10k kelly hose factory

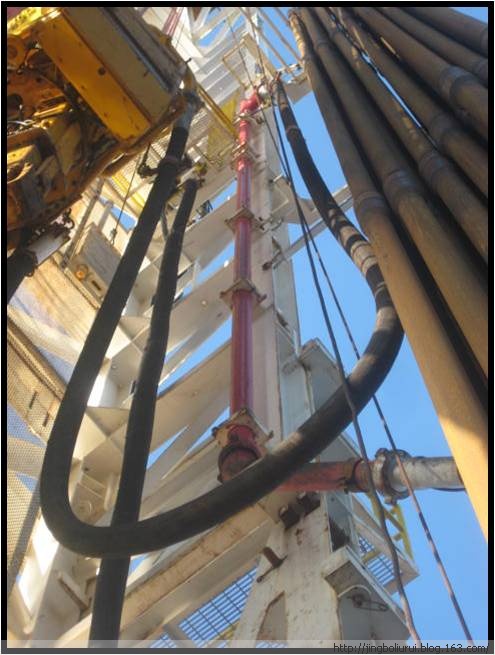

Kelly hose is used to connect the standpipe to the swivel. It allows the drill string to be raised and lowered while the drill fluid is pumped through it. Kelly line usually contains two layers of plated steel cables to reach 5000 psi operating pressure. Inside tube is made of special NBR to improve abrasion and corrosion capability. Rubber cover is compatible with the ozone, sunlight and oils for a long time. It is supplied with multiple end fittings – API flanges, threads, butt-welded union and other as specified.

Owing to over twenty years market experiences in supplying high-pressure flexible oilfield rubber hoses, Hebei Qianli Rubber Products Co., Ltd. has been an important partner of many famous customers including America, East Asia, Africa and other countries and regions in the world.

Oilfield drilling hoses are vital components for rig drilling systems. Rotary drilling hose, mud hose, cement hose, Kelly hose, vibrator hose are working under high-pressure. Once the hose failure, it will cause catastrophic damage to the equipment, body health and property. Our professional engineers can help you solve any problem in safe storage, handling and other technical problems.

Drilling hoses should work in harsh environments. Therefore, high performance such as abrasion resistance, pressure capacity and life expectancy should be paid much attention to when you select them. If you have any problem with the drill hoses, contact us – bond@hebeiqianli.com.

Our drilling hoses are equipped with API end fittings – flanges, NPT threads and butt-weld unions to meet requirements on the market. Bespoke end fittings are also available.

Flexible drilling rubber hoses play an important role in petroleum extraction. They should suffer high operating pressure, extreme operating temperature, abrasion and other inferior elements. Our special compounded synthetic rubber has been proven an effective and economical way to reject these problems. All our oilfield drill hoses are manufactured as API 7K or other related specifications.

Steel cable reinforcement loads most working pressure up to 15,000psi. The wires are usually zinc-plating or copper platting to improve steel wire resistant against rust and corrosion. Due to the thick reinforcement, the hoses should be handled or stored in correct way to avoid kicking or crushing. They will substantially decrease their rated operating pressure.

Rotary hose, Kelly hose, cement hose, mud hose, jumper hose and vibrator hose and choke & kill hoses are the most popular oilfield rubber hoses. They convey high-pressure drilling fluid from one place to another. Many end fittings are provided to satisfy different applications. Most end fittings are made according to API standards. Special order is also available.

Flexible connection between standpipe and swivel (Rotary Drilling) or between pump and standpipe (Rotary Vibrator) for pumping mud at extra high pressure in oil drilling and exploration work. Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotarydrilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

API 7K Rotary Drilling hoses also called oilfield drilling hoses, vibrator hoses, mud hoses, cementing hoses, kelly hoses, de-coking hoses, for the steady high pressure oilfield service. PME Grade D and Grade E rotary hose are designed and produced for mud delivery and cement service on the drilling rigs, by pumping mud at extra high pressure in oilfield drilling operation and exploration.

PME Rubber High Pressure Rotary Drilling Hoses, API 7K Certification, Grade A, Grade B, Grade C, Grade D, Grade E, Grade F.The rotary connection between mud pump and standpipe is called mud hose or kelly hose.

Drilling rotary and vibrator hoses (High Pressure Drilling Hoses) are designed as API 7K Spec as the flexible connection between the standpipe and swivel for pumping mud at a very high pressure in oil drilling and exploration. This hose features high strength spiral steel wire reinforcement which provides a very flexible connection capable of withstanding high pumping pressures at API working pressures, also called mud hose, cement hose, kelly hose or shock-resistant hose.

Our high pressure drilling hoses are often equipped with API end fittings. Connection type covers LP, NPT, TBG and BSPT thread, welding or integral forged union or flange.

Drilling hose(rotary hose)made according to API 7K spec, applies for flexible hose connection between the top of oil drilling stand pipe and vertical moved swivel joint in well drilling, well cementing, work-over and down-hole servicing operation. drilling hose is also used to adjust the installation mistake between drilling pipe line and stand pipe to avoid shake, sometimes to transfer high pressure oil and water base mud with the lowest aniline point of 60°C from the swivel pipe in high pressure, and down-hole operation high medium such as water, oil etc, drilling rotary hose can be used for prefect work too.

We have the ability to take your defective hydraulic hoses and fix it on the spot. With our vast inventory of hose sizes and connectors, we can look at your current hydraulic hose and then supply you with an exact match with the correct fittings. We have the ability to perform this specialized serviced at the following locations: Clewiston, Davie, Ft Myers, Miami and West Palm Beach.

We also have the ability to recycle and reuse your existing hose couplings from your worn out hose possibly saving you hundreds of dollars. In our installation process, we blow a foam through our hoses to flush out any metal filings that may reside in the new hose and form a protective coat to insure that your engine will not be contaminated.

8613371530291

8613371530291