracks after hydraulic pressure dissipates.

A vertical or horizontal separator used to separate gas, oil and water. The water is removed to prevent corrosion and the formation of hydrates or tight emulsions.

Used to prevent gas lock, this tubular and perforated device works by allowing the lighter gas to rise, while the fluids make their way to the pump. It works like this: fluids first enter the anchor, while gas rises and exits the anchor through the perforations at the top. The rest of the fluids enter the anchor through a mosquito bill which allows all the gas to escape before fluids enter the pump.

The process of injecting gas into a reservoir to maintain the pressure created by the gas drive. This process also reduces the decline rate of the original reservoir drive. There are two main types of gas injection: non-miscible oil and miscible oil injection.

In well testing this refers to the ratio of produced gas to produced oil (also known as GOR); in production, this is the volume ratio of gas vs. oil that comes out of solution at standard conditions.

Developed by the American Petroleum Institute, this standard measures the density of liquid as expressed by degrees. The lower the degree, the heavier the liquid.

As the name suggests, the high pressure control valve is used to control fluids up to pressures of 6000 psig. The valves range from 2 to 10 inches long and are used to release fluid from areas of natural gas production.

A drilling technique that consists of vertical drilling down to a particular depth, and then involves turning at a right angle to drill horizontally within a specified reservoir.

A pumping method that uses a downhole pump without sucker rods. Specifically, two reciprocating hydraulic pumps are used; the first pump powers the second, production pump. Single and double tubing strings can both be used to pump multiple wells from a main source. When a single string is used, power oil travels down the string to the pump, and a mix of power oil and fluid is returned through the casing tub annulus. When two strings are used, power oil travels down one string, while the other returns the exhaust and produced fluid.

Generally speaking, improved oil recovery is any activity that increases oil production and recovery factor. However, in the restricted sense, it’s a process (like water flooding or gas flooding) that adds energy to the reservoir to increase oil production and recovery factor. Improved oil recovery allows further oil extraction beyond typical methods.

In this electric well log, the conductivity of a formation is measured. In other surveys, the resistivity is measured. Conductivity measurements work because oil-bearing formations are less conductive than water-bearing formations.

As the name hints, an injection well is a well where fluids are injected into an underground stratum. Also called an input well, this process increases reservoir pressure and displaces oil.

Abbreviated as IDC, these costs are inclusive of everything needed to drill and prepare wells for oil and gas production. Includes costs associated with ground clearing, construction of derricks and pipelines, and wages, among a plethora of other costs.

A written agreement between multiple land operating partners that details how the land will be developed, who will pay for the exploration and development, and when this development will happen.

This steel piece turns the drill stem as the rotary table turns; typically suspended from the swivel through the rotary table and then connected to the top joint of the drill pipe.

A long hollow steel bar that’s used to connect the upper end of a drill string. Kelly bushing is a sleeve in the rotary table that allows the Kelly to freely move up and down during drilling. Kelly bushing also plays a part in the measurement of well depth, as well depth is measured from the Kelly bushing, down to the bottom of the well.

Occurs when water, gas, oil, or other fluid enters the wellbore during drilling when the pressure created by the column of drilling fluid is lower in comparison to the pressure created by fluids in the drilled formation. When not addressed, kicks may cause blowouts.

The agreement formed by the owner of the property and the interested exploration and development party. The property owner gives the lessee exclusive rights to search for and extract any minerals found on the property.

The most common definition of a liner is a pipe used below existing casing to case an open hole. A liner extends from the setting depth up into another string of casing above the lower end of the oil string. Other types of liners include: a short type of perforated pipe that’s placed opposite of a producing formation to prevent loose sand from entering the well; liners in jet perforating guns are conically shaped and are used to increase the efficiency of the charge by improving the jet penetrability; cylinder liners are replaceable tubes created to fit inside the cylinder of an engine or a pump.

A diaphragm used to control the flow of liquid and gas; often found in oil and water dump valves. Used in systems with working pressures up to 300 psig.

The owner of the gas, oil, or other minerals when they’re naturally occuring in a reservoir. Frequently, mineral owners will contract a oil or gas lease with a third-party to extract the minerals.

A mixture of hydrocarbons and non-hydrocarbons (like Hydrogen Sulfide or Nitrogen) in the same gaseous space or in a mixture of crude oil in underground preserves

A contract between the mineral owner and the company interested in drilling that gives the interested company rights to explore and produce oil and gas for a specified term. The lease is usually given for royalty payments in return.

The party or person responsible for the drilling and operation of a well, and the maintenance of the leased land. All of the operator’s responsibilities will be detailed in the JOA.

Used to describe instances where the pressure used to drill (from the drilling fluids) is more than the pressure of the oil or gas within the reservoir.

After deducting the expenses from the oil production, the amount of production that’s left is known as profit oil. This oil will be shared among participating parties and the host government based on the production sharing contract.

Simply put, a reservoir is the rock body in which oil or gas is stored. Common reservoir rocks are limestones, dolomites, or sandstones – all rocks that are porous, permeable, or naturally fractured. A reservoir can be filled with oil, volatile oil, dry gas, and gas condensate.

The machine used to drive rotational power to the drill stem while still allowing vertical movement of the pipe for rotary drilling. Most moden rotary machines have a rotary or master brushing used to turn the kelly bushing, which then allows vertical movement of the kelly while the stem is turning.

Once a reservoir has been fully extracted using the primary production method, the well or field moves into secondary recovery. Secondary recovery methods frequently include gas injection or water flooding – the goal being to repressurize the reservoir for additional oil recovery.

Also known as SOR, steam-oil ratio is used to rate the efficiency of steam injection oil production. The ratio measures the volume of steam needed to create one unit volume of oil and the lower the ratio, the more efficiently the steam is being used.

A type of improved recovery method used to restore formation pressure, improve oil displacement, or improve reservoir fluid flow. Can also be used to extract additional oil after the secondary recovery.

A pipe with a small diameter or a tube threaded at both ends. Tubing is lowered into a completed well so that oil and gas can be produced through the string of tubing.

A type of fixed price drilling contract where a drilling contractor is required to drill to a specific depth and provide ample equipment so the operator only needs to turn a valve to see oil or gas flow.

A horizontal, vertical, or spherical vessel that separates well fluids into gas and total liquid. The oil leaves the vessel through the bottom, while gas leaves through the top.

A type of sand formation where the grains of sand don’t stick to each other. When an unconsolidated sandstone produces oil, it frequently is mixed with sand unless properly controlled.

In geophysics, velocity is described as medium-distance divided by traveltime. Velocity can be measured vertically, laterally, and azimuthally and measured with laboratory measurements, acoustic logs, vertical seismic profiles, and velocity analysis of seismic data.

A heavy crude oil with a viscosity above 10 cp, a gravity below 22.3 degrees API, and low hydrogen-to-carbon ratios. Viscous oil also boasts higher acid numbers as well as high nitrogen and heavy-metal content.

The production of oil due to the expansion of underlying water and rock, which then forces oil into the wellbore. Both bottom water drive and edgewater drive are commonly used. Bottom water involves oil that’s totally in contact with water, whereas with edgewater, only a small portion of the oil touches water.

Challenger International has been serving our faithful customers for over 30 years because of our dedication to adjusting to your individual needs. Our experience means we are well established in providing oil field drilling service equipment and production service equipment. Our professional consulting services, are always the best solution to bring the best prices to you, our customer, in the least time possible.

Kelly Bushing Height (KB): The height of the drilling floor above the ground level. Many wellbore depth measurements are taken from the Kelly Bushing. The Kelly bushing elevation is calculated by adding the ground level to the Kelly bushing height.

1. n. [Drilling] An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table.

A Kelly bushing (some people call “rotary Kelly bushing”) engages a master bushing via four pins and rollers inside a Kelly bushing to allow a Kelly to move up or down freely while it is rotated or in a static mode. This video demonstrates how to make a connection via a Kelly system.

Kelly bushing is that elevated device positioned right on top of the rotary table and used to transmit torque from the rotary table to the kelly. The kelly bushing is designed to be the connection between the rotary table and the kelly.

1. n. [Drilling] An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table.

The kelly is used to transmit rotary motion from the rotary table or kelly bushing to the drillstring, while allowing the drillstring to be lowered or raised during rotation.

1. adj. [Drilling] Referring to the condition that occurs when the kelly is all the way down, so drilling progress cannot continue. A connection must be made, which has the effect of raising the kelly up by the length of the new joint of drillpipe added, so drilling can resume.

This means that Top Drives can drill about 90 feet before making a connection, whereas with a Kelly System, you will make a connection at about 30 feet deep. Another difference between a Kelly and a Top Drive is that a Top Drive System allows rotation and circulation while back reaming out of a hole.

Kelly drive system is capable to drill with one single drill pipe. On other hand TDS is capable to drill with drill pipe stand. One drill pipe stand is made of three drill pipe joints together.

Kelly bars operate by transferring the torque and crowd force from a rotary drive tool to the drilling tool. Many kelly bars can be applied to any type of piling rig that is available on the market. Kelly bars can be divided into two main types: friction kelly bars and interlocking kelly bars.

The wear bushing is housed in the head or in the spool and is secured by means of two tie down screws to protect it against damage or wear during drilling. It is installed or retrieved with either a simple installation tool or with the HCC combined tool.

Kelly Saver Subs refer to a sub used between the Kelly or top head drive and the drill pipe. It is usually a pin to pin sub that takes the wear abuse to protect the drill pipe and the drive connection. Mills can furnish these subs along with the fluted, hex, or square Kelly Bar drive itself.

Measured Depth (MD) is the length of the wellbore measured along its length. True Vertical Depth (TVD), is the absolute vertical distance between a datum, such as the rotary table, and a point in the wellbore.

A mechanical device for rotating the kelly. The kelly spinner is typically pneumatic. It is a relatively low torque device, useful only for the initial makeup of threaded tool joints. It is not strong enough for proper torque of the tool joint or for rotating the drillstring itself.

This means that Top Drives can drill about 90 feet before making a connection, whereas with a Kelly System, you will make a connection at about 30 feet deep. Another difference between a Kelly and a Top Drive is that a Top Drive System allows rotation and circulation while back reaming out of a hole.

Kelly bars are key components in the execution of boreholes with hydraulic rotary drilling rigs. They transfer the torque of the rotary drive and the crowd pressure of the crowd system concurrently to the drilling tool.

A kelly drive is a type of well drilling device on an oil or gas drilling rig that employs a section of pipe with a polygonal (three-, four-, six-, or eight-sided) or splined outer surface, which passes through the matching polygonal or splined kelly (mating) bushing and rotary table.

A conventional rotary rig or rotary table rig or kelly drive rig is a drilling rig where the rotation of the drill string and bit is applied from a rotary table on the rig floor.

Kelly drive system is capable to drill with one single drill pipe. On other hand TDS is capable to drill with drill pipe stand. One drill pipe stand is made of three drill pipe joints together.

Kelly bars operate by transferring the torque and crowd force from a rotary drive tool to the drilling tool. Many kelly bars can be applied to any type of piling rig that is available on the market. Kelly bars can be divided into two main types: friction kelly bars and interlocking kelly bars.

An adapter that serves to connect the rotary table to the kelly. The kelly bushing has an inside diameter profile that matches that of the kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table. The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the kelly itself through the square or hexagonal flat surfaces between the kelly and the kelly bushing. The kelly then turns the entire drillstring because it is screwed into the top of the drillstring itself. Depth measurements are commonly referenced to the KB, such as 8327 ft KB, meaning 8327 feet below the kelly bushing.

The global kelly drive market was valued at $1.6 billion in 2021, and is projected to reach $2.3 billion by 2031, growing at a CAGR of 3.7% from 2022 to 2031.

Report Key HighlightersThe kelly drive market is consolidated in nature with few players such as NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH. that hold significant share of the market.

The study covers in-depth analysis of 16 countries from different regions including North America, Europe, Asia-Pacific, and LAMEA. In addition, country-wise data of every country has been provided for better understanding of kelly drive market dynamics in every country.

A kelly drive is a particular kind of well drilling tool which uses a section of pipe with a polygonal or splined outer surface and feeds it through a rotary table and matching kelly (mating) bushing which have the same shape or splines. The Kelly is a long, four- or six-sided steel bar having a hole bored through the center to allow drilling fluid to pass through. The kelly bushing allows the drill string to be lifted or lowered while it rotates by transferring rotating motion from the rotary table or kelly bushing to the drill string. Crewmembers make up several attachments to the kelly. The attachments include the upper kelly cock, the lower kelly cock (drill pipe safety valve), and the kelly saver sub.

Kelly drilling is one of the most used dry rotary drilling techniques. The kelly drive is used to create large-diameter bored piles (from a size of approx. 500 mm). With the increasing drilling activities is booting the kelly drive market share in coming year. The kelly drive works with almost any kind of rock and soil. According to kelly drive market forecast, the demand for short rotary drilling instruments, such as augers, core barrels, buckets, and specialized drilling tools which are used to move the dirt will be more in the market. The drill rod which is also known as a kelly bar, is a typical component of this drilling technique. The strong kelly bars enables deep drilling and help in boosting the kelly drive market trend in forecast period.

Globally, there has been a surge in oil exploration activity, which is driving the demand for kelly drive in rig and drilling industry. Apart from the pandemic time, a boom in exploration has tripled over the last five years. Kelly drive market analysis showcase the owing to a global boom in exploration of oil reserves, several oil companies are getting into the rig sector. With the ongoing expansion in petroleum products, large oil extraction companies are contracting with drilling equipment manufacturers for the rent and sale of drilling equipment. Oil exploration companies and equipment companies collaborate to provide offshore support services that can increase production. Factor such as oil exploration activities is likely to boost the market for kelly drive in near future.

Advances in technology and equipment have enabled more oil and natural gas to be recovered from the length of each well, improving production and reducing the environmental footprint of energy production. Kelly drive is cheaper however, technology is slow, inefficient, and unsafe as compared to the other technology which are present or coming in the market. These factors may restrain customers from using kelly drive; thus, hampering the market growth.

With combination of seismic surveys and drilling wells, companies are doing the search of oil reserve and deposits beneath the surface of the earth. Exploration projects can be expensive, time-consuming, and risky, drilling a well may cost tens of millions of dollars. Several factors are considered the number of wells to be drilled, recovery method, type of installation to be used, separation systems for the gas & fluids, and how the oil and gas will be transported to a processing facility. High demand for the petroleum products in the market resulting into several new excavations projects in different regions. This factor is anticipated to increase the sales of kelly drive; thus, creating lucrative kelly drive market opportunities.

The kelly drive market is segmented into product type, and region. On the basis of product type, the market is bifurcated into cleaners, braking oil, grease and lubes, degreaser, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

In 2021, the square kelly segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.6% during the forecast period. With the increasing horizontal drilling operations result in increasing demand for square kelly in the market. To increase the output from a single well, drilling square kelly equipment are being used frequently in the market. Square Kelly is advantageous for end-users, however equipment can be used for both onshore and offshore drilling operations. Drilling activities are becoming more challenging which are demanding the high quality of kelly equipment. Several oil firms engage in new types of drilling on land, such as horizontal well drilling which covers a significantly larger area under the earth. With the increasing horizontal well drilling creates the opportunity for square kelly segment in global kelly drive market.

In 2021, the kelly bar segment was the largest revenue generator, and is anticipated to grow at a CAGR of 4.0% during the forecast period. With the increasing number of excavation projects and finding of deep oil reserves will increase the demand for kelly bars in the market. Companies are entering into the agreement for the drilling operations which is driving the kelly bars market. Today, reserves are found very deep under the land of sea which require the high strength bars for handling the pressure. Vertical and horizontal drilling activities are increasing which is increasing the demand for different shapes of kelly bars.

In 2021, the onshore segment was the largest revenue generator, and is anticipated to grow at a CAGR of 3.8% during the forecast period. The rise in production activities and decrease in non-productive time are anticipated to propel the market for the onshore segment during the coming years. The onshore oilfields in North America and LAMEA have witnessed a high market share, regions mainly focus on efficiency improvement, decline in non-productive drilling activity time, and enhancement in health, safety, and environment aspects while drilling.

The North America kelly drive market size is projected to grow at the highest CAGR during the forecast period. The region is experiencing more drilling activities of oil and gas extraction as the demand for oil-related goods rises worldwide. Kelly drive equipment is particularly helpful for drilling through hard rock and getting to the oil deposits. The Kelly Drive can be used to reduce operational expenses in drilling operations. For field operators and engineers, it ensures long-term project success and a high rate of return.

LAMEA was the second-largest contributor in terms of revenue in the global kelly drive market in 2021, and is anticipated to grow at a CAGR of 3.8% during the forecast period. Accelerated investment across the upstream sector along with crude oil price recovery will foster the drilling activities in the region. Robust growth in petrochemical products demand along with increase in industrial and commercial activities across the developing economies will boost the kelly drive market growth in LAMEA region.

For instance, The natural gas production in Saudi Arabia has been planned to increase by two-fold in the coming decade, which is expected to result in increased drilling activities related to gas production.

The leading players operating in the global kelly drive market include, NOV Inc., SANY Group, BAUER Maschinen GmbH (Subsidiary of BAUER Group), Jereh Global Development LLC (As a Subsidiary of Jareh Group) and Liebherr-International Deutschland GmbH, Bridges Equipment LTD, Lake Petro., TEXAS INTERNATIONAL OILFIELD TOOLS, LTD, Goldman, Tianhe Oil Group Co. Ltd., XI"AN KINGWELL OILFIELD MACHINERY CO.,LTD, El Didi Group.

Key benefits for stakeholdersPorter’s five forces analysis helps analyze the potential of buyers & suppliers and the competitive scenario of the industry for strategy building.

It outlines the current Kelly drive market trends and future estimations from 2021 to 2031 to understand the prevailing opportunities and potential investment pockets.

The invasion of Russia has further worsened an already precarious scenario for the energy and drilling markets, notably in Europe. To minimize the possibility of an interruption in Russian oil and gas supply, oil and gas corporations must collaborate with governments. In longer term, the sector needs to increase its adaptability and relevance in a rapidly evolving energy environment. The scenario brought about by the conflict between Russia and Ukraine influences the Kelly Drive market as well. Many projects that were previously underway in the nations are now on hold, and new projects are being delayed, which has slowed the market"s expansion in recent years.

"I am very satisfied with both the service and professionalism that Total Depth Tools has provided. I have had a personal and business relationship with Jeremiah Belk for several years and will continue to use him for my drill pipe and miscellaneous equipment purchases in the future. Jeremiah is steadfast in his approach and always follows through with his promises. Total Depth Tools offers great communication, has a fast turnaround on quotes/orders, and provides excellent prices! Based on my experience, I am confident in my recommendation of Total Depth Tools and their products."

Absentee Bid - A procedure which allows a bidder to participate in the bidding process without being physically present. Generally, a bidder submits an offer on an item prior to the auction. Absentee bids are usually handled under an established set of guidelines by the auctioneer or his representative.

Accredited Investor - A person or institution deemed capable of understanding and affording the financial risks associated with the acquisition of unregistered securities. The federal securities laws define the term accredited investor in Rule 501 of Regulation D as:a bank, insurance company, registered investment company, business development company, or small business investment company;

a natural person with income exceeding $200,000 in each of the two most recent years or joint income with a spouse exceeding $300,000 for those years and a reasonable expectation of the same income level in the current year; or

Abandon - A well is permanently plugged and abandoned if it is drilled and found to be a dry hole, or in the case of a producing well, it is not economically productive.

Acidizing- A technique for increasing the flow of oil and/or gas into a well. Hydrochloric acid is pumped into the oil-bearing rock. The acid dissolves limestone in the producing zone enlarging pores and flow into the well bore with less restrictions.

Anticline - A geological term describing a fold in the earth"s surface with strata sloping downward on both sides from a common crest. Anticlines frequently have surface manifestations like hills, knobs, and ridges. At least 80 percent of the world"s oil and gas has been found in anticlines.

"As Is"- Selling a property without warranties as to the condition and/or the fitness of the property for a particular use. Buyers are solely responsible for examining and judging the property for their own protection. Otherwise known as "As Is, Where Is" and "In its Present Condition."

Auction With Reserve - An auction in which the seller or his agent reserves the right to accept or decline any and all bids. A minimum acceptable price may or may not be disclosed and the seller reserves the right to accept or decline any bid within a specified time. See absolute auction for the definition of an auction without reserve.

Authorization for Expenditure (AFE) - An estimate of the costs of drilling and completing a proposed well, which the operator provides to each working-interest owner before the well is drilled. Various categories of costs are typically listed as "dry hole" costs (the costs to drill to the casing point; these are costs that would be incurred if no indications of hydrocarbons are found), completion cost (the additional costs to complete the well), and the total cost.

BCF- Billion cubic feet (or gas). In the U.S. oil and gas industry, the cubic foot is the standard unit of measurement of gas at atmospheric pressure.

Behind Pipe- If a well drills through more than one pay zone and is completed in the deepest productive reservoir, casing is set all the way down to the producing zone. Viewed from (a perspective) inside the borehole, reserves in the shallower pay zones up the hole are behind the casing (pipe).

Bidder`s Choice- A method of sale whereby the successful high bidder wins the right to choose a property or properties from a grouping of similar or like-kind properties. After the high bidder"s selection, the property is deleted from the group, and the second round of bidding commences, with the high bidder in round two choosing a property, which is then deleted from the group and so on, until all properties are sold.

Bit - A bit is the drilling tool that bores or cuts into the earth. There are two basic types: the cable tool bit which moves up and down the hole, striking the bottom, chipping away the rock, and the rotary bit which revolves to grind the rock. The rotary is the modern technique used in most drilling operations.

Blind Pool - An oil and gas limited partnership which has not committed to a specific prospect, lease, or property at the time of the limited partners subscribe.

Blowout - The uncontrolled flow of gas, oil or other fluids from a well. This happens when the down-hole pressure gas is not properly balanced by the weight of drilling mud.

Blowout Preventer (BOP) - The equipment installed at the wellhead to control pressures in the annular space between the casing and drill pipe or tubing during drilling, completion, and workover operations. Also known as a Christmas tree.

Casing - Steel pipe which screws together and is lowered into the hole after drilling is complete. It is cemented in place to protect both subsurface formations (such as groundwater) and the wellbore. A surface casing is set first to protect groundwater. The production casing is the last one set. The production tubing (through which hydrocarbons flow to the surface) will be suspended inside the production casing.

Casing Point - After a well has been drilled to its objective depth, the operator is faced with a very important decision, whether to commit additional dollars to "set pipe" and attempt a completion or to abandon the well as non-commercial. This decision point separates the drilling and completion phases of operation, and in many cases, changes the participation percentages of investors.

Cementing or "Setting Pipe" - A process whereby cement is pumped into the hole between the walls of the hole and the outside of the casing. Upon hardening, the cement holds the pipe in place and prevents fluid movement in the hole.

Circulation - The continuous pumping of drilling fluid ("mud") from mud tanks at the surface: down through the drill pipe, out the nozzles of the drill bit, and back to the surface through the space between the drill pipe and the borehole. The flow of mud moves the rock cuttings and carries them up to the mud system, by the shale shaker.

Coiled Tubing- A long, small diameter pipe flexible enough to be stored on and deployed from a large, truck-mounted roll. It is used to replace jointed pipe in certain types of drilling, completion, and workover operations.

Completion - A general term referring to all activities necessary to put a well on production after it has been drilled to casing point. The completion phase of operations generally includes cleaning out the well bore, setting the casing and tubing into the hole, adding surface equipment (pumps, tanks, meters) and perforating the casing so that oil or gas can flow into the well and be brought to surface. Once a well is completed, it is ready to produce oil or gas.

Condensate - Hydrocarbons naturally occurring in the gaseous phase in the reservoir that condense into a liquid at the surface (due to the change in pressure and temperature).

Conditions of Sale - The legal terms that govern the conduct of an auction, including acceptable methods of payment, terms, buyer"s premiums, possession, reserves and any other limiting factors of an auction. They are usually included in published advertisements or announced by the auctioneer prior to the start of the auction.

Daily Drilling Report - A record / report of the daily operations on a working drilling rig and, traditionally, phoned, faxed, emailed, or radioed in to the office of the drilling company and possibly the operator every morning.

Density Log - A special radioactivity log for open-hole surveying that responds to variations in the specific gravity of formations. It is a contact log (i.e., the logging tool is held against the wall of the hole). It emits neutrons and then measures the secondary gamma radiation that is scattered back to the detector in the instrument. The density log is an excellent porosity-measure device, especially for shaley sands. Some trade names are Formation Density Log, Gamma-Gamma Density Log, and Densilog.

Depletion- The reduction in value of mineral deposits as it is produced. Oil and gas are wasting assets, in that proceeds from the well represent both income and return of capital.

Depletion Allowance - An allowance granted on taxable income from oil and gas by the Federal and most State Governments. The current Federal rate is 15% of gross income.

Depletion (Gas) Drive- When a well drills into an oil accumulation, free gas in the gas cap above the oil zone, expands. This forces the oil to flow into the wellbore, helping to force oil to flow into the wellbore and up to the surface ("solution gas drive").

Desander - A centrifugal device for removing sand from drilling fluid to prevent abrasion of the pumps. It may be operated mechanically or by a fast-moving stream of fluid inside a special cone-shaped vessel, in which case it is sometimes called a hydro-cyclone.

Desilter - A centrifugal device, similar to a desander, used to remove very fine particles, or silt, from drilling fluid to lower the amount of solids in the fluid.

Die Insert - A removable, hard-steel, serrated piece that fits into the jaws of the tongs and firmly grips the body of the drill pipe, drill collars, or casing while the tongs are making up or breaking out the pipe.

Dipmeter Survey - An oil well surveying method that determines the direction and angle of formation dip in relation to the borehole. It records data that permit computation of both the amount and direction of formation dip relative to the axis of the hole and thus provides information about the geologic structure of the formation. It is also called a dipmeter log or dip log.

Displacement Fluid - In well cementing, the fluid, usually drilling mud or salt water, that is pumped into the well after the cement is pumped into it to force the cement out of the casing and into the annulus (the space between the casing and the outer wall of the well bore).

Down-dip - A term used in a hydrocarbon reservoir that is not flat, i.e., a dipping formation. In such a formation, oil is found down-dip from the gas.

Downhole Motor - A drilling tool made up in the drill string directly above the bit. It causes the bit to turn while the drill string remains fixed. It is used most often as a deflection tool in directional drilling, where it is made up between the bit and a bent sub (or, sometimes, the housing of the motor itself is bent). Two principal types of downhole motor are the positive-displacement motor and the downhole turbine motor.

Drawworks - The hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus lowers or raises the drill stem and bit.

Drill Bit - The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and utilizes the hydraulic force of the fluid stream to improve drilling rates.

Drill Collars - A heavy, thick-walled tube, usually steel, used between the drill pipe and the bit in the drill stem, used to stiffen the drilling assembly an put weight on the bit so that the bit can drill.

Drill Pipe- The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe are generally approximately 30 feet long are coupled together by means of tool joints.

Drill Rig - The equipment used to drill an oil and gas well. There are two types; rotary and cable tools. The rotary type is more modern and efficient.

Drill Stem Test (DST) - A method of formation testing. The basic drill stem test tool consists of a packer or packers, valves or ports that may be opened and closed from the surface, and two or more pressure-recording devices. The tool is lowered on the drill string to the zone to be tested. The packer or packers are set to isolate the zone from the drilling fluid column.

Drill String - The column, or string, of drill pipe with attached tool joints that transmits fluid and rotational power from the kelly bushing to the drill collars and the bit. Often, the term is loosely applied to include both drill pipe and drill collars.

Drilling Break- A sudden increase in the rate of drilling. Usually it indicates that the drill bit is penetrating a porous layer of strata and/or can indicate crossing a fault.

Drilling Engine - An internal-combustion engine used to power a drilling rig. These engines are used on a rotary rig and are usually fueled by diesel fuel, although liquefied petroleum gas, natural gas, and, very rarely, gasoline can also be used.

Drilling Fluid (Mud) - Circulating fluid, one function of which is to lift cuttings out of the wellbore and to the surface. It also serves to cool the bit and to counteract downhole formation pressure.

Electric Log - An electrical survey made on uncased holes. A special tool is lowered into the hole which ejects an electrical current into the rock and records its resistance to the current. The data from the survey is used by the geologist to determine the nature of the rock and its contents.

Electronic Flow Meter - A device used for monitoring barrels of oil and MCF of gas flowing from the wellhead. Measurements are typically expressed in real time, actual flow cumulative flow and historical data.

Enhanced Oil Recovery (EOR)- Refers to a variety of secondary and tertiary recovery processes to increase the amount of oil removed from a reservoir, typically by injecting a liquid (e.g., water, surfactant) or gas (e.g., nitrogen, carbon dioxide).

Exploratory Well - A hole drilled to find oil or gas in an area previously considered unproductive area or to extend the limit of a known oil or gas reservoir.

Fishing - The procedure of locating and retrieving an object (a "fish") that has accidentally fallen into, or been left in the borehole, and must be retrieved before mechanical operations can be resumed.

Flooding- One of the methods of enhanced oil recovery. The general method involves pumping (injecting) a fluid (commonly water) into the reservoir, through wells located around the perimeter of an oil field. The "pressure front" that is created, flushes oil toward the central part of the field, resulting in increased production.

Flowing Well - A well capable of producing oil or gas by its own energy without the aid of a mechanical pump. Normally a pump is put on the well after the pressure reduction inhibits the rate of production.

Fluorescence - An optical property of some materials: Hydrocarbons glow emitting visible light when they absorb radiation from an ultraviolet source. Liquid crude oils fluorescence with colors that range from brown to yellow to green to blue. The color may give some indication of the density of the oil and its chemical characteristics.

Farmout Agreement - An arrangement in which the responsibility of exploration and development is shifted (by assignment) from the working interest owner to another party. Under the farmout agreement: An operator is obligated to perform a specified exploration and drilling program to earn a working interest in the property.

Field - An area consisting of a single reservoir or multiple reservoirs all grouped on, or related to, the same individual geological structural feature or stratigraphic condition. The field name refers to the surface area, although it may refer to both the surface and the underground productive formations.

Fracturing - A procedure undertaken to attempt to increase the flow of oil or gas from a well. A fluid is pumped into the reservoir, with tremendous forces that the reservoir rock is physically broken and split open. usually the "frac fluid" carries small pellets or beads mixed in with it; the idea is for them to get caught in the fractures and prop them open (the beads or pellets are called the propping agent or proppant). As the pumping pressures are gradually released at the surfaces, the natural reservoir pressures will force the "frac fluid" out of the reservoir, and back into the well as the well begins to flow. The proppant remains behind., holding the fractures open, thereby increasing the flow of oil or gas from the reservoir into the well. This procedure is also called hydraulic fracturing. "To frac a well" means to hydraulically fracture a reservoir in a well.

Gas Lift - A method of secondary recovery similar to gas injection, except that the injection well and the production well are both the same well. Dry natural gas is pumped down through the space between the casing and the production tubing, and into the reservoir. Gas dissolves into the oil increasing the oil"s ability to flow, and reservoir pressure is increased around the well. The procedure of injecting gas and then flowing the oil-and-gas mixture is carried on intermittently. The gas is separated from the mixture at the surface, where it is stored for re-injection.

Gas-Oil Ratio (GOR) - The volume of gas produced along with the oil from an oil well, usually described in MCF (thousands of cubic feet of gas) per barrel of oil.

General Partner- In a limited partnership, the general partner is responsible for managing the partnership"s activities (and is commonly the party that put the deal together).

Gravity - A standard adopted by the American Petroleum Institute for measuring the density of a liquid. Gravity is expressed in degrees with lower numbers indicating heavier liquids and higher numbers indicating lighter liquids.

Horizontal Drilling- The new and developing technology that makes it possible to drill a well from the surface, vertically down to a particular depth and then to turn a right angle, and continue drilling horizontally within a specified reservoir, or an interval of a reservoir.

Hot Oiling - Production of parafinic crude oil usually tends to decline rapidly (as the paraffins in the oil clog the porosity surrounding the well bore). Hot oiling is a method of (temporarily) alleviating this situation by using heating equipment and special procedures to increase the temperature in the reservoir close to the borehole, thereby liquefying the paraffin, and unclogging the pore spaces.

Hydrocarbons - A large class of organic compounds composed of hydrogen and carbon atoms, including crude oil, natural gas and natural gas condensates.

Injection Well- A well where gas or water is injected back into the reservoir, usually to increase pressure and thereby stimulate production. In a gas injection well, gas is reinjected into the upper gas portion of the reservoir. Water injection wells are typically found offshore.

Intangible Drilling Costs (IDC"s) - These costs include the amounts necessary for the drilling of wells and the preparation of wells for the production of oil and gas, such as wages, fuel, repairs, hauling, supplies, clearing of ground and geological work in preparation for the drilling, construction of derricks, tanks, pipelines, and other physical structures necessary for drilling.

Integrated - When applied to an oil company, it indicates a firm that operates in both the upstream and downstream sectors (from exploration through refining and marketing).

Joint Venturers- Any persons, firms, corporations or other entities that are admitted into a joint venture either as additional or substitute joint venturers and that are then owners of a unit or units in a joint venture.

Kelly Bushing (KB) - Part of the drilling rig, the Kelly is a long hollow steel bar that connects to the upper most end of the drill string. it is square or hexagonal in cross-section. The Kelly bushing is a "sleeve" in the rotary table through which the Kelly can freely move up and down during drilling. The depth to a particular zone for a well is generally measured from the Kelly bushing, which can be anywhere from about 5 to 50 feet above ground level (dependent on the type and size of drilling rig used).

Lease- A contract by which the owner of the mineral rights to a property conveys to another, the exclusive right to explore for and develop minerals on the property, for a specified period of time. The conveying party is "lessor"; the mineral rights owner. The recipient is "lessee". The terms of the lease are typically negotiated between company, and the owner of the mineral rights.

Lease Bonus - Money paid to a landowner or other holder of mineral rights by the lessee for the execution of an oil and gas lease in addition to any rental or royalty obligations specified in the lease.

Lifting Costs - The cost involved in lifting (pumping) oil from a producing reservoir in a well, up to the surface, including the lease operating cost.

Lime Stone- Sedimentary rock mostly consisting of calcium carbonate. On a world-wide scale, limestone reservoirs contain more oil and gas reserves than any other type of reservoir rocks.

Limited Partnership - A partnership in which the general partner or partners manage the partnership"s activity and are solely liable for them. The limited partners are liable only to the extent of their contributions (and assessments), and they have limited control over policy decisions.

Listing - An employment contract between principal and agent that authorizes the agent (such as a broker) to perform services for the principal and his property.

Listing Agreement - A contract executed by the auctioneer and the seller which authorizes the auctioneer to conduct the auction and sets out the terms of the agreement and the rights and responsibilities of each party.

Logs - Records made from data-gathering devices lowered into the wellbore. The devices transmit signals to the surface which are then recorded on film and used to make the record describing the formation"s porosity, flu

8613371530291

8613371530291