rig kelly bushing manufacturer

The Kelly Drive Bushing acts as an adapter that serves to connect the rotary table to the Kelly. The Kelly bushing has an inside diameter profile that matches that of the Kelly, usually square or hexagonal. It is connected to the rotary table by four large steel pins that fit into mating holes in the rotary table. The rotary motion from the rotary table is transmitted to the bushing through the pins, and then to the kelly itself through the square or hexagonal flat surfaces between the Kelly and the Kelly drive bushing. The Kelly then turns the entire drillstring because it is screwed into the top of the drillstring itself.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Distributor and manufacturer of new and rebuilt oilfield drilling equipment & supplies including mud pumps and parts. Drilling equipment includes swivels, mud pumps, rotary table & draw works. Drilling supplies include tongs, roller chains, valves, drive bushings & rotary heads. Mud pump supplies include duplex & triplex liners & piston & pony rods. Pump parts include crossheads, slides & cranks. Catheads, washpipes, bearings, union pipes, pump heads, pipe nipples, crankshafts, roller chain sprockets & chain & pump drives are available. Capabilities include contractors" equipment repairing services. Drilling equipment & supplies are used in oilrigs.

As ARK Drilling our machine are avaible for both Mud and Air Drilling operations. Mud operations with Mud Pumps and Air Drilling operations with high pressure compressors. Our rigs hose lines desinged for high pressure of water&mud and air.

These 2 important is very important for drilling rig owner. After years when your machine needs maintenance you wont need our factory send you parts for maintenance. If you will have any trouble while drilling you will able to solve your problem easly finding spare parts at your local market and changing parts will be not complicated as Hydraulic system top drive drilling rigs.

Start shopping at Alibaba.com to discover wholesale rotary kelly bushing at incredible prices.Browse through rotary kelly bushing for any type of vehicle.Bearings can be produced from a broad variety of materials, such as different steel, rubber, plastic, brass, and ceramic. These materials, each having their own benefits that render them appropriate to specific operations, including noise level, mass, weight, capacity, and resistance, and a series of options to match your individual needs and requirements.

This particular type of rolling component has had a lengthy lifespan, originally made popular in bicycles then, automobiles. It decreases spinning rubbing while withstanding axial and radial loads and has the potential to be used across a broad spectrum of different industries, of which aerospace, agricultural and machinery, wagons and other automobiles, skateboards, and of course fidget spinners!

However, getting a bushing that is properly functioning is critical to a comfortable and smooth ride, as they maintain the car in good conditions. We have variously available bushings including, grounding bushing, polyurethane bushings, energy suspension bushings, brass bushings, and even drill bushings.Buy our selection of rotary kelly bushing now. For those of you who are looking for quality wholesale rotary kelly bushing at a bargain price, well then you should look no further! At Alibaba.com, you may find a great array of quality automotive accessories and everything at an awesome price.

Jiangsu Xinxiang share Co., Ltd was founded in 1994, its predecessor was established in 1955, it‘s located in high-tech industrial concentration zone of Nantong City, Jiangsu Province; near to a new developing international deep-water port Yangkou Port which commitment to ship 200,000 tons goods; world famous modern city Shanghai is only 2.5 hours away from it by car; company registered capital is 60,000,000 RMB, the total assets is 119.85 million RMB, it covers an area of 160,000 square meters and currently over 500 employees. Jiangsu Xinxiang Share Co., Ltd is "self-import and export enterprise", "private technology enterprises in Jiangsu Province", "high-tech enterprises in Jiangsu Province", it is top ten companies of the first national large and medium-sized industrial enterprises in independent innovation capacity of the industry; it accessed to API7, 7K, 8A, 8C, and has the right to use the logo, and also passed the ISO9001:2000 quality system certification in the earlier stage within the same industry.

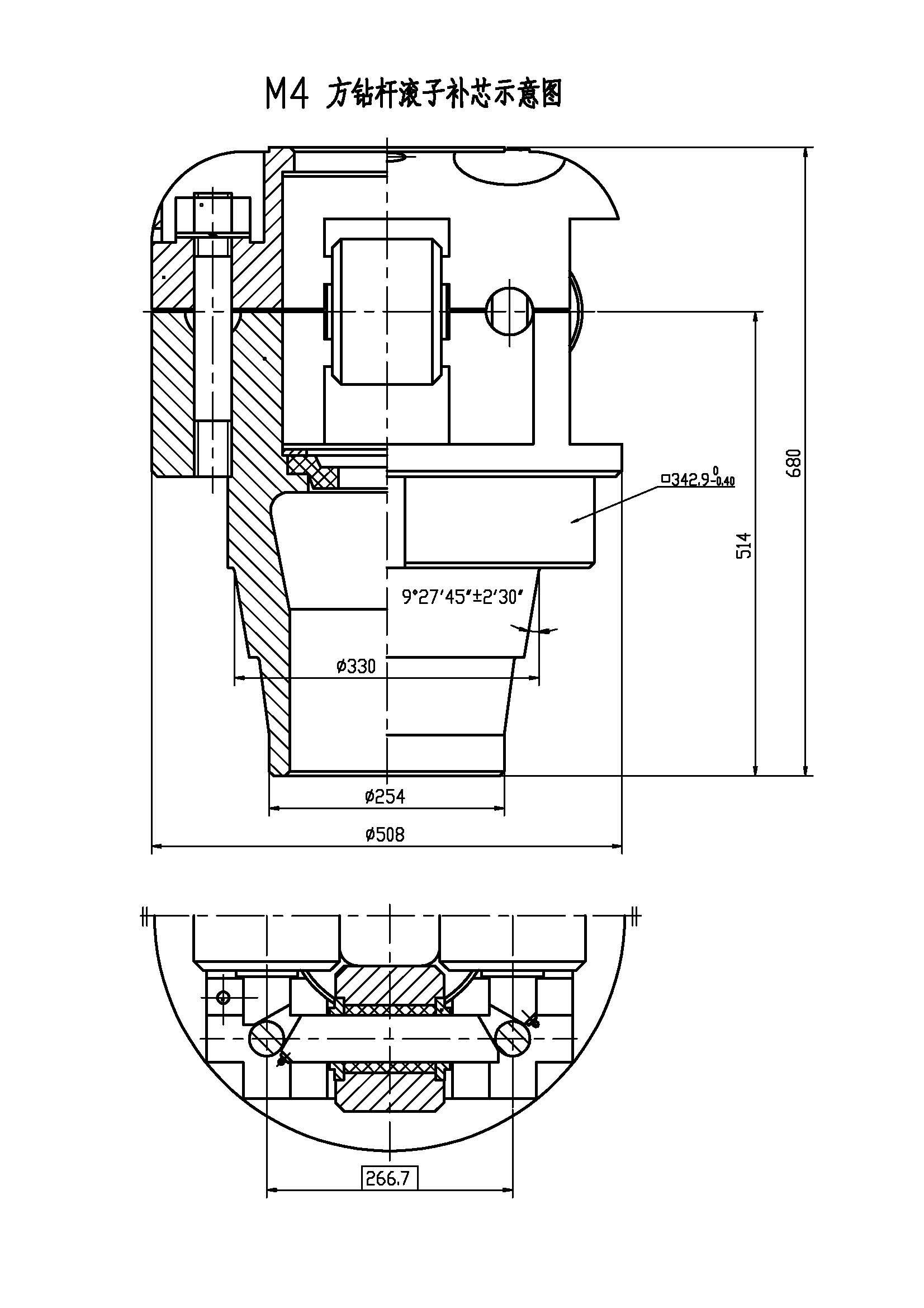

The roller Kelly bushings designed to match with API master bushing for driving the Kelly Suitable for hex type Kelly and Square type Kelly The drive section designed in pin type and square shoulder, strictly match API rotary table The rollers specially heat-treated for extending Kelly"s service time, replaced easily Conforming to API Spec 7K

Supplying drill rig replacement parts has been the specialty of Drilling Supply and Manufacturing (DSM) since it first opened its doors in 1977. Today, it is not only known as a supplier of essential replacement parts, it is also known as a drill rig manufacturer and rebuilder.

“We manufacture and sell parts for Gardner-Denver, Mayhew, Midway and Badger drill rigs, and make custom parts for many other rigs,” Ken Young, DSM general manager, claims. Starting with 12 acres of land and just 3,750 square feet of building space in Austin, Texas, the company has grown to fill three buildings totaling 300,000 square feet. “We still have room to grow,” Ken adds, “but not much.”

In 1977, Young came to Austin to join forces with Palmer and Stanley Martin (father and son) to form DSM. Ken had been a partner and manager of the Midway Supply & Manufacturing in Odessa, Texas, (the manufacturer of Midway Drill Rigs) until he sold out in 1974. As a condition of the sale, he remained with Midway for three years after the change in ownership. At this point in his life, Ken considered a number of options in the drilling business before moving to Austin and forming a partnership with the Martin’s.

Palmer Martin began his career in the drilling business in 1945 and opened his own machine shop, Martin Machine Corp., in 1963. From 1963 to 1977, Palmer manufactured parts for Midway Supply & Manufacturing, where he dealt with Ken Young. Palmer’s son, Stanley Martin, began helping out at the family machine shop at the age of 13 and is today the general shop manager and consulting engineer for the company. “Designing drill rig parts and components is not an easy task, “Stanley notes.

DSM is active in the drill rig manufacturing business today, making and marketing the DSM Bob Cat 1000W, 1500W, and other custom rigs. DSM also manufactures rotary tables, Drawworks, PTOs, floating subs, slips, fishing tools and swivels.

“We do a lot of drill collar and cross-over sub work, too,” Ken says. “We make most of the parts right here in our own shop using special lathes and equipment. We make all of our own kelly bushing and slips. We have our own sand-casting molds, but have the casting done outside.”

Skilled employees are a key component of DSM’s success. “We employ a number of former drillers at DSM,” Ken explains. “Drillers make some of the best mechanics and parts people. They understand the needs of our customers whey they call needing replacement parts in a hurry. Parts people have to know a lot about drill rigs in order to locate the problem area and match up the parts for rigs of a given manufacturer and year model,” he adds. Ken’s son, Randy, is DSM’s parts manager. He’s also involved in outside sales.

In 1986, DSM dedicated a complete hydraulic parts and repair shop – DSM Fluid Power – to serve the needs of drill rig owners and operations. This shop maintains the largest hydraulic test equipment in central Texas.

On Dec. 12, 1991, DSM purchased the Mayhew/Gardner-Denver Water Well Division from Cooper Industries, which included all blueprints, patent rights and molds.

Kelly Bushing, also known as Drive Bushing, is a drilling device that is used to connect a Kelly with a rotary table. This tool is used to fit inside the head where the Kelly fits. The Kelly driver is used to rotate the Kelly. This tool also works along with other drilling tools.

JOT manufacture Pin Drive Kelly Bushing for onshore & offshore Drilling Operations, suitable for a range of 20½” to 49½” Rotary Table, works as connecting equipment between Rotary Table & Kelly.

The Secretary"s citation was directed at the kelly bushing and rotary table on petitioner"s oil drilling rig number 23 at Sidney, Montana. The kelly bushing and rotary table, located in the center of the derrick floor, are part of the power system which transmits torque from the rig"s engines to the drilling bit. They rotate at speeds of 45 to 200 rpm during drilling. The kelly bushing rests on the rotary table. The derrick floor covers most of the rotary table, but the kelly bushing and a six to eight inch band of the rotary table at the base of the kelly bushing are exposed.

The Secretary cited petitioner for failing to guard the kelly bushing and exposed portions of the rotary table. Petitioner contested the citation, contending (1) the kelly bushing used by petitioner was not hazardous because it had recessed bolts rather than protruding "j-bolts" found on older models; (2) alternatively, the use of a guard would create an equal or greater hazard; and (3) the Secretary was collaterally estopped from relitigating these issues because they had been decided adversely to the Secretary in similar proceedings brought against other drilling companies.

The administrative law judge"s finding that the unguarded kelly bushing and rotary table constituted a hazard is "supported by substantial evidence on the record considered as a whole ...." 29 U.S.C. § 660(a). See National Steel & Shipbuilding Co. v. OSHRC, 607 F.2d 311, 316 (9th Cir. 1979).

Petitioner concedes old style kelly bushings with protruding "j-bolts" constitute a hazard since the protruding bolts may catch hoses, chains, or other equipment commonly used in the vicinity of the rotating parts. Petitioner contends, however, that the modern design of the kelly bushing used on its rig eliminates this hazard by countersinking the bolts into the bushing housing. The Secretary presented evidence that employees on petitioner"s rig regularly passed within two feet of the rotating parts, that some employees were inexperienced, that there were chains, hoses, and tools on the rig floor, and that the floor was often wet and muddy. The judge concluded that in such circumstances the "relative smoothness" of the modern bushing would not eliminate the demonstrated hazards posed by the "j-bolt" design, and that the danger remained that employees would fall on the rotating surface, that objects would fall onto and be propelled off the rotating surface, and that chains or other objects would wrap around the bushing. The administrative law judge"s conclusion was supported by the testimony of the Secretary"s witnesses and by the occurrence of two accidents on other rigs, reported in Brinkerhoff Signal, Inc., OSHRC No. 79-2589 (1980), in which an employee was killed and another lost both legs when a chain in one instance, and a water hose in another, became entangled in modern kelly bushings of the same manufacturer as that used on petitioner"s rig.

Petitioner"s other objections to the finding that a hazard existed have no merit. Testimony that the safety precautions undertaken by the drilling industry included a standard practice not to permit employees to approach moving parts during drilling was not impressive in light of direct evidence, including photographs, reflecting a contrary practice on petitioner"s rig. The compliance officer"s testimony that a citation might or might not be issued when an unguarded kelly bushing was present did not reflect inconsistency in regulation, but rather, as the officer testified, that surrounding circumstances, including working conditions and safety procedures, would determine whether employees were exposed to a hazard because of the unguarded machinery. The fact that some state regulatory schemes did not require guards, and that the company that manufactured petitioner"s kelly bushing also manufactured a kelly guard but did not require that both be purchased together, were only distantly relevant, if relevant at all. There was sufficient evidence that the exposed portion of the rotary table, as distinguished from the kelly bushing, was also hazardous, since it increased the danger that employees might fall. Finally, there is no merit in petitioner"s claim that the administrative law judge committed reversible error by considering previous uncontested citations against petitioner because the citations had not been admitted into evidence. The record is unclear whether the compliance officer"s testimony regarding the citations was excluded as well as the citations themselves. In any event, the citations were of little relevance in finding a hazard and the judge does not appear to have relied on them. If error occurred, it was harmless. See General Dynamics Corp. v. OSHRC, 599 F.2d 453, 463-64 (1st Cir. 1979).

Petitioner"s failure to seek a variance is sufficient alone to sustain the administrative law judge"s rejection of petitioner"s defense that available machine guards would have created a greater hazard than the unguarded kelly bushing and rotary table. It is desirable to reach the factual merits of the issue, however, in light of the Fifth Circuit"s decision in Fred Wilson Drilling Co. v. Marshall, 624 F.2d 38.

In that case, the administrative law judge concluded "that use of a Kelly bushing guard would pose serious hazards, but concluded that an unguarded bushing, on balance, presented the more unsafe situation." 624 F.2d at 39. On review, the Fifth Circuit Court of Appeals held the ALJ"s finding was not supported by substantial evidence. The court concluded that on the administrative record before it, "given the present state of development, a Kelly bushing like Wilson"s constitutes more of a hazard guarded than unguarded." Id. at 40. The guard considered in the Wilson case was one designed by Kelly Bushing Guard Manufacturing Company. Id.

In contrast, as we have seen, the record in this case contained substantial evidence that the kelly bushing and rotary table in the circumstances of their use on petitioner"s rig posed a serious hazard to petitioner"s employees. The record also discloses exhaustive consideration of the effectiveness and relative safety of guards for kelly bushings and rotary tables with particular emphasis on recent models developed by Varco International Inc., the manufacturer of the kelly bushing used on petitioner"s rig. Petitioner"s witnesses testified to a variety of possible hazards associated with the use of guards for kelly bushings. However, the Secretary"s witness testified to design features of the Varco guard that reduced or eliminated these risks, and reported Varco had received no complaints or reports of accidents involving the Varco guards. The administrative law judge noted that the testimony regarding hazards from guards was based primarily upon guards of older types, particularly Childress"s "clam shell" guard, and that petitioner"s expert witnesses had not seen a kelly bushing guard or had not seen the newer Varco guards or talked with persons who had used them. The judge noted that earlier cases, including Fred Wilson Drilling Co., had not dealt with "developing refinements in kelly bushing guards," particularly the Varco guard, first marketed in 1977.

The administrative law judge"s finding that petitioner had "failed to prove [its] affirmative defense that properly designed guards present a hazard or that a greater hazard results from guarding the rotating rotary table or kelly bushing" is supported by substantial evidence.

Petitioner argues that whether an unguarded kelly bushing and rotary table of the kind involved in this case constitutes a violation of 29 C.F.R. Sec. 1910.212(a) has been decided against the Secretary in several prior cases, and the Secretary is estopped from relitigating the issue.440 U.S. 147, 155, 99 S. Ct. 970, 974, 59 L. Ed. 2d 210 (1979). Petitioner responds that the administrative law judge did not reject collateral estoppel on this ground, but rather on the ground that application of the doctrine would be contrary to public policy, and his decision may be affirmed only on the ground on which it was based. See SEC v. Chenery Corp., 318 U.S. 80, 63 S. Ct. 454, 87 L. Ed. 626 (1943).

The thrust of the judge"s position was that estoppel was inappropriate because in the earlier cases administrative law judges had ruled for and against the Secretary in cases involving various types of kelly bushings and kelly bushing guards and the "equation of employer-employee safety is an ever changing one," involving "new knowledge and developments involving potential safety or hazards." The judge also noted that in this case there was no pattern of harassment of a particular employer as there had been in Continental Can Co. v. Marshall, 603 F.2d 590 (7th Cir. 1979). It is evident from the remainder of the opinion as well as from these remarks that the administrative law judge on the basis of the approach taken in prior cases and in light of rapidly developing knowledge regarded the issue in each case to be whether the particular kelly bushing in the circumstances in which it was used presented a hazard to the employees and, if so, whether the hazard exceeded that of a kelly bushing protected by the guarding devices available at the time.

The judges in this and prior cases focused on such factors as the precise configuration of the kelly bushing and rotary table involved, how clean and free of tools the derrick floor was kept, whether the employer had and enforced safety rules preventing employees from entering the danger zone, whether and how often employees performed functions close to dangerous equipment, the experience of the workforce, and the availability of safe and feasible guards. None of the cases petitioner relies on found modern kelly bushings were not hazardous or that Varco kelly bushing guards posed a greater hazard. In Grey Wolf II, for example, the judge specifically conditioned his finding of no hazard on the employer"s excellent housekeeping and stringent safety rules, and indicated he would have found a violation had the employer used a kelly spinning chain, which could get caught in the kelly bushing, and which was used at petitioner"s rig. The court in Fred Wilson Drilling Co. was aware of no accidents involving modern kelly bushings and concluded, on balance, not that the kelly bushing was not hazardous, but that the kelly guard at issue in that case, which was not a Varco guard, constituted more of a hazard than the unguarded kelly bushing. 624 F.2d at 40.

The NOV CUL & CB Casing Bushings are inserted directly into the rotary table and insure that the casing being run is perfectly aligned with the center of the hole. Model CU is a solid bushing and model CB is a split bushing. All of the bushings accept bowls of different sizes to accommodate a wide range of casing. Using CMS-XL or CP-S slips, since these bushings fit into the rotary table, the casing string can be easily rotated during cementing operations.

8613371530291

8613371530291