kelly hose failure price

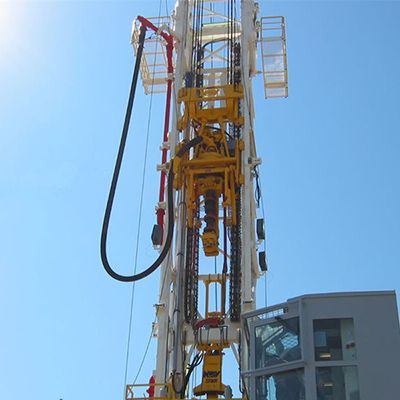

Flexible connection between standpipe and swivel (Rotary Drilling) or between pump and standpipe (Rotary Vibrator) for pumping mud at extra high pressure in oil drilling and exploration work. Meets the high demands of directional drilling and down linking with negative pressure pulses and elevated temperatures. This hose can also be used as a Motion Compensator hose for stabilization of rotary drilling and pumping equipment against vertical wave action on offshore drill platforms. The Motion Compensator hose is not recommended for phosphate ester fluids.

Flexible drilling rubber hoses play an important role in petroleum extraction. They should suffer high operating pressure, extreme operating temperature, abrasion and other inferior elements. Our special compounded synthetic rubber has been proven an effective and economical way to reject these problems. All our oilfield drill hoses are manufactured as API 7K or other related specifications.

Steel cable reinforcement loads most working pressure up to 15,000psi. The wires are usually zinc-plating or copper platting to improve steel wire resistant against rust and corrosion. Due to the thick reinforcement, the hoses should be handled or stored in correct way to avoid kicking or crushing. They will substantially decrease their rated operating pressure.

Rotary hose, Kelly hose, cement hose, mud hose, jumper hose and vibrator hose and choke & kill hoses are the most popular oilfield rubber hoses. They convey high-pressure drilling fluid from one place to another. Many end fittings are provided to satisfy different applications. Most end fittings are made according to API standards. Special order is also available.

Hammer lock unions are available in a variety of working pressures, and with metal seals or various elastomeric seals. Figure 1502 units are typically used in extreme applications such as Kelly Hose service. Warning, never assemble any combination of male sub, wing nut, or segments that are not absolutely positively identified and assured to be identical in figure number, size, and pressure rating. Mismatched components will result in hazardous connections that can result in catastrophic failure. Hammer lock union components that cannot be positively identified must never be used. Never expose standard service products to sour gas fluids. For more information, see our catalog page found under the Resources tab.

A little more than three years ago, Eaton Corp.’s Hydraulics division announced a breakthrough technology with its LifeSense Hose, a smart hydraulic hose condition-monitoring system that detects failure-related events in a hose and sends notices that the product is approaching the end of its useful life.

Eaton developed the LifeSense hydraulic hose to combat the high costs associated with hose failure and replacement. On one end of the spectrum, running a hose until it fails or ruptures can be extremely costly, in terms of hose and fluid loss but also because of damage to machines and critical downtime. On the other hand, using a predictive maintenance schedule—in which hoses are switched out based on rated operating hours—can also be expensive. In this situation, machine owners could be losing money by replacing a hose too soon, because it could still have a long life in it.

According to Product Manager Kelly Floyd, the LifeSense diagnostics unit helps determine how much life is left in a hose. She said that about 80% of the types of failures machine operators and owners see can be detected with LifeSense. Obviously, an accident that ruptures a hose can’t be avoided, for instance.

For example, said Floyd, a municipality who normally spends $97,000 on critical hoses actually spends $97,000 plus $39,000 in unplanned downtime, equaling a total cost of $136,000. By converting to LifeSense, first year costs are $173,000 (initial spend) plus $8000 (downtime), equaling $181,000. In year two, however, the costs drop to $48,000 (two-year spend) plus $8000 (unplanned downtime), equaling just $56,000. So although the up-front costs of LifeSense are greater in the first year, the municipality would save $80,000 in just two years. That’s a big savings, said Kelly.

The LifeSense hose features a protective hose sleeve and a sensor assembly on the hose. The sensor sends signals to a hose diagnostics unit that is housed in the cab of the vehicle. This unit features lights or alarms to notify the operator of a problem with each hose assembly. A red light signals a hose failure is imminent, while a flashing light indicates a sensor is loose or a wire has failed.

The signals can be sent over a wired or wireless network. Currently, Eaton’s wired diagnostics includes wire lengths of 10, 25, 50, and 150 ft, rated at 12 or 24 VDC. The hose diagnostic unit can monitor up to 11 hose assemblies.

The wireless option also operates on a 12- or 24-VDC system, for monitoring up to 100 hoses with a 433 MHz frequency communication protocol. Although the sensors continuously monitor data, it will transmit operating data only once per shift (every seven hours) or as a vehicle passes through the gateway (for example, as a vehicle leaves a garage or enters it, where a gateway is housed). Alerts may be sent via the gateway or through text message via WiFi or Ethernet. The data is accessed through Eaton’s LifeSense web portal, which offers data on system monitoring, hose installation, and connection status. Currently, the wireless sensor has a battery life that is greater than six years but Eaton is currently working on a battery that will recharge itself.

LifeSense hose is currently available in two-wire braid designs in sizes -08, -12 and -16 (1/2, ¾, and 1 in.), rated for 293, 215, and 172 bar, respectively (4250, 3125, and 2500 psi). Eaton plans to offer -04 and -06 wire-braid designs as well as spiral hose in the near future. Eaton is also exploring cellular and satellite expansion of the wireless diagnostics options, with CANBus interface development also under way.

Owing to over twenty years market experiences in supplying high-pressure flexible oilfield rubber hoses, Hebei Chengrui Kelly Hose Co. Ltd. has been an important partner of many famous customers including America, East Asia, Africa and other countries and regions in the world.

Oilfield drilling hoses are vital components for rig drilling systems. Rotary drilling hose, mud hose, cement hose, Kelly hose, vibrator hose are working under high-pressure. Once the hose failure, it will cause catastrophic damage to the equipment, body health and property. Our professional engineers can help you solve any problem in safe storage, handling and other technical problems.

Drilling hoses should work in harsh environments. Therefore, high performance such as abrasion resistance, pressure capacity and life expectancy should be paid much attention to when you select them.

8613371530291

8613371530291